Search results for: 'press operator'

- Related search terms

- Pressure lead

- Pressure lead',(;))#- --

- pressure tank

- Operator program

- pressure gauge

-

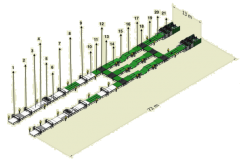

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More -

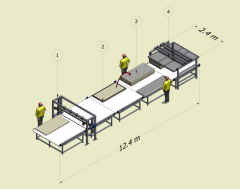

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

J-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEWJ-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEW TOTAL POWER: 45 KW VOLTAGE: PER CUSTOMER REQUIREMENT, SPECIFY WHEN ORDERING TOTAL WEIGHT: 15000 KGS OVERALL DIMENSIONS: 12300 x 3400 x 3000mm WITH CE CERTIFICATE REQUIRES (2) 40-FOOT HIGH CUBE CONTAINERS TO SHIP QUANTITY: 1 Learn More

J-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEWJ-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEW TOTAL POWER: 45 KW VOLTAGE: PER CUSTOMER REQUIREMENT, SPECIFY WHEN ORDERING TOTAL WEIGHT: 15000 KGS OVERALL DIMENSIONS: 12300 x 3400 x 3000mm WITH CE CERTIFICATE REQUIRES (2) 40-FOOT HIGH CUBE CONTAINERS TO SHIP QUANTITY: 1 Learn More -

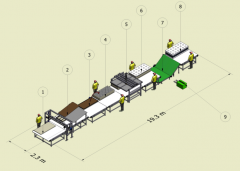

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

J-3995 USED MATTRESS COMPRESSION MACHINE, 4 PIECES PER MINUTEJ-3995 USED MATTRESS COMPRESSION MACHINE, 4 PIECES PER MINUTE VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz POWER: 1.5 KW IN GOOD RUNNING CONDITION AVAILABLE IMMEDIATELY DIMENSIONS, CONSISTS OF TWO PARTS: COMPRESSING UNIT : 100” LENGTH X 87” WIDE X 95” HEIGHT. SEAL UNIT : 130” LENGTH X 32” WIDE X 75” HEIGHT. QUANTITY: 1 Learn More

J-3995 USED MATTRESS COMPRESSION MACHINE, 4 PIECES PER MINUTEJ-3995 USED MATTRESS COMPRESSION MACHINE, 4 PIECES PER MINUTE VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz POWER: 1.5 KW IN GOOD RUNNING CONDITION AVAILABLE IMMEDIATELY DIMENSIONS, CONSISTS OF TWO PARTS: COMPRESSING UNIT : 100” LENGTH X 87” WIDE X 95” HEIGHT. SEAL UNIT : 130” LENGTH X 32” WIDE X 75” HEIGHT. QUANTITY: 1 Learn More -

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTER

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTERABLE TO DO ROLLING TESTS ON MATTRESSES

DURABILITY TEST FOR THE BED SURFACE:

1. USES INDEPENDENT CONTROL SYSTEM. PLC CONTROL SEPARATELY. COOPERATE WITH COLOR TOUCH SCREEN. IT IS

CONVENIENT AND VISUAL TO OPERATE. THE TESTING PROCESS AND THE RUNNING STATUS BE CLEAR TO US, TEST TIMES CAN

BE SET FREELY.

2. SPECIAL LIFT DEVICE IS CONVENIENT TO LIFT UP THE HEAVY ROLLER AND EASY TO MOVE IT TO THE TEST AREA OF THE

MATTRESS. THEN PUT DOWN THE ROLLER AND MAKE ITS OWN WEIGHT FULLY LOAD TO THE SURFACE OF THE MATTRESS.

3.ROLLER CAN MOVE UP AND DOWN IN THE TESTING PROCESS, TO ADAPT TO CONCAVE AND CONVEX SURFACE OF THE

MATTRESS.

4. WHEN DOING DURABILITY TEST OF EDGE, ROLLER CAN BE MOVED TO THE “PARKING” AREA BEHIND THE INSTRUMENT.

5. DURABILITY TEST FOR THE EDGE IS DRIVEN BY SERVO MOTOR; IT IS QUIET, STEADY AND RELIABLE TO OPERATE.

6. INCORPORATES ADVANCED PHOTOELECTRIC SENSE TECHNOLOGY. THE BEGINNING POSITION OF THE CENTER LINE OF THE

CUSHION SURFACE RETURN TO THE HOME POSITION AUTOMATICALLY.

DURABILITY TEST FOR BED EDGE :

ADOPT INDEPENDENT CONTROL SYSTEM, USING DEDICATED HIGH-PRECISION AND HIGH INTELLIGENT ARAM CONTROLLER

AND SPECIAL TEST SOFTWARE. IT CAN RUN UNDER WINDOWS SYSTEM ON PC, IT IS OPERATED ALL BY SOFTWARE, THE

INTERFACE OF SOFTWARE IS EASY TO OPERATE.

SPECIAL TEST SOFTWARE ON PC, WINDOWS OPERATING PAGE, A HIGH DEGREE OF COMPATIBILITY.

TEST PROGRAM HAS ALREADY BEEN SET ON THE SOFTWARE ON PC ACCORDING TO THE TEST REQUIREMENT. A KEY TO TEST.

IT IS CONVENIENT FOR OPERATOR TO LEARN AND SAVE THE TRAINING TIME.

THE CURVE WINDOW OF TEST SOFTWARE DISPLAY THE VALUES OF FORCE AND SHIFT IN REAL TIME, COORDINATE MODEL.

LOADING CUSHION ON THE EDGE AND LOADING CUSHION WHICH IS USED FOR MEASURING USE GENERIC CONNECTION

HEAD THAT CAN BE IN INTERCHANGED. SHARING A SET OF DRIVING DEVICE, SAVE SPACE AND COST.

ADJUSTABLE RACK. THE PRESSURE PLATE CAN BE ADJUSTED THE POSITION ALONG THE DIRECTION OF X AND Y. IT CAN

MEASURE EACH POINT OF THE MATTRESS. IT IS DIFFERENT FROM THE TRADITION WAY TO SEPARATE. THE TEST CAN BE

FINISHED WITHOUT MOVING THE SAMPLE.

SAVE A LOT OF TESTING TIME, GREATLY REDUCES THE WORKING INTENSITY, OPERATORS CAN ACHIEVE SINGLE OPERATION,

SAVE THE COMPANY COST.

FORCE SENSOR AVOIDS DAMAGE TO THE CORE COMPONENTS BECAUSE IT CAN MAKE PROTECTION WHEN IT IS OVERLOAD.ROLLING TEST SPEED: 16±2CYCLES PER MINUTE (OR SPECIFIED BY CUSTOMER)

Learn More

CYLINDER ROLLER: 1400N, THE MIDDLE DIAMETER: 300mm, BOTH ENDS DIAMETER: 250mm, LENGTH: 1000

HEXAGON STYLE WOODEN ROLLER: SIZE AS STANDARD REQUIREMENT

COUNTER: 0~999999 CAN BE SET.

THE CONTROL WAY OF ROLLING: TOUCH SCREEN + PLC CONTROL

LOADING CUSHION ON THE EDGE: BUTTOCKS SHAPE, 380mm X 495mm

LOADING PARTS ON THE EDGE: THE MIDPOINT ON THE LONG EDGE OF THE MATTRESS.200 mm FROM EDGE.

LOADING FORCE ON THE EDGE: 1000N

LOADING TIME ON THE EDGE: 3S

POSITION OF MEASUREMENT: MATTRESS CENTER, LEFT AND RIGHT ARE BOTH 250mm, THE MIDPOINT ON THE LONG EDGE

OF THE MATTRESS 200 mm INWARD.

LOADING PLATE OF MEASUREMENT: DIAMETER 355mm, RADIUS OF CURVATURE OF THE END R800mm

CAPACITY OF FORCE SENSOR: 2KN

LOADING SPEED OF MEASUREMENT: 90±5mm/MIN

STROKE: 500mm

DRIVE MOTOR: SERVO MOTOR -

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEW

V-1724 MATTRESS WRAPPING WITH PRESSING UNIT AND ROLLING UP – NEWFLATTEN ALL TYPES OF MATTRESSES AND ROLL UP THE FLAT POCKET SPRING MATTRESSES.

FLATTENING AND ROLLING MATTRESSES HAS THE ADVANTAGE OF MINIMIZING THE STORAGE AREA AND

FACILITATE THE TRANSPORTATION AND LOWER TRANSPORTATION COSTS.

PRODUCTION CAPACITY: 3 MATTRESSES PER MINUTE FOR NORMAL PACKING.

MATTRESS SIZE: MIN. 700 X 1900mm TO MAX. 2100 X 2100mm

MATTRESS HEIGHT: 50mm TO 400mm

PRESSING SYSTEM: PNEUMATIC FOR NORMAL PACKING, HYDRAULIC SYSTEM FOR FLATTENING AND ROLL PACKING

PNEUMATIC PRESSURE: 482 KGS (8 BARS)

HYDRAULIC PRESSURE: 65 TON

WIDTH OF FILM ROLLS: MIN. 2200 mm TO MAX. 2650 mm

MAX. DIAMETER OF FILM ROLLS: 320mm

MAX. WEIGHT OF FILM ROLLS: 200 KGS

TYPE OF NYLON: PE FILM

THICKNESS OF FILM: 50 TO 150 MICRON (5 TO 15)

POWER REQUIREMENTS: 3 PHASE 380 V OR AS PER CUSTOMER

TOTAL ELECTRIC DRAW: 20 KW

WEIGHT: APPROX. 10 TONS

NUMBER OF OPERATORS: 1

QUALITY STANDARD: CE

WARRANTY: 2 YEARS

FINAL ROLL PACKING TUBE DIAMETER: 250 TO 400 mm

YouTube Video 1: https://youtu.be/7e3-3FtaQdE

YouTube Video 2: https://youtu.be/LrmcQ18A1zM

QUANTITY: 1

Learn More -

M-7900 PATTERN TEMPLATE SEWING MACHINE

M-7900 PATTERN TEMPLATE SEWING MACHINEREFERENCE NUMBER: M-7900

PATTERN TEMPLATE SEWING MACHINE

PATTERN TEMPLATE SEWING MACHINE

COMPUTER-CONTROLLED, PROGRAMMABLE

MAXIMUM SPEED: 3,000 STITCHES PER MINUTE

MAXIMUM SEWING SPEED: 10 METERS PER MINUTE

MAXIMUM MOVING SPEED: 80 METERS PER MINUTE

QUANTITY: 1

Learn More -

K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSESREFERENCE NUMBER: K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSES ONE LOCATION, SMALL SPACE REQUIREMENT AND EXTREME FUNCTIONALITY ENABLE AUTOMATIC OPERATION OF TIPPING, GLUEING THE FABRIC AND FINAL ASSEMBLY OF THE MATTRESS. WITH THIS LINE YOU CAN CONSTANTLY MANAGE THE QUANTITY OF GLUE BY TYPE OF PRODUCT REGARDLESS OF THE SIZE OR THE SHAPE, DETERMINE THE POINTS OF BONDING IN RELATION TO PROGRAMS AND CUSTOMIZED RECIPES, QUANTIFY A CERTAIN COST. QUANTITY AVAILABLE: 1 Learn More

K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSESREFERENCE NUMBER: K-4724 AUTOMATIC LINE FOR HOT-MELT GLUING FOAM MATRESSES ONE LOCATION, SMALL SPACE REQUIREMENT AND EXTREME FUNCTIONALITY ENABLE AUTOMATIC OPERATION OF TIPPING, GLUEING THE FABRIC AND FINAL ASSEMBLY OF THE MATTRESS. WITH THIS LINE YOU CAN CONSTANTLY MANAGE THE QUANTITY OF GLUE BY TYPE OF PRODUCT REGARDLESS OF THE SIZE OR THE SHAPE, DETERMINE THE POINTS OF BONDING IN RELATION TO PROGRAMS AND CUSTOMIZED RECIPES, QUANTIFY A CERTAIN COST. QUANTITY AVAILABLE: 1 Learn More -

K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINEREFERENCE NUMBER: K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINE DIMENSIONS: 1462 X 1060 X 1988mm POWER 500W VOLTAGE 220V 50HZ SINGLE PHASE WEIGHT 300KG USED FOR COMFORTER PACKING & BAGGING EASY TO OPERATION WITH 1 OPERATOR ELECTRICITY KEY PARTS ADOPT SIEMENS BRAND, STABLE & THEIR LOCAL SERVICE WILL SUPPORT YOU CHANGEABLE DIFFERENT DIMENSION PLATE MAIN STRUCUTRE MADE BY COMPUTERIZED LASER CUTTING MACHINE, STABLE & DURABLE CHANGEABLE PRESSING PLATES MEET DIFFERENT NEED. DIFFERENT POWER CONDITION AND SAFE STANDARD CAN BE ORDERED ACCORDING TO THE CLIENT’S LOCAL REQUIREMENT. QUANTITY AVAILABLE: 1 Learn More

K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINEREFERENCE NUMBER: K-3844 COMFORTER (QUILTER) PACKING AND BAGGING MACHINE DIMENSIONS: 1462 X 1060 X 1988mm POWER 500W VOLTAGE 220V 50HZ SINGLE PHASE WEIGHT 300KG USED FOR COMFORTER PACKING & BAGGING EASY TO OPERATION WITH 1 OPERATOR ELECTRICITY KEY PARTS ADOPT SIEMENS BRAND, STABLE & THEIR LOCAL SERVICE WILL SUPPORT YOU CHANGEABLE DIFFERENT DIMENSION PLATE MAIN STRUCUTRE MADE BY COMPUTERIZED LASER CUTTING MACHINE, STABLE & DURABLE CHANGEABLE PRESSING PLATES MEET DIFFERENT NEED. DIFFERENT POWER CONDITION AND SAFE STANDARD CAN BE ORDERED ACCORDING TO THE CLIENT’S LOCAL REQUIREMENT. QUANTITY AVAILABLE: 1 Learn More