Search results for: 'Spare Pa'[0]'

- Related search terms

- Spare+Pa

- Spare+part

- Spare+Pa'[0]

- Spare parts name 7-2

- Spare+parts+name+6

-

T-2034 SIEMENS ELECTRICAL GEAR, 480 VOLT

T-2034 SIEMENS ELECTRICAL GEAR, 480 VOLTSIEMENS LOW VOLTAGE EQUIPMENT:

SIEMENS TYPE WL LOW VOLTAGE SWITCHGEAR

5000 AMP MAIN BUS, 3 PHASES-3 WIRES, 480 VOLT, 50/60HZ, 100KA INTERRUPTING CAPACITY

SINGLE ENDED SOURCE OR DOUBLE ENDED SOURCE SUBSTATIONS AVAILABLE.

5000A AND 1600A SIEMENS TYPE WL CIRCUIT BREAKERS, MECHANICALLY OPERATED, ELECTRICALLY OPERATED, AND ADJUSTABLE TRIP SETTINGS.SWITCHGEAR FEATURES:

-MODBUS (RS-485) COMMUNICATIONS TO POWER METER AND BREAKERS.

-SIEMENS 9610 DIGITAL POWER METER

-PROTECTIVE RELAYS, BASLER BE1-87T TRANSFORMER DIFFERENTIAL (ANSI 87T FUNCTION), BASLER BE1-47N PHASE SEQUENCE, UNDER VOLTAGE, OVER VOLTAGE (ANSI 47, 27, & 59 FUNCTION), BASLER BE1-50 TIMED OVERCURRENT / INSTANTANEOUS (ANSI 50 /51 FUNCTION), BASLER BE1-25 SYNC CHECK (ANSI 25 FUNCTION)

-SIEMENS TVSS TRANSIENT VOLTAGE SURGE SUPPRESSOR

-ARC FLASH SAFETY PROVISIONS FOR “CLOSED DOOR REMOTE RACKING MOTOR” (LIMITED RACKING MOTORS AVAILABLE)

-MIMIC BUS ON FRONT OF SWITCHGEAR

-TEST PLUGS FOR MAINTENANCE TESTING OF COMPONENTS

-INFRASCAN PORTS IN REAR OF SWITCHGEAR

-SIEMENS SWITCHGEAR AND BREAKERS ARE CURRENTLY IN PRODUCTION SO SPARE PARTS AND UPGRADES ARE READILY AVAILABLE.SIEMENS LOW VOLTAGE EQUIPMENT INVENTORY:

AF= AMP FRAME, AT= AMP TRIP, M.O.= MECHANICALLY OPERATED, E.O.= ELECTRICALLY OPERATED.

ITEM 001

MANUFACTURER: SIEMENS

CURRENT RATING: 5000 AMP

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 100 KA

TIE BREAKER: QTY 0 NONE

SECTIONS: 4

TYPE: WL LV SWITCHGEAR

VOLTAGE RATING: 480 VOLT

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 5000 AF/AT M.O.& E.O

FEEDER BREAKERS: QTY 10 1600 AF / 1200AT M.O.& E.O.

FUTURE PROVISIONS: 2ITEM 002

MANUFACTURER: SIEMENS

CURRENT RATING: 3200 AMP

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 100 KA

TIE BREAKER: QTY 0 NONE

SECTIONS: 6

TYPE: WL LV SWITCHGEAR

VOLTAGE RATING: 480 VOLT

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3200 AF/AT M.O.& E.O

FEEDER BREAKERS: QTY 14 (9)1600 AF / 1200AT (5)1600 AF / 800AT M.O.& E.O.

FUTURE PROVISIONS: 6ITEM 003

MANUFACTURER: SIEMENS

CURRENT RATING: 5000 AMP

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 100 KA

TIE BREAKER: QTY 1 5000 AF/AT M.O.& E.O

SECTIONS: 5

TYPE: WL LV SWITCHGEAR

VOLTAGE RATING: 480 VOLT

HERTZ: 50 / 60

MAIN BREAKER: QTY 2 5000 AF/AT M.O.& E.O

FEEDER BREAKERS: QTY 1600 AF / 1200AT M.O.& E.O.4160 VOLTAGE SWITCH GEAR

SIEMENS MEDIUM VOLTAGE SWITCHGEAR:

SIEMENS TYPE GMSG MEDIUM VOLTAGE SWITCHGEAR

2000 AMP MAIN BUS, 4760 VOLT, 50/60HZ, 63KA INTERRUPTING CAPACITY

SINGLE ENDED SOURCE OR DOUBLE ENDED SOURCE SUBSTATIONS AVAILABLE.

3000A, 2000A AND 1200A SIEMENS TYPE GMSG CIRCUIT BREAKERS, MECHANICALLY OPERATED, ELECTRICALLY OPERATED, WITH ADJUSTABLE SOLID STATE PROTECTIVE RELAYS.SWITCHGEAR FEATURES:

-FIBER-OPTIC AND MODBUS (RS-485) COMMUNICATIONS TO POWER METER AND RELAYS.

-SIEMENS 9610 DIGITAL POWER METER

-PROTECTIVE RELAYS, BASLER BE1-87T TRANSFORMER DIFFERENTIAL (ANSI 87T FUNCTION), BASLER BE1-87B BUS DIFFERENTIAL (ANSI 87B FUNCTION), SIEMENS TYPE 7SJ6215 TOC AND INSTANTANEOUS (ANSI 50 /51 FUNCTION), ABB CIRCUIT SHIELD SYNC CHECK (ANSI 25 FUNCTION).

-LINE VT’S AND BUS VT’S

-CONTROL POWER TRANSFORMER

-ARC FLASH SAFETY PROVISIONS FOR “CLOSED DOOR REMOTE RACKING MOTOR”, RECEPTACLES FOR REMOTE RACKING AND REMOTE OPERATION OF BREAKERS.

-MIMIC BUS ON FRONT OF SWITCHGEAR.

-TEST PLUGS FOR MAINTENANCE TESTING OF COMPONENTS.

-INFRASCAN PORTS IN REAR OF SWITCHGEAR

-SIEMENS SWITCHGEAR AND BREAKERS ARE CURRENTLY IN PRODUCTION SO SPARE PARTS AND UPGRADES ARE READILY AVAILABLE.11 SECTIONS:

SIEMENS MEDIUM VOLTAGE SWITCHGEAR INVENTORY:

AF= AMP FRAME, M.O.= MECHANICALLY OPERATED, E.O.= ELECTRICALLY OPERATED.

ITEM 004

MANUFACTURER: SIEMENS

CURRENT RATING: 2000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (6) 1 THRU 6

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 2000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 8 (2)2000AF (6)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 005

MANUFACTURER: SIEMENS

CURRENT RATING: 2000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (6) 1 THRU 6

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 2000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 8 (2)2000AF (6)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 006

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 1 3000AF M.O. & E.O.

SECTIONS: (5) 11 THRU 15

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 0 NONE

FEEDER BREAKERS: QTY 5 (5)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 0ITEM 007

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (5) 16 THRU 20

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 8 (2)2000AF (6)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 008

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 1 3000AF M.O. & E.O.

SECTIONS: (5) 11 THRU 15

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 5 (5)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 009

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 1 3000AF M.O. & E.O.

SECTIONS: (5) 6 THRU 10

LINE VT’S: 0

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 5 (4)1200AF (1) 2000AF M.O.& E.O.

CPT: 0

BUS VT’S: 1 (3 PHASES)ITEM 010

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (5) 1 THRU 5

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 7 (7)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 011

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (5) 16 THRU 20

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 7 (7)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 012

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (5) 1 THRU 5

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 7 (7)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)ITEM 013

MANUFACTURER: SIEMENS

CURRENT RATING: 3000A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 1 3000 AF, M.O.& E.O

SECTIONS: (5) 6 THRU 10

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 3000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 4 (4)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES) USEDITEM 014

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (4) 1 THRU 4

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 4.76 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

FEEDER BREAKERS: QTY 3 (3)1200AF M.O.& E.O.

CPT: 1

BUS VT’S: 1 (3 PHASES)4160 SIEMENS MEDIUM VOLTAGE MCC EQUIPMENT INVENTORY:

SIEMENS 81000 SERIES MEDIUM VOLTAGE MCC STARTERS AND CUBICLES:

SIEMENS TYPE 81000 MEDIUM VOLTAGE STARTERS AND MV-MCC

1200 AMP MAIN BUS, 4160 VOLT, 60HZ, 50KA INTERRUPTING CAPACITY, 3 PHASES, NEMA 1

SINGLE ENDED SOURCE OR DOUBLE ENDED SOURCE MV-MCC AVAILABLE.

1200A TYPE 81000 SERIES STARTERS, ELECTRICALLY OPERATED, WITH ADJUSTABLE SOLID STATE PROTECTIVE RELAYS.MV-MCC AND STARTER FEATURES:

-FIBER-OPTIC AND MODBUS (RS-485) COMMUNICATIONS TO RELAYS.

-PROTECTIVE RELAYS, SIEMENS TYPE 7SJ6215 TOC AND INSTANTANEOUS (ANSI 50 /51 FUNCTION), GENERAL ELECTRIC MULTILIN M60 MOTOR PROTECTION RELAYS.

-BUS VT’S

-CONTROL POWER TRANSFORMER

-MIMIC BUS ON FRONT OF SWITCHGEAR.

-INFRASCAN PORTS IN REAR OF SWITCHGEAR

-SIEMENS MV-MCC AND STARTERS ARE CURRENTLY IN PRODUCTION SO SPARE PARTS AND UPGRADES ARE READILY AVAILABLE.

-DRAW-OUT VACUUM TECHNOLOGY CONTROLLERS

-LOAD BREAK ISOLATION SWITCHES.

37 SECTIONS:ITEM 015

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 150A/5AITEM 016

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 150A/5AITEM 017

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 018

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 019

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 020

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 021

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 022

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 023

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 024

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 025

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (1) SIEMENS 7SJ6215 (7) G.E. MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 8-May

CURRENT TRANSFORMERS: (8) SETS 150A/5AITEM 026

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: ( (6) G.E. MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4/6

CURRENT TRANSFORMERS: (6) SETS 150A/5AITEM 027

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (1) SIEMENS 7SJ6215 (7) G.E. MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 5/8

CURRENT TRANSFORMERS: (6) SETS 150A/5A (2) SETS 75A / 5AITEM 028

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (8) G.E. MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 5/8

CURRENT TRANSFORMERS: (4) SETS 150A/5A (4) SETS 75A / 5AITEM 029

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 030

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 031

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 032

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 033

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 034

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 035

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 036

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 037

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 038

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 039

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 040

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 041

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 042

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 043

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 044

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 045

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (6) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (6) SETS 200A/5AITEM 046

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (4) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 3 / 4

CURRENT TRANSFORMERS: (4) SETS 200A/5AITEM 047

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (4) SIEMENS 7SJ6215

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 3 / 4

CURRENT TRANSFORMERS: (4) SETS 200A/5AITEM 048

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES

MOTOR PROT. RELAYS: (2) SIEMENS 7SJ6215 (4) GE MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 4 / 6

CURRENT TRANSFORMERS: (4) SETS 75A/5A (2) SETS 150A/5AITEM 049

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES (2)

MOTOR PROT. RELAYS: (2) SIEMENS 7SJ6215 (4) GE MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 5 / 6

CURRENT TRANSFORMERS: (2) SETS 75A/5A (4) SETS 150A/5AITEM 050

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES (2)

MOTOR PROT. RELAYS: (1) SIEMENS 7SJ6215 (5) GE MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 5 / 6

CURRENT TRANSFORMERS: (2) SETS 75A/5A (4) SETS 150A/5AITEM 051

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

PRIMARY DISC. SWITCH: YES (2)

MOTOR PROT. RELAYS: (2) SIEMENS 7SJ6215 (4) GE MULTILIN M60

TYPE: 81000 SERIES

VOLTAGE RATING: 4.16KV

HERTZ: 60HZ

SECTIONS / FEEDERS: 5 / 6

CURRENT TRANSFORMERS: (6) SETS 150A/5ASIEMENS 15KV MEDIUM VOLTAGE SWITCHGEAR INVENTORY:

SIEMENS 15KV MEDIUM VOLTAGE SWITCHGEAR:

SIEMENS TYPE 15KV GMSG MEDIUM VOLTAGE SWITCHGEAR

1200 AMP MAIN BUS, 15,000 VOLT, 50/60HZ, 63KA INTERRUPTING CAPACITY

SINGLE ENDED SOURCE SUBSTATION AVAILABLE.

1200A SIEMENS TYPE GMSG CIRCUIT BREAKERS, MECHANICALLY OPERATED, ELECTRICALLY OPERATED, WITH ADJUSTABLE SOLID STATE PROTECTIVE RELAY.SWITCHGEAR FEATURES:

-FIBER-OPTIC AND MODBUS (RS-485) COMMUNICATIONS TO RELAY.

-SIEMENS 9610 DIGITAL POWER METER

-SIEMENS TYPE 7SJ6215 TOC AND INSTANTANEOUS (ANSI 50 /51 FUNCTION

-LINE VT’S

-INFRASCAN PORTS IN REAR OF SWITCHGEAR

-SIEMENS SWITCHGEAR AND BREAKERS ARE CURRENTLY IN PRODUCTION SO SPARE PARTS AND UPGRADES ARE READILY AVAILABLE.AF= AMP FRAME, M.O.= MECHANICALLY OPERATED, E.O.= ELECTRICALLY OPERATED.

ITEM 052

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASESS, 3 WIRES

INTERRUPTING RATING: 63 KAIC

TIE BREAKER: QTY 0 NONE

SECTIONS: (1) 1

LINE VT’S: 1 (3 PHASES)

TYPE: GMSG

VOLTAGE RATING: 15 KV

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 2000 AF, M.O.& E.O

FEEDER BREAKERS: QTY 0 NONE

CPT: 0

BUS VT’S: 0SIEMENS 38KV MEDIUM VOLTAGE SWITCHGEAR:

SIEMENS TYPE 38KV MEDIUM VOLTAGE SWITCHGEAR

1200 AMP MAIN BUS, 38,000 VOLT, 50/60HZ, 40KA INTERRUPTING CAPACITY

SINGLE ENDED SOURCE SUBSTATIONS AVAILABLE.

SIEMENS TYPE 38KV 3AH3 CIRCUIT BREAKERS, MECHANICALLY OPERATED, ELECTRICALLY OPERATED, WITH ADJUSTABLE SOLID STATE PROTECTIVE RELAYS.SWITCHGEAR FEATURES:

-FIBER-OPTIC AND MODBUS (RS-485) COMMUNICATIONS TO PROTECTIVE RELAYS.

-PROTECTIVE RELAYS, SIEMENS TYPE 7SJ6215 TOC AND INSTANTANEOUS (ANSI 50 /51 FUNCTION)

-EXTERNAL CONTROL POWER TERMINALS.

-INFRASCAN PORTS IN REAR OF SWITCHGEAR

-SIEMENS SWITCHGEAR AND BREAKERS ARE CURRENTLY IN PRODUCTION SO SPARE PARTS AND UPGRADES ARE READILY AVAILABLE.

-38KV TYPE 3AH3 VACUUM BREAKERS, 1200A.SIEMENS 38KV 3AH3 MEDIUM VOLTAGE SWITCHGEAR INVENTORY:

AF= AMP FRAME, M.O.= MECHANICALLY OPERATED, E.O.= ELECTRICALLY OPERATED.

ITEM 053

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 054

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 055

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 056

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 057

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 058

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 059

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 060

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 061

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 062

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 063

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 064

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 065

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 066

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 067

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 068

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 069

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 070

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 1 1200 AF, M.O.& E.O

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 2ITEM 071

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1ITEM 072

MANUFACTURER: SIEMENS

CURRENT RATING: 1200A

CONFIGURATION: 3 PHASES, 3 WIRES

INTERRUPTING RATING: 40 KAIC

FEEDER BREAKER: QTY 0 NONE

TYPE: 38KV 3AH3

VOLTAGE RATING: 38,000

HERTZ: 50 / 60

MAIN BREAKER: QTY 1 1200 AF, M.O.& E.O

SECTIONS: 1TRANSFORMERS

ABB LIQUID FILLED TRANSFORMERS:

ITEM 073

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.32%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 08 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 074

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.30%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 08 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 075

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.28%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 10 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 076

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.20%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 09 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 077

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.34%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 09 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 078

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.48%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 06 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 079

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.47%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 06 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 080

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.25%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 10 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 081

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.34%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 09 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 082

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.29%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 10 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 083

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.22%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 09 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 084

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 480Y-277

IMPEDANCE: 7.32%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 10 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 3000 / 3360

B.I.L. HV / LV: 200KV / 30KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 21066 LBS.ITEM 085

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 4160Y-2402

IMPEDANCE: 11.11%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 08 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 12000 / 13440

B.I.L. HV / LV: 200KV / 60KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 65852 LBS.ITEM 086

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 4160Y-2402

IMPEDANCE: 11.18%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 08 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 12000 / 13440

B.I.L. HV / LV: 200KV / 60KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 65852 LBS.ITEM 087

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 4160Y-2402

IMPEDANCE: 11.56%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 10 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 12000 / 13440

B.I.L. HV / LV: 200KV / 60KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 65852 LBS.ITEM 088

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 4160Y-2402

IMPEDANCE: 11.54%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 09 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 12000 / 13440

B.I.L. HV / LV: 200KV / 60KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 65852 LBS.ITEM 089

MANUFACTURER: ABB

TYPE: 3 PHASES

CLASS: KNAN / KNAF

VOLTAGES HV / LV: 33640 / 4160Y-2402

IMPEDANCE: 11.56%

TAP CHANGER: 5 POSITION, NO LOAD

FANS: YES

DATE OF MANUFACTURE: 10 / 2010

CONFIGURATION: DELTA-WYE (DYN1)

INSULATION FLUID: SILICONE

KVA RATING: 12000 / 13440

B.I.L. HV / LV: 200KV / 60KV

FREQUENCY: 60HZ

INSTRUCTION BOOK #: PC-1002

TOTAL WEIGHT: 65852 LBS.SIEMENS MV GROUND AND TEST DEVICES:

GMSG GROUND AND TEST DEVICES (SWITCHGEAR ACCESSORIES) SHOULD BE SOLD AS A SAFETY UPGRADE.

ITEM 090

MANUFACTURER: SIEMENS

RATED CURRENT: 1200A, 2000A, & 3000A

FREQUENCY: 50 HZ / 60HZ

OP. DUTY CYCLE: NOT LISTED

MAIN CONTACTS: VACUUM INTERRUPTER

CLOSE COIL: 125 VDC RANGE100-140

QUANTITY OF STYLE: (1) UPPER CUBICLE (1) LOWER CUBICLE

TYPE: GMSG-EO TYPE B

RATED VOLTAGE: 15 KV

RATED SHORT CIRCUIT: 63KA

INSTRUCTION BOOK#: E50001-U229-A408-X-US00

CHARGING MOTOR: 125 VDC RANGE100-140

TRIP COIL: 125 VDC RANGE70-140EMAIL US FOR PRICE & PICTURES

Learn More

INCLUDE OUR REFERENCE NUMBER -

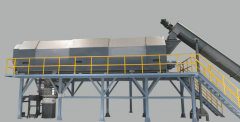

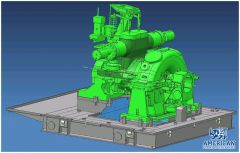

COGENERATION PLANT 1.2 MEGAWATTSREFERENCE NUMBER: T-6985 COGENERATION PLANT 1.2 MEGAWATTS NEAR NEW COGENERATION SYSTEM WITH MODULAR DESIGN THAT HAS NEVER BEEN RUN IN PRODUCTION: THIS SYSTEM IS A 1.2-MEGAWATT POWER PLANT AND CAN BURN BARK, SAWDUST, AGRICULTURAL WASTES SUCH AS PEANUT SHELLS, RICE HULLS, STRAW, ANIMAL RESIDUE, WET WOOD, ETC. THIS SYSTEM WILL CONVERT SUCH WASTE PRODUCTS INTO USEABLE THERMAL AND ELECTRICAL ENERGY. THIS SOLID WASTE STREAM CAN BE CONVERTED INTO PARTICLE FORM BY THE USE OF A COMMERCIAL SHREDDER, CONVEYED TO A SILO FOR STORAGE, AND THEN FED AUTOMATICALLY INTO THE MULTI-ZONE BURNER. STEAM IS GENERATED THROUGH A LOW PRESSURE 275 DEGREE (DE-RATED FROM 300 DEGREE) STAINLESS STEEL BOILER WITH A HEAT EXCHANGER. INLET STEAM IS 475 PSIG AT 700 DEGREES FTT WITH A MAXIMUM OF 22,000 LBS/HOUR BUT COULD BE INCREASED TO 24,000 LBS/HOUR. EXHAUST STEAM PRESSURE IS 3" HGA AT 5449 RPM BUT DESIGNED TO RUN AT 4" ABSOLUTE VACUUM. STEAM IS TRANSFERRED TO THE 3-STAGE BACK PRESSURE TURBINE RATED AT 1654HP DETUNED TO 1200HP TO MATCH THE GENERATOR. THIS SYSTEM COMES COMPLETE WITH GENERATOR CONTROL CENTER, BOILER CONTROL CENTER, COMBUSTION CONTROL CENTER, CONTROL ROOM SWITCHBOARD, TURBINE OIL SYSTEM, DUST DELIVERY CONTROL SYSTEM, SWITCHGEAR AND PLC CONTROLS. THIS PLANT WAS NEW IN 2005/2006 WHEN INSTALLED AND HAS NEVER BEEN RUN EXCEPT FOR PERMITTING FUNCTION. THE TURBINE GEARBOX AND GENERATOR WERE OEM REBUILT. THE COMPANY PURCHASED THIS SYSTEM WITH A GUARANTEE THE BURNER COULD MEET NOX STANDARDS. AFTER INSTALLATION, THE BURNER COULD NOT EFFICIENTLY BURN FIBER WITH HIGH FORMALDEHYDE CONTENT. CONSEQUENTLY, THE BURNER COULD NOT MEET THOSE NOX STANDARDS THAT ARE ONE OF THE MOST STRINGENT SET OF STANDARDS IN NORTH AMERICA. THESE MULTI-STAGE BURNERS ARE USED THROUGHOUT NORTH AMERICA AND MEET OR EXCEED NOX CONTROL STANDARDS IN OTHER AREAS WITHOUT PROBLEMS. THIS COGEN SYSTEM CAN BE PROFESSIONALLY DISMANTLED, ALL EQUIPMENT TAGGED FOR REINSTALLATION AND SHIPPED TO YOUR FACILITY, REASSEMBLED, AND CONNECTED TO YOUR PRESENT ELECTRICAL GRID SYSTEM. IT WOULD TAKE APPROXIMATELY 10 WEEKS TO DISMANTLE THE PLANT AND 15 TRUCKS TO SHIP THE EQUIPMENT TO YOUR PLANT SITE, AND APPROXIMATELY 16 WEEKS TO REASSEMBLE. THIS PLANT WOULD INCLUDE EVERYTHING NEEDED EXCEPT FUEL PROCESSING (GRINDING), STORAGE AND A TRANSFORMER TO SUPPLY POWER TO YOUR FACILITY. SHIPMENT OF THE PLANT WOULD BE BROKEN DOWN AS FOLLOWS: FIVE 53' TRAILER VANS TO LEGAL WEIGHT TEN 53' FLATBED TRAILERS TOTAL WEIGHT OF COGEN PLANT EQUIPMENT = 581,000 LBS. TIE-DOWN GEAR, CHAINS, BLOCKS AND CHOKES = 6,000 LBS. GROSS CUBIC SETTING OF CARGO = 67,840 CUBIC FEET MACHINERY PROPOSAL USED 1.2-MEGAWATT POWER PLANT CONSISTING OF THE FOLLOWING: DESCRIPTION OF EQUIPMENT 3-STAGE BURNER BOILER EGR FAN ID FAN SUPPLY WATER TANK SERVICE WATER PUMP WATER SOFTNER AND FILTER BOILER WATER PUMP SYSTEM DUAL CYCLONE SEPARATOR ELECTROSTATIC PRECIPITATOR ESP TRANSFORMER ESP PUMP SYSTEM CONDENSER PUMP SYSTEM STEAM TURBINE SENTINEL GENERATOR GENERATOR CONTROL CENTER BOILER CONTROL CENTER COMBUSTION CONTOL CENTER PLANT #2 SWITCHGEAR CONTROL ROOM SWITCHBOARD TURBINE OIL SYSTEM DUST DELIVERY CONTROL SYSTEM CONDENSER CONTROL PANEL ESP CONTROL PANEL TURBINE OIL CONTROL PLANT #1 POWER SWITCHGEAR COGENERATION PROJECT LOADING ANALYSIS BOILER FEEDWATER TANK LOADPOINT: LP4 FOOTING LENGTH 9.00 FT WIDTH 9.00 FT DEPTH 0.67 FT COUNT 1 EA CUBIC FT 54.03 CUFT TOTAL CU FT 54.03 CUFT LOAD CENT. HT. 4.00 FT MACHINE FOOT: LENGTH 6.00 FT WIDTH 6.00 FT COUNT 1.00 EA TYPE 1 MACHINE WT. 16,000 LBS FOOTING WT. 8,104 LBS FOOTING LOAD 197.53 LBS/SQFT SOIL LOADING 297.58 LBS/SQFT *TANK ASSEMBLY IS BOLTED DOWN 1=EVENLY DISTRIBUTED ACROSS BASE 2=CONCENTRATED FOOTPRINT APPROX. PSF WHICH IS DISTRIBUTED OVER ENTIRE SLAB COGENERATION PROJECT LOADING ANALYSIS STEAM UNIT LOADPOINT: LP3 - FOOTING LENGTH 25.00 FT - 13.00 FT WIDTH 14.00 FT - 3.00 FT DEPTH 1.00 FT - 2.00 FT COUNT 1 EA - 3 EA CUBIC FT 350.00 CUFT - 234.00 CUFT TOTAL CU FT 584.00 CUFT LOAD CENT. HT. 8.00 FT MACHINE FOOT: LENGTH 10.30 FT WIDTH 1.00 FT COUNT 3.00 EA TYPE 2 MACHINE WT. 53,000 LBS FOOTING WT. 52,500 LBS FOOTING LOAD 151.43 LBS/SQFT SOIL LOADING 301.43 LBS/SQFT *BOILER ASSEMBLY IS BOLTED DOWN 1=EVENLY DISTRIBUTED ACROSS BASE 2=CONCENTRATED FOOTPRINT APPROX. 1,715.21 PSF WHICH IS DISTRIBUTED OVER ENTIRE SLAB COGENERATION PROJECT LOADING ANALYSIS CONDENSOR UNIT LOADPOINT: LP2 FOOTING LENGTH 23.00 FT WIDTH 3.00 FT DEPTH 3.00 FT COUNT 6 EA CUBIC FT 1,242.00 CUFT TOTAL CU FT LOAD CENT. HT. NA* FT MACHINE FOOT: LENGTH 2.00 FT WIDTH 2.00 FT COUNT 6.00 EA TYPE 2 MACHINE WT. 40,000 LBS FOOTING WT. 186,300 LBS FOOTING LOAD 1,666.67 LBS/SQFT SOIL LOADING 546.62 LBS/SQFT *CONDENSOR ASSEMBLY IS WELDED DOWN 1=EVENLY DISTRIBUTED ACROSS BASE 2=BASE PAD LOADING IS CONDCENTATED COGENERATION PROJECT LOADING ANALYSIS TURBINE-GENERATOR SET LOADPOINT: LP6 FOOTING LENGTH 21.00 FT WIDTH 9.00 FT DEPTH 1.00 FT COUNT 1 EA CUBIC FT 189.00 CUFT TOTAL CU FT 189.00 CUFT LOAD CENT. HT. 3.50 FT MACHINE FOOT: LENGTH 6.00 FT WIDTH 6.00 FT COUNT 1.00 EA TYPE 1 MACHINE WT. 38,000 LBS FOOTING WT. 28,350 LBS FOOTING LOAD 201.06 LBS/SQFT SOIL LOADING 351.06 LBS/SQFT * ASSEMBLY IS BOLTED DOWN 1=EVENLY DISTRIBUTED ACROSS BASE 2=CONCENTRATED FOOTPRINT APPROX. NA PSF WHICH IS DISTRIBUTED OVER ENTIRE SLAB COGENERATION PROJECT LOADING ANALYSIS COMBUSTION UNIT LOADPOINT: LP1 LENGTH 24.75 FT WIDTH 8.50 FT DEPTH 1.00 FT COUNT 1 EA CUBIC FT 210.38 CUFT TOTAL CU FT LOAD CENT. HT. 6.50 FT MACHINE FOOT: LENGTH 24.58 FT WIDTH 7.60 FT COUNT 1.00 EA TYPE 1 MACHINE WT. 80,000 LBS FOOTING WT. 31,556 LBS FOOTING LOAD 428.25 LBS/SQFT SOIL LOADING 597.17 LBS/SQFT *BURNER ASSEMBLY IS BOLTED DOWN 1=EVENLY DISTRIBUTED ACROSS BASE COGENERATION PROJECT LOADING ANALYSIS WET ESP UNIT LOADPOINT: LP5 FOOTING LENGTH 9.00 FT WIDTH 9.00 FT DEPTH 0.67 FT COUNT 1 EA CUBIC FT 54.03 CUFT TOTAL CU FT 54.03 CUFT LOAD CENT. HT. 9.00 FT MACHINE FOOT: LENGTH 6.00 FT WIDTH 6.00 FT COUNT 1.00 EA TYPE 1 MACHINE WT. 38,000 LBS FOOTING WT. 8,104 LBS FOOTING LOAD 469.14 LBS/SQFT SOIL LOADING 569.19 LBS/SQFT * ASSEMBLY IS BOLTED DOWN 1=EVENLY DISTRIBUTED ACROSS BASE 2=CONCENTRATED FOOTPRINT APPROX. NA PSF WHICH IS DISTRIBUTED OVER ENTIRE SLAB COGENERATION CONCRETE FOOTING LOADING ANALYSIS LIVE + LOAD DEAD FOOT WIND THICKNESS YDS WIEGHT POINT DESCRIPTION WEIGHT LENGTH WIDTH QTY PSF LOAD LBS INCHES LBS 1 COMBUSTION UNIT 80,000 25 8 1 400 12 7.41 2 CONDENSER STRUCTURE 80,000 3 3 6 1,481 36 6.00 3 STEAM GENERATOR 105,500 3 12 3 977 12 4.00 4 BOILER FEED WATER TANK 16,000 9 9 1 198 4 1.00 5 WESP UNIT 38,000 8 8 1 594 12 2.37 6 TURBINE GEN SET 32,000 6 23 1 232 12 5.11 7 SILO* 230,000 21 21 1 345,000 36 49.00 330,750 PAVE UNDER STEAM UNIT 12 28 1 4 4.15 MISC. STEEL FOOTINGS 1.5 1.5 15 12 1.25 MISC AREA PAVEMENT 72 5 1 4 4.44 84.73 8.47 FACTOR ESTIMATED CONCRETE USAGE 93.20 YARDS * SPECIFICATION MIGHT CHANGE WHEN ENGINEERING DRAWINGS COME FROM MANUFACTURER FUEL METERING BIN FUEL IS TRANSFERRED FROM A STORAGE BIN TO THE METERING BIN. THE METERING BIN IS PROVIDED TO PLACE A SUPPLY OF FUEL IN CLOSE PROXIMITY TO THE COMBUSTION SYSTEM AND ASSURE A CONSTANT SUPPLY OF FUEL TO THE COMBUSTION SYSTEM. THIS IS USUALLY A SMALL BIN PROVIDING UP TO TWO HOURS OF FUEL STORAGE CLOSE TO THE COMBUSTION SYSTEM. BIN IS SUPPLIED WITH A HATCH AND A SIGHT GLASS FOR EASILY DETERMINING THE QUANTITY OF FUEL PRESENT. THE METERING BIN IS EQUIPPED WITH A LIVE BOTTOM AUGER SYSTEM TO ASSURE A CONSTANT FLOW OF FUEL TO THE COMBUSTION SYSTEM. THE FUEL FLOWS INTO A SCREW CONVEYOR THAT TRANSPORTS THE FUEL TO THE COMBUSTION SYSTEM. THIS BIN IS EQUIPPED WITH HIGH- AND LOW-LEVEL SENSORS. FAILURE OF THE FUEL TRANSFER CONVEYORS OR A PROBLEM WITH THE PRIMARY FUEL STORAGE DEVICES IS SIGNALED WHEN THE METERING BIN LEVEL IS LOW FOR AN ADJUSTABLE PERIOD OF TIME. THE DRIVE MOTOR AND LEVEL SWITCHES ARE WIRED TO A JUNCTION BOX ON THE METERING BIN. METERING BIN SIZES WILL VARY ACCORDING TO THE FUEL NEEDS OF THE COMBUSTION SYSTEM. THESE BINS ARE SUPPLIED WITH OPEN TOPS WHEN THE CUSTOMER IS RESPONSIBLE FOR DELIVERY OF FUEL TO THE METERING BIN. THESE BINS WILL USUALLY BE ELEVATED ABOVE THE COMBUSTION UNIT FEED SCREW CONVEYOR. LEGS CAN BE PROVIDED WITH THESE UNITS TO SUPPORT THE METERING BINS FROM THE FLOOR OR THE CUSTOMER CAN PROVIDE SUPPORTS AS APPROPRIATE. THE UNITS ARE SUPPORTED FROM BELOW AT THE FOUR CORNERS OF THE BIN. COMBUSTION SYSTEM THE COMBUSTION SYSTEM CONSISTS OF SEVERAL COMPONENTS AS FOLLOWS: 1. FUEL FEED ROTARY AIR LOCK 2. FUEL FEED TRANSITION HOPPER AND HIGH/LOW LEVEL SENSORS 3. FUEL FEED SCREW CONVEYOR, EQUIPPED WITH VARIABLE FREQUENCY DRIVE 4. PRIMARY COMBUSTION CHAMBER, CONTAINING: A. CERAMIC WALL AND ARCH SYSTEM B. THREE LEVEL COMBUSTION AIR INLETS WITH INDIVIDUAL ADJUSTMENTS AND COMBUSTION AIR FANS. COMBUSTION AIR FANS ARE EQUIPPED WITH VARIABLE FREQUENCY DRIVES C. STATIONARY GRATE SYSTEM FOR INTRODUCTION OF PRIMARY AND SECONDARY COMBUSTION AIR D. ASH AUGER SCREWS FABRICATED OF HIGH TEMPERATURE STAINLESS STEEL FOR ASSURING PROPER DISTRIBUTION OF THE FIRE WITHIN THE FIRE BOX AND AUTOMATIC REMOVAL OF THE ASH REMAINING FROM THE COMBUSTION OF THE FUEL MATERIAL. 1. SECONDARY COMBUSTION CHAMBER A. CERAMIC WALL AND ARCH SYSTEM B. PROVIDES FOR AN EXTENDED DWELL TIME TO ASSURE COMPLETE COMBUSTION OF THE COMBUSTION BYPRODUCT GASES PRIOR TO LEAVING THE COMBUSTION SYSTEM. 1. HOT GAS TRANSITION FOR COMBUSTION UNIT TO HEAT EXCHANGER UNIT 2. HOT GAS DUCT WORK FROM HEAT EXCHANGER TO THE DUST COLLECTION EQUIPMENT 3. DUST COLLECTION EQUIPMENT, DESIGN DEPENDING ON FUEL AND SYSTEM SIZE 4. DUCT WORK FROM DUST COLLECTION EQUIPMENT TO INDUCED DRAFT FAN 5. INDUCED DRAFT FAN, EQUIPPED WITH VARIABLE FREQUENCY DRIVE OR AUTOMATICALLY ADJUSTABLE DAMPER, DEPENDING ON SYSTEM DESIGN AND APPLICATION. 6. EXHAUST GAS STACK, DIAMETER AND HEIGHT DEPENDING ON SYSTEM DESIGN AND APPLICATION. THE COMBUSTION SYSTEM IS PREFABRICATED TO THE EXTENT THAT IS ALLOWABLE FOR NECESSARY SHIPPING RESTRICTIONS. IN GENERAL, THE PRIMARY COMBUSTION CHAMBER IS COMPLETELY PREFABRICATED IN THE SHOP. COMBUSTION AIR FANS AND MANIFOLDS ARE INSTALLED ON THE JOB SITE. THE SIZES OF THE COMBUSTION SYSTEMS FOR THE 600 SERIES ARE APPROXIMATELY 8 FEET WIDE. THE LENGTH OF THE UNITS IS APPROXIMATELY 25 FEET. THE OVERALL HEIGHT OF THE UNIT IS APPROXIMATELY 8 FEET. THE PRIMARY COMBUSTION CHAMBERS ARE SHIPPED COMPLETE. THE EXTENDED COMBUSTION CHAMBERS ARE SHIPPED AS COMPONENTS. STEAM BOILER SYSTEMS THE STEAM BOILER SYSTEM CONSIST OF THE NEEDED EQUIPMENT ITEMS TO PRODUCE STEAM ENERGY FROM THE HOT GASES PRODUCED BY THE CHALLENGER COMBUSTION SYSTEMS. THE BOILER IS A 300PSIG, 18,819 LBS. PER HOUR. THIS SYSTEM IS MADE UP OF THE FOLLOWING COMPONENTS: HEAT RECOVERY STEAM GENERATOR (HRSG) BOILER FEEDWATER PUMP SKID BOILER FEEDWATER STORAGE VESSEL FEEDWATER TREATMENT SKID THE HRSG UNITS ARE SIZED TO RECOVER APPROXIMATELY 75 80% OF THE THERMAL ENERGY ENTERING THE DEVICE. THE STEAM ENERGY OUTPUT IS DETERMINED BY ESTABLISHING THE THERMAL ENERGY RELEASED BY THE COMBUSTION SYSTEM TO THE HOT GASES THAT WILL BE ENTERING THE HRSG. THE STEAM FLOW OUTPUT IS DETERMINED BY ESTABLISHING THE DESIRED STEAM PRESSURE AND THE HEAT INPUT. STEAM PRODUCTION WILL VARY ACCORDING TO THE QUANTITY AND TEMPERATURE OF THE HOT GASES PRODUCED IN THE COMBUSTION SYSTEM AND THE TEMPERATURE OF THE BOILER FEEDWATER AS WELL AS THE STEAM PRESSURE DESIRED. SYSTEM INCLUDES: ECONOMIZER - INSTALLED IN OUTLET OF HRSG CONDENSATE HEATER - STEAM OPERATED - INSTALLED IN THE BOILER FEEDWATER STORAGE VESSEL SOOT BLOWER - INSTALLED IN THE HRSG TO MINIMIZE THE EFFECTS OF ASH CARRY DEAERATOR - INSTALLED IN THE BOILER FEEDWATER STORAGE VESSEL THIS HEAT RECOVERY STEAM GENERATOR UNIT WAS DESIGNED AS A FIRE TUBE BOILER FOR A SINGLE PASS OF THE HOT GASES THROUGH THE UNIT WITH STEAM PRESSURES UP TO 300 PSIG. THE UNIT WAS DESIGNED WITH AMPLE STEAMING VOLUME TO ASSURE A GOOD QUALITY OF STEAM GENERATION. STEAM IS OF A QUALITY SUFFICIENT TO ENTER INTO A STEAM TURBINE GENERATOR UNIT. BOILER FEEDWATER PUMP PACKAGE IN ADDITION TO THE BOILER, A BOILER FEED WATER PUMP PACKAGE IS INCLUDED. THIS PACKAGE CONSISTS OF A PREFABRICATED SKID CONTAINING TWO BOILER FEEDWATER PUMPS AND NECESSARY PIPING AND VALVES. ONE PUMP IS THE DESIGNATED “RUN” PUMP AND THE OTHER IS A DESIGNATED “SPARE” PUMP. A FLOW METER, PRESSURE GAUGES AND TEMPERATURE GAUGE ARE PROVIDED FOR MONITORING THE PERFORMANCE OF THE PACKAGE. PUMPS ARE SIZED FOR 125% OF DESIGN CAPACITY AND ARE INTENDED TO RUN CONTINUOUSLY TO MAINTAIN DESIRED BOILER DRUM LEVEL. PUMP PACKAGES ARE SIZED TO MATCH THE HEAT RECOVERY STEAM GENERATOR UNITS. BOILER FEEDWATER STORAGE TANK THE SYSTEM ALSO INCLUDES A BOILER FEED WATER STORAGE TANK. THIS PACKAGE CONSISTS OF AN INSULATED TANK FOR STORAGE OF CONDENSATE AND BOILER FEEDWATER FOR THE BOILER SYSTEM. THE TANK IS CONSTRUCTED TO A 15 PSIG RATING AND CAN BE OPERATED AT A PRESSURE OF 5 PSIG IF NECESSARY. STANDARD DESIGNS CALL FOR VENTED TANKS. A FLOW METER FOR CONDENSATE RETURN AND A FLOW METER FOR MAKEUP WATER ARE PROVIDED. A PRESSURE GAUGE, LEVEL GAUGE AND TEMPERATURE GAUGE ARE PROVIDED FOR MONITORING THE CONDITION OF THE CONDENSATE WITHIN THE TANK. THE TANK IS PROVIDED WITH A STAND TO ELEVATE THE TANK ABOVE THE SUCTION OF THE BOILER FEEDWATER PUMPS. IN SOME CASES, IT WILL BE DESIRABLE TO LOCATE THE TANK ABOVE THE INLET TO THE BOILER. THE STANDS FOR THESE APPLICATIONS ARE TO BE PROVIDED BY THE CUSTOMER. THE TANK IS SIZED TO PROVIDE FOR OPERATION OF THE BOILER AT FULL OUTPUT FOR A PERIOD OF UP TO 20 MINUTES. THE TANK IS ALSO EQUIPPED WITH INSTRUMENTATION TO TIE THE UNIT INTO THE OVERALL COMBUSTION/BOILER CONTROL SYSTEM. THE FOLLOWING DEVICES/INPUTS ARE PROVIDED: TEMPERATURE SENSOR, PRESSURE SENSOR, LEVEL SENSOR, AND FIVE POINT LEVEL SWITCH FOR ALARMS AND SHUTDOWN LOGIC. THE PACKAGE IS ALSO EQUIPPED WITH AN AUTOMATIC WATER VALVE TO PROVIDE MAKEUP WATER IN THE EVENT THE WATER LEVEL REACHES THE LOW-LEVEL ALARM POSITION. THIS IS PROVIDED THROUGH A FLOAT OPERATED VALVE. THE TANK AND CONTROL DEVICES ARE PRE-PACKAGED WITH ALL CONTROL DEVICES WIRED TO A JUNCTION BOX MOUNTED ON THE UNIT. THE OPERATING VOLTAGE FOR THE CONTROL DEVICES IS 24VDC. THE TANK IS ALSO INSULATED TO REDUCE HEAT LOSS TO THE ATMOSPHERE. DEAERATORS A DEAERATOR HAS BEEN PROVIDED TO REMOVE UNWANTED OXYGEN AND OTHER NON-CONDENSABLE GASES FROM THE BOILER FEEDWATER. THE DEAERATOR IS PROVIDED FOR THIS PURPOSE. THIS IS GENERALLY A REQUIRED ITEM ON 150 AND 300 PSIG STEAM SYSTEMS. THIS IS A REQUIRED DEVICE ON ALL STEAM SYSTEMS PROVIDING STEAM FOR STEAM TURBINE GENERATOR APPLICATIONS. FEEDWATER TREATMENT PACKAGES BOILER FEED WATER MUST BE OF HIGH QUALITY, ALL CONTAMINANTS THAT WOULD DAMAGE THE BOILER OR STEAM TURBINES MUST BE REMOVED FROM THE FEED WATER STREAM. THERE ARE GENERALLY THREE AREAS OF CONCERN. FIRST, THE WATER MUST BE FREE FROM SOLIDS SUCH AS SAND OR OTHER CONTAMINANTS. SECOND, DISSOLVED MINERALS SUCH SODIUM AND POTASSIUM MUST BE REMOVED. THIRD, NON-CONDENSABLE GASES SUCH AS OXYGEN AND CARBON DIOXIDE MUST BE REMOVED. THE REMOVAL OF THESE CONTAMINANTS REQUIRES A THREE STAGE REMOVAL PLAN. FIRST, ALL WATER ENTERING THE BOILER SYSTEM SHOULD BE FILTERED. SECOND, THE WATER SHOULD PASS THROUGH A WATER SOFTENER UNIT OF SOME TYPE AND THIRD, CHEMICALS WILL BE ADDED TO THE WATER TO ASSIST IN THE REMOVAL OF THE NON-CONDENSABLE GASES AND OTHER CONTAMINANTS. THE FEED WATER TREATMENT PACKAGE WILL INCLUDE THE FOLLOWING EQUIPMENT: 1. WATER FILTER - DUAL UNIT 2. WATER SOFTENER - DUAL UNIT 3. CHEMICAL FEED PUMPS (3) - SEPARATE ASSEMBLY THIS EQUIPMENT IS PREPACKAGED ON A SKID. THE CONTROLS AND PUMP MOTORS ARE PRE-WIRED TO A JUNCTION BOX ON THE PACKAGE. THE CHEMICAL ADDITIVES PUMPS ARE PACKAGED INTO A PUMP STAND. THE STAND IS DESIGNED TO BE LOCATED IN A POSITION AGAINST A WALL WHERE THE CONTAINERS FOR THE VARIOUS BOILER FEEDWATER CHEMICALS CAN BE PLACED. STEAM TURBINE GENERATOR SYSTEMS AN ELLIOT MODEL 2DYR3-MULTISTAGE TURBINE WILL BE USED FOR THE SYSTEM. IT CONSISTS OF THE FOLLOWING: 5449 RPM, INLET STEAM PRESSURE 475 PSIG, INLET STEAM TEMPERATURE 700’HGA, EXHAUST STEAM PRESSURE 3” HGA, MAXIMUM INLET STEAM TEMPERATURE 750 FTT, RATED POWER 1654 HP WITH ALL HAND VALVES OPEN. IT INCLUDES: 1. GEAR REDUCER 2. ELECTRIC GENERATOR A. INDUCTION B. SYNCHRONOUS 1. LUBRICATION SYSTEM 2. INSTRUMENTATION / CONTROLS 3. GENERATOR BREAKER THE BASIC COMPONENTS WERE ASSEMBLED INTO A SKID PACKAGE. THE PACKAGE WAS PREASSEMBLED AND SHIPPED AS A COMPLETED ASSEMBLY. THE CONTROLS AND GENERATOR BREAKER ARE PRE-ASSEMBLED AND TESTED PRIOR TO BEING SHIPPED TO THE CUSTOMER. STEAM CONDENSER SYSTEMS THE PURPOSE OF A STEAM CONDENSER SYSTEM IS TO TAKE THE STEAM THAT EXITS THE STEAM TURBINE GENERATOR UNIT AND CONDENSE IT TO WATER SO THAT IT MAY BE RETURNED TO THE BOILER FEEDWATER SYSTEM. THIS ALLOWS FOR THE CONSERVATION OF THERMAL ENERGY, WATER AND THE ASSOCIATED BOILER FEEDWATER TREATMENT CHEMICALS. A WATER-COOLED DESIGN CONDENSER HAS BEEN INCLUDED. AIR COOLED CONDENSER SYSTEMS THE AIR COOLED CONDENSER SYSTEM IS MADE UP OF FRAMES THAT CONTAIN MULTIPLE ROWS OF CARBON STEEL TUBES THAT ARE WRAPPED WITH AN ALUMINUM FIN. THIS FINNED ARRANGEMENT ALLOWS THE CARBON STEEL TUBE TO CONDUCT THERMAL ENERGY INTO THE AIR SURROUNDING THE UNIT. IN ORDER TO MAXIMIZE THE HEAT DISSIPATION, THE UNITS ARE SUPPLIED WITH FANS TO MOVE THE COOLER AMBIENT AIR PAST THE FINNED TUBES. AIR POLLUTION CONTROL EQUIPMENT A COMPLETE AIR POLLUTION CONTROL SYSTEM WITH EQUIPMENT REQUIRED FOR THIS PROJECT HAS BEEN INCLUDED, BASED ON LOCAL REQUIREMENTS. THE EQUIPMENT AVAILABLE CONSISTS OF THE FOLLOWING: 1. MULTICLONE - THESE UNITS ARE DESIGNED TO REMOVE PARTICULATE MATTER THAT IS AS SMALL AS 10 MICRONS IN SIZE. SINCE AIR EMISSIONS ARE GENERALLY BASED ON A QUANTITY OF EMISSIONS ON AN ANNUAL BASIS, THOSE QUANTITIES MUST BE ESTIMATED AND QUANTIFIED. WHERE THE EMISSIONS FROM THE MULTICLONE UNIT EXCEED THOSE QUANTITIES, THEN ADDITIONAL EQUIPMENT MUST BE USED. 2. BAG HOUSES - THESE UNITS CONSIST OF MULTIPLE HIGH TEMPERATURE RATED DUST COLLECTION BAGS. THESE BAGS CAN BE PROVIDED IN DIFFERENT TYPES AND CONFIGURATIONS AS WELL AS COATED AND UNCOATED TO ACHIEVE DIFFERING COLLECTION EFFICIENCIES. THE DESIGN OF THE BAG HOUSE SYSTEMS WILL VARY ACCORDING TO LOCAL REQUIREMENTS. 3. SCRUBBERS - THESE SYSTEMS CONSIST OF A SPRAY TOWER, WATER COLLECTION BASIN, A CIRCULATING WATER PUMP SYSTEM AND A MIST ELIMINATOR SECTION. THESE UNITS INTRODUCE A FINE SPRAY OF WATER INTO THE EXHAUST GASES. THIS FINE MIST OF WATER DROPLETS ATTRACT THE DUST PARTICLES AND THE DUST PARTICLES ARE COLLECTED ON THE FINE WATER DROPLETS. THESE WATER DROPLETS THEN FALL INTO THE COLLECTION BASIN. SOME AMOUNT OF THE SPRAY IS CARRIED UP THE TOWER, THIS WATER IS COLLECTED IN A MIST ELIMINATOR SECTION OF THE TOWER AND THE COLLECTED WATER IS CHANNELED TO THE COLLECTION BASIN. A SMALL AMOUNT OF WATER IS CONTINUOUSLY BLED FROM THE COLLECTION BASIN TO REMOVE THE COLLECTED PARTICULATE MATERIAL. THIS IS GENERALLY INTRODUCED INTO THE COMBUSTION UNIT AND REMOVED BY THE ASH COLLECTION SYSTEM THAT IS A PART OF THE COMBUSTION SYSTEM. SOME SMALL AMOUNT OF WATER IS EVAPORATED AS THE COMBUSTION GASES ARE COOLED TO APPROXIMATELY 150F. A CONTINUOUS MAKE UP WATER SUPPLY IS REQUIRED. 4. WET ELECTROSTATIC PRECIPITATORS - IN SYSTEMS REQUIRING AN ADDITIONAL LEVEL OF PARTICULATE CONTROL AN ELECTROSTATIC COLLECTION UNIT IS ADDED TO THE TOP OF THE SCRUBBER SYSTEM. THIS ELECTROSTATIC UNIT REPLACES THE MIST ELIMINATOR THAT IS PROVIDED AS A PART OF THE SCRUBBER DESCRIBED ABOVE. THIS UNIT REMOVES A HIGHER PERCENTAGE OF THE DUST/WATER PARTICLES FROM THE EXHAUST GAS STREAM. CONTROL AND POWER DISTRIBUTION CONTROLS THIS COGEN PLANT HAS FULLY INTEGRATED ALL ASPECTS OF THE COGENERATIONS FACILITIES EQUIPMENT PACKAGE INTO A SINGLE CONTROL SYSTEM. THIS IS ACCOMPLISHED USING PROGRAMMABLE LOGIC CONTROLLERS AND TOUCH SCREEN OPERATOR INTERFACE DEVICES TO CREATE A WINDOW ON THE ENTIRE SYSTEM. THIS SYSTEM WAS DESIGNED FOR A MINIMUM OF OPERATOR ATTENTION. SOFTWARE IS CONFIGURED TO PRESENT CLEAR WINDOWS INTO THE FACILITIES OPERATIONS. THIS COGENERATION SYSTEM WAS SET UP WITH DUAL OPERATOR INTERFACES TO ASSURE A VIEW OF MULTIPLE OPERATING COMPONENTS AT ALL TIMES. POWER DISTRIBUTION THE POWER DISTRIBUTION EQUIPMENT IS PROVIDED AS FOLLOWS. BUT, IN GENERAL THE FOLLOWING DESCRIPTION WILL APPLY. EACH COGENERATION SYSTEM WILL BE PROVIDED WITH A FACILITY MAIN BREAKER. THIS MAIN BREAKER WILL BE PROVIDED AT THE PRIMARY VOLTAGE OF THE GENERATOR PORTION OF THE PROJECT. IN MOST CASES THIS WILL BE 480 V, 3 PH AND 60 Hz OR 400 V, 3 PH AND 50 Hz. CUSTOMERS WILL SPECIFY THE INTERCONNECTION VOLTAGE REQUIREMENTS FOR A GIVEN APPLICATION. THIS DISCUSSION IS PRESENTED BASED ON THE NOMINAL 480 VAC SYSTEM. THIS EQUIPMENT PACKAGE IS SHIPPED IN TWO PIECES; ONE INCLUDES THE MAIN BREAKER AND THE GENERATOR BREAKER AND THE OTHER INCLUDES THE VARIOUS FACILITY BRANCH BREAKERS FOR PROVIDING POWER TO THE VARIOUS SYSTEM PANELS. THE TWO PIECES ARE JOINED TOGETHER WITH A BUS SPLICE KIT ONCE INSTALLED AT THE CUSTOMER’S FACILITY. THE POWER DISTRIBUTION SYSTEM IS DESIGNED AS A MOTOR CONTROL CENTER TO FACILITATE EASY EQUIPMENT ADDITIONS IN THE FUTURE. Learn More