Search results for: 'Reference Number: J-''

- Related search terms

- Reference Number

- reference nu

- reference nu'

- Reference+No

- reference number -

-

J-1132 STAUBLI JACQUARD MACHINESREFERENCE NUMBER: J-1132 (1212ZMTDXX11) J STAUBLI JACQUARD MACHINES STAUBLI JACQUARD CX 880/2688 YEAR 2001 – 2400 HOOKS MODEL: CX 880/2688 2400 HOOKS YEAR: 2001 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES QUANTITY: 1 STAUBLI JACQUARD CX 870/2688 YEAR 2000 – 2400 HOOKS MODEL: CX 870/2688 2400 HOOKS YEAR: 2000 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES STAUBLI JACQUARD DX 110/2688 YEAR 2008 – 2400 HOOKS MODEL: DX 110/2688 2400 HOOKS YEAR: 2008 CONTROLLER JC6 MODULES M6 CARDAN SHAFT AND ACCESSORIES QUANTITY AVAILABLE: 3 Learn More

J-1132 STAUBLI JACQUARD MACHINESREFERENCE NUMBER: J-1132 (1212ZMTDXX11) J STAUBLI JACQUARD MACHINES STAUBLI JACQUARD CX 880/2688 YEAR 2001 – 2400 HOOKS MODEL: CX 880/2688 2400 HOOKS YEAR: 2001 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES QUANTITY: 1 STAUBLI JACQUARD CX 870/2688 YEAR 2000 – 2400 HOOKS MODEL: CX 870/2688 2400 HOOKS YEAR: 2000 CONTROLLER JC5 MODULES M4 CARDAN SHAFT AND ACCESSORIES STAUBLI JACQUARD DX 110/2688 YEAR 2008 – 2400 HOOKS MODEL: DX 110/2688 2400 HOOKS YEAR: 2008 CONTROLLER JC6 MODULES M6 CARDAN SHAFT AND ACCESSORIES QUANTITY AVAILABLE: 3 Learn More -

M-4677 DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mmREFERENCE NUMBER: M-4677 (111123ASMD10RC) L DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mm (2) X DORNIER HTV S/8J – WIDTH 2000mm – YEAR 1994 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS, WITH FANCY BEAM LOOMS ARE WELL KEPT, RUNNING PRESENTLY INSPECTION & IMMEDIATE DELIVERY AVAILABLE QUANTITY AVAILABLE: 6 Learn More

M-4677 DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mmREFERENCE NUMBER: M-4677 (111123ASMD10RC) L DORNIER JACQUARD LOOMS YEAR 1994-1996 WIDTH 1900mm-2000mm (2) X DORNIER HTV S/8J – WIDTH 2000mm – YEAR 1994 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS (2) X DORNIER HTV S78J – WIDTH 1900mm – YEAR 1996 WITH STAUBLI CX860 JACQUARD, JC4 CONTROLLER, 2688 HOOKS, WITH FANCY BEAM LOOMS ARE WELL KEPT, RUNNING PRESENTLY INSPECTION & IMMEDIATE DELIVERY AVAILABLE QUANTITY AVAILABLE: 6 Learn More -

K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003REFERENCE NUMBER: K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003 PICANOL GAMMAX WORKING WIDTH: 3200mm YEAR: 2003 WITH STAUBLIC JACQUARD 8/J 8 COLORS + JACQUARD 1000mm FLANGE, SUMO MOTOR ELO/ETU WITH STAUBLI JACQUARD CS 960 3072 HOOKS FORMAT (1920 HOOKS INSTALLED) YEAR 1994 (TOTALLY REFURBISHED IN 2003) WITH NEW M4 MODULES AND NEW JC5 CONTROLLER NEW DROPBOX 6 WEFT FEEDERS 2 CLOTH ROLLERS 1 WARP BEAM QUANTITY AVAILABLE: 2 Learn More

K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003REFERENCE NUMBER: K-6686 PICANOL GAMMAX WITH STAUBLI JACQUARD WIDTH 3200mm YEAR 2003 PICANOL GAMMAX WORKING WIDTH: 3200mm YEAR: 2003 WITH STAUBLIC JACQUARD 8/J 8 COLORS + JACQUARD 1000mm FLANGE, SUMO MOTOR ELO/ETU WITH STAUBLI JACQUARD CS 960 3072 HOOKS FORMAT (1920 HOOKS INSTALLED) YEAR 1994 (TOTALLY REFURBISHED IN 2003) WITH NEW M4 MODULES AND NEW JC5 CONTROLLER NEW DROPBOX 6 WEFT FEEDERS 2 CLOTH ROLLERS 1 WARP BEAM QUANTITY AVAILABLE: 2 Learn More -

M-4868 PUB BREWERY 20HLREFERENCE NUMBER: M-4868 (1111275NKG10RX) L PUB BREWERY 20HL SPECIFICATION: 1. MALT HANDLING - CYLINDER-CONIC MALT SILO WITH 25M³ CONTENT, MADE IN FIBRE GLASS / PLASTIC, STANDING OUTDOOR ON STEEL CONSTRUCTION - MALT CONVEYORS / SPIRAL CONVEYOR INTO 1ST FLOOR - 2-ROLLER MALT MILL - GRIST CASE - FALL PIPE IN MASH COPPER (FOR DUST FREE MASHING-IN) - GIBBET-LIFT FOR BAGGED SPECIAL MALTS 2. BREWHOUSE TOWER BREWHOUSE FOR 20 HL / BREW, COMPLETE IN STAINLESS STEEL, BUILT 1994, STEAM HEATED, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, 2 CRANE EYELET, 2 STAINLESS STEEL PLATFORM, WITH: - MASH- / WORT COPPER WITH BOTTOM HEATING ZONE AND INTERIOR COOKER, SIDEWAYS AGITATOR, MANWAY ENTRANCE HATCH, LIGHTNING, STEAM REGULATION VALVE - LAUTER TUN, WITH STAINLESS STEEL RAKING MACHINE WITH SEW-DRIVE FROM TOP, WITH SPENT GRAINS SLIDER, STAINLESS STEEL FALSE BOTTOM, SPENT GRAINS HATCH, VERTICAL SIGHT GLASS, LIGHTNING, SPRAY HEAD, DOME LID WITH BUILT IN CONTROL CABINET - SPINDLE STATION WITH WASHING TABLE IN STAINLESS STEEL, ABOUT 1,5M WALL ASSEMBLED - HOT WATER TANK, WITH 30 HL, IN STAINLESS STEEL, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, HEATABLE, WITH MANWAY IN THE WALL, LEVEL DISPLAY - PRESSURE RAISING PUMP - WORT COOLING, 1-STAGE PLATE APPARATUS - WORT AERATION IN STAINLESS STEEL 3. FERMENTING- AND STORAGE TANKS - 5 CCTS, WITH 40 HL NET / 46 HL GROSS CONTENT, ALL TANKS 3 BAR, BUILT 1994, STANDING ON FEET, PI-ISOLATED FULLY WELDED WITH STAINLESS STEEL JACKET, WITH JACKET COOLING FROM CONE BELOW TO ½ WALL 60 LT COOLING JACKET 3 BAR, WITH MANWAY IN THE WALL, 2 OUTLETS WITH BUTTERFLY VALVES, TEMPERATURE SENSOR PT100, SPRAY HEAD, PULLED DOWN CLEANING PIPE WITH BUTTERFLY VALVE, BUNGING ARMATURE, OVER PRESSURE VALVE, SAMPLER, 2 CRANE EYELETS, 2 OF THE TANKS WITH LEVEL DISPLAY - DIGITAL TEMPERATURE CONTROL FOR 5 TANKS IN STAINLESS STEEL CONTROL CABINET - CIRCULATING PUMP IN STAINLESS STEEL, MOBILE, WITH SWITCH - MANY GOOD BEER HOSES - 6 X 10 HL BEER DISPENSING TANKS, MAKE DUO TANK, BUILT 2002, 3,0 / 4,3 BAR, COOL ABLE, ISOLATED WITH STAINLESS STEEL-JACKET FULLY WELDED, FOR INLINE-OPERATION, LYING IN RACK, SCREWED STAINLESS STEEL RACK, WITH PRESSURE ARMATURE, OUTLET ARMATURE WITH REDUCTION TO BARE CONNECTION, MANWAY WITH BIG SIGHT GLASS IN MANWAY LED - PANEL FOR 3 TYPES OF BEER 4. FILLING COMBINED BOTTLE-/KEGGING PLANT, WITH 1 CLEANING TUB, HEATED AND 1 REBUILT KEG: - BOTTLE CLEANING MACHINE FOR CLEANING OF 8 BOTTLES INSIDE AND OUTSIDE, FOR UP TO 2LT BOTTLES - BOTTLE FILLING STATION WITH HUB CYLINDER FROM BELOW, WITH SPLINTER PROTECTION - COMBINED KEG-CLEANING- AND FILLING STATION - BUILT IN CONTROL CABINET WITH SIEMENS S5 CONTROL AND OPERATING CONSOLE OP 7 5. OTHER EQUIPMENT - STEAM BOILER FOR ABOUT F280 KG/H, WITH GAS BURNER, FULLY SERVICED ON 4TH AUGUST 2014, BUILT IN 1994 - CONDENSATE TUB IN STAINLESS STEEL AT WALL AND SECOND SMALL S/S-TUB - WATER TREATMENT - STEAM REGULATION AND CONDENSATE VALVES IN CYCLE - STAINLESS STEEL CHIMNEY PLANT ABOUT 8-10M - AIR COMPRESSOR WITH WIND KETTLE, BUILT 1994 - COOLING PLANT / COLD WATER PLANT, MAKE L&R KÄLTETECHNIK, TYPE: WRK-17/SL/-5, PLANT BUILT 1997, COOLING AGENT R 407 C, WITH NEW COMPRESSOR AND NEW PLATE HEAT EXCHANGER IN 2014 FOR 10,000 € INVESTED, EVAPORATOR WITH 2 VENTILATOR OUTSIDE HANGING ON THE WALL 6.1 OTHERS - ABOUT 100 KETS, MAKE SCHÄFER, PLUS-KEGS, FLAT FITTING IN DIFFERENT SIZES, NEUTRAL - PARTY-KEGS, WITH BAVARIAN TAP, PU-COVERED IN BLACK AND WITH WOOD-OPTIC - ABOUT 800 NEUTRAL CLIP LOCK BOTTLES EACH 1 LT 6.2 DIMENSIONS THE ROOM HEIGHT IN BREWHOUSE AND CCTS IS 4.50M. THE PLANT AS ASSEMBLED ON 10.75 X 4.38M. PLEASE NOTE THAT THE BREWERY IS ONLY AVAILABLE AS A SINGLE SALE QUANTITY AVAILABLE: 1 Learn More

M-4868 PUB BREWERY 20HLREFERENCE NUMBER: M-4868 (1111275NKG10RX) L PUB BREWERY 20HL SPECIFICATION: 1. MALT HANDLING - CYLINDER-CONIC MALT SILO WITH 25M³ CONTENT, MADE IN FIBRE GLASS / PLASTIC, STANDING OUTDOOR ON STEEL CONSTRUCTION - MALT CONVEYORS / SPIRAL CONVEYOR INTO 1ST FLOOR - 2-ROLLER MALT MILL - GRIST CASE - FALL PIPE IN MASH COPPER (FOR DUST FREE MASHING-IN) - GIBBET-LIFT FOR BAGGED SPECIAL MALTS 2. BREWHOUSE TOWER BREWHOUSE FOR 20 HL / BREW, COMPLETE IN STAINLESS STEEL, BUILT 1994, STEAM HEATED, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, 2 CRANE EYELET, 2 STAINLESS STEEL PLATFORM, WITH: - MASH- / WORT COPPER WITH BOTTOM HEATING ZONE AND INTERIOR COOKER, SIDEWAYS AGITATOR, MANWAY ENTRANCE HATCH, LIGHTNING, STEAM REGULATION VALVE - LAUTER TUN, WITH STAINLESS STEEL RAKING MACHINE WITH SEW-DRIVE FROM TOP, WITH SPENT GRAINS SLIDER, STAINLESS STEEL FALSE BOTTOM, SPENT GRAINS HATCH, VERTICAL SIGHT GLASS, LIGHTNING, SPRAY HEAD, DOME LID WITH BUILT IN CONTROL CABINET - SPINDLE STATION WITH WASHING TABLE IN STAINLESS STEEL, ABOUT 1,5M WALL ASSEMBLED - HOT WATER TANK, WITH 30 HL, IN STAINLESS STEEL, ISOLATED AND COVERED WITH STAINLESS STEEL SHEET, HEATABLE, WITH MANWAY IN THE WALL, LEVEL DISPLAY - PRESSURE RAISING PUMP - WORT COOLING, 1-STAGE PLATE APPARATUS - WORT AERATION IN STAINLESS STEEL 3. FERMENTING- AND STORAGE TANKS - 5 CCTS, WITH 40 HL NET / 46 HL GROSS CONTENT, ALL TANKS 3 BAR, BUILT 1994, STANDING ON FEET, PI-ISOLATED FULLY WELDED WITH STAINLESS STEEL JACKET, WITH JACKET COOLING FROM CONE BELOW TO ½ WALL 60 LT COOLING JACKET 3 BAR, WITH MANWAY IN THE WALL, 2 OUTLETS WITH BUTTERFLY VALVES, TEMPERATURE SENSOR PT100, SPRAY HEAD, PULLED DOWN CLEANING PIPE WITH BUTTERFLY VALVE, BUNGING ARMATURE, OVER PRESSURE VALVE, SAMPLER, 2 CRANE EYELETS, 2 OF THE TANKS WITH LEVEL DISPLAY - DIGITAL TEMPERATURE CONTROL FOR 5 TANKS IN STAINLESS STEEL CONTROL CABINET - CIRCULATING PUMP IN STAINLESS STEEL, MOBILE, WITH SWITCH - MANY GOOD BEER HOSES - 6 X 10 HL BEER DISPENSING TANKS, MAKE DUO TANK, BUILT 2002, 3,0 / 4,3 BAR, COOL ABLE, ISOLATED WITH STAINLESS STEEL-JACKET FULLY WELDED, FOR INLINE-OPERATION, LYING IN RACK, SCREWED STAINLESS STEEL RACK, WITH PRESSURE ARMATURE, OUTLET ARMATURE WITH REDUCTION TO BARE CONNECTION, MANWAY WITH BIG SIGHT GLASS IN MANWAY LED - PANEL FOR 3 TYPES OF BEER 4. FILLING COMBINED BOTTLE-/KEGGING PLANT, WITH 1 CLEANING TUB, HEATED AND 1 REBUILT KEG: - BOTTLE CLEANING MACHINE FOR CLEANING OF 8 BOTTLES INSIDE AND OUTSIDE, FOR UP TO 2LT BOTTLES - BOTTLE FILLING STATION WITH HUB CYLINDER FROM BELOW, WITH SPLINTER PROTECTION - COMBINED KEG-CLEANING- AND FILLING STATION - BUILT IN CONTROL CABINET WITH SIEMENS S5 CONTROL AND OPERATING CONSOLE OP 7 5. OTHER EQUIPMENT - STEAM BOILER FOR ABOUT F280 KG/H, WITH GAS BURNER, FULLY SERVICED ON 4TH AUGUST 2014, BUILT IN 1994 - CONDENSATE TUB IN STAINLESS STEEL AT WALL AND SECOND SMALL S/S-TUB - WATER TREATMENT - STEAM REGULATION AND CONDENSATE VALVES IN CYCLE - STAINLESS STEEL CHIMNEY PLANT ABOUT 8-10M - AIR COMPRESSOR WITH WIND KETTLE, BUILT 1994 - COOLING PLANT / COLD WATER PLANT, MAKE L&R KÄLTETECHNIK, TYPE: WRK-17/SL/-5, PLANT BUILT 1997, COOLING AGENT R 407 C, WITH NEW COMPRESSOR AND NEW PLATE HEAT EXCHANGER IN 2014 FOR 10,000 € INVESTED, EVAPORATOR WITH 2 VENTILATOR OUTSIDE HANGING ON THE WALL 6.1 OTHERS - ABOUT 100 KETS, MAKE SCHÄFER, PLUS-KEGS, FLAT FITTING IN DIFFERENT SIZES, NEUTRAL - PARTY-KEGS, WITH BAVARIAN TAP, PU-COVERED IN BLACK AND WITH WOOD-OPTIC - ABOUT 800 NEUTRAL CLIP LOCK BOTTLES EACH 1 LT 6.2 DIMENSIONS THE ROOM HEIGHT IN BREWHOUSE AND CCTS IS 4.50M. THE PLANT AS ASSEMBLED ON 10.75 X 4.38M. PLEASE NOTE THAT THE BREWERY IS ONLY AVAILABLE AS A SINGLE SALE QUANTITY AVAILABLE: 1 Learn More -

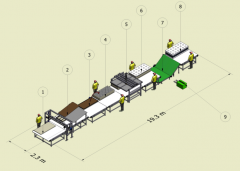

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

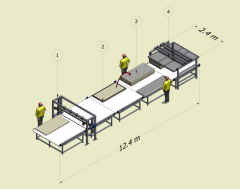

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

R-8867 JUKI LK 1900B-SS –NEW, YEAR 2015

R-8867 JUKI LK 1900B-SS –NEW, YEAR 2015REFERENCE NUMBER: R-8867

Learn More

JUKI LK 1900B-SS – NEW

YEAR: 2015

QUANTITY: 1 -

J-1302 TSUDAKOMA SIZING MACHINES FOR FILAMENT

J-1302 TSUDAKOMA SIZING MACHINES FOR FILAMENTREFERENCE NUMBER: J-1302

Learn More

MAKE: TSUDAKOMA JAPAN

MODEL: KB20 and KS200

YEAR: 1994 and 1989

QUANTITY: 2 -

L-2308 JAPSEW J-300-D-TT SEWING MACHINE FOR MOCK HAND-STITCHING WITH THREAD TRIMMER

L-2308 JAPSEW J-300-D-TT SEWING MACHINE FOR MOCK HAND-STITCHING WITH THREAD TRIMMERREFERENCE NUMBER: L-2308

JAPSEW J-300-D-TT SEWING MACHINE FOR MOCK HAND-STITCHING WITH THREAD TRIMMER

QUANTITY: 1

Learn More -

R-7540 OSTHOFF DOUBLE-JET SINGEING & DESIZING RANGE, YEAR 2002 – 3200mm

R-7540 OSTHOFF DOUBLE-JET SINGEING & DESIZING RANGE, YEAR 2002 – 3200mmREFERENCE NUMBER: R-7540

Learn More

OSTHOFF DOUBLE-JET SINGEING & DESIZING RANGE

TYPE U 97/2

WORKING WIDTH 3200mm

ROLLER WIDTH 3400mm

YEAR 2002

QUANTITY: 1