Search results for: 'elect'

- Related search terms

- electrica

- electroni

- electronic c''

- Electrical ca

- Electrical l

-

M-3349 TOYOTA AIR JET LOOMSREFERENCE NUMBER: M-3349 (88013DYN7U)-D TOYOTA AIRJET LOOMS TOYOTA AIR JET LOOM QTY MODEL=JA2S-190TP-T610 TOTAL 60 LOOMS 60 STAUBLI POSITIVE TAPPET CAM MOPTION TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 60SETS 1 REPEAT GEAR FOR EACH LOOM 60SETS PROFILE REED SYSTEM REED SPACE 190 CM 60 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 60 OIL BATH LUBRICATION FOR MAIN UNITS 60 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 60 HIGH TORQE INDUCTION MOTOR WITH SOLENOID BRAKE (4P-3PHASE,3.5KW) 60 MAIN CONTROL COMPUTER WITH 32 BYTES CPU 60 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER COMMUNICATION NETWORK 60 TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 60 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM 60 AUTOMATIC FAULT ALRAM FUNCTION 60 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 60 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 60 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 60 TAPERED SUB NOZZLE 60 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 60 DIRECT DRIVE SOLENOID VALVE FOR MAIN & SUB NOZZLE 60 TWO INDEPENDENT SUB NOZZLE TANKS 60 TAPERED TUNNEL REED 60 AUTOMATIC TIMING CONTROLLER (ATC) 60 AUTOMATIC BRAKE SYSTEM (ABS) 60 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 60 CENTRALIZED REGULATOR 60 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 60 AUTOMATIC LET OFF ADJUSTMENT 60 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 60 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 60 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 60 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MM CLOTH DIA 60 DOUBLE PRESS CLOTH ROLLS 60LOOM METAL SPRAYED SURFACE TAKE UP ROOLER 60 RING TAMPLE-3ROWS -24RING 60SET ROTARY LENO SELVEDGE AT L+R SIDE WITH ELECTRIC STOP MOTION 60SET DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) 60 ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6 PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BAREL DIA 90 CLOTH ROLLER 100 MM DIA 90 REED 60PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 6000PER LOOM DROPPER- (165-11-0.3) 6000PER LOOM QUANTITY: 60 TOYOTA AIR JET LOOM QTY MODEL=JA2S-280TP-T610 TOTAL 12 LOOM. 12 STAUBLI POSITIVE TAPPET CAM MOPTION 12SETS TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 12SETS 1 REPEAT GEAR FOR EACH LOOM 12SETS PROFILE REED SYSTEM REED SPACE 280 CM 12 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 12 OIL BATH LUBRICATION FOR MAIN UNIT 12 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 12 HIGH TORQE INDUCTION MOTOR WITH SOLENOID 12 BRAKE (4P-3PHASE,3.5KW) MAIN CONTROL COMPUTER WITH 32 BYTES CPU 12 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER 12 COMMUNICATION NETWORK TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 12 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM AUTOMATIC FAULT ALRAM FUNCTION 12 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 12 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 12 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 12 TAPERED SUB NOZZLE 12 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 12 DIRECT DRIVE SOLENIOD VALVE FOR MAIN & SUB NOZZLE 12 TWO INDEPENDENT SUB NOZZLE TANKS 12 TAPERED TUNNEL REED 12 AUTOMATIC TIMING CONTROL (ATC) 12 AUTOMATIC BRAKE SYSTEM (ABS) 12 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 12 CENTRALIZED REGULATOR 12 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 12 AUTOMATIC LET OFF ADJUSTMENT 12 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 12 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 12 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 12 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MMCLOTH DIA 12 DOUBLE PRESS CLOTH ROLLS 12LOOM METAL SPRAYED SURFASE TAKE UP ROOLER 12 RING TAMPLE-3ROW -30RING 12SET OCCUPIED WITH TUCK IN DEVICE WITH COMPLETE ACCESSORIES DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BARREL DIA 18 CLOTH ROLLER 100 MM DIA 18 REED 12PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 8000PER LOOM DROPPER- (165-11-0.3) 8000PER LOOM QUANTITY AVAILABLE: 12 LOOMS 20 LOOMS HAVE GEAR FOR TUCK IN DEVICE, GEAR BOX AT LEFT SIDE 1 INVERTER FOR 36 LOOMS ( 2 INVERTERS FOR ALL 72) 2 ATLAS COPCO ZR-315 COMPRESORS AND DRYER MD-1000 AVAILALE AT ADDITIONAL COST Learn More

M-3349 TOYOTA AIR JET LOOMSREFERENCE NUMBER: M-3349 (88013DYN7U)-D TOYOTA AIRJET LOOMS TOYOTA AIR JET LOOM QTY MODEL=JA2S-190TP-T610 TOTAL 60 LOOMS 60 STAUBLI POSITIVE TAPPET CAM MOPTION TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 60SETS 1 REPEAT GEAR FOR EACH LOOM 60SETS PROFILE REED SYSTEM REED SPACE 190 CM 60 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 60 OIL BATH LUBRICATION FOR MAIN UNITS 60 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 60 HIGH TORQE INDUCTION MOTOR WITH SOLENOID BRAKE (4P-3PHASE,3.5KW) 60 MAIN CONTROL COMPUTER WITH 32 BYTES CPU 60 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER COMMUNICATION NETWORK 60 TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 60 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM 60 AUTOMATIC FAULT ALRAM FUNCTION 60 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 60 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 60 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 60 TAPERED SUB NOZZLE 60 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 60 DIRECT DRIVE SOLENOID VALVE FOR MAIN & SUB NOZZLE 60 TWO INDEPENDENT SUB NOZZLE TANKS 60 TAPERED TUNNEL REED 60 AUTOMATIC TIMING CONTROLLER (ATC) 60 AUTOMATIC BRAKE SYSTEM (ABS) 60 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 60 CENTRALIZED REGULATOR 60 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 60 AUTOMATIC LET OFF ADJUSTMENT 60 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 60 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 60 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 60 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MM CLOTH DIA 60 DOUBLE PRESS CLOTH ROLLS 60LOOM METAL SPRAYED SURFACE TAKE UP ROOLER 60 RING TAMPLE-3ROWS -24RING 60SET ROTARY LENO SELVEDGE AT L+R SIDE WITH ELECTRIC STOP MOTION 60SET DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) 60 ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6 PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BAREL DIA 90 CLOTH ROLLER 100 MM DIA 90 REED 60PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 6000PER LOOM DROPPER- (165-11-0.3) 6000PER LOOM QUANTITY: 60 TOYOTA AIR JET LOOM QTY MODEL=JA2S-280TP-T610 TOTAL 12 LOOM. 12 STAUBLI POSITIVE TAPPET CAM MOPTION 12SETS TYPE 1620 CAM BOX WITH 7 SHAFT 6 CAMS WITH 1 SPACER FOR EACH LOOM 12SETS 1 REPEAT GEAR FOR EACH LOOM 12SETS PROFILE REED SYSTEM REED SPACE 280 CM 12 LOWER BUILT ONE PIECE BOX TYPE SIDE FRAME FOR HIGH SPEED OPERATION 12 OIL BATH LUBRICATION FOR MAIN UNIT 12 TWO SIDES CRANK DRIVE BEATING WITH OIL BATH 12 HIGH TORQE INDUCTION MOTOR WITH SOLENOID 12 BRAKE (4P-3PHASE,3.5KW) MAIN CONTROL COMPUTER WITH 32 BYTES CPU 12 DISTRIBUTED CONTROL SYSTEM BY OPTICAL FIBER 12 COMMUNICATION NETWORK TOUCH SCREEN FUNCTION PANEL WITH MULTI- WINDOW DISPLAY 12 AUTOMATIC INITIAL CONDITION - (ICS) SYSTEM AUTOMATIC FAULT ALRAM FUNCTION 12 WEEKLY EFFICIENCY GRAPH DISPLAY & DOWN TIME 12 CAUSE DISLPAY BEAM CLOTH ESTIMATOR 12 2 COLOUR MIXING DEVICE BY ELECTRIC DRUM POLE (EDP) 12 TAPERED SUB NOZZLE 12 LOW AIR PRESURE & HIGH PROPULSIVE MAIN NOZZLE 12 DIRECT DRIVE SOLENIOD VALVE FOR MAIN & SUB NOZZLE 12 TWO INDEPENDENT SUB NOZZLE TANKS 12 TAPERED TUNNEL REED 12 AUTOMATIC TIMING CONTROL (ATC) 12 AUTOMATIC BRAKE SYSTEM (ABS) 12 TIMING CHEKER WITH GRAPH DISPLAY ON FUNCTION PANEL 12 CENTRALIZED REGULATOR 12 ELECTRONIC LET OFF MOTION BY DIGITAL AC SERVO MOTOR 12 AUTOMATIC LET OFF ADJUSTMENT 12 FELL FORWARD DEVICE FOR STOP MARK PREVENTION 12 POSITIVE EASING MOTION WITH TWIN BACK ROLLER 12 MECHANICAL TAKE UP MOTION BY CHANGE GEAR 12 ON LOOM TAKE UP MOTION FOR MAXIMUM -600MMCLOTH DIA 12 DOUBLE PRESS CLOTH ROLLS 12LOOM METAL SPRAYED SURFASE TAKE UP ROOLER 12 RING TAMPLE-3ROW -30RING 12SET OCCUPIED WITH TUCK IN DEVICE WITH COMPLETE ACCESSORIES DOUBLE FEELER FOR WEFT STOP MOTION -(REFLECTING TYPE ) ELECTRIC WARP STOP MOTION BY SIX LINES CONTACT BAR 6PER LOOM YARN BEAM SET WITH 1000 MM FLANGE & 178 MM BARREL DIA 18 CLOTH ROLLER 100 MM DIA 18 REED 12PIECE HEALD FRAMES 7 PER LOOM HEALD WIRE (331MML) C TYPE 8000PER LOOM DROPPER- (165-11-0.3) 8000PER LOOM QUANTITY AVAILABLE: 12 LOOMS 20 LOOMS HAVE GEAR FOR TUCK IN DEVICE, GEAR BOX AT LEFT SIDE 1 INVERTER FOR 36 LOOMS ( 2 INVERTERS FOR ALL 72) 2 ATLAS COPCO ZR-315 COMPRESORS AND DRYER MD-1000 AVAILALE AT ADDITIONAL COST Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

T-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mmT-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mm HIGH SPEED BOBBIN WINDING MACHINE SIZE: 1920 X 850 X 1500mm 1 SIDE 1920 X 1200 X 1500mm 2 SIDES CONFIGURATION: 4 SPINDLES/ SET 1 SIDE; 8 SPINDLES/ SET 2 SIDE BOBBIN SPEC: 10″ (280mm TO 300mm) TRANVERSE: 250mm TAKE-UP PACKAGE: CYLINDRICAL (0°); CONE, CAN WINDING 8KG YARN POWER SUPPLY: THREE-PHASE 380V 50/60Hz (ORDERED SEPARATELY) ZINC ALLOY DRUM YARN SENSOR: ELECTRONIC YARN BREAK STOP PACKAGING: WOODEN BOX QUANTITY: 2 SETS (8 SPINDLES) LCL Learn More

T-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mmT-9838 HIGH SPEED BOBBIN WINDING MACHINE, TRAVERSE 250mm HIGH SPEED BOBBIN WINDING MACHINE SIZE: 1920 X 850 X 1500mm 1 SIDE 1920 X 1200 X 1500mm 2 SIDES CONFIGURATION: 4 SPINDLES/ SET 1 SIDE; 8 SPINDLES/ SET 2 SIDE BOBBIN SPEC: 10″ (280mm TO 300mm) TRANVERSE: 250mm TAKE-UP PACKAGE: CYLINDRICAL (0°); CONE, CAN WINDING 8KG YARN POWER SUPPLY: THREE-PHASE 380V 50/60Hz (ORDERED SEPARATELY) ZINC ALLOY DRUM YARN SENSOR: ELECTRONIC YARN BREAK STOP PACKAGING: WOODEN BOX QUANTITY: 2 SETS (8 SPINDLES) LCL Learn More -

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More -

T-7125 CARDING WILLOW, WORKING WIDTH 1500mmT-7125 CARDING WILLOW, WORKING WIDTH 1500mm TYPE OF FIBRES: ALPACA OR WOOL WILLOW CARDING IS EQUIPPED WITH MECHANICAL AND ELECTRICAL DRIVES CAPACITY: UP TO 1500 KGS/HOUR WORKING WIDTH: 1500mm QUANTITY: 1 Learn More

T-7125 CARDING WILLOW, WORKING WIDTH 1500mmT-7125 CARDING WILLOW, WORKING WIDTH 1500mm TYPE OF FIBRES: ALPACA OR WOOL WILLOW CARDING IS EQUIPPED WITH MECHANICAL AND ELECTRICAL DRIVES CAPACITY: UP TO 1500 KGS/HOUR WORKING WIDTH: 1500mm QUANTITY: 1 Learn More -

AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm)AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm) MACHINE PARTS: 1. VACUUM LOADER - 1 SET 2. HOPPER DRYER - 1 SET 3. SINGLE SCREW EXTRUDER - 1 SET 4. HYDRAULIC SCREEN CHANGER - 1 SET 5. METERING PUMP - 1 SET 6. T-DIE - 1 SET 7. BARREL TYPE FORMING MACHINE - 1 SET 8. ELECTROSTATIC ELECTRET DEVICE - 1 SET 9. SLIT AND COILER - 1 SET 10. HOT AIR SYSTEM - 1 SET Learn More

AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm)AA-1191 – SOURCE INFO MELT BLOWN CLOTH PRODUCTION LINE, VERTICAL TYPE (WIDTH: 600mm) MACHINE PARTS: 1. VACUUM LOADER - 1 SET 2. HOPPER DRYER - 1 SET 3. SINGLE SCREW EXTRUDER - 1 SET 4. HYDRAULIC SCREEN CHANGER - 1 SET 5. METERING PUMP - 1 SET 6. T-DIE - 1 SET 7. BARREL TYPE FORMING MACHINE - 1 SET 8. ELECTROSTATIC ELECTRET DEVICE - 1 SET 9. SLIT AND COILER - 1 SET 10. HOT AIR SYSTEM - 1 SET Learn More -

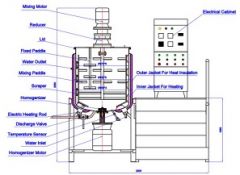

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More -

J-5436 BEDDING MACHINERYJ-5436 BEDDING MACHINERY Learn More

J-5436 BEDDING MACHINERYJ-5436 BEDDING MACHINERY Learn More -

TT-7602 CATERPILLAR 16CM32C DIESEL GENERATOR SETS, 7.68 MW, YEAR 2004, 50 HzTT-7602 CATERPILLAR 16CM32C DIESEL GENERATOR SETS, 7.68 MW, YEAR 2004, 50 Hz !!!ASK FOR MORE DETAILS!!! EXCEPTIONAL CONDITION LOW HOURS HEAVY FUEL OIL/DIESEL TOTAL OUTPUT: 107.52 MW INDIVIDUAL OUTPUT: 7.68 MW PER GENERATOR CONDITION: EXCELLENT, LOW OPERATING HOURS FUEL TYPE: HEAVY FUEL OIL (HFO) / DIESEL QUANTITY: 14 GENERATORS Learn More

TT-7602 CATERPILLAR 16CM32C DIESEL GENERATOR SETS, 7.68 MW, YEAR 2004, 50 HzTT-7602 CATERPILLAR 16CM32C DIESEL GENERATOR SETS, 7.68 MW, YEAR 2004, 50 Hz !!!ASK FOR MORE DETAILS!!! EXCEPTIONAL CONDITION LOW HOURS HEAVY FUEL OIL/DIESEL TOTAL OUTPUT: 107.52 MW INDIVIDUAL OUTPUT: 7.68 MW PER GENERATOR CONDITION: EXCELLENT, LOW OPERATING HOURS FUEL TYPE: HEAVY FUEL OIL (HFO) / DIESEL QUANTITY: 14 GENERATORS Learn More -

TT-7395 COMPLETE CHOCOLATE PRODUCTION LINETT-7395 COMPLETE CHOCOLATE PRODUCTION LINE QUANTITY: 1 Learn More

TT-7395 COMPLETE CHOCOLATE PRODUCTION LINETT-7395 COMPLETE CHOCOLATE PRODUCTION LINE QUANTITY: 1 Learn More