Search results for: 'Mattress fi'

- Related search terms

- mattress+s

- mattress mach

- mattress+machine

- Mattress B

- Mattress mac

-

M-3561 LINE FOR THERMO BONDED WADDING YEAR 1987 - FOR MATTRESS AND BUILDING SECTOR, ETC

M-3561 LINE FOR THERMO BONDED WADDING YEAR 1987 - FOR MATTRESS AND BUILDING SECTOR, ETCREFERENCE NUMBER: M-3561

LINE FOR THERMO BONDED WADDING YEAR 1987 - FOR MATTRESS AND BUILDING SECTOR, ETC

LINE FOR THERMO BONDED WADDING -YOC 1987 - FOR MATTRESS AND BUILDING SECTOR, ETC.

( ESPECIALLY IN POLYESTER + NATURAL FIBERS MIXED).

THE LINE HAS A PRODUCTION OF 350/400 KGS PER HOUR WITH A WORKING WIDTH FROM 150 CMS INTIL 240.

COMPOSITION :

. BONINO LOADER WORKING WIDTH mm. 2800

. BONINO CARDING MACHINE WORKING WIDTH mm. 2800 SINGLE DOFFER

. TECHNOPLANTS CROSS LAPPER WORKING WIDTH ENTRY/EXIT mm. 3000

. SICAM OVEN - 2 FIELDS. WORKING WIDTH 2400 mm. + COOLING SECTION

. TECNICA TESSSILE CUTTING MACHINE WITH HORIZONTAL AND VERTICAL CUT WORKING WIDTH mm. 3000

. MECAP PACKAGING MACHINE FOR ROLLS

QUANTITY: 1

Learn More -

E-8761 ROLL PACKING MACHINE FOR FOAM MATTRESSESINVENTORY NUMBER: E-8761 ROLL PACKING MACHINE FOR FOAM MATTRESSES FOR SALE: UP TO 72" WIDTH (1800mm) UP TO 11" FOAM THICKNESS (280mm) TOTAL ELECTRICAL POWER IS 8kw QUANTITY AVAILABLE: 1 Learn More

E-8761 ROLL PACKING MACHINE FOR FOAM MATTRESSESINVENTORY NUMBER: E-8761 ROLL PACKING MACHINE FOR FOAM MATTRESSES FOR SALE: UP TO 72" WIDTH (1800mm) UP TO 11" FOAM THICKNESS (280mm) TOTAL ELECTRICAL POWER IS 8kw QUANTITY AVAILABLE: 1 Learn More -

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More -

M-3006 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)

M-3006 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)REFERENCE NUMBER: M-3006

AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)

AUTOMATIC MATTRESS WRAPPER

SINGLE/QUEEN/KING

WITH 14 ROLLERS AT THE ENTRANCE CONVEYOR

WIDTH OF ROLLERS: 86”

WITH (2) SEALERS: LENGTH 100”

MAX. DISTANCE BETWEEN THE SEALERS: 80 ¾”

MAX. HEIGHT OF SEALERS FROM TABLE: APPROX. 9”

THIS WRAPPER HAS A FIXED HEIGHT OF 17”

IT INCLUDES (1) METAL TABLE AT THE END OF THE ENTRANCE

WIDTH OF TABLE: 72”

DEPTH OF TABLE: 51”

WRAPPER EXIT WIDTH: 83”

MAX. DISTANCE BETWEEN RIGHT AND LEFT SIDE OF THE BAGGER: 89 ½”

MAX. WORKING HEIGHT: 17” (430mm)

THE INSIDE DISTANCE BETWEEN THE RIGHT SEALER AND LEFT SEALER: 76 ½”

Learn More -

MAMMUT 2 HEAD PANEL QUILTING MACHINE2 HEAD PANEL QUILTING MACHINE WITH AUTOMATIC FABRIC FEED Learn More

MAMMUT 2 HEAD PANEL QUILTING MACHINE2 HEAD PANEL QUILTING MACHINE WITH AUTOMATIC FABRIC FEED Learn More -

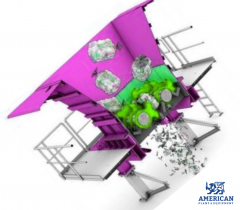

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More -

C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992REFERENCE NUMBER: C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992 SPECIFICATIONS: 1 PC. AIRLAY NONWOVEN LINE FEHRER V 21 K 12 2200 MM WORKING WIDTH, YEAR OF CONSTRUCTION 1992, SECOND-HAND THE LINE IS CONSISTING OF: 1 PC. CHUTE FEEDER TEMAFA WITH CONDENSER. 1 PC. WEIGHTING UNIT KUKLA WITH CONTINUOUS BELT. 1 PC. FEEDING UNIT, CONTINUOUS BELT TYPE FEHRER - FEEDING V 21. 1 PC. WEB FORMING UNIT FEHRER V 21. 2200 mm WORKING WIDTH. 1 PC. AERODYNAMIC CARD FEHRER K 12, 2200 mm WORKING WIDTH. 1 PC. NEEDLE LOOM FEHRER NL 9 S, 2200 mm WORKING WIDTH. SINGLE BOARD DOWN STROKE MACHINE, 3000 NEEDLES/M. MAX. 1500 STROKES/MIN. WITH OUTLET ROLLERS. 1 PC. WINDER WITH LONGITUDINAL CUTTER. (NO CROSS CUTTER AVAILABLE.) 1 PC. COMPLETE DUST COLLECTION UNIT. THE V 21 K 12 LINE IS SUITABLE FOR A WEIGHT RANGE OF APPROX. 400 TO 2000 GR/SWM AND A CAPACITY OF UP TO 600 KG/H, DEPENDING ON FIBERS. THE CONTROL PANELS, FILTERS ETC. ARE IN A GOOD CONDITION. 1 PC. RANDOM CARDING MACHINE FEHRER K 12 (REF. NO. 2133817). 2300 mm WORKING WIDTH, YEAR OF CONSTRUCTION UNFORTUNATELY NOT KNOWN. WITH OPENING MACHINE K 12. WITH ONE ASSELIN NEEDLE LOOM MODEL 169, STROKE HEIGHT 0-30 MM. 2.800 mm WORKING WIDTH. WITH ONE FEHRER NEEDLE LOOM NL 12, 1200 STROKES/MIN. 60 mm STROKE HEIGHT, 2.400 mm WORKING WIDTH. INCL. CUTTING AND ROLLING SECTION. THE LINE CONSISTS OF K 12 SECTION ONLY. V 21 SECTION IS NOT INCLUDED. PREVIOUSLY USED FOR 200 TO 2000 GR/SQM. THE MINIMUM IS 200 GR/SQM. MAINLY USED TO PRODUCE HIGH QUALITY MATTRESS MATERIAL IN A SQM-RANGE OF 300-1200 G/SQM MADE FROM JUTE FIBRES. IN GENERAL ALMOST ALL TYPES OF FIBERS CAN BE PROCESSED. IT IS A GOOD MACHINE FOR NATURAL FIBERS. 1 PC. AIRLAY LINE ROLANDO / FEHRER V21/K12 (REF. NO. 2226950). 4400 MM WORKING WIDTH. THE LINE IS CONSISTING OF: - HOPPER FEEDER ROLANDO, CASTING IRON. - CHEMINEE FEEDER WITH AUTOMATIC REGULATED FEEDING ROLANDO. - SQUARE METER MEASURING UNIT AND CONTROL SYSTEM MADE BY FEHRER TYPE E-PW. - OPENER FEHRER V 21, 4400 MM WORKING WIDTH. - RANDOM CARDING MACHINE FEHRER K 12, 4400 MM WORKING WIDTH. THE LINE HAS WORKED ON 1000 GR / SQM AND UP. QUANTITY AVAILABLE: 1 Learn More

C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992REFERENCE NUMBER: C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992 SPECIFICATIONS: 1 PC. AIRLAY NONWOVEN LINE FEHRER V 21 K 12 2200 MM WORKING WIDTH, YEAR OF CONSTRUCTION 1992, SECOND-HAND THE LINE IS CONSISTING OF: 1 PC. CHUTE FEEDER TEMAFA WITH CONDENSER. 1 PC. WEIGHTING UNIT KUKLA WITH CONTINUOUS BELT. 1 PC. FEEDING UNIT, CONTINUOUS BELT TYPE FEHRER - FEEDING V 21. 1 PC. WEB FORMING UNIT FEHRER V 21. 2200 mm WORKING WIDTH. 1 PC. AERODYNAMIC CARD FEHRER K 12, 2200 mm WORKING WIDTH. 1 PC. NEEDLE LOOM FEHRER NL 9 S, 2200 mm WORKING WIDTH. SINGLE BOARD DOWN STROKE MACHINE, 3000 NEEDLES/M. MAX. 1500 STROKES/MIN. WITH OUTLET ROLLERS. 1 PC. WINDER WITH LONGITUDINAL CUTTER. (NO CROSS CUTTER AVAILABLE.) 1 PC. COMPLETE DUST COLLECTION UNIT. THE V 21 K 12 LINE IS SUITABLE FOR A WEIGHT RANGE OF APPROX. 400 TO 2000 GR/SWM AND A CAPACITY OF UP TO 600 KG/H, DEPENDING ON FIBERS. THE CONTROL PANELS, FILTERS ETC. ARE IN A GOOD CONDITION. 1 PC. RANDOM CARDING MACHINE FEHRER K 12 (REF. NO. 2133817). 2300 mm WORKING WIDTH, YEAR OF CONSTRUCTION UNFORTUNATELY NOT KNOWN. WITH OPENING MACHINE K 12. WITH ONE ASSELIN NEEDLE LOOM MODEL 169, STROKE HEIGHT 0-30 MM. 2.800 mm WORKING WIDTH. WITH ONE FEHRER NEEDLE LOOM NL 12, 1200 STROKES/MIN. 60 mm STROKE HEIGHT, 2.400 mm WORKING WIDTH. INCL. CUTTING AND ROLLING SECTION. THE LINE CONSISTS OF K 12 SECTION ONLY. V 21 SECTION IS NOT INCLUDED. PREVIOUSLY USED FOR 200 TO 2000 GR/SQM. THE MINIMUM IS 200 GR/SQM. MAINLY USED TO PRODUCE HIGH QUALITY MATTRESS MATERIAL IN A SQM-RANGE OF 300-1200 G/SQM MADE FROM JUTE FIBRES. IN GENERAL ALMOST ALL TYPES OF FIBERS CAN BE PROCESSED. IT IS A GOOD MACHINE FOR NATURAL FIBERS. 1 PC. AIRLAY LINE ROLANDO / FEHRER V21/K12 (REF. NO. 2226950). 4400 MM WORKING WIDTH. THE LINE IS CONSISTING OF: - HOPPER FEEDER ROLANDO, CASTING IRON. - CHEMINEE FEEDER WITH AUTOMATIC REGULATED FEEDING ROLANDO. - SQUARE METER MEASURING UNIT AND CONTROL SYSTEM MADE BY FEHRER TYPE E-PW. - OPENER FEHRER V 21, 4400 MM WORKING WIDTH. - RANDOM CARDING MACHINE FEHRER K 12, 4400 MM WORKING WIDTH. THE LINE HAS WORKED ON 1000 GR / SQM AND UP. QUANTITY AVAILABLE: 1 Learn More -

YY-2840 KAWASAKI ROBOTIC ARM (INCLUDING BASE AND NEEDLE PLATE CLAMP), FOR MOVING MATTRESS TOPPERS AND POLYURETHANE FOAM SHEETS SO THAT THEY CAN BE LAMINATEDYY-2840 KAWASAKI ROBOTIC ARM (INCLUDING BASE AND NEEDLE PLATE CLAMP), FOR MOVING MATTRESS TOPPERS AND POLYURETHANE FOAM SHEETS SO THAT THEY CAN BE LAMINATED DESCRIPTION: 1. ROBOT PARAMETERS: INCORPORATING KAWASAKI FOUR AXIS ROBOTS; ARM SPAN 3200mm, BEARING CAPACITY 180KG; MECHANICAL ARM NEEDLE PLATE FIXTURE PARAMETERS; FIXTURE BEARING 50KG CLAMPING RANGE: LENGTH 1800, WIDTH 1000~1800; NEEDLE DEPTH CONTROL: 20mm NEEDLE DIAMETER: 1.5mm. Quantity: 1 Learn More

YY-2840 KAWASAKI ROBOTIC ARM (INCLUDING BASE AND NEEDLE PLATE CLAMP), FOR MOVING MATTRESS TOPPERS AND POLYURETHANE FOAM SHEETS SO THAT THEY CAN BE LAMINATEDYY-2840 KAWASAKI ROBOTIC ARM (INCLUDING BASE AND NEEDLE PLATE CLAMP), FOR MOVING MATTRESS TOPPERS AND POLYURETHANE FOAM SHEETS SO THAT THEY CAN BE LAMINATED DESCRIPTION: 1. ROBOT PARAMETERS: INCORPORATING KAWASAKI FOUR AXIS ROBOTS; ARM SPAN 3200mm, BEARING CAPACITY 180KG; MECHANICAL ARM NEEDLE PLATE FIXTURE PARAMETERS; FIXTURE BEARING 50KG CLAMPING RANGE: LENGTH 1800, WIDTH 1000~1800; NEEDLE DEPTH CONTROL: 20mm NEEDLE DIAMETER: 1.5mm. Quantity: 1 Learn More -

YY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTEYY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTE TECHNICAL PARAMETERS: 1. POWER SUPPLY: 380V/50Hz OR 220V 50/60Hz 2. POWER: 80KW (INCLUDE A HOT MELT GLUE MACHINE) 3. STABLE SPEED: 0 TO 50 METERS PER MINUTE(5 LAYERS) 4. DIMENSION: LENGTH 20000 X WIDTH 5000 X HEIGHT 3500mm 5. WEIGHT: 13T 6. YUNG PRESS: ≥0.6MPA 1.2M³/MIN 7. PRODUCTS’ SPECIFICATIONS: WIDTH(300 TO 600mm), LENGTH(400 TO 1000mm) 8. THE CORE SIZE: WIDTH(300 TO 500MM), LENGTH(400 TO 800mm) 9. SAP WEIGHT: 10 TO 50G/㎡ 10. WOODEN PULP WEIGHT: 40 TO 110G/㎡ 11. AUTOMATIC TENSION CONTROL 12. SINGLE SAP APPLICATOR 13. ABSORBENT CORE PREPARATION UNIT 14. ABSORBENT LAYER CROSS CUTTING UNIT 15. BACK SHEET APPLICATION AND EDGE FOLDING UNIT 16. HOT MELT GLUING UNIT 17. FINISHED PRODUCTS EMBOSSING UNIT 18. WIDTH FOLDING UNIT 19. FINISHED PRODUCTS CUTTING UNIT 20. LENGTH FOLDING UNIT DELIVERY TIME: 100 DAYS QUANTITY: 1 Learn More

YY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTEYY-2003 PET PAD MAKING MACHINE, 100 PADS PER MINUTE TECHNICAL PARAMETERS: 1. POWER SUPPLY: 380V/50Hz OR 220V 50/60Hz 2. POWER: 80KW (INCLUDE A HOT MELT GLUE MACHINE) 3. STABLE SPEED: 0 TO 50 METERS PER MINUTE(5 LAYERS) 4. DIMENSION: LENGTH 20000 X WIDTH 5000 X HEIGHT 3500mm 5. WEIGHT: 13T 6. YUNG PRESS: ≥0.6MPA 1.2M³/MIN 7. PRODUCTS’ SPECIFICATIONS: WIDTH(300 TO 600mm), LENGTH(400 TO 1000mm) 8. THE CORE SIZE: WIDTH(300 TO 500MM), LENGTH(400 TO 800mm) 9. SAP WEIGHT: 10 TO 50G/㎡ 10. WOODEN PULP WEIGHT: 40 TO 110G/㎡ 11. AUTOMATIC TENSION CONTROL 12. SINGLE SAP APPLICATOR 13. ABSORBENT CORE PREPARATION UNIT 14. ABSORBENT LAYER CROSS CUTTING UNIT 15. BACK SHEET APPLICATION AND EDGE FOLDING UNIT 16. HOT MELT GLUING UNIT 17. FINISHED PRODUCTS EMBOSSING UNIT 18. WIDTH FOLDING UNIT 19. FINISHED PRODUCTS CUTTING UNIT 20. LENGTH FOLDING UNIT DELIVERY TIME: 100 DAYS QUANTITY: 1 Learn More -

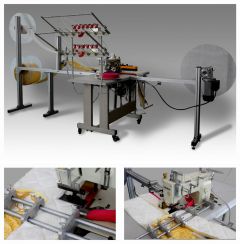

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINE

L-5049 FAUX PILLOW-TOP AUTO SEWING MACHINEREFERENCE NUMBER: L-5049

Learn More

AUTO SEWING MACHINE

MAX. STITCH LENGTH: 6mm

PRESSER FOOT HEIGHT: 10mm

QUANTITY: 1