Search results for: 'roller+die'

-

J-4844 SAMCO 6062 SMALL DIE PRESS, 60” WIDE x 22” DEEPJ-4844 SAMCO 6062 SMALL DIE PRESS, 60” WIDE x 22” DEEP QUANTITY: 1 Learn More

J-4844 SAMCO 6062 SMALL DIE PRESS, 60” WIDE x 22” DEEPJ-4844 SAMCO 6062 SMALL DIE PRESS, 60” WIDE x 22” DEEP QUANTITY: 1 Learn More -

TT-2411 EUROMEC / CARLE MONTANARI PHARMACEUTICAL CANDY MANUFACTURING LINE, YEAR 1992 TO 2015TT-2411 EUROMEC / CARLE MONTANARI PHARMACEUTICAL CANDY MANUFACTURING LINE, YEAR 1992 TO 2015 QUANTITY: 1 Learn More

TT-2411 EUROMEC / CARLE MONTANARI PHARMACEUTICAL CANDY MANUFACTURING LINE, YEAR 1992 TO 2015TT-2411 EUROMEC / CARLE MONTANARI PHARMACEUTICAL CANDY MANUFACTURING LINE, YEAR 1992 TO 2015 QUANTITY: 1 Learn More -

TT-1790 COMPLETE BRAMPTON 5 LAYER 104” BLOWN FILM LINE, YEAR 1995TT-1790 COMPLETE BRAMPTON 5 LAYER 104” BLOWN FILM LINE, YEAR 1995 LINE CAN BE SEEN RUNNING UNTIL SEPTEMBER. HAS RUN LLDPE, LDPE, EVOH AND NYLON. QUANTITY: 1 Learn More

TT-1790 COMPLETE BRAMPTON 5 LAYER 104” BLOWN FILM LINE, YEAR 1995TT-1790 COMPLETE BRAMPTON 5 LAYER 104” BLOWN FILM LINE, YEAR 1995 LINE CAN BE SEEN RUNNING UNTIL SEPTEMBER. HAS RUN LLDPE, LDPE, EVOH AND NYLON. QUANTITY: 1 Learn More -

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More -

T-8216 COMPLETE WOOD/HEMP PELLET PLANT, 2 TO 3 TONS/HOURT-8216 COMPLETE WOOD/HEMP PELLET PLANT, 2 TO 3 TONS/HOUR 2-3 TONS/HOURS COMPLETE WOOD/HEMP PELLET PLANT SYSTEM PREVIOUSLY USED ON HEMP. LAST RUN AT 40,000 TO 60,000 LBS/DAY ON 12-HOUR DAYS OR 2.5 TONS PER HOUR IN GOOD CONDITION QUANTITY: 1 Learn More

T-8216 COMPLETE WOOD/HEMP PELLET PLANT, 2 TO 3 TONS/HOURT-8216 COMPLETE WOOD/HEMP PELLET PLANT, 2 TO 3 TONS/HOUR 2-3 TONS/HOURS COMPLETE WOOD/HEMP PELLET PLANT SYSTEM PREVIOUSLY USED ON HEMP. LAST RUN AT 40,000 TO 60,000 LBS/DAY ON 12-HOUR DAYS OR 2.5 TONS PER HOUR IN GOOD CONDITION QUANTITY: 1 Learn More -

L-3886 CHICKEN FEED PRODUCTION LINE

L-3886 CHICKEN FEED PRODUCTION LINEREFERENCE NUMBER: L-3886

Learn More

1) RECEIVING PROCESS

HEIGHT: 12 METERS

POWER: 1.5 KW

2) GRINDING AND MIXING PROCESS

LENGTH: 1.5 METERS

POWER: 1.5 KW

3) PELLETIZING AND BAGGING PROCESS

CAPACITY: 2 TO 3 TONS PER HOUR, PER UNIT

POWER: 37 KW

4) AUXILIARY PROCESS

POWE: 1.5 KW

5) ELECTRIC CONTROL SYSTEM

POWER: 3 PHASE, 380 VOLTS, 50 Hz -

C-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MW

C-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MWC-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MW

A. ONCE THROUGH STEAM GENERATOR

B. BARGE

C. CHILLERS

D. AIR COMPRESSOR

E. GAS TURBINE

F. STEAM TURBINE

G. FEEDWATER SYSTEM

H. CLOSED COOLING WATER SYSTEM

I. AUXILIARY COOLING WATER SYSTEM

J. CONDENSATE POLISHING UNIT (CPU)

K. WASTE WATER SYSTEM

L. PLANT ELECTRICAL SYSTEM

M. BLACK START DG SET

N. PLANT CONTROLS AND INSTRUMENTATION

O. PLANT FIRE FIGHTING SYSTEM

P. START UP VACUUM SYSTEM

Q. STEAM TURBINE DEAERATING CONDENSERQUANTITY: 1 PLANT

Learn More -

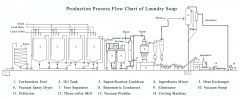

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More