Search results for: 'Sett'

-

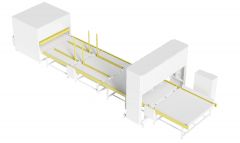

TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022 -FOR CARPET INDUSTRY WORKING WIDTH: MINIMUM 1200mm, MAXIMUM 4000mm WORKING SPEED: 7 METERS PER MINUTE PRIMARY GOODS: RUG AND BLANKET AND FABRIC COATING TYPE: PVC PLANT CAN BE USE FOR CARPET, FELT AND FABRIC FIRST FELT IS LAMINATED ON THE BACK FROM THE CARPET SECOND DOTTING FLEXIBLE PVC BACKING CARPET FELT PLANT IS BRAND NEW 2022 EXCLUSIVE TRANSPORT, FLIGHT TICKETS, HOTEL ACCOMODATION, FOOD & DRINKS QUANTITY: 1 Learn More

TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022 -FOR CARPET INDUSTRY WORKING WIDTH: MINIMUM 1200mm, MAXIMUM 4000mm WORKING SPEED: 7 METERS PER MINUTE PRIMARY GOODS: RUG AND BLANKET AND FABRIC COATING TYPE: PVC PLANT CAN BE USE FOR CARPET, FELT AND FABRIC FIRST FELT IS LAMINATED ON THE BACK FROM THE CARPET SECOND DOTTING FLEXIBLE PVC BACKING CARPET FELT PLANT IS BRAND NEW 2022 EXCLUSIVE TRANSPORT, FLIGHT TICKETS, HOTEL ACCOMODATION, FOOD & DRINKS QUANTITY: 1 Learn More -

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

YY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOURYY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOUR FEATURES: - WITH WATER CIRCULATION COOLING SYSTEM. - PLC PROGRAMMED CONTROL SYSTEM, DISPLAY SCREEN FOR SETTING PARAMETERS. - OPERATOR: 1 PERSON. QUANTITY: 1 Learn More

YY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOURYY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOUR FEATURES: - WITH WATER CIRCULATION COOLING SYSTEM. - PLC PROGRAMMED CONTROL SYSTEM, DISPLAY SCREEN FOR SETTING PARAMETERS. - OPERATOR: 1 PERSON. QUANTITY: 1 Learn More -

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More -

TT-1389 LAB RING SPINNING FRAMETT-1389 LAB RING SPINNING FRAME KEY SPECIFICATION: CONTROL MODE: TOUCH SCREEN & PLC NUMBER OF SPINDLES: 6 APPLICABLE FIBER LENGTH: 22 TO 50mm DRAFT RANGE: 10 TO 50 DRAFT CONTROL: AUTOMATIC ROLLER DIAMETER: FRONT ROLLER: Φ25mm, MIDDLE ROLLER: Φ25mm BACK ROLLER: Φ25mm CENTER DISTANCE OF ROLLERS: FRONT AND MIDDLE: 43mm FRONT AND BACK: 143mm PRESSURE MODE: SPRING CRADLE TWIST SETTABLE RANGE: 200 TO 2,000 TWIST/M RING DIAMETER: RING NOT NEEDED IF THERE IS NO NEED FOR TWISTING FUNCTION. THIS MACHINE WILL USE A SHAFT TO MOVE THE YARN UP AND DOWN TO WIND ON THE PIRN TOTAL KW: 1.5 KW VOLTAGE: 220 VOLTS, 3-PHASE, 60 Hz WEIGHT: 650 KG DIMENSIONS: 1750 x 760 x 1950mm SPINDLE SPEED: 3800 RPM QUANTITY: 1 SET Learn More

TT-1389 LAB RING SPINNING FRAMETT-1389 LAB RING SPINNING FRAME KEY SPECIFICATION: CONTROL MODE: TOUCH SCREEN & PLC NUMBER OF SPINDLES: 6 APPLICABLE FIBER LENGTH: 22 TO 50mm DRAFT RANGE: 10 TO 50 DRAFT CONTROL: AUTOMATIC ROLLER DIAMETER: FRONT ROLLER: Φ25mm, MIDDLE ROLLER: Φ25mm BACK ROLLER: Φ25mm CENTER DISTANCE OF ROLLERS: FRONT AND MIDDLE: 43mm FRONT AND BACK: 143mm PRESSURE MODE: SPRING CRADLE TWIST SETTABLE RANGE: 200 TO 2,000 TWIST/M RING DIAMETER: RING NOT NEEDED IF THERE IS NO NEED FOR TWISTING FUNCTION. THIS MACHINE WILL USE A SHAFT TO MOVE THE YARN UP AND DOWN TO WIND ON THE PIRN TOTAL KW: 1.5 KW VOLTAGE: 220 VOLTS, 3-PHASE, 60 Hz WEIGHT: 650 KG DIMENSIONS: 1750 x 760 x 1950mm SPINDLE SPEED: 3800 RPM QUANTITY: 1 SET Learn More -

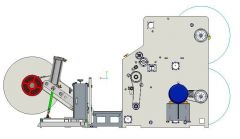

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

TT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBYTT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBY OMNIPLUSSUMMUM-F-4-R WIDTH 2200mm YEAR 2014 TO 2016 WEIGHT 3100KG 4 COLORS WITH 4 PICANOL 1131 X2 WEFT FEEDERS 4 COLORS, PATTERN MONITORED BY MICROPROCESSOR QUANTITY: 2 Learn More

TT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBYTT-1176 PICANOL SUMMUM AIRJET, WIDTH 2200mm, YEAR 2014 TO 2016, DOBBY OMNIPLUSSUMMUM-F-4-R WIDTH 2200mm YEAR 2014 TO 2016 WEIGHT 3100KG 4 COLORS WITH 4 PICANOL 1131 X2 WEFT FEEDERS 4 COLORS, PATTERN MONITORED BY MICROPROCESSOR QUANTITY: 2 Learn More -

TT-1151 NOWOROLL S FIBRE BALLING MACHINE, YEAR 2015TT-1151 NOWOROLL S FIBRE BALLING MACHINE, YEAR 2015 QUANTITY: 1 Learn More

TT-1151 NOWOROLL S FIBRE BALLING MACHINE, YEAR 2015TT-1151 NOWOROLL S FIBRE BALLING MACHINE, YEAR 2015 QUANTITY: 1 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

TT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTETT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTE MAXIMUM BUN SIZE: LENGTH 3000mm x WIDTH 2200mm x HEIGHT 1300mm MAIN FEATURES OF CONTOUR CUTTER: 1. ELIMINATES THE NEED TO MAKE, REPAIR AND STORE TEMPLATES; 2. INTEGRATED DESIGN & CUTTING PROGRAM. JUST DESIGN AND CUT; 3. COST SAVINGS BY AUTOMATICALLY ARRANGING THE PRODUCT (NESTING OF SHAPES TO MAXIMIZE MATERIAL USAGE) 4. SUPPORTS NUMERIC INSTRUMENTS; 5. HIGHER MATERIAL UTILIZATION RESULTING FROM COMPUTER AIDED NESTING OF SHAPES; 6. CUT SPEED CAN BE SET TO ARRIVE AT THE BEST CUT SPEED FOR DIFFERENT FOAMS; 7. CAN PRE-CUT ON THE COMPUTER TO CHECK CUTTING COURSE; Learn More

TT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTETT-1002 CNC DUAL FAST WIRE (HORIZONTAL & VERTICAL) CONTOUR CUTTER, CUT SPEED 10 METERS PER MINUTE MAXIMUM BUN SIZE: LENGTH 3000mm x WIDTH 2200mm x HEIGHT 1300mm MAIN FEATURES OF CONTOUR CUTTER: 1. ELIMINATES THE NEED TO MAKE, REPAIR AND STORE TEMPLATES; 2. INTEGRATED DESIGN & CUTTING PROGRAM. JUST DESIGN AND CUT; 3. COST SAVINGS BY AUTOMATICALLY ARRANGING THE PRODUCT (NESTING OF SHAPES TO MAXIMIZE MATERIAL USAGE) 4. SUPPORTS NUMERIC INSTRUMENTS; 5. HIGHER MATERIAL UTILIZATION RESULTING FROM COMPUTER AIDED NESTING OF SHAPES; 6. CUT SPEED CAN BE SET TO ARRIVE AT THE BEST CUT SPEED FOR DIFFERENT FOAMS; 7. CAN PRE-CUT ON THE COMPUTER TO CHECK CUTTING COURSE; Learn More