Search results for: 'par'A=0'

-

L-1436 MATEC DOUBLE CLYINDER SOCK MACHINES SILVER 1L NEW GENERATION YEAR 2004

L-1436 MATEC DOUBLE CLYINDER SOCK MACHINES SILVER 1L NEW GENERATION YEAR 2004REFERENCE NUMBER: L-1436

Learn More

MODEL: SILVER 1L NEW GENERATION

YEAR: 2004

NEEDLES: 168

GAUGE: 14

QUANTITY: 40

MODEL: SILVER 1L NEW GENERATION

YEAR: 2004

NEEDLES: 200

GAUGE: 17

QUANTITY: 10 -

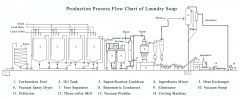

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

P-5091 REBUILT PROBAT ROASTER 90 OR 120 KILOS

P-5091 REBUILT PROBAT ROASTER 90 OR 120 KILOSP-5091 REBUILT PROBAT ROASTER 90 OR 120 KILOS

AUTOMATIC PROBAT ROASTER - 90 KILO

COMPLETE WITH :

SUCTION GROUP TO FEED GREEN COFFEE TO THE ROASTER

HOPPER FOR COFFEE WITH AUTOMATIC DOWNLOAD

ROASTING DRUM WITH SCRAPERS TO MOVE GREEN COFFEE

AUTOMATIC SHUTTER WITH SAFETY POSITION AND LIMIT SWITCH

COOLING BASIN WITH ACCIDENT PREVENTIONS, SCRAPERS AND FUN FOR COOLING AIR

HOT CIRCUIT WITH GAS BURNER COMPLETE WITH FUN WITH PARTIAL RECYCLE OF HOT AIR AND UNLOADING TANK TO RECOLLECT SOLID PARTS

3 FLAME BURNER CONTROLLED BY PROBES SET BY THE CONTROL PANEL

CONTROL PANEL WITH TOUCH SCREEN FIRE FIGHTING DEVICE WITH OPENING ELECTRO-VALVES, VOLUMETRIC COUNTER.

THE DEVICE IS INSTALLED BOTH ON THE DRUM AND ON THE COOLING BASIN

VALUE WITH REBUILT:

NEW DESTONER

OVERHAULED AFTERBURNER

REBUILT 90 KILO CE STANDARDS WITH 12 MONTH WARRANTYAUTOMATIC PROBAT ROASTER - 120 KILO

COMPLETE WITH :

LOADING HOPPER FOR GREEN COFFEE TO GO TO ROASTER

PNEUMATIC PLANT

INSULATION ON ALL PARTS OF MACHINE

AUTOMATIC SHUTTER WITH SAFETY POSITION AND LIMIT SWITCH

COOLING BASIN WITH ACCIDENT PREVENTIONS, SCRAPERS

HOT CIRCUIT WITH GAS BURNER COMPLETE WITH FAN WITH PARTIAL RECYCLE OF HOT AIR AND UNLOADING TANK TO RECOLLECT SOLID PARTS

3 FLAME BURNER CONTROLLED BY PROBES SET BY THE CONTROL PANEL

CONTROL PANEL WITH TOUCH SCREEN FIRE FIGHTING DEVICE WITH OPENING ELECTRO-VALVES, VOLUMETRIC COUNTER.

THE DEVICE IS INSTALLED BOTH ON THE DRUM AND ON THE COOLING BASIN

VALUE WITH REBUILT:

NEW DESTONER WITH SUCTION CUP AND DUMPER

NEW INSULATED BOX FOR AFTERBURNER WITH ADJUSTABLE THERMO REGULATORS

REBUILT 120 KILO CE STANDARDS WITH 12 MONTH WARRANTYQUANTITY: 1

Learn More -

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

C-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGEC-4355 FULL-AUTO WET TISSUE FOLDING MACHINE Y-12 AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

OFFER 001

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

PRODUCTION TYPE: BABY WET TISSUE

PRODUCTION PROCESS: CONNECT TO Y-2700 FOLDING MACHINE (OR Y-12 FOLDING MACHINE) → FEEDING WIPE AUTOMATIC →CONVEYING TO PACKING MACHINE → SETTING PACKING FILM → SETTING WINDOW HOLE LABEL → CENTRAL SEALING →END SEALING AND RECIPROCATING CUT → OUTPUT FINISHED PRODUCTS.

MAINTECHNICAL PARAMETER: (SUITABLE TO PACK: 5 TO 120PCS/BAG)

PRODUCT SPEED: 55 TO 60 BAG/MIN

DIAMETER OF RAW FILM ROLL: ≤380mm

WIDTH OF RAW FILM ROLL: ≤420mm

WRAPPING MATERIAL: PP, OPP, PET, PE, AND ALL SUITABLE FILMS

SHAPES OF PACKING: PILLOW TYPE PACKAGING

PACKING LENGTH: 110 TO 300mm (TOUCH SCREEN SETABLE)

PACKING WIDTH: 80 TO 150mm (ADJUSTABLE)

HEIGHT OF PACKING: 10 TO 100mm (ADJUSTABLE)

HORIZONTAL SEALING PATTERN: RECIPROCATION HEAT SEALING

DRIVE MOTOR PATTERN: ALL SERVO DRIVE

CONTROL PATTERN: YASKAWA SIMOTION CONTROL SYSTEM

OPERATION INTERFACE: 7 INCH LCD

FILM SUPPLY SYSTEM: SERVO DRIVE

HORIZONTAL SYSTEM: SERVO DRIVE

FEEDING SYSTEM: SERVO DRIVE

LABELING SYSTEM: SERVO DRIVE

PUNCHING SYSTEM: SERVO DRIVE

HORIZONTAL PROTECTION: TORQUE OVERLOAD PROTECTION

AIR REQUIREMENTS: 0.5 TO 0.8 MPA 0.01 M3/MIN

ELECTRIC POWER REQUIREMENTS: 380VAC 50/60HZ

GENERAL POWER: 7.6KW

DIMENSION OF MACHINE: 3610 × 1150 × 1900mm

STANDARD EQUIPMENT: DATE PRINTING UNIT, PUNCHING UNIT, LABELLING UNIT, INSERTING CORNER UNIT, ELECTRICAL EYE TRACKING AUTOMATICALLY

(2) SYSTEM CHARACTER

1. THE PACKING FILM ADOPTS MECHNICAL TENSION CONTROL

2. TWO LABEL MACHINE, ONE SUB-LABELING, THE OTHER IS ANTI-COUNTERFEITING LABEL

3. PUNCHING AT THE PACKING FILM AUTOMATICALLY

4. HEATING PRINTING (DATE) DEVICE

5. FOUR BACK AND FORTH TRANSVERSE SEALING DEVICE WITHINSERT CORNER BY CYLINDER FORM

6. EIGHT SERVO MOTORS, CONTROLLING FEEDING PACKING FILM, TRANSVERSE SEALING, FEEDING TISSUE RESPECTIVELY

7. LENGTHWAYS SEALING DEVICE, CONTROL THEOPEN-CLOSEBY CYLINDER. THE SEALING WHEEL ARE APART AUTOMATICALLY WHEN THE MACHINE STOPS

8. PUNCHING, LABELING AND THE EYE MARK’S RELATIVED POSITION CAN BE SET IN THE TOUCH SCREEN.

9. AUTOMATIC FEEDING RAW MATERIAL DEVICE

10. COLOUR TOUCH SCREEN, MOTION SYSTEM CONTROL

11. MAIN MOTOR ADOPTS FAMOUS BRAND

12. MAIN MACHINE ADOPTS FRAMES FORMOFFER 002

Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

YASKAWA ELECTRICITY FROM JAPAN

ITEM NUMBER: 1

MOTION CONTROLLER

JEPMC-MP2300S-E

YASKAWA

QUANTITY: 1

ITEM NUMBER: 2

EXTENDED MODULE

R7K4FML-6-DCA32A

YASKAWA

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR/SERVO UNIT

SGMJV-08ADE6S /SGDV-5R5A11A

YASKAWA 750W

QUANTITY: 5

ITEM NUMBER: 4

SERVO MOTOR/SERVO UNIT

SGMGV-13ADC61 /SGDV-120A11A

YASKAWA 1.3KW

QUANTITY: 1

ITEM NUMBER: 5

SERVO MOTOR/SERVO UNIT

SGMGV-20ADA61/SGDV-180A11A

YASKAWA 1.8KW

QUANTITY: 1

ITEM NUMBER: 6

SERVO MOTOR/SERVO UNIT

SGMGV-09ADC61/SGDV-7R6A11A

YASKAWA 0.85 KW

QUANTITY: 1

ITEM NUMBER: 7

POWER CABLE + ENCODER CABLE

JZZP-CVM09/JZSP-CVP02-05

YASKAWA 850W

QUANTITY: 1

ITEM NUMBER: 8

POWER CABLE + ENCODER CABLE

JZSP-CMM00-05 JZSP-CMP00-05

YASKAWA 750W

QUANTITY: 7

ITEM NUMBER: 9

POWER CABLE + ENCODER CABLE

JZSP-CVM30-05 JZSP-CVP02-5

YASKAWA 1.3KW, 1.8KW

QUANTITY: 2

ITEM NUMBER: 10

COMMUNICATION CABLE

JEPMC-W6002-05

QUANTITY: 12

ITEM NUMBER: 11

TERMINAL RESISTANCE

JEPMC-W6022-E

QUANTITY: 2

ITEM NUMBER: 12

TOUCH PANEL

WEINVIEW

7 INCH

QUANTITY: 1

ITEM NUMBER: 13

AIR BREAK SWITCH

LG

QUANTITY: 12

ITEM NUMBER: 14

RESIDUAL CURRENT CIRCUIT BREAKER

CHINT

QUANTITY: 1

ITEM NUMBER: 15

CONTACTOR (SWITCH)

SCHNEIDER

QUANTITY: 1

ITEM NUMBER: 16

POWER SWITCH

M&W

350W

QUANTITY: 1

ITEM NUMBER: 17

SOLID STATE RELAY (SSR)

ANV

QUANTITY: 6

ITEM NUMBER: 18

TEMPERATURE CONTROLLER

DTE10P

QUANTITY: 1

ITEM NUMBER: 19

RELAY

OMRON

QUANTITY: 4OFFER 003

Y-12 BABY WIPES FOLDING MACHINE

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40-80G/㎡

FOLDING WAY: “Z” SHAPE (POP UP AND NON-POP UP)

CUTTING UNITE:

A. DOUBLE PAPER SHELVES

B. 10 LANES OR 12 LANES, 2 ROLLS

C. RAW MATERIAL ROLL WIDTH: 900 TO 1200mm

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZOFFER 004

Learn More

Y-12 WET TISSUE FOLDING MACHINE

MAIN PARTS

ITEM NUMBER: 1

PLC

FX3U-32T

MITSUBISHI (JAPAN)

QUANTITY: 1

ITEM NUMBER: 2

SERVO MOTOR (CONTROL THE DISTANCE OF TISSUE

ASD-B2-2023-B, ECMA-E21320RS

3.0KW DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 3

SERVO MOTOR (RECEIVING TISSUE)

ASD-B2-0721-B, ECMA-C20807RS

750W DELTA (TAIWAN)

QUANTITY: 1

ITEM NUMBER: 4

TURBINE WORM REDUCER MOTOR

WPDA120-1:10-Y100L2-4

3KW NANJING UTTON (CHINA)

QUANTITY: 1

ITEM NUMBER: 5

INVERTER

SB70G4

4KW SENLON

QUANTITY: 1

ITEM NUMBER: 6

TOUCH SCREEN

7INCH

WECON

QUANTITY: 1

ITEM NUMBER: 7

AIR SWITCH

LG

QUANTITY: 1

ITEM NUMBER: 8

SWITCHING POWER SUPPLY

S-100-24

SHANGHAI MINGWEI (CHINA)

QUANTITY: 1

ITEM NUMBER: 9

INDICATOR LIGHT

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 10

EMERGENCY STOP SWITCH

SCHNEIDER

SCHNEIDER (GERMAN)

QUANTITY: 1

ITEM NUMBER: 11

POTENTIOMETER

5KΩ

QUANTITY: 1

ITEM NUMBER: 12

ROTARY ENCODER

INCREMENTAL POLE OUTPUT

KOYO (JAPAN)

QUANTITY: 1

ITEM NUMBER: 13

RELAY

OMRON

OMRON (JAPAN)

QUANTITY: 5

ITEM NUMBER: 14

PROXIMITY SWITCH

AUTONICS

AUTONICS (KOREA)

QUANTITY: 2 -

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

E-9567 FOAM RE-BONDING MACHINE AND CRUSHING MACHINEINVENTORY NUMBER: E-9567 FOAM RE-BONDING MACHINE AND CRUSHING MACHINE FOR SALE: FOAM RE-BONDING MACHINE (WITH STEAM) MODEL: 10B QUANTITY: 1 FOAM GRINDER (WITH AIR BLOWER) QUANTITY: 1 QUANTITY AVAILABLE: 2 Learn More

E-9567 FOAM RE-BONDING MACHINE AND CRUSHING MACHINEINVENTORY NUMBER: E-9567 FOAM RE-BONDING MACHINE AND CRUSHING MACHINE FOR SALE: FOAM RE-BONDING MACHINE (WITH STEAM) MODEL: 10B QUANTITY: 1 FOAM GRINDER (WITH AIR BLOWER) QUANTITY: 1 QUANTITY AVAILABLE: 2 Learn More -

M-5221 NONWOVEN LINE WIDTH 2500mm

M-5221 NONWOVEN LINE WIDTH 2500mmREFERENCE NUMBER: M-5221 (1313565TNY12RX) L

NONWOVEN LINE WIDTH 2500mmCARD FEEDING

CARDINGQUANTITY AVAILABLE: 1

Learn More -

M-4313 SPINNING BARMAG FOR POLYESTER YARN -YEAR 2000REFERENCE NUMBER: M-4313 (1010HAYEXX9) K SPINNING BARMAG FOR POLYESTER YARN -YEAR 2000 BRAND BARMAG YEAR PLANT 2000 QUANTITY AVAILABLE: 1 Learn More

M-4313 SPINNING BARMAG FOR POLYESTER YARN -YEAR 2000REFERENCE NUMBER: M-4313 (1010HAYEXX9) K SPINNING BARMAG FOR POLYESTER YARN -YEAR 2000 BRAND BARMAG YEAR PLANT 2000 QUANTITY AVAILABLE: 1 Learn More -

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More

M-5138 SQUARE COTTON PAD PRODUCTION MACHINEREFERENCE NUMBER: M-5138 (12121745V11UX) L SQUARE COTTON PAD PRODUCTION MACHINE MODEL: XF SPEED: 1800 TO 3000 PCS/MINUTE PRODUCT SIZE: WIDTH: 40 TO 100mm, LENGTH 40 TO 100mm RAW MATERIAL SIZE: 1000mm, DIAMETER LESS THAN 1000mm POWER: 380V FREQUENCY: 50 HZ TOTAL POWER: 4.5KW DIMENSION: LENGTH: 2500mm, WIDTH: 1900mm, HEIGHT: 1600mm WEIGHT: 2500KG QUANTITY AVAILABLE: 1 Learn More -

M-3803 SCHLAFHORST SRZ SE ACO 288 FOR COTTON DENIM YARNS YEAR 1993-1995

M-3803 SCHLAFHORST SRZ SE ACO 288 FOR COTTON DENIM YARNS YEAR 1993-1995REFERENCE NUMBER: M-3803

SCHLAFHORST SRZ SE ACO 288 FOR COTTON DENIM YARNS YEAR 1993-1995

SCHLAFHORST OPEN END SPINNING MACHINES FOR COTTON DENIM YARNS

SCHLAFHORST SRZ SE 9 ACO 288

7 X YEAR 1993

1 X YEAR 1995

240 ROTORS PER MACHINE

ROTOR TYPE: BELCORO 340BD

NAVAL: KN4 (SCHLAFHORST)

PIECER: TWO (2) PER MACHINE

DOFFER/SHUTTLE: ONE (1) PER MACHINE

COROLAB CLEARING SYSTEM INSTALLED PER MACHINE

NO WAXING DEVICES

(1) STARTER STATION PER MACHINE

COMBING ROLL: B174

SLUBBING DEVICE: ENGINEERED TO MODEL AMSLER MACHINE

VOLTAGE: 480/60HZ

(5) SPARE SECTIONS (48 POSITIONS COMPLETE, 48 POSITIONS WITH SPIN BOX, BUT WINDING ENDS MISSING, 24 POSITIONS STRIPPED OF PARTS)

(3) SPARE PIECERS (MOST PARTS MISSING)

(1) SPARE DOFFER

(1) SPARE SHUTTLE

QUANTITY: 8

Learn More