Search results for: 'Reference+No'

-

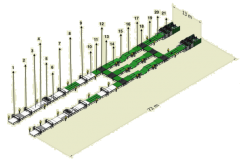

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More -

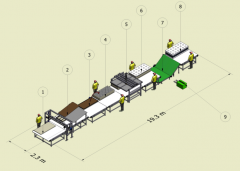

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

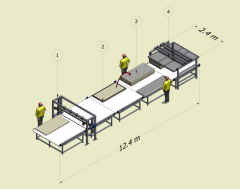

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

G-3980 MANUAL POCKET SPRING ASSEMBLY MACHINE

G-3980 MANUAL POCKET SPRING ASSEMBLY MACHINEREFERENCE NUMBER: G-3980

MANUAL POCKET SPRING ASSEMBLY MACHINE

THIS MACHINE CAN MAKE BOTH SIDE BY SIDE AND CROSS ASSEMBLING

DIMENSIONS: 3500mm×1425mm x 1400mm(EXCEPT THE WORKTABLE)

SPRING HEIGHT: 125 TO 180mm

SPRING DIAMETER: Ø50 TO Ø80mm

MAX WORKING WIDTH: 32 PCS OF SPRING

GLUING TYPE: LINE OR POINT

NON-WOVEN WIDTH: ≤2200mm

NON-WOVEN: ≥50G/M²

AIR PRESSURE: 6KGS/CM3

MAX NON-WOVEN DIAMETER: Ø400mm

WORKING EFFICIENCY: 3 ROWS/MIN(32COILS/ROW)

POWER: 3.5KW

WEIGHT: 750kg

UP AND DOWN NON-WOVEN: WITHOUT

Learn More -

YY-2214 MATTRESS ROLLING PRESS 5 STATIONS (ROLLING STATION 270-500mm VARIABLE DIAMETER)YY-2214 MATTRESS ROLLING PRESS 5 STATIONS (ROLLING STATION 270-500mm VARIABLE DIAMETER) DETAILS OF THE PRODUCT TO BE ROLLED OR FOLDED AND ROLLED PRODUCT: FOAM, MEMORY FOAM, LATEX, BONNELL SPRING AND POCKET SPRING MATTRESSES. MAXIMUM SIZE TO ROLL: 1800 X 2000 X 300 mm FOAM MAXIMUM SIZE TO ROLL: 1800 X 2000 X 200 mm BONNELL SPRINGS MAXIMUM SIZE FOLD AND ROLL: 1800 X 2000 X 200 mm FOAM ONLY MAXIMUM DENSITY 35 KG/M QUANTITY: 1 Learn More

YY-2214 MATTRESS ROLLING PRESS 5 STATIONS (ROLLING STATION 270-500mm VARIABLE DIAMETER)YY-2214 MATTRESS ROLLING PRESS 5 STATIONS (ROLLING STATION 270-500mm VARIABLE DIAMETER) DETAILS OF THE PRODUCT TO BE ROLLED OR FOLDED AND ROLLED PRODUCT: FOAM, MEMORY FOAM, LATEX, BONNELL SPRING AND POCKET SPRING MATTRESSES. MAXIMUM SIZE TO ROLL: 1800 X 2000 X 300 mm FOAM MAXIMUM SIZE TO ROLL: 1800 X 2000 X 200 mm BONNELL SPRINGS MAXIMUM SIZE FOLD AND ROLL: 1800 X 2000 X 200 mm FOAM ONLY MAXIMUM DENSITY 35 KG/M QUANTITY: 1 Learn More -

G-3651-A POCKET SPRING ASSEMBLY MACHINES (NEW): 07A MANUAL POCKET SPRING ASSEMBLING MACHINE

G-3651-A POCKET SPRING ASSEMBLY MACHINES (NEW): 07A MANUAL POCKET SPRING ASSEMBLING MACHINEREFERENCE NUMBER: G-3651-A

POCKET SPRING ASSEMBLY MACHINES (NEW):

07A MANUAL POCKET SPRING ASSEMBLING MACHINE

MANUAL POCKET SPRING ASSEMBLING MACHINE, MAINLY USE FOR ASSEMBLING DIFFERENT SIZE OF MATTRESS INNER. MANUEL INPUT THE SPRING LINE ON TO PRESS BOARD SPRAY OVERTURN PRESS, WHOLE ACTION WILL BE FINISHED AUTOMATIC. EASY CONTROL, HIGHLY EFFICIENCY.

DIMENSIONS: 3500MM×1640MM×1580MM

SPRING HEIGHT: 125-180MM

SPRING DIAMETER: ∮50-∮80MM

MAX WORKING WIDTH: 32PCS OF SPRING

GLUING TYPE: LINE/POINT

NON-WOVEN WIDTH: ≤2200MM

NON-WOVEN: ≥50G/M2

AIR PRESSURE: 6KGS/

MAX NON-WOVEN DIAMETER: ∮400MM

WORKING EFFICIENCY: 3ROWS/MIN(32COILS/ROW)

POWER: 4.5KW

WEIGHT: 880KG

Learn More -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More -

G-3652-C AUTOMATIC POCKET SPRING MACHINES

G-3652-C AUTOMATIC POCKET SPRING MACHINESREFERENCE NUMBER: G-3652-C

AUTOMATIC POCKET SPRING MACHINES

MODEL 08P AUTOMATIC POCKET SPRING MACHINE

WITH TWO SIDE OVERLAP WELDING BY ULTRASONIC UNIT IN THE MIDDLE OF THE POCKET. THE COIL SPRING IS STRONGER AND MORE DURABLE. ONE ULTRASONIC UNIT SO THE COST IS REDUCED. SERVO MOTOR CONTROL.

DIMENSIONS: 3400mm(L)×1160mm(W)×1600mm(H)

OUTPUT: 65 COILS PER MIN

TYPE OF SPRING

NON-WOVEN: 65-100G/M2

NON-WOVEN ROLL DIAMETER: 500mm

SPRING DIAMETER: ∮1.8 PER∮2.2mm

SPRING HEIGHT (AFTER POCKETED): 125mm-180mm

WEIGHT: 1600kg

SPRING DIAMETER: ∮60mm TO∮75mm

SPRING CIRCLE: 6.5-9 CIRCLES

VOLTAGE: AC 3 PHASE 380V

POWER: 16KW

AIR PRESSURE: 6KGS/CM3

Learn More -

G-3653 AUTOMATIC POCKET SPRING PRODUCTION LINE

G-3653 AUTOMATIC POCKET SPRING PRODUCTION LINEREFERENCE NUMBER: G-3653

AUTOMATIC POCKET SPRING PRODUCTION LINE

MODEL 08PA AUTOMATIC POCKET SPRING PRODUCTION LINE

MAIN PARAMETER:

PART OF MACHINE: SL-08P+SL-08A

DIMENSIONS(L×W×H): 9.75×1.4×1.85M (EXCEPT THE WORKTABLE)

COIL SHAPE: CYLINDRICAL OR BARREL

SPRING DIAMETER: TOP & BOTTOM Φ45-60Mmm CENTER Φ60-80mm

SPRING HEIGHT (INSIDE THE NON-WOVEN): 130 TO 180mm

STEEL WIRE DIAMETER: Φ1.8 TO Φ2.2Mmm

POCKETED WIDTH OF NON-WOVEN FABRIC: 410 TO 520mm

TYPE OF SEALING: ULTRASONIC

PRODUCTION: 65 PCS/MINUTE

POWER REQUIREMENT: 21 KW

COMPRESSED AIR PRESSURE: 6KGS/CM³

WEIGHT: APPROX. 3.3 TONS

Learn More -

T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020 THE MATTRESS DRILL IS DESIGNED FOR DRILLING FOAM PANELS THE MACHINE CAN PROCESS VARIOUS TYPES OF FOAM IN SEVERAL DIFFERENT SIZES. SOME TYPES OF FOAM CAN DAMAGE THE DRILLS WHILE DRILLING. FOR THIS REASON WE ALWAYS TEST DRILL THE CUSTOMERS FOAM. THE DRILL MACHINE IS EASY TO OPERATE AND DOES NOT PRODUCE DUST WHILE IT IS OPERATING. THE EXCESS MATERIAL (FROM THE DRILLING) IS AUTOMATICALLY REMOVED. THE DRILLS CAN BE CHANGED IN LINE BY HAND. Learn More

T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020 THE MATTRESS DRILL IS DESIGNED FOR DRILLING FOAM PANELS THE MACHINE CAN PROCESS VARIOUS TYPES OF FOAM IN SEVERAL DIFFERENT SIZES. SOME TYPES OF FOAM CAN DAMAGE THE DRILLS WHILE DRILLING. FOR THIS REASON WE ALWAYS TEST DRILL THE CUSTOMERS FOAM. THE DRILL MACHINE IS EASY TO OPERATE AND DOES NOT PRODUCE DUST WHILE IT IS OPERATING. THE EXCESS MATERIAL (FROM THE DRILLING) IS AUTOMATICALLY REMOVED. THE DRILLS CAN BE CHANGED IN LINE BY HAND. Learn More