Search results for: 'Electric di'

- Related search terms

- electrica

- Electric di'[0]

- Electrical c

- Electrical ca

- electric''

-

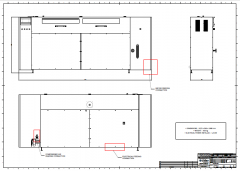

Y-2005 FACE MASK MACHINE, CAPACITY 120 MASKS PER MINUTE

Y-2005 FACE MASK MACHINE, CAPACITY 120 MASKS PER MINUTECAPACITY: 0 TO 120 PIECES PER MINUTE

MASKES MASKS WITH 1 TO 3 LAYERS

MACHINE IS MADE OF ALUMINUM ALLOY

ELECTRICITY: 220 VOLTS 50/60HZ (AS PER CUSTOMER)

DIMENSIONS: (L) 4300 x (W) 4200 x (H) 1850mm

POWER 8.5 KW

AIR PRESSURE 0.6 MPAQUANTITY: 1

Learn More -

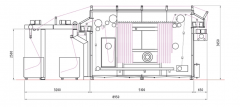

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPE

V-1807 AUTOMATIC FACE MASK WITH OUTER EAR LOOP MACHINE, 120 MASKS PER MINUTE, FLAT TYPEI. FUNCTION

Learn More

THE MACHINE IS FULLY AUTOMATIC EAR TO LOOP MASK MAKING MACHINE. THIS MACHINE INCLUDES ONE SET OF CS-175 AND 2 SETS CS-WD175 AND BY A UNIT OF AUTOMATED DISPENSER. MASK BODIES PRODUCED ON THE MASK MACHINE CAN BE ALLOCATED ONTO 2 SETS OF SUBSEQUENT MACHINES CONTROLLED BY PLC AT THE SPEED OF 0 TO 120 PIECES PER MINUTE. ALL OF OPERATIONS OF THE MACHINE ARE CONTROLLED THROUGH TOUCH SCREEN OR PLCS.

II. PROCESS

AFTER THE MACHINE MAKES THE MASK BODY, THE CONVEYOR BELT STRUCTURE TRANSPORTS THE MASK BODY PIECE TO THE CONNECTING CONVEYOR. THROUGH THE CONNECTION CONVEYOR MASK PLATE TO THE CONVEYOR BELT, AGAIN THROUGH THE CONVEYOR BELT THE MASK IS TRANSPORTED TO THE EAR PIECE SECTION TO THE FRONT OF THE MACHINE ABOVE THE FIRST MASK PLATE, FINALLY THROUGH THE CYLINDER DOWN THE MASK ONTO MASK EAR MACHINE DISC, FOLLOWED UP BY EAR MASKS FOR THE EARS OF THE BELT WELDING MACHINE AND THEN IT’S COMPLETE.

III. FEATURES:

1. MACHINE FRAME IS MADE OF ALUMINUM ALLOY, PREVENTED FROM RUST;

2. THE MACHINE CAN MAKE 1 TO 3 TYPES OF MASK BLANKS ACCORDING TO WHAT THE CUSTOMER REQUIRES.

3. THE SIZE OF THE MASK BLANK AND THE FOLDING LOCATION CAN BE ADJUSTED;

4. THE DIRECTION OF THE EAR LOOP IS OUTSIDE;

5. A COMPUTER PROGRAM CONTROL AND PHOTOELECTRIC DETECTION ACHIEVES A HIGH RELIABILITY AND LOW FAILURE RATE. -

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAY

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAYSee all pictures: https://ibb.co/album/gpK9bF

#1 GRIBETZ MPLUS PATTERN LINK 90 TACK AND JUMP 3 BAR WITH PANEL CUTTER 4 POS CREEL

#2 GRIBETZ GI4300 TACK AND JUMP 90" 3 BAR WITH PANEL CUTTER 3 POS CREEL

# 3 EMCO 2 BAR 1X3 WITH PANEL CUTTER, YEAR 2001 (FOR PARTS)

#4 EMCO COMPUSTITCH 3 BAR

WITH JAMES CASH K-10 PANEL CUTTER#5 GRIBETZ GI2300 90" SET UP FOR BORDERS 4 POS CREEL

#6 EMCO 9000 COMPUSTITCH 1X3X6 BUT RUNNING 1X6

WITH BORDER CUTTER JAMES CASH K-10 1997#7 EMCO 9000 COMPUSTITCH 3 BAR 1 POSITION CREEL

WITH BORDER CUTTER JAMES CASH K-10#8 GRIBETZ 3 BAR 92"

WITH JAMES CASH K-12#9 TAPE EDGE WITH SINGER 300UX6 STEEL TABLE 55 X 81

#10 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#11 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#12 ATLANTA ATTACHEMENT TAPE EDGE WITH PFAFF 5625 WITH STAINLESS STEEL TABLE 60 X 80

#13 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX6 WITH STAINLESS STEEL TABLE 60 X 80

#14 PORTER TAPE EDGE PFAFF DISSASSEMBLED HEAD TABLE SIZE 60 X 82

#15 ATLANTA ATTACHMENT TAPE EDGE WITH PFAFF 5625 STAINLESS STEEL TABLE 59 X 79

#16 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGERS 300UX5 STAINLESS STEEL TABLE 60 X 80 16"H

#17 BUILD UP TABLES MOSTLY 60 X 80 OF WHICH 15 ARE GLOBAL SYSTEMS AND 2 ARE HOME MADE

#19 ? SMALL BALER CONSOLIDATED MODEL STDS-2 36' WIDE X 18" FRONT TO BACK X 50"H

#20 SCREW UNBALER ATLANTA ATTACHMENT FOR 18 INNERSPRING CAPACITY

#21 PIQUA BALER 58 X 31 X 54" TALL 220 VOLT

#22 SCREW UNBALER WBSCO

#23 CART FOR INNERSPRING BALE

#24 GRIBETZ PANEL CUTTER ( I HAVE ALL THE INFO ALREADY)

#25 LAMINATOR GRIBETZ STRATA WITH HOT ROLL AND FELT BLANDET FOR LAMINATING WITH WEB SUBSTRATE (ROTARY HEAT PRESS) MODEL GLM011 220 VOLT , 2 POS CREEL

#26 HORIZONTAL FOAM CUTTER ESCO MODEL HTX 51-88 PU+

88" WIDE , X 118" LONG , KNIFE GRINDERS , SUCTION TABLE

TOUCH SCREEN PANEL , ELECTRICAL CONTROL PANEL

AUTOMATIC LUBRICATION BINKS MODEL 80-600 SG2 PLUS#27 VERTICAL FOAM CUTTER MODEL EL-4

112" WIDE

OUTSIDE TABLE 73"

INSIDE TABLE 74"

FENCE 8" PLUS 16 " EXTENSION

68" THROAT

112" OVERALL HEIGHT

194" TOTAL RAIL WIDTH#28 PORTER SERGER FLANGER MODEL 4000 WITH AIR FLOTATION TABLE

220 VOLT#29 ATLANTA ATTACHMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#30 ATLANTA ATTACHEMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#31 SINGER LONG ARM REPAIR 25"

#32 ATLANTA ATTACHEMENT RUFFLER

MODEL 13XXMF#33 ATLANTA ATTATCHMENT 9 NEEDLE SEWING MACHINE (MULTINEEDLE) MODEL 4000D

#34 SINGLE NEEDLE SIT DOWN MACHINES OF WHICH 3 ARE PORTER

#35 AVANCE EMBROIDERY MACHINE

#36 GALKIN "X" SEWING MACHINE FOR HANDLES

GAP5OBT-3 , JUKI MODEL LK1900CV#37 ATLANTA ATTACHMENT DOUBLE BORDER SERGER 25" OPENING , PEGASUS HEAD

MODEL E521-130 AND EX5203-M03#38 ATLANTA ATTACHMENT BINDER FOR HANDLE MAKING

#39 ANDERSON MULTISLITTER 10 BLADES 92" WIDE

#40 ANDERSON STAND ALONE PANEL CUTTER 103"WIDE WITH 2 EDGE SLITTERS AND ONE CROSS CUTTER

WITH 1049 HOURS ON THE CLOCK#41 CONVEYOR FOR SEW DEPARTMENTE 34" WIDE OVER 100 FEET LONG

#42 TOYOTA FORKLIFTS 6270 LBS CAPACITY MODEL 71CCUT5 (TWO)

ONE NISSAN FORKLIFT

ONE CATERPILLAR FORKLIFT#43 ONE GLUE STATION 4 GUNS , SABA GUNS , NOT THERE (BELONG TO SABA)

#44 240 FEET LONG CONVEYOR FEEDING MATTRESS WRAPPING DEPARTMENT

#45 TWO MERELLO WRAPPERS 20 INCH MAX HEIGHT X 88 " WIDE, YEAR 2016

#46 TECNOMAC (ITALY) MATTRESS ROLL AND PACK MACHINE MODEL TK381 YEAR 2015

Learn More

400 VOLT X 50HZ X 30 KW

8 BAR AIR PRESSURE -

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILL

J-2216 DOWN & FEATHER FILLING MACHINE, 4 WEIGH SCALES, 1 NOZZLE, 1400 GRAMS PER FILL -1400 GRAMS PER FILLFOR FILLING DOWN FEATHER PILLOWS

FILLING RANGE: 1 TO 120 GRAMS (70% FEATHER & 30% DOWN)

WEIGHING SYSTEM: 4 SETS

POWER: 4.5 KW

VOLTAGE: 220 / 380 V, 3-PHASE

AIR PRESSURE: 0.5 TO 0.7 MPA

ACCURATE WEIGHING RESULTS WITH TOLERANCE OF ONLY 1 GRAM

WORKING TABLE DIMENSIONS: 1200 x 2400mm (FOR CUSTOMERS FILLING PILLOWS AND QUILTS)

WORKING TABLE DIMENSIONS FOR PILLOWS ONLY: 1200 x 1200mm (EASIER TO FIT IN A 20 FOOT CONTAINER)

OPERATION CAN BE HANDLED BY ONLY 1 EMPLOYEE

INCLUDES ONE AUTOMATIC FILLING TABLE WITH FOOT SWITCH AND CLAMP DEVICE

THE WORKER STEPS ON THE FOOT SWITCH AND THE CLAMP DEVICE WILL RUN TO CLAMP THE PILLOW BAG

THE FILLING PROCESS AUTOMATICALLY STARTS TO FILL THE PILLOW AND AFTER FINISHING THE CLAMP DEVICE WILL RESET

DURING THIS PERIOD, THE WORKER MAY SEAL THE PILLOW WITH SEWING MACHINE

FOUR HOPPER SYSTEM FOR CONSTANT SUPPLY

ONE KEY FOR CHARGE AND RECHARGE REDUCES WASTED TIME

HIGH-QUALITY, RELIABLE ELECTRICAL COMPONENTS

PREPROGRAMMABLE FOR UP TO 50 GROUPS OF RECIPES WITH EACH RECIPE CONTAINING UP TO 60 SETS OF DIFFERENT FILLING PARTS FOR THE SAME PRODUCTION

FULLY ENCLOSED DESIGN TO KEEP ENVIRONMENT CLEAN AND REDUCE MATERIAL WASTE

AUTOMATIC, ACCURATE WEIGHING WITH LOAD CELL TO ENSURE PRODUCTION QUALITY

CE CERTIFICATE INCLUDED

FLOORSPACE 4000mm LONG X 3000mm WIDE X 2500mm HIGH

TABLE FOR PILLOWS IS 1200 X 1200mm

Learn More

QUANTITY: 1 -

J-1592 CIBITEX EASYWASH FABRIC WASHING SYSTEM

J-1592 CIBITEX EASYWASH FABRIC WASHING SYSTEMMAKE: CIBITEX

THE MOST INNOVATIVE, VERSATILE AND COMPACT SYSTEM FOR PROFESSIONAL WASHING DESIGNED FOR SMALL AND MEDIUM VOLUMES OF DIGITALLY PRINTED FABRICS

UNIT COMES WITH 3 STAGE BOILER

VOLTAGE: 400 V 50/60Hz

MAXIMUM WORKING WIDTH: 2200mm

MAXIMUM WATER TEMPERATURE: 95 °C

MAXIMUM INTERNAL CONTENT (DEPENDING ON FABRIC): 200 METERS

MAXIMUM WATER CONSUMPTION: 5 L/MIN

AVERAGE ELECTRICAL CONSUMPTION: 5,6kWh

DIMENSIONS: 3270 X 560 X 1380mm

WEIGHT: 400kgQUANTITY: 1

Learn More -

J-1589 MS PRINTING SOLUTIONS ECOVAPOR 110 FABRIC STEAMER, 110 METER CAPACITY – YEAR 2016

J-1589 MS PRINTING SOLUTIONS ECOVAPOR 110 FABRIC STEAMER, 110 METER CAPACITY – YEAR 2016MAKE: MS PRINTING SOLUTIONS

MODEL: ECOVAPOR 110

FABRIC CAPACITY: 110 M

ROLLER WIDTH: 2200mm

SATURATED STEAM OPERATION: 102 TO 106 ⁰C

STEAM CONSUMPTION: 400 TO 600 KG/H

HIGH TEMPERATURE OPERATION: 180 ⁰C

TEMPERATURE DIATHERMIC OIL: 260 ⁰C

INSTALLED THERMIC POWER: 64,000 KCAL/H

WORKING SPEED: 2 TO 20 METERS/MINUTE

DWELL TIME: 5,5 TO 55 MINUTES

INSTALLED ELECTRIC POWER: 16 kVA

AIR COMPRESSED CONSUMPTION: 2 L/MIN

AIR COMPRESSED SUPPLY: 2 BAR

VOLTAGE: 400V 50/60HzQUANTITY: 1

Click here to watch the videos of this machine on YouTube.

Learn More -

M-8007 SAMPLE COFFEE ROASTER, CAPACITY 50 TO 200 GRAMS

M-8007 SAMPLE COFFEE ROASTER, CAPACITY 50 TO 200 GRAMSREFERENCE NUMBER: M-8007

SAMPLE COFFEE ROASTER, CAPACITY 50 TO 200 GRAMS

SPECIFICATIONS:

CAPACITY: 50 GRAMS TO 200 GRAMS

POWER: 230V – 50/60HZ

GAS: NATURAL AND PROPANE OR HEATING: ELECTRICAL HEATING

EXHAUST: Ø 80mm

WEIGHT: 85KG

Learn More -

T-1138 LORIS BELLINI APPC/LV 150 HANKS CABINET DYEING MACHINE, YEAR 1988 RECONDITIONED 2016

T-1138 LORIS BELLINI APPC/LV 150 HANKS CABINET DYEING MACHINE, YEAR 1988 RECONDITIONED 2016REFERENCE NUMBER: T-1138

LORIS BELLINI APPC/LV 150 HANKS CABINET DYEING MACHINE, YEAR 1988 RECONDITIONED 2016

HANKS CABINET DYEING MACHINE

UNDER PRESSURE TEMPERATURE 110°C

WITH EXTRACTABLES BASKETS

MODEL LORIS BELLINI APPC/LV 150

YEAR 1988 FULLY RECONDITIONED 2016

QUANTITY: 1

Learn More -

T-1139 OBEM HANKS CABINET DYEING MACHINE, YEAR 1989 RECONDITIONED 2017

T-1139 OBEM HANKS CABINET DYEING MACHINE, YEAR 1989 RECONDITIONED 2017REFERENCE NUMBER: T-1139

OBEM HANKS CABINET DYEING MACHINE, YEAR 1989 RECONDITIONED 2017

HANKS CABINET DYEING MACHINE

UNDER PRESSURE TEMPERATURE 110°C

WITH EXTRACTABLES BASKETS

BRAND OBEM

TYPE MBC 350/06/CE

YEAR 1989 FULLY RECONDITIONED 2017

QUANTITY: 1

Learn More -

L-5737 LAUNDEROMETER

L-5737 LAUNDEROMETERREFERENCE NUMBER: L-5737

LAUNDEROMETER

FOR ALL KINDS OF COTTON, WOOL, HEMP, SILK, CHEMICAL FIBER AND OTHER TEXTILES

STANDARDS: GB/T3921.1, GB/T3921.5, ISO105 D01, ISO105 C01, ISO105

C05, ISO105 D01, ISO105, BS1006, GB/T5711, JIS L 0844, JIS L 0860, AATCC 61

TOUCH SCREEN DISPLAY

QUANTITY: 1

Learn More