Search results for: 'machine+tr'

- Related search terms

- machine+trico

- machine+tricot

- machine+tr'A=0

- machine+trim+0

- machine+track

-

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More -

A-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mmA-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600mm PRODUCTION SPEED: 13 TO 17 M/min EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 22KW PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 300 TO 400 KG / 24 HOURS DIMENSION: 15000 X 3000 X 3000 mm WEIGHT: 5000 TO 6000 KGS POWER (TOTAL KW): 96 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 15 DAYS Learn More

A-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mmA-2523 MELTBLOWN FABRIC PRODUCTION MACHINE 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600mm PRODUCTION SPEED: 13 TO 17 M/min EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 22KW PRODUCT WEIGHT RANGE: 5000 TO 6000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 300 TO 400 KG / 24 HOURS DIMENSION: 15000 X 3000 X 3000 mm WEIGHT: 5000 TO 6000 KGS POWER (TOTAL KW): 96 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 15 DAYS Learn More -

TT-8601 BENNINGER SLASHER INDIGO LINE, YEAR 2003 RECONDITIONED 2021TT-8601 BENNINGER SLASHER INDIGO LINE, YEAR 2003 RECONDITIONED 2021 1. BENNINGER SLASHER INDIGO LINE 2. YEAR: 2003 RECONDITIONED 2021 3. RUNNING AT THE MOMENT IN PERFECT CONDITION Learn More

TT-8601 BENNINGER SLASHER INDIGO LINE, YEAR 2003 RECONDITIONED 2021TT-8601 BENNINGER SLASHER INDIGO LINE, YEAR 2003 RECONDITIONED 2021 1. BENNINGER SLASHER INDIGO LINE 2. YEAR: 2003 RECONDITIONED 2021 3. RUNNING AT THE MOMENT IN PERFECT CONDITION Learn More -

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More

NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7REFERENCE NUMBER: T-6989 NONWOVEN FABRIC PRODUCTION PLANTS WITH MALIWATT AND MALIVLIES 3600mm GAUGE 14 AND 7 ITEM 001 PRODUCTION PLANT OF NON-WOVEN FABRIC PLANT IS COMPLETE IN AN EXCELLENT STATE OF MAINTENANCE WITH DRUMS OF 2000mm IN DIAMETER LIKE THE SAME DIAMETER DOFFERS, HIGH WORK 2200mm, 2500 X 4200mm, ALL MACHINES ARE ELECTRONICALLY MANAGED BY PLC, WEIGHT SCALE WITH LOAD CELLS, IT IS THERE IS ALSO THE COMPLETE AUTOMATED FIBER PREPARATION IN ADDITION, THERE IS 1 LOOM FOR NONWOVEN MALIWATT WITH THREAD AND 1 MALIVLIES LOOM WITHOUT SEWING THREAD INTERTWINES THE FIBERS AND PRODUCES A NON-WOVEN FABRIC ALSO USED FOR THE PRODUCTION OF ANTI-COVID-19 FACIAL MASKS FABRIC PRODUCTION PLANTS IN BLOCK FABRIC OR FOR SINGLE UNITS IN GOOD CONDITION AND STILL IN PRODUCTION TODAY THE DESCRIPTION OF THE PLANTS BELOW: ITEM 002 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1980 FOR MODEL CARD WORKING HEIGHT 2200mm DRUM DIAMETER 1700mm DOFFER 1270mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, PLANT IN GOOD CONDITION QUANTITY: 2 ITEM 003 MALIWATT 3600 TYPE 14013 GAUGE 7 YEAR OF CONSTRUCTION 1981 CARD MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC AT THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 004 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 OCTIR MODEL CARD WORKING HEIGHT 2500mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% LENGTH FIBER 60mm, 3.4 DTEX, IMPLANT IN EXCELLENT CONDITION QUANTITY: 1 ITEM 005 MALIWATT 3600 TYPE 14013 GAUGE 14 YEAR OF CONSTRUCTION 1981 CARD FOR MODEL FOR WORKING HEIGHT 2200mm DIAMETERS 1700mm AND DOFFER 1270mm, CONSISTING OF FRONT TRAIN AND A CARD WITH RIGID SEAL AT THE FRONT AND ORDINARY ELASTIC ON THE 1ST CARD. THE LINE CONSISTS OF SILOS, LOADER, FRONT END, CARDER, CROSS LAPPER CORMATEX SAGITTARIO LINE, FIBER USED 70% COTTON AND 30% VISCOSE, PLANT IN GOOD GENERAL CONDITION. QUANTITY: 1 ITEM 006 MALIWATT 3600 TYPE 14011 GAUGE 14 YEAR OF CONSTRUCTION 1976 BOISSON MODEL CARD WORKING HEIGHT 2000mm, RIGID FRONT GASKET AND 1ST ELASTIC CARD, ORDINARY FINENESS, THE LINE IS COMPOSED OF SILOS, AVAN TRAIN LOADER AND ONE CARD, NENCINI CROSS LAPPER, FIBER USED MIXED POLYESTER AND VISCOSE 70/30% FIBER LENGTH 60mm, 3.4 DTEX, IMPLANT IN FAIR GENERAL CONDITION QUANTITY: 1 DESCRIPTION: ALL PRODUCTION LINES ARE FULLY FUNCTIONAL AND ARE STILL PRODUCTION ALL THE PLANTS ARE COMPOSED OF FORWARD TRAIN AND ONE CARD DOES NOT HAVE FIBER CROSSING AND THE PRODUCTION OF ARTICLES WITH MELANGE COLORS IS PROBLEMATIC, ANOTHER HANDICAP THAT I HAVE DETECTED THE PLANT DOES NOT HAVE FIBER PREPARATION AND STORAGE, THERE ARE BALES AND SILOS OPENERS WITH FEEDING CONVEYORS BUT THE FIBER USED IS NOT WELL MIXED, CURRENTLY THEY PRODUCE NON-WOVEN FABRICS FOR PRINTING. ALL MALIWATTS THE ELECTRICAL SYSTEM AND THE ELECTRONIC BAR HEATING SYSTEM HAVE BEEN REBUILT; THE CROSS LAPPERS HAVE ALSO BEEN UPDATED IN THE ELECTRONICS. THE SELLER SELLS THE PLANT IS NOT PROFITABLE AND THEY PLAN TO REINVEST IN DIFFERENT PRODUCTIONS IN ADDITION, THERE ARE ALSO VARIOUS ACCESSORIES FOR PRODUCTION SUCH AS BALE OPENERS, CALENDERS, CONVEYOR TROLLEYS ETC. Learn More -

TT-8579 FABRIC BEAM DYEING MACHINE, WIDTH 1500mmTT-8579 FABRIC BEAM DYEING MACHINE, WIDTH 1500mm 1. FABRIC BEAM DYEING WINDER MACHINE 2. FABRIC TYPE WOVEN TYRICOT OR SATIN FABRIC 3. FABRIC WIDTH 1500mm 4. BEAM WIDTH 2000mm (MAX.) Learn More

TT-8579 FABRIC BEAM DYEING MACHINE, WIDTH 1500mmTT-8579 FABRIC BEAM DYEING MACHINE, WIDTH 1500mm 1. FABRIC BEAM DYEING WINDER MACHINE 2. FABRIC TYPE WOVEN TYRICOT OR SATIN FABRIC 3. FABRIC WIDTH 1500mm 4. BEAM WIDTH 2000mm (MAX.) Learn More -

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More

Y-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mmYY-3210 RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS 2000 TO 3800 KG PER HOUR, WORKING WIDTH 460mm WLS ROLLING & SCORING THE RED LINE "WLS -GIMBEL SYSTEM" FOR MAXIMUM OUTPUTS: 2000 TO 3800 KG/HR. FEATURES: - CONDITION: REFURBISHED - MANUFACTURER: WLS - USAGE: CHEWING GUM FORMING LINE - CAPACITY: 2.000 KG/HR. - WORKING WIDTH: 460mm - PIECES’ DIMENSIONS: ACCORDING TO THE CUSTOMERS NEED Learn More -

TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021 AVAILABILITY SHORT DELIVERY TIMES UPON AGREEMENT. Learn More

TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021TT-3155 SITOLA SCC-W HORIZONTAL CNC CONTOUR CUTTING MACHINE, YEAR 2021 AVAILABILITY SHORT DELIVERY TIMES UPON AGREEMENT. Learn More -

TT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINESTT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINES ITEM 001 F+K FLAT BOTTOM BAG MACHINE (GREEN) NO PRINTER ITEM 002 HOLWEG RS.1 (MACHINE F6- BLUE) HOLWEG PERFORATION BAG MACHINE IN OPERATION ITEM 003 W+H /GERMAN MADE/ MACHINE FOR THE PRODUCTION OF TRIANGULAR CONICAL BAGS BY W&H ROTATION IN LINE WITH A 2 COLOR PRINTER. YEAR OF PRODUCTION: UNKNOWN – A GOOD CONDITION – SEE PHOTO ATTACHED- VIDEO ON DEMAND Learn More

TT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINESTT-3899 F+K FLAT BOTTOM / HOLWEG PERFORATION / W+H BAG MACHINES ITEM 001 F+K FLAT BOTTOM BAG MACHINE (GREEN) NO PRINTER ITEM 002 HOLWEG RS.1 (MACHINE F6- BLUE) HOLWEG PERFORATION BAG MACHINE IN OPERATION ITEM 003 W+H /GERMAN MADE/ MACHINE FOR THE PRODUCTION OF TRIANGULAR CONICAL BAGS BY W&H ROTATION IN LINE WITH A 2 COLOR PRINTER. YEAR OF PRODUCTION: UNKNOWN – A GOOD CONDITION – SEE PHOTO ATTACHED- VIDEO ON DEMAND Learn More -

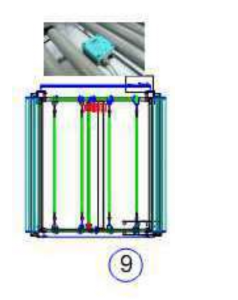

YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY)YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY) Z 600 E - FOR FOAM WITH TRICOT ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS QUANTITY: 3 Learn More

YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY)YY-2749 ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE FOR MATTRESS STACKING, VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS, PRODUCED UP TO 10 M HEIGHT, MACHINE N. 9, MACHINE NAME BRAND GRASSI (ITALY) Z 600 E - FOR FOAM WITH TRICOT ELECTRONIC AUTOMATIC VERTICAL STOCK-MACHINE VERSATILE AND INTUITIVE ADAPTED TO ALL PRODUCTION LINE WITH HEIGHT CUSTOMIZED ON BUILDINGS QUANTITY: 3 Learn More -

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More