Search results for: 'Comp'

- Related search terms

- Compl

- Complete

- Complete p

- Comple

- complete a

-

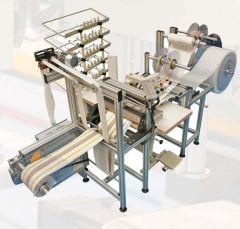

M-3015 MECA/TARGET TA90 COMPUTERIZED QUILTING MACHINE-90”-YEAR 1999

M-3015 MECA/TARGET TA90 COMPUTERIZED QUILTING MACHINE-90”-YEAR 1999REFERENCE NUMBER: M-3015

MECA/TARGET TA90 COMPUTERIZED QUILTING MACHINE-90”-YEAR 1999

MECA-TARGET COMPUTERIZED QUILTING MACHINE

MODEL TA90

WITH MECA MODEL TGLUNI PANEL CUTTER

TYPE/MODEL: TA90

YEAR: 1999

WITH (3) BARS: 10mm×60mm×135mm

MACHINE WORKING WIDTH: 90”(2286mm)

WITH (1) COMPUTER

MACHINE TOTAL WEIGHT: 4000KG

ELECTRICAL FEATURES: V500 HZ60 PHASE3 KW10

PNEUMATIC FEATURES: 6 BARS

CONSUMPTION: 320 1/H

WITH (1) FOAM CREEL WHICH HAS (2) THREAD RACKS (ONE AT THE TOP AND THE OTHER AT THE BOTTOM)

(1) CATWALK

(1) CLOTH TRAY

(45) LOOPERS

QUANTITY: 1

Learn More -

V-0008 MODERN LATE MODEL MATTRESS MANUFACTURING MACHINES

V-0008 MODERN LATE MODEL MATTRESS MANUFACTURING MACHINESREFERENCE NUMBER: V-0008- MODERN LATE MODEL MATTRESS MANUFACTURING MACHINES PORTER SERGER FLANGER MODEL 2000 PORTER SERGER FLANGER MODEL 1000 PORTER DOUBLE BORDER SERGER PORTER AUTOMATIC LABEL ATTACHING MODEL PALS4000 ATLANTA ATTACHMENT BORDER MEASURE, HANDLE MAKER AND ATTACHER WITH AUTO CUT AND CLOSING MODEL 3300R ATLANTA ATTACHMENT TAPE EDGE , STAINLESS TOP WITH SINGER 300U SEW HEAD. MODEL 1345 ATLANTA ATTACHMENT RUFFLER MODEL 1335 ATLANTA ATTACHMENT HANDLE MAKER 4 INCH MODEL 1959 Y 28 B ATLANTA ATTACHEMENT BOX SPRING STAPLER GRIBETZ COMPUTERIZED CHAINSTITCH QUILTER 3 BAR BEIGE-86” GRIBETZ COMPUTERIZED CHAINSTITCH QUILTER 3 BAR BLUE-86” MECA TARGET QUILTER 3 BAR COMPUTERIZED CHAIN MODEL TA90 WITH PANEL CUTTER 1999- 90” MATTRESS AUTOTUFT TUFTING MACHINE – LIKE NEW , 200 MATTRESSES PER 8 HOUR SHIFT SPUHL ANDERSON PANEL CUTTER PC6 , 95 INCH

Learn More -

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More -

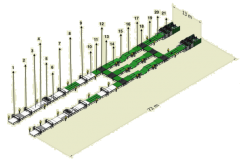

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More -

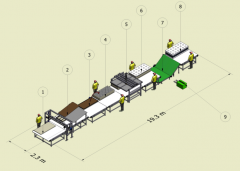

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

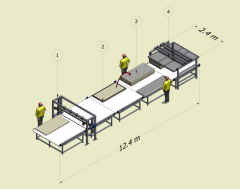

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More -

TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRYREFERENCE NUMBER: L-6890 TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRY ITEM 001 TEXPA LONGITUDINAL HEMMING MACHINE YEAR 2005 QUANTITY: 1 ITEM 002 TEXPA CROSS HEMMING AND LABEL SEWING MACHINE YEAR: 2005 MODEL: QRSN POSSIBILE TO SEW THREE TYPES OF LABELS: U, V, FLAG PFAFF SEWING MACHINES EQUIPPED FOR TERRY TOWEL WORKING WIDTH: 300mm TO 2000mm QUANTITY: 1 STATUS: STOPPED, NOT DISMANTLED DELIVERY: DISMANTLING AND LOADING WILL NEED 3 WEEKS, REQUIRES TWO 40 FT CONTAINERS TO SHIP Learn More

TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRYREFERENCE NUMBER: L-6890 TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRY ITEM 001 TEXPA LONGITUDINAL HEMMING MACHINE YEAR 2005 QUANTITY: 1 ITEM 002 TEXPA CROSS HEMMING AND LABEL SEWING MACHINE YEAR: 2005 MODEL: QRSN POSSIBILE TO SEW THREE TYPES OF LABELS: U, V, FLAG PFAFF SEWING MACHINES EQUIPPED FOR TERRY TOWEL WORKING WIDTH: 300mm TO 2000mm QUANTITY: 1 STATUS: STOPPED, NOT DISMANTLED DELIVERY: DISMANTLING AND LOADING WILL NEED 3 WEEKS, REQUIRES TWO 40 FT CONTAINERS TO SHIP Learn More -

HPFJ-1111 POLYMAT FOR UPHOLSTERY, MATTRESS TOPPERS, MATS AND SEAT CUSHIONS

HPFJ-1111 POLYMAT FOR UPHOLSTERY, MATTRESS TOPPERS, MATS AND SEAT CUSHIONS• Air permeable

The mesh openings on two sides and the porous structure allow free air flow and vapor emission from all six sides, effectively inhibiting the growth of molds, bacteria and mites and thus preventing skin itches.• Stress-relieving and body-fitting

The hardness is moderate to reduce the body stress so that human body can fully relax without feeling any compression, avoiding blocking blood flow. There are 40 supporting points per square centimeter, providing meticulous support and fitting the material to the natural curve of human body.• Easy-to-wash and fast-dry

The material is made from functional fiber, which neither absorbs moisture nor easily reacts chemically with oil and dirt. Water stays no more than one second on the material, while sweat, dirt, and dust can be washed away easily. Therefore, the surface can be cleaned with minimum effort, preventing the growth of mites and bacteria.• Eco-friendly and non-toxic

The pure fabric can be fully recycled upon disposal. The combustion products of sponge are cyanides, which are highly toxic; on the contrary, the products of complete combustion of 3D spacer material are water and carbon dioxide, which are non-toxic and totally safe.• Rollable and portable.

With superior rollability, it can be easily carried into and out of an elevator, taken to outdoor activities, or stores easily when the seasons change.

Learn More

CONSTRUCTED OF 100% POLYESTER

FEATURES: AIR-PERMEABLE, WATER-PERMEABLE, ECO-FRIENDLY, NON-TOXIC, 100% RECYCLED, ANTI-STATIC, ANTI-MITE, ELASTIC, FLAME-RETARDANT, ETC.

NET “X” STRUCTURE

FOR UPHOLSTERY, MATTRESS TOPPERS, MATS, SEAT CUSHIONS, ETC.

NO# NAME LENGTH x WIDTH DIMENSIONS APPROX. INCHES THICKNESS

1 CUSHION 450x450mm 17.7 x 17.7 8 INCHES

2 BABY BED 600x1200mm 23.6 x 47.2 8 INCHES

3 STUDENT BED 1000x2000mm 39.3 x 78.7 8 INCHES

4 1.2 METER BED 1200x2000mm 47.2 x 78.7 8 INCHES

5 1.5 METER BED 1500x2000mm 59 x 78.7 8 INCHES

6 1.8 METER BED 1800x2000mm 70.8 x 78.7 8 INCHES

7 QUEEN BED 1524 x 2032mm 60 x 80 8 INCHES -

J-2184 HORIZONTAL CONVEYOR, 90 METERS LONG, 2400mm WIDE - NEW

J-2184 HORIZONTAL CONVEYOR, 90 METERS LONG, 2400mm WIDE - NEWREFERENCE NUMBER: J-2184

HORIZONTAL CONVEYOR, 90 METERS LONG, 2400mm WIDE - NEWMOTORIZED BELT-DRIVEN CONVEYOR

CONVEYING LENGTH: 90 METERS

CONVEYING WIDTH: 2400mm

CONVEYOR HEIGHT: 800mm

CONVEYING SPEED: 0 TO APPROXIMATELY 40 METERS PER MINUTE

BELTS: 200mm WIDTH x 6 PIECES, EACH 90 METERS LONG

DRIVING ROLL DIAMETER: 157mm

DRIVEN ROLL DIAMETER: 75mm

CENTER TO CENTER SPACING OF 2 ROLLS: 500mm

2 MOTORS, EACH 5.5 KW (CONVEYOR IS COMPOSED OF A TOTAL OF 4 SECTIONS. ONE 5.5 KW MOTOR DRIVES TWO SECTIONS)

1 INVERTER, 11 KW (DRIVES BOTH OF THE 5.5 KW MOTORS)

VOLTAGE: 220 VOLTS, 3-PHASE, 60 HzLEAD TIME: 45 WEEKDAYS FROM RECEIPT OF DEPOSIT

QUANTITY: 1

Learn More