Search results for: 'General'

- Related search terms

- General Electric

- general electric lm2500 gas turbine engines

- General vacuum

- general electric 1200 amp

- General electric 2500

-

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More -

YY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINEYY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINE GENERAL DESCRIPTION: WIDTH OF PRODUCT: 3.2M; WEIGHT RANGE: 15 TO 170G/M2; PRODUCTION CAPACITY: 556KG/H (BASED ON PRODUCT WITH BASIS WEIGHT OF 50G/M2 OR ABOVE, AND WITH WIDTH OF 3.2M AND FABRIC DELIVERING SPEED OF 58M/MIN). THE DESIGNED ANNUAL CAPACITY IS 4000 TONS PET SPUNBONDED NONWOVEN FABRICS (OUTPUT CALCULATION IS BASED ON THE PRODUCT WITH BASIS WEIGHT OF 50G/M2 AND WITH WIDTH OF 3.2M AND 8000 WORKING HOURS ANNUALLY AND AT FABRIC CONVEYING SPEED OF 58M/MIN, AND THE EFFICIENCY OF 95%). PROCESS SPEED: 10M/MIN TO 150M/MIN; FIBER FINENESS: 1.0 TO 3.0 DPF; MACHINERY DIMENSIONS (L×W×H): 25M×18M×10.5M (FOR REFERENCE ONLY AND DEPENDS ON THE ACTUAL DESIGN). TOTAL INSTALLED POWER: 1492KW (ACTUAL POWER CONSUMPTION: APPROXIMATELY 746KW). Learn More

YY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINEYY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINE GENERAL DESCRIPTION: WIDTH OF PRODUCT: 3.2M; WEIGHT RANGE: 15 TO 170G/M2; PRODUCTION CAPACITY: 556KG/H (BASED ON PRODUCT WITH BASIS WEIGHT OF 50G/M2 OR ABOVE, AND WITH WIDTH OF 3.2M AND FABRIC DELIVERING SPEED OF 58M/MIN). THE DESIGNED ANNUAL CAPACITY IS 4000 TONS PET SPUNBONDED NONWOVEN FABRICS (OUTPUT CALCULATION IS BASED ON THE PRODUCT WITH BASIS WEIGHT OF 50G/M2 AND WITH WIDTH OF 3.2M AND 8000 WORKING HOURS ANNUALLY AND AT FABRIC CONVEYING SPEED OF 58M/MIN, AND THE EFFICIENCY OF 95%). PROCESS SPEED: 10M/MIN TO 150M/MIN; FIBER FINENESS: 1.0 TO 3.0 DPF; MACHINERY DIMENSIONS (L×W×H): 25M×18M×10.5M (FOR REFERENCE ONLY AND DEPENDS ON THE ACTUAL DESIGN). TOTAL INSTALLED POWER: 1492KW (ACTUAL POWER CONSUMPTION: APPROXIMATELY 746KW). Learn More -

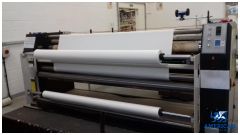

J-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mmJ-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mm 3 POSITION CREEL FOR: SCRIM GLUE FABRICS AREA 4000 x 3000mm QUANTITY: 1 Learn More

J-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mmJ-3785 GRIBETZ STRATA LAMINATOR, YEAR 2016, WORKING WIDTH 1400 TO 2200mm 3 POSITION CREEL FOR: SCRIM GLUE FABRICS AREA 4000 x 3000mm QUANTITY: 1 Learn More -

YY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTEYY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTE APPLICATION AREA: MATTRESS INDUSTRY, FOAM LAMINATION SYSTEM. MATERIALS: FINISHED OR SEMI-FINISHED MATTRESS, FOAM, FELT, QUILTED PANEL. GENERAL FEATURES: IT FLIPS THE MATTRESSES OF VARYING SIZES AND WEIGHTS WITHOUT REQUIRING ANY ADJUSTMENT. AS MATTRESSES ARE HELD BY PNEUMATIC ARMS, ANY RISK OF DEFORMATION DURING FLIPPING IS AVOIDED. WITH THE HELP OF ITS SENSORS, IT CAN DETECT AUTOMATICALLY WHETHER THERE IS A MATTRESS IN THE MACHINE. THE SAFETY BARRIER SURROUNDING THE MACHINE PROVIDES A SAFE WORKING ENVIRONMENT. FEATURES A LONG-LIFE FESTO BRAND PNEUMATIC SYSTEM WITH LOW AIR CONSUMPTION. STANDARD: SAFETY BARRIER, PNEUMATIC FLIPPING SYSTEM, PVC CONVEYOR. QUANTITY: 1 Learn More

YY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTEYY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTE APPLICATION AREA: MATTRESS INDUSTRY, FOAM LAMINATION SYSTEM. MATERIALS: FINISHED OR SEMI-FINISHED MATTRESS, FOAM, FELT, QUILTED PANEL. GENERAL FEATURES: IT FLIPS THE MATTRESSES OF VARYING SIZES AND WEIGHTS WITHOUT REQUIRING ANY ADJUSTMENT. AS MATTRESSES ARE HELD BY PNEUMATIC ARMS, ANY RISK OF DEFORMATION DURING FLIPPING IS AVOIDED. WITH THE HELP OF ITS SENSORS, IT CAN DETECT AUTOMATICALLY WHETHER THERE IS A MATTRESS IN THE MACHINE. THE SAFETY BARRIER SURROUNDING THE MACHINE PROVIDES A SAFE WORKING ENVIRONMENT. FEATURES A LONG-LIFE FESTO BRAND PNEUMATIC SYSTEM WITH LOW AIR CONSUMPTION. STANDARD: SAFETY BARRIER, PNEUMATIC FLIPPING SYSTEM, PVC CONVEYOR. QUANTITY: 1 Learn More -

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More

T-8028 HIGH SPEED SOFT WINDING MACHINET-8028 HIGH SPEED SOFT WINDING MACHINE SIZE: 2050 X 750 X 1500mm SINGLE-SIDE CONFIGURATION: 6 SPINDLES/SET WEIGHT: 150KG QUANTITY: 1 SET (6 SPINDLES) Learn More -

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More -

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More -

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More