Search results for: 'Control pa'"'

- Related search terms

- Control pan

- Control pan'

- Control+pa'||'

- Control+pa'"'

- control pro'

-

C-3980 KRAFT PAPER MAKING MACHINE WITH GAS BOILER, CAPACITY 3 TO 5 T/D, NET PAPER WIDTH 1200mm

C-3980 KRAFT PAPER MAKING MACHINE WITH GAS BOILER, CAPACITY 3 TO 5 T/D, NET PAPER WIDTH 1200mmC-3980 KRAFT PAPER MAKING MACHINE WITH GAS BOILER, CAPACITY 3 TO 5 T/D, NET PAPER WIDTH 1200mm

KRAFT PAPER MAKING MACHINE

WITH GAS BOILER

CAPACITY: 3 TO 5 T/D KRAFT PAPER MACHINE

1092 KRAFT CORRUGATED PAPER MACHINE

WITH RECYCLE PAPER AS RAW MATERIAL

TECHNICAL PARAMETER:

OUTPUT: KRAFT PAPER, CORRUGATED PAPER

WEIGHT: 60 TO 180G/M2

NET PAPER WIDTH: 1200mmQUANTITY: 1

Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More -

TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES)TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES) DOUBLE SHAFT SLITTING & REWINDING MACHINE FOR PAPER, ADHENSIVE TAPE, LABEL ETC. EFFECTIVE WIDTH: 1300mm (51 INCHES) UNWIND DIAMETER: 1000mm (40 INCHES) MINIMUM SLITTING WIDTH: 5mm (0.196 INCHES) REWIND DIAMETER: 650mm (25.5 INCHES) MACHINE SPEED: 300 METERS/MIN. POWER SOURCE: PLEASE ADVISE VOLTAGE REQUIRED AIR SOURCE: 5 KGS (SUPPLIED BY USER) QUANTITY: 1 Learn More

TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES)TT-2994 DOUBLE SHAFT SLITTER REWINDER (VERTICAL), WIDTH 1300mm (51 INCHES) DOUBLE SHAFT SLITTING & REWINDING MACHINE FOR PAPER, ADHENSIVE TAPE, LABEL ETC. EFFECTIVE WIDTH: 1300mm (51 INCHES) UNWIND DIAMETER: 1000mm (40 INCHES) MINIMUM SLITTING WIDTH: 5mm (0.196 INCHES) REWIND DIAMETER: 650mm (25.5 INCHES) MACHINE SPEED: 300 METERS/MIN. POWER SOURCE: PLEASE ADVISE VOLTAGE REQUIRED AIR SOURCE: 5 KGS (SUPPLIED BY USER) QUANTITY: 1 Learn More -

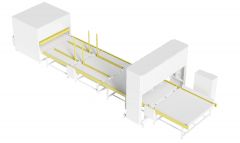

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More -

F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More -

M-5299 AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPEREFERENCE NUMBER: M-5299 (131324QND12UF) L AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE MODEL: CS-2HS EQUIPPED WITH TWO SERVO MOTORS & 90° TRANSFER CLIPPER DIMENSIONS (LxWxH): 4850mm x 3880mm x 1180mm WEIGHT: 2800KG QUANTITY AVAILABLE: 1 Learn More

M-5299 AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPEREFERENCE NUMBER: M-5299 (131324QND12UF) L AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE AUTOMATIC WOVEN BAG CONVERSION LINE CUTTING-SEWING TYPE MODEL: CS-2HS EQUIPPED WITH TWO SERVO MOTORS & 90° TRANSFER CLIPPER DIMENSIONS (LxWxH): 4850mm x 3880mm x 1180mm WEIGHT: 2800KG QUANTITY AVAILABLE: 1 Learn More -

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More -

MTU CONTAINERIZED DIESEL GENERATOR PLANT, 30.5 MW, YEAR 2017 AND 2018REFERENCE NUMBER: T-6933 MTU CONTAINERIZED DIESEL GENERATOR PLANT, 30.5 MW, YEAR 2017 AND 2018 MTU CONTAINERIZED DIESEL GENERATOR PLANT 30.5 MW FIFTEEN (15) MTU16V4000G63 EXHAUST EMISSION OPTIMIZED DIESEL ENGINES COUPLED TO HIGH PERFORMANCE MECC ALTE ECO46 2L/4A ALTERNATORS, RATED AT 2546 KVA/2033 KW STANDBY POWER AND 2303 KVA / 1842 KW PRIME POWER, 1500 RPM, 400 VOLT, 50 Hz, YEAR OF MANUFACTURE: 2017 AND 2018, ONLY 150 TO 200 HOURS SINCE NEW. EACH GENERATOR IS HOUSED IN A 40 FT SOUND ATTENUATED CONTAINER. SKID MOUNTED RADIATOR DESIGNED FOR HIGH END TEMPERATURES, 40 FT HI CUBE CONTAINER WITH SWITCH GEAR ROOM AND CONTROL ROOM, EQUIPMENT INCLUDES: CONTROL PANELS, CONTROL SYSTEM, BREAKER PANELS, HEATERS, BATTERY CHARGER, SWITCH GEAR, TRANSFORMERS, FUEL TANK SYSTEM AND ETC. COMPLETE POWER PLANT IN MODULE DESIGN THAT CAN BE EASILY TRANSPORTED AND SET UP WITHIN DAYS TO GENERATOR STEADY STREAM OF ELECTRICAL POWER. (15) ALL PURPOSE 40 FT SOUND ATTENUATED CONTAINERS WITH MTU16V4000G63 GENERATORS SETS. RATING: 2546 KVA/2033 KW STANDBY POWER AND 2303 KVA / 1842 KW PRIME POWER RADIATOR: SKID MOUNTED RADIATOR DESIGNED FOR HIGH END TEMPERATURES RADIATOR DESIGN: TECNO GROUP TG00094AA 30M/S REDUCED AIRFLOW RADIATOR WITH ELECTRIC POWERED COOLING FAN POWER BOX: CP6 MODEL: HMW‐2200‐T5 STD 2200KVA V400 / 50 Hz AS20 YEAR: 2017 AND 2018 HOURS: 150 TO 200 HOURS ONLY VOLTAGE: 400V, 3PH, 50 Hz ENGINE: MTU 16V4000G63 EXHAUST EMISSION OPTIMIZED ENGINE ENGINE SPEED: 1500 RPM STARTING SYSTEM: 24V ELECTRIC WITH OPTIMA YELLOW TOP BATTERIES AND BATTERY ISOLATOR ENGINE GOVERNOR: ADEC ALTERNATOR: MECC ALTE ECO46 2L/4A WITH MAUX EXCITATION, OIL PRIMER AND CENTRIFUGE FITTED AS CONFIRMED BY MTU, SET MOUNTED 4000A 4P MOTORIZED BREAKERS. CONTROL PANEL: AS5 WITH FREE ISSUE COMAP IG‐NTC‐BB + INTELIVISION 5 COMPONENTS AIR CIRCUIT BREAKER PANEL: 4 POLE: 4000A SCHNEIDER NW04 MOTORIZED H2 100KA BREAKING CAPACITY WITH MICROLOGIC 6.0A TRIP UNIT HEATER: THERMOSTATICALLY CONTROLLED 9KW 400V 3 PHASE WATER JACKET HEATER WITH CIRCULATION PUMP BATTERY CHARGER: DEEPSEA DSE9470 10A INTELLIGENT MAINS BATTERY CHARGER INCLUDING: AUTOMATIC ELECTRIC PRE‐LUBE PUMP; SET MOUNTED 2000A NEUTRAL EARTHLING CONTACTOR WITH CT; FUEL RETURN COOLER; CENTRIFUGAL OIL FILTER (MTU) & PRIMARY WATER SEPARATOR FILTER. INCLUDING: AUTOMATIC ELECTRIC PRE‐LUBE PUMP; SET MOUNTED 2000A NEUTRAL EARTHING CONTACTOR WITH CT; FUEL RETURN COOLER; CENTRIFUGAL OIL FILTER (MTU) & PRIMARY WATER SEPARATOR FILTER. TRANSFORMERS QUANTITY 4: 4MVA GBE OIL IMMERSED, FREE BREATHING STEP UP POWER TRANSFORMERS WITH OIL CONSERVATOR AND COPPER WINDINGS; 3 PHASE, 400‐33 KV; 50 Hz QUANTITY 1: 2MVA GBE OIL IMMERSED, FREE BREATHING STEP UP POWER TRANSFORMERS WITH OIL CONSERVATOR AND COPPER WINDINGS; 3 PHASE, 400‐33 KV; 50 Hz HV SWITCHGEAR CONTAINER PURPOSE BUILT 40 FT HI CUBE CONTAINER WITH HEATING LIGHTING AND POWER INSTALLED. LINED WITH ROCK WOOL INSULATED PANELS INCLUDES HIGH LEVEL LOUVER WITH FAN AND LOW‐LEVEL LOUVER FOR NATURAL AIR FLOW. SPLIT INTO TWO SECTIONS/ROOMS WITH A CONTROL ROOM ON ONE SIDE AND SWITCH GEAR IN THE OTHER ROOM WITH 33 KV ABB RING SAFE SWITCHGEAR CONTROL SYSTEM REMOTE COMMUNICATION AND LOAD SUMMATION CONTROL PANEL (RCLSP) 1 X COMAP IM‐NTC BB BASE BOX CONTROLLER (SITE LOAD VALUE MONITORING & INTEGRATION) 1 X COMAP IBNT INTERNET BRIDGE (BROADBAND INTERFACE) 1 X COMAP ILB+ LOCAL BRIDGE (LOCAL & PC REMOTE INTERFACE) 1 X 230/240V DC PSU 1 SET OF CONTROL MINIATURE CIRCUIT BREAKERS 1 SET OF CAN BUS INTERFACE TERMINALS BELDON 3106A CANBUS COMMUNICATION CABLING & CAT 5E ETHERNET COMMUNICATION CABLES COMAP MAINSPRO G59‐3 PROTECTION RELAY (OVER/UNDER VOLTS, Hz & VECTOR SHIFT) FUEL TANK SYSTEM QUANTITY 4 X 40,000L FUEL TANKS; DOUBLE SKINNED; DD50 FUEL POLISHING SYSTEM; BUND ALARM; OVERFILL ALARM AND CONTENTS GAUGE WITH ADJUSTABLE VOLT FREE LEVEL ALARM. QUANTITY 1 X 20,000L FUEL TANKS; DOUBLE SKINNED; DD50 FUEL POLISHING SYSTEM; BUND ALARM; OVERFILL ALARM AND CONTENTS GAUGE WITH ADJUSTABLE VOLT FREE LEVEL ALARM. Learn More

MTU CONTAINERIZED DIESEL GENERATOR PLANT, 30.5 MW, YEAR 2017 AND 2018REFERENCE NUMBER: T-6933 MTU CONTAINERIZED DIESEL GENERATOR PLANT, 30.5 MW, YEAR 2017 AND 2018 MTU CONTAINERIZED DIESEL GENERATOR PLANT 30.5 MW FIFTEEN (15) MTU16V4000G63 EXHAUST EMISSION OPTIMIZED DIESEL ENGINES COUPLED TO HIGH PERFORMANCE MECC ALTE ECO46 2L/4A ALTERNATORS, RATED AT 2546 KVA/2033 KW STANDBY POWER AND 2303 KVA / 1842 KW PRIME POWER, 1500 RPM, 400 VOLT, 50 Hz, YEAR OF MANUFACTURE: 2017 AND 2018, ONLY 150 TO 200 HOURS SINCE NEW. EACH GENERATOR IS HOUSED IN A 40 FT SOUND ATTENUATED CONTAINER. SKID MOUNTED RADIATOR DESIGNED FOR HIGH END TEMPERATURES, 40 FT HI CUBE CONTAINER WITH SWITCH GEAR ROOM AND CONTROL ROOM, EQUIPMENT INCLUDES: CONTROL PANELS, CONTROL SYSTEM, BREAKER PANELS, HEATERS, BATTERY CHARGER, SWITCH GEAR, TRANSFORMERS, FUEL TANK SYSTEM AND ETC. COMPLETE POWER PLANT IN MODULE DESIGN THAT CAN BE EASILY TRANSPORTED AND SET UP WITHIN DAYS TO GENERATOR STEADY STREAM OF ELECTRICAL POWER. (15) ALL PURPOSE 40 FT SOUND ATTENUATED CONTAINERS WITH MTU16V4000G63 GENERATORS SETS. RATING: 2546 KVA/2033 KW STANDBY POWER AND 2303 KVA / 1842 KW PRIME POWER RADIATOR: SKID MOUNTED RADIATOR DESIGNED FOR HIGH END TEMPERATURES RADIATOR DESIGN: TECNO GROUP TG00094AA 30M/S REDUCED AIRFLOW RADIATOR WITH ELECTRIC POWERED COOLING FAN POWER BOX: CP6 MODEL: HMW‐2200‐T5 STD 2200KVA V400 / 50 Hz AS20 YEAR: 2017 AND 2018 HOURS: 150 TO 200 HOURS ONLY VOLTAGE: 400V, 3PH, 50 Hz ENGINE: MTU 16V4000G63 EXHAUST EMISSION OPTIMIZED ENGINE ENGINE SPEED: 1500 RPM STARTING SYSTEM: 24V ELECTRIC WITH OPTIMA YELLOW TOP BATTERIES AND BATTERY ISOLATOR ENGINE GOVERNOR: ADEC ALTERNATOR: MECC ALTE ECO46 2L/4A WITH MAUX EXCITATION, OIL PRIMER AND CENTRIFUGE FITTED AS CONFIRMED BY MTU, SET MOUNTED 4000A 4P MOTORIZED BREAKERS. CONTROL PANEL: AS5 WITH FREE ISSUE COMAP IG‐NTC‐BB + INTELIVISION 5 COMPONENTS AIR CIRCUIT BREAKER PANEL: 4 POLE: 4000A SCHNEIDER NW04 MOTORIZED H2 100KA BREAKING CAPACITY WITH MICROLOGIC 6.0A TRIP UNIT HEATER: THERMOSTATICALLY CONTROLLED 9KW 400V 3 PHASE WATER JACKET HEATER WITH CIRCULATION PUMP BATTERY CHARGER: DEEPSEA DSE9470 10A INTELLIGENT MAINS BATTERY CHARGER INCLUDING: AUTOMATIC ELECTRIC PRE‐LUBE PUMP; SET MOUNTED 2000A NEUTRAL EARTHLING CONTACTOR WITH CT; FUEL RETURN COOLER; CENTRIFUGAL OIL FILTER (MTU) & PRIMARY WATER SEPARATOR FILTER. INCLUDING: AUTOMATIC ELECTRIC PRE‐LUBE PUMP; SET MOUNTED 2000A NEUTRAL EARTHING CONTACTOR WITH CT; FUEL RETURN COOLER; CENTRIFUGAL OIL FILTER (MTU) & PRIMARY WATER SEPARATOR FILTER. TRANSFORMERS QUANTITY 4: 4MVA GBE OIL IMMERSED, FREE BREATHING STEP UP POWER TRANSFORMERS WITH OIL CONSERVATOR AND COPPER WINDINGS; 3 PHASE, 400‐33 KV; 50 Hz QUANTITY 1: 2MVA GBE OIL IMMERSED, FREE BREATHING STEP UP POWER TRANSFORMERS WITH OIL CONSERVATOR AND COPPER WINDINGS; 3 PHASE, 400‐33 KV; 50 Hz HV SWITCHGEAR CONTAINER PURPOSE BUILT 40 FT HI CUBE CONTAINER WITH HEATING LIGHTING AND POWER INSTALLED. LINED WITH ROCK WOOL INSULATED PANELS INCLUDES HIGH LEVEL LOUVER WITH FAN AND LOW‐LEVEL LOUVER FOR NATURAL AIR FLOW. SPLIT INTO TWO SECTIONS/ROOMS WITH A CONTROL ROOM ON ONE SIDE AND SWITCH GEAR IN THE OTHER ROOM WITH 33 KV ABB RING SAFE SWITCHGEAR CONTROL SYSTEM REMOTE COMMUNICATION AND LOAD SUMMATION CONTROL PANEL (RCLSP) 1 X COMAP IM‐NTC BB BASE BOX CONTROLLER (SITE LOAD VALUE MONITORING & INTEGRATION) 1 X COMAP IBNT INTERNET BRIDGE (BROADBAND INTERFACE) 1 X COMAP ILB+ LOCAL BRIDGE (LOCAL & PC REMOTE INTERFACE) 1 X 230/240V DC PSU 1 SET OF CONTROL MINIATURE CIRCUIT BREAKERS 1 SET OF CAN BUS INTERFACE TERMINALS BELDON 3106A CANBUS COMMUNICATION CABLING & CAT 5E ETHERNET COMMUNICATION CABLES COMAP MAINSPRO G59‐3 PROTECTION RELAY (OVER/UNDER VOLTS, Hz & VECTOR SHIFT) FUEL TANK SYSTEM QUANTITY 4 X 40,000L FUEL TANKS; DOUBLE SKINNED; DD50 FUEL POLISHING SYSTEM; BUND ALARM; OVERFILL ALARM AND CONTENTS GAUGE WITH ADJUSTABLE VOLT FREE LEVEL ALARM. QUANTITY 1 X 20,000L FUEL TANKS; DOUBLE SKINNED; DD50 FUEL POLISHING SYSTEM; BUND ALARM; OVERFILL ALARM AND CONTENTS GAUGE WITH ADJUSTABLE VOLT FREE LEVEL ALARM. Learn More -

TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012 1. USED JENBACHER GENERATOR SYSTEM 2. CONSISTING OF (2) MODEL JGS 620F JENBACHER NATURAL GAS GENSETS 3. EACH RATED 3.356 MW; 2.9 MW NET OUTPUT; 1500 RPM; 3/50/11KV 4. YEAR BUILT 2012 5. REPORTED 20,000 HOURS AND 23,000 HOURS. CONTROLLED BY (1) PANEL. 6. BRAND: JENBACHER 7. MODEL: JGS 620F 8. USED EQUIPMENT FACTS ABOUT THIS MACHINE 9. FUEL TYPE: NATURAL GAS QUANTITY: 1 Learn More

TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012TT-7849 JENBACHER JGS 620F GENERATOR SYSTEM, 6.712 MW TOTAL, 11KV, 20K/23K HOURS, NATURAL GAS, 2012 1. USED JENBACHER GENERATOR SYSTEM 2. CONSISTING OF (2) MODEL JGS 620F JENBACHER NATURAL GAS GENSETS 3. EACH RATED 3.356 MW; 2.9 MW NET OUTPUT; 1500 RPM; 3/50/11KV 4. YEAR BUILT 2012 5. REPORTED 20,000 HOURS AND 23,000 HOURS. CONTROLLED BY (1) PANEL. 6. BRAND: JENBACHER 7. MODEL: JGS 620F 8. USED EQUIPMENT FACTS ABOUT THIS MACHINE 9. FUEL TYPE: NATURAL GAS QUANTITY: 1 Learn More