Search results for: 'Reference Number: J'

- Related search terms

- Reference Number:

- Reference Number: J-

- reference nu

- reference number -

- reference number -v-21

-

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGEC-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

OFFER 001

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

PRODUCTION TYPE: BABY WET TISSUE

PRODUCTION PROCESS: CONNECT TO Y-2700 FOLDING MACHINE (OR Y-12 FOLDING MACHINE) → FEEDING WIPE AUTOMATIC →CONVEYING TO PACKING MACHINE → SETTING PACKING FILM → SETTING WINDOW HOLE LABEL → CENTRAL SEALING →END SEALING AND RECIPROCATING CUT → OUTPUT FINISHED PRODUCTS.

MAINTECHNICAL PARAMETER: (SUITABLE TO PACK: 5 TO 120PCS/BAG)

PRODUCT SPEED: 55 TO 60 BAG/MIN

DIAMETER OF RAW FILM ROLL: ≤380mm

WIDTH OF RAW FILM ROLL: ≤420mm

WRAPPING MATERIAL: PP, OPP, PET, PE, AND ALL SUITABLE FILMS

SHAPES OF PACKING: PILLOW TYPE PACKAGING

PACKING LENGTH: 110 TO 300mm (TOUCH SCREEN SETABLE)

PACKING WIDTH: 80 TO 150mm (ADJUSTABLE)

HEIGHT OF PACKING: 10 TO 100mm (ADJUSTABLE)

HORIZONTAL SEALING PATTERN: RECIPROCATION HEAT SEALING

DRIVE MOTOR PATTERN: ALL SERVO DRIVE

CONTROL PATTERN: YASKAWA SIMOTION CONTROL SYSTEM

OPERATION INTERFACE: 7 INCH LCD

FILM SUPPLY SYSTEM: SERVO DRIVE

HORIZONTAL SYSTEM: SERVO DRIVE

FEEDING SYSTEM: SERVO DRIVE

LABELING SYSTEM: SERVO DRIVE

PUNCHING SYSTEM: SERVO DRIVE

HORIZONTAL PROTECTION: TORQUE OVERLOAD PROTECTION

AIR REQUIREMENTS: 0.5 TO 0.8 MPA 0.01 M3/MIN

ELECTRIC POWER REQUIREMENTS: 380VAC 50/60HZ

GENERAL POWER: 7.6KW

DIMENSION OF MACHINE: 3610 × 1150 × 1900mm

STANDARD EQUIPMENT: DATE PRINTING UNIT, PUNCHING UNIT, LABELLING UNIT, INSERTING CORNER UNIT, ELECTRICAL EYE TRACKING AUTOMATICALLY

(2) SYSTEM CHARACTER

1. THE PACKING FILM ADOPTS MECHNICAL TENSION CONTROL

2. TWO LABEL MACHINE, ONE SUB-LABELING, THE OTHER IS ANTI-COUNTERFEITING LABEL

3. PUNCHING AT THE PACKING FILM AUTOMATICALLY

4. HEATING PRINTING (DATE) DEVICE

5. FOUR BACK AND FORTH TRANSVERSE SEALING DEVICE WITHINSERT CORNER BY CYLINDER FORM

6. EIGHT SERVO MOTORS, CONTROLLING FEEDING PACKING FILM, TRANSVERSE SEALING, FEEDING TISSUE RESPECTIVELY

7. LENGTHWAYS SEALING DEVICE, CONTROL THEOPEN-CLOSEBY CYLINDER. THE SEALING WHEEL ARE APART AUTOMATICALLY WHEN THE MACHINE STOPS

8. PUNCHING, LABELING AND THE EYE MARK’S RELATIVED POSITION CAN BE SET IN THE TOUCH SCREEN.

9. AUTOMATIC FEEDING RAW MATERIAL DEVICE

10. COLOUR TOUCH SCREEN, MOTION SYSTEM CONTROL

11. MAIN MOTOR ADOPTS FAMOUS BRAND

12. MAIN MACHINE ADOPTS FRAMES FORMOFFER 002

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

YASKAWA ELECTRICITY FROM JAPAN

ITEM NUMBER: 1

MOTION CONTROLLER

JEPMC-MP2300S-E

YASKAWA

QUANTITY: 1

ITEM NUMBER: 2

EXTENDED MODULE

R7K4FML-6-DCA32A

YASKAWA

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR/SERVO UNIT

SGMJV-08ADE6S /SGDV-5R5A11A

YASKAWA 750W

QUANTITY: 5

ITEM NUMBER: 4

SERVO MOTOR/SERVO UNIT

SGMGV-13ADC61 /SGDV-120A11A

YASKAWA 1.3KW

QUANTITY: 1

ITEM NUMBER: 5

SERVO MOTOR/SERVO UNIT

SGMGV-20ADA61/SGDV-180A11A

YASKAWA 1.8KW

QUANTITY: 1

ITEM NUMBER: 6

SERVO MOTOR/SERVO UNIT

SGMGV-09ADC61/SGDV-7R6A11A

YASKAWA 0.85 KW

QUANTITY: 1

ITEM NUMBER: 7

POWER CABLE + ENCODER CABLE

JZZP-CVM09/JZSP-CVP02-05

YASKAWA 850W

QUANTITY: 1

ITEM NUMBER: 8

POWER CABLE + ENCODER CABLE

JZSP-CMM00-05 JZSP-CMP00-05

YASKAWA 750W

QUANTITY: 7

ITEM NUMBER: 9

POWER CABLE + ENCODER CABLE

JZSP-CVM30-05 JZSP-CVP02-5

YASKAWA 1.3KW, 1.8KW

QUANTITY: 2

ITEM NUMBER: 10

COMMUNICATION CABLE

JEPMC-W6002-05

QUANTITY: 12

ITEM NUMBER: 11

TERMINAL RESISTANCE

JEPMC-W6022-E

QUANTITY: 2

ITEM NUMBER: 12

TOUCH PANEL

WEINVIEW

7 INCH

QUANTITY: 1

ITEM NUMBER: 13

AIR BREAK SWITCH

LG

QUANTITY: 12

ITEM NUMBER: 14

RESIDUAL CURRENT CIRCUIT BREAKER

CHINT

QUANTITY: 1

ITEM NUMBER: 15

CONTACTOR (SWITCH)

SCHNEIDER

QUANTITY: 1

ITEM NUMBER: 16

POWER SWITCH

M&W

350W

QUANTITY: 1

ITEM NUMBER: 17

SOLID STATE RELAY (SSR)

ANV

QUANTITY: 6

ITEM NUMBER: 18

TEMPERATURE CONTROLLER

DTE10P

QUANTITY: 1

ITEM NUMBER: 19

RELAY

OMRON

QUANTITY: 4OFFER 003

Y-12 BABY WIPES FOLDING MACHINE

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40-80G/㎡

FOLDING WAY: “Z” SHAPE (POP UP AND NON-POP UP)

CUTTING UNITE:

A. DOUBLE PAPER SHELVES

B. 10 LANES OR 12 LANES, 2 ROLLS

C. RAW MATERIAL ROLL WIDTH: 900 TO 1200mm

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZOFFER 004

Learn More

Y-12 WET TISSUE FOLDING MACHINE

MAIN PARTS

ITEM NUMBER: 1

PLC

FX3U-32T

MITSUBISHI (JAPAN)

QUANTITY: 1

ITEM NUMBER: 2

SERVO MOTOR (CONTROL THE DISTANCE OF TISSUE

ASD-B2-2023-B, ECMA-E21320RS

3.0KW DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR (RECEIVING TISSUE)

ASD-B2-0721-B, ECMA-C20807RS

750W DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 4

TURBINE WORM REDUCER MOTOR

WPDA120-1:10-Y100L2-4

3KW NANJING UTTON (CHINA)

QUANTITY: 1

ITEM NUMBER: 5

INVERTER

SB70G4

4KW SENLON

QUANTITY: 1

ITEM NUMBER: 6

TOUCH SCREEN

7INCH

WECON

QUANTITY: 1

ITEM NUMBER: 7

AIR SWITCH

LG

QUANTITY: 1

ITEM NUMBER: 8

SWITCHING POWER SUPPLY

S-100-24

SHANGHAI MINGWEI (CHINA)

QUANTITY: 1

ITEM NUMBER: 9

INDICATOR LIGHT

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 10

EMERGENCY STOP SWITCH

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 11

POTENTIOMETER

5KΩ

QUANTITY: 1

ITEM NUMBER: 12

ROTARY ENCODER

INCREMENTAL POLE OUTPUT

KOYO (JAPAN)

QUANTITY: 1

ITEM NUMBER: 13

RELAY

OMRON

OMRON (JAPAN)

QUANTITY: 5

ITEM NUMBER: 14

PROXIMITY SWITCH

AUTONICS

AUTONICS (KOREA)

QUANTITY: 2 -

P-4139 JLG MANLIFT G9-43A YEAR 2010

P-4139 JLG MANLIFT G9-43A YEAR 2010REFERENCE NUMBER: P-4139

JLG MANLIFT G9-43A YEAR 2010JLG MANLIFT

TYPE: G9-43A

YEAR: 2010

SIZE: 9000

HOURS: 2738

DESCRIPTION:

JOHN DEERE TURBO DIESEL

50 INCHES CARRIAGE

48 INCHES PALLET FORKS

AUX HYDRAULICSQUANTITY: 1

EMAIL US FOR PRICE & PICTURES

Learn More

INCLUDE OUR REFERENCE NUMBER -

TT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBYTT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBY ITEM 001 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2002 QUANTITY: 10 ITEM 002 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2001 QUANTITY: 8 ITEM 003 BRAND: SULZER MODEL: L5400 WIDTH: 1900mm YEAR OF MANUFACTURE: 2003 QUANTITY: 2 NOTE: ALL LOOMS HAVE A TANGENTIAL WINDER Learn More

TT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBYTT-5705 SULZER L5300 AND L5400 LOOMS, WIDTH 1900mm, YEAR 2000 TO 2002, DOBBY ITEM 001 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2002 QUANTITY: 10 ITEM 002 BRAND: SULZER MODEL: L5300 WIDTH: 1900mm YEAR OF MANUFACTURE: 2001 QUANTITY: 8 ITEM 003 BRAND: SULZER MODEL: L5400 WIDTH: 1900mm YEAR OF MANUFACTURE: 2003 QUANTITY: 2 NOTE: ALL LOOMS HAVE A TANGENTIAL WINDER Learn More -

C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150REFERENCE NUMBER: C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150 SPECIFICATIONS: Make Jakob Muller (Switzerland) YEAR CONSTRUCTIONS: 2001 Type M JET MBJL 1/1150 QUANTITY AVAILABLE: 2 Learn More

C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150REFERENCE NUMBER: C-1163 AIRJET MÜLLER LABEL WEAVING MACHINES w/JACQUARD, YEAR 2001, REED WIDTH 1150 SPECIFICATIONS: Make Jakob Muller (Switzerland) YEAR CONSTRUCTIONS: 2001 Type M JET MBJL 1/1150 QUANTITY AVAILABLE: 2 Learn More -

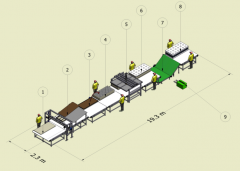

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

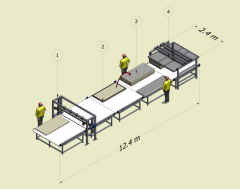

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

K-6361 FIDES ASSEMBLER YEAR 1998-16 JAWSREFERENCE NUMBER: K-6361 FIDES ASSEMBLER YEAR 1998-16 JAWS HELICAL MOTOR (2) T80-C4 MOTOVARIO 220 V 4.4 AMPS. 60 HZ 0.92 KW 1410 KWM MGM BA80B4 ASSEMBLER MOTOR 220 V 4.9 AMPS. 60 HZ 0.75 KW 1400 RPM AIR CONSUMPTION AT 6 BAR N / A CONNECTION CABLE 4 X 21.15 MM2 AIR PIPE ½ "NPT LUBRICATING OIL DEPOSIT 4 LITRE QUANTITY AVAILABLE: 1 Learn More

K-6361 FIDES ASSEMBLER YEAR 1998-16 JAWSREFERENCE NUMBER: K-6361 FIDES ASSEMBLER YEAR 1998-16 JAWS HELICAL MOTOR (2) T80-C4 MOTOVARIO 220 V 4.4 AMPS. 60 HZ 0.92 KW 1410 KWM MGM BA80B4 ASSEMBLER MOTOR 220 V 4.9 AMPS. 60 HZ 0.75 KW 1400 RPM AIR CONSUMPTION AT 6 BAR N / A CONNECTION CABLE 4 X 21.15 MM2 AIR PIPE ½ "NPT LUBRICATING OIL DEPOSIT 4 LITRE QUANTITY AVAILABLE: 1 Learn More -

R-8867 JUKI LK 1900B-SS –NEW, YEAR 2015

R-8867 JUKI LK 1900B-SS –NEW, YEAR 2015REFERENCE NUMBER: R-8867

Learn More

JUKI LK 1900B-SS – NEW

YEAR: 2015

QUANTITY: 1 -

J-1302 TSUDAKOMA SIZING MACHINES FOR FILAMENT

J-1302 TSUDAKOMA SIZING MACHINES FOR FILAMENTREFERENCE NUMBER: J-1302

Learn More

MAKE: TSUDAKOMA JAPAN

MODEL: KB20 and KS200

YEAR: 1994 and 1989

QUANTITY: 2 -

L-2308 JAPSEW J-300-D-TT SEWING MACHINE FOR MOCK HAND-STITCHING WITH THREAD TRIMMER

L-2308 JAPSEW J-300-D-TT SEWING MACHINE FOR MOCK HAND-STITCHING WITH THREAD TRIMMERREFERENCE NUMBER: L-2308

JAPSEW J-300-D-TT SEWING MACHINE FOR MOCK HAND-STITCHING WITH THREAD TRIMMER

QUANTITY: 1

Learn More