Search results for: 'two for'

-

TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM FOR CONTINUOUS FILAMENT YARN APPLICATIONS (MULTIFILAMENT) YEAR 2020 AVAILABLE FOR IMMEDIATE SALE QUANTITY: 1 Learn More

TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020TT-2274 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM, YEAR 2020 FIBRE EXTRUSION TECHNOLOGIES LIMITED FET-100 SERIES PILOT MELT SPINNING SYSTEM FOR CONTINUOUS FILAMENT YARN APPLICATIONS (MULTIFILAMENT) YEAR 2020 AVAILABLE FOR IMMEDIATE SALE QUANTITY: 1 Learn More -

YY-2386 SQUARE BOTTOM PAPER BAG MACHINE W&H MOD. TRIUMPH 3YY-2386 SQUARE BOTTOM PAPER BAG MACHINE W&H MOD. TRIUMPH 3 LIST OF FORMAT PLATES, GEARS AND PRINTING CYLINDERS ON REQUEST. MACHINE IN REALLY NICE CONDITIONS. QUANTITY: 1 Learn More

YY-2386 SQUARE BOTTOM PAPER BAG MACHINE W&H MOD. TRIUMPH 3YY-2386 SQUARE BOTTOM PAPER BAG MACHINE W&H MOD. TRIUMPH 3 LIST OF FORMAT PLATES, GEARS AND PRINTING CYLINDERS ON REQUEST. MACHINE IN REALLY NICE CONDITIONS. QUANTITY: 1 Learn More -

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mmYY-2313 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1800mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400 METERS PER MINUTE SLITTING WIDTH: 30 TO 1800mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø1000mm; MACHINE WEIGHT: 5000 KG; TOTAL MOTOR POWER: 31KW; DIMENSIONS: W 3500 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3 " (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 11KW X 2; TRACTION MOTOR: 11KW; MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

TT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORSTT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORS BASIC MACHINE MONITORING: INTEGRATED MICROPROCESSOR, MONITORING AND CONTROLLING ALL MAJOR MECHANICAL AND ELECTRONIC FUNCTIONS. WITH KEYBOARD AND DISPLAY. SENSITIVITY OF DETECTION AND CONTROL THROUGH MICROPROCESSOR WITH 4 COLOR LIGHT COLUMN FOR STOP INDICATIONS. QUANTITY: 24 Learn More

TT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORSTT-1963 OMNI PLUS (800) LENO, WIDTH 3400mm, FOUR AND FIVE CAMS PER LOOM, TWO COLOR SELECTORS BASIC MACHINE MONITORING: INTEGRATED MICROPROCESSOR, MONITORING AND CONTROLLING ALL MAJOR MECHANICAL AND ELECTRONIC FUNCTIONS. WITH KEYBOARD AND DISPLAY. SENSITIVITY OF DETECTION AND CONTROL THROUGH MICROPROCESSOR WITH 4 COLOR LIGHT COLUMN FOR STOP INDICATIONS. QUANTITY: 24 Learn More -

J-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTSJ-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTS MAKE: GE MODEL: LM6000 PA YEAR: 1993 42 MW 50 Hz DUAL FUEL 10,500 VOLTS CONDITION: USED, 12,000 HOURS QUANTITY: 1 Learn More

J-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTSJ-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTS MAKE: GE MODEL: LM6000 PA YEAR: 1993 42 MW 50 Hz DUAL FUEL 10,500 VOLTS CONDITION: USED, 12,000 HOURS QUANTITY: 1 Learn More -

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More

YY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mmYY-2260 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, SLITTING WIDTH 30 TO 1700 mm, WINDING DIAMETER UP TO 1400mm SUITABLE MATERIALS REEL-SHAPED PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0 TO 400M/MIN; SLITTING WIDTH: 30 TO 1700mm; UNWINDING DIAMETER: MAXIMUM Ø1400mm; WINDING DIAMETER: Ø610mm; MACHINE WEIGHT: 1800KG; TOTAL MOTOR POWER: 29KW; DIMENSIONS: W 3200 × L 3500 × H 1900 (mm); RETRACTABLE PAPER CORE: 3" (DIAMETER Φ76mm DIAMETER Φ92mm); CORRECTION ACCURACY: ≤ 0.30mm; TENSION SETTING RANGE: 2 ~ 30KG; WINDING MOTOR POWER: 7.5KW X 2; TRACTION MOTOR: 7.5KW; MACHINE COLOR STANDARD WHITE (OR AS REQUIRED). QUANTITY: 1 Learn More -

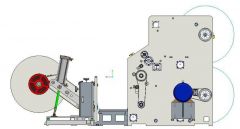

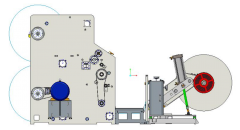

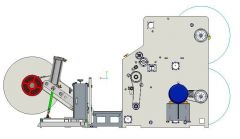

YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE)YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE) DESCRIPTION: PACKING MACHINE WITH THE ADVANTAGES OF SMALL SIZE, LIGHT WEIGHT, HIGH EFFICIENCY, SEMI FUNCTIONAL, ETC., SUITABLE FOR PACKING COFFEE STICK, MEAT, BISCUIT, BLISTER, BOTTLES, VIALS, PILLOW BAGS, ETC. REMARK: SEALING: TWO SIDES WITH PLUG-IN. QUANTITY: 1 Learn More

YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE)YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE) DESCRIPTION: PACKING MACHINE WITH THE ADVANTAGES OF SMALL SIZE, LIGHT WEIGHT, HIGH EFFICIENCY, SEMI FUNCTIONAL, ETC., SUITABLE FOR PACKING COFFEE STICK, MEAT, BISCUIT, BLISTER, BOTTLES, VIALS, PILLOW BAGS, ETC. REMARK: SEALING: TWO SIDES WITH PLUG-IN. QUANTITY: 1 Learn More -

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

J-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIOJ-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIO Learn More

J-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIOJ-4517 REBUILT/RUNNING CONDITION PELLETIZING LINE, STRAND TYPE, MODEL BCC38 EXTRUDER, 30:1 L/D RATIO Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More