Search results for: 'can'

- Related search terms

- can coiler

- cann

- Can a

- Cans

- can be seen

-

G-6521 POTATO CHIPS PRODUCTION LINE 200KG/HREFERENCE NUMBER: G-6521 POTATO CHIPS PRODUCTION LINE 200KG/H 1. WASHING MACHINE 2. PEELING MACHINE 3. TRIMMING MACHINE 4. SLICER FEEDER 5. SLICER 6. WASHING MACHINE 7. BLANCHING MACHINE 8. GAS TYPE CONTINUOUS FRYING MACHINE 9. FLAVORING MACHINE QUANTITY AVAILABLE: 1 Learn More

G-6521 POTATO CHIPS PRODUCTION LINE 200KG/HREFERENCE NUMBER: G-6521 POTATO CHIPS PRODUCTION LINE 200KG/H 1. WASHING MACHINE 2. PEELING MACHINE 3. TRIMMING MACHINE 4. SLICER FEEDER 5. SLICER 6. WASHING MACHINE 7. BLANCHING MACHINE 8. GAS TYPE CONTINUOUS FRYING MACHINE 9. FLAVORING MACHINE QUANTITY AVAILABLE: 1 Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More -

A-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPEA-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPE FLUORESCENT UV LAMP IS IMPORTED FOR THIS ACCELERATED AGING TEST CHAMBER. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND DEW. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP TO SIMULATES THE EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. THE TESTED MATERIAL IS PLACED IN A LOOP PROGRAM THAT ALTERNATES LIGHT AND MOISTURE AT A CERTAIN TEMPERATURE. THE MATERIAL WAS TESTED FOR ACCELERATED WEATHERABILITY. UV CHAMBER CAN RE-CREATE HAZARDS THAT OCCUR OUTDOORS FOR MONTHS OR YEARS.THE TYPES OF HAZARDS INCLUDE: DISCOLORATION, CHALKINESS, POWDER LIGHT, CRACKING, TURBIDITY, BUBBLES, BRITTLE, STRENGTH, DECAY, OXIDATION, ETC. THIS MACHINE INCLUDES SPRAY DEVICE. Learn More

A-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPEA-2611 ULTRAVIOLET AGING TESTING CHAMBER BOX TYPE FLUORESCENT UV LAMP IS IMPORTED FOR THIS ACCELERATED AGING TEST CHAMBER. CAN SIMULATE HARM BY SUNLIGHT, RAINWATER AND DEW. UV WEATHER RESISTANCE CHAMBER USE FLUORESCENT UV LAMP TO SIMULATES THE EFFECT OF SUNLIGHT, CONDENSATION MOISTURE IS USED TO SIMULATE DEW. THE TESTED MATERIAL IS PLACED IN A LOOP PROGRAM THAT ALTERNATES LIGHT AND MOISTURE AT A CERTAIN TEMPERATURE. THE MATERIAL WAS TESTED FOR ACCELERATED WEATHERABILITY. UV CHAMBER CAN RE-CREATE HAZARDS THAT OCCUR OUTDOORS FOR MONTHS OR YEARS.THE TYPES OF HAZARDS INCLUDE: DISCOLORATION, CHALKINESS, POWDER LIGHT, CRACKING, TURBIDITY, BUBBLES, BRITTLE, STRENGTH, DECAY, OXIDATION, ETC. THIS MACHINE INCLUDES SPRAY DEVICE. Learn More -

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More -

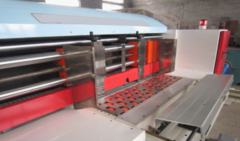

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More -

TT-1037 SINGLE COLUMN TENSILE STRENGTH TESTERTT-1037 SINGLE COLUMN TENSILE STRENGTH TESTER KEY SPECIFICATIONS CAPACITY: 50N, 100N, 200N, 500N, 1KN, 2KN, 2.5KN, 5KN DISPLAY: COMPUTER DISPLAY FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RANGE: 1000mm STROKE RESOLUTION: 0.001mm TEST SPEED: 0.001-1000mm/MIN CAN SET ON DISPLAY, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON. SPECIMEN DAMAGE AUTOMATIC STOP MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 120W POWER SUPPLY: AC 220V 50-60Hz 10A DIMENSIONS: APPROX 500 X 400 X 1450mm WEIGHT: 60KG ACCESSORIES: STANDARDS ACCESSORIES: 1 SET MANUAL GRIPS, 1 PC LOAD CELL, 1 PC ENGLISH OPERATION SOFTWARE, 1 PC CABLE CONNECT WITH PC OPTION ACCESSORIES: OPTIONAL DESKTOP COMPUTER OPTIONAL OTHER GRIPS QUANTITY: 1 Learn More

TT-1037 SINGLE COLUMN TENSILE STRENGTH TESTERTT-1037 SINGLE COLUMN TENSILE STRENGTH TESTER KEY SPECIFICATIONS CAPACITY: 50N, 100N, 200N, 500N, 1KN, 2KN, 2.5KN, 5KN DISPLAY: COMPUTER DISPLAY FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RANGE: 1000mm STROKE RESOLUTION: 0.001mm TEST SPEED: 0.001-1000mm/MIN CAN SET ON DISPLAY, WITH UP & DOWN FAST ADJUSTMENT BUTTON OF GRIPS FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON. SPECIMEN DAMAGE AUTOMATIC STOP MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER: 120W POWER SUPPLY: AC 220V 50-60Hz 10A DIMENSIONS: APPROX 500 X 400 X 1450mm WEIGHT: 60KG ACCESSORIES: STANDARDS ACCESSORIES: 1 SET MANUAL GRIPS, 1 PC LOAD CELL, 1 PC ENGLISH OPERATION SOFTWARE, 1 PC CABLE CONNECT WITH PC OPTION ACCESSORIES: OPTIONAL DESKTOP COMPUTER OPTIONAL OTHER GRIPS QUANTITY: 1 Learn More -

TT-1019 NSC SCHLUMBERGER WORSTED MACHINES GC14 PREPARATION LINE, YEAR 1993 TO 1994TT-1019 NSC SCHLUMBERGER WORSTED MACHINES GC14 PREPARATION LINE, YEAR 1993 TO 1994 QUANTITY: 1 Learn More

TT-1019 NSC SCHLUMBERGER WORSTED MACHINES GC14 PREPARATION LINE, YEAR 1993 TO 1994TT-1019 NSC SCHLUMBERGER WORSTED MACHINES GC14 PREPARATION LINE, YEAR 1993 TO 1994 QUANTITY: 1 Learn More -

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More