Search results for: 'foam c'

- Related search terms

- foam mac

- foam+machi

- foam r

- foam+r

- foam+co'

-

V-0051 FOAM RECYCLING MACHINE (FOR POLYURETHANE FOAM AND FOAM RUBBER)REFERENCE NUMBER: V-0051 FOAM RECYCLING MACHINE (FOR POLYURETHANE FOAM AND FOAM RUBBER) QUANTITY AVAILABLE: 1 Learn More

V-0051 FOAM RECYCLING MACHINE (FOR POLYURETHANE FOAM AND FOAM RUBBER)REFERENCE NUMBER: V-0051 FOAM RECYCLING MACHINE (FOR POLYURETHANE FOAM AND FOAM RUBBER) QUANTITY AVAILABLE: 1 Learn More -

E-6673 NEW FOAM SHREDDERINVENTORY NUMBER: E-6673 NEW FOAM SHREDDER MODEL: 205 QUANTITY AVAILABLE: 1 Learn More

E-6673 NEW FOAM SHREDDERINVENTORY NUMBER: E-6673 NEW FOAM SHREDDER MODEL: 205 QUANTITY AVAILABLE: 1 Learn More -

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More -

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More -

TT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mmTT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mm FILLMATIC STUFFING MACHINE WORKING WIDTH 2000mm TYPE OF MACHINE: FU 200/24 LENGTH: 65” 1650mm LENGTH WITH INFEED CONVEYOR: + +) 18.3” 4650mm 15’3” WIDTH: 114” 2900mm 9’6” HEIGHT: 57” 1450mm WEIGHT: 2100 KG INSTALLED LOAD: 6.05 KW 400 V 50 Hz THREE PHASE NUMBER OF FILLING ARMS: 8 LENGTH OF FILLING ARMS: 49” 1250mm MACHINE ADJUSTMENT: 24.4 - 78.74 WIDTH: 620 TO 2000mm MINIMUM WIDTH WITH 4 PISTOLS: 27.55 700mm HEIGHT: 5.51” - 9.44 - 140 TO 240mm MATTRESS WIDTH: 78.74” - 2000mm MATTRESS HEIGHT: 11.02” - 280mm TYPE OF MATTRESSES TO BE WRAPPED: INNER SPRING, ALL FOAM, LATEX WORKING SPEED: 30 M/MIN. +) MAXIMUM HEIGHT DEPENDS ON FOAM DENSITY AND COMPRESSABILITY. MINIMUM HEIGHT AND WIDTH MAY NOT BE ATTAINED AT THE SAME TIME. + +) CONTAINED WITHIN SCOPE OF DELIVERY. QUANTITY: 1 Learn More

TT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mmTT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mm FILLMATIC STUFFING MACHINE WORKING WIDTH 2000mm TYPE OF MACHINE: FU 200/24 LENGTH: 65” 1650mm LENGTH WITH INFEED CONVEYOR: + +) 18.3” 4650mm 15’3” WIDTH: 114” 2900mm 9’6” HEIGHT: 57” 1450mm WEIGHT: 2100 KG INSTALLED LOAD: 6.05 KW 400 V 50 Hz THREE PHASE NUMBER OF FILLING ARMS: 8 LENGTH OF FILLING ARMS: 49” 1250mm MACHINE ADJUSTMENT: 24.4 - 78.74 WIDTH: 620 TO 2000mm MINIMUM WIDTH WITH 4 PISTOLS: 27.55 700mm HEIGHT: 5.51” - 9.44 - 140 TO 240mm MATTRESS WIDTH: 78.74” - 2000mm MATTRESS HEIGHT: 11.02” - 280mm TYPE OF MATTRESSES TO BE WRAPPED: INNER SPRING, ALL FOAM, LATEX WORKING SPEED: 30 M/MIN. +) MAXIMUM HEIGHT DEPENDS ON FOAM DENSITY AND COMPRESSABILITY. MINIMUM HEIGHT AND WIDTH MAY NOT BE ATTAINED AT THE SAME TIME. + +) CONTAINED WITHIN SCOPE OF DELIVERY. QUANTITY: 1 Learn More -

YY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTEYY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTE APPLICATION AREA: MATTRESS INDUSTRY, FOAM LAMINATION SYSTEM. MATERIALS: FINISHED OR SEMI-FINISHED MATTRESS, FOAM, FELT, QUILTED PANEL. GENERAL FEATURES: IT FLIPS THE MATTRESSES OF VARYING SIZES AND WEIGHTS WITHOUT REQUIRING ANY ADJUSTMENT. AS MATTRESSES ARE HELD BY PNEUMATIC ARMS, ANY RISK OF DEFORMATION DURING FLIPPING IS AVOIDED. WITH THE HELP OF ITS SENSORS, IT CAN DETECT AUTOMATICALLY WHETHER THERE IS A MATTRESS IN THE MACHINE. THE SAFETY BARRIER SURROUNDING THE MACHINE PROVIDES A SAFE WORKING ENVIRONMENT. FEATURES A LONG-LIFE FESTO BRAND PNEUMATIC SYSTEM WITH LOW AIR CONSUMPTION. STANDARD: SAFETY BARRIER, PNEUMATIC FLIPPING SYSTEM, PVC CONVEYOR. QUANTITY: 1 Learn More

YY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTEYY-1486 ASSEMBLY CONVEYOR WITH FLIPPER, 1 MATTRESS PER MINUTE APPLICATION AREA: MATTRESS INDUSTRY, FOAM LAMINATION SYSTEM. MATERIALS: FINISHED OR SEMI-FINISHED MATTRESS, FOAM, FELT, QUILTED PANEL. GENERAL FEATURES: IT FLIPS THE MATTRESSES OF VARYING SIZES AND WEIGHTS WITHOUT REQUIRING ANY ADJUSTMENT. AS MATTRESSES ARE HELD BY PNEUMATIC ARMS, ANY RISK OF DEFORMATION DURING FLIPPING IS AVOIDED. WITH THE HELP OF ITS SENSORS, IT CAN DETECT AUTOMATICALLY WHETHER THERE IS A MATTRESS IN THE MACHINE. THE SAFETY BARRIER SURROUNDING THE MACHINE PROVIDES A SAFE WORKING ENVIRONMENT. FEATURES A LONG-LIFE FESTO BRAND PNEUMATIC SYSTEM WITH LOW AIR CONSUMPTION. STANDARD: SAFETY BARRIER, PNEUMATIC FLIPPING SYSTEM, PVC CONVEYOR. QUANTITY: 1 Learn More -

TT-2901 TRANS-FOAMERS ROLL 32 MATTRESS ROLLPACKING MACHINE – NEW, WIDTH 1800mm, YEAR 2022TT-2901 TRANS-FOAMERS ROLL 32 MATTRESS ROLLPACKING MACHINE – NEW, WIDTH 1800mm, YEAR 2022 MACHINE TYPE: MATTRESS ROLLPACKING MACHINE BRAND: TRANS-FOAMERS YEAR: 2022 CONDITION: NEW MACHINE QUANTITY: 1 Learn More

TT-2901 TRANS-FOAMERS ROLL 32 MATTRESS ROLLPACKING MACHINE – NEW, WIDTH 1800mm, YEAR 2022TT-2901 TRANS-FOAMERS ROLL 32 MATTRESS ROLLPACKING MACHINE – NEW, WIDTH 1800mm, YEAR 2022 MACHINE TYPE: MATTRESS ROLLPACKING MACHINE BRAND: TRANS-FOAMERS YEAR: 2022 CONDITION: NEW MACHINE QUANTITY: 1 Learn More -

T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020 THE MATTRESS DRILL IS DESIGNED FOR DRILLING FOAM PANELS THE MACHINE CAN PROCESS VARIOUS TYPES OF FOAM IN SEVERAL DIFFERENT SIZES. SOME TYPES OF FOAM CAN DAMAGE THE DRILLS WHILE DRILLING. FOR THIS REASON WE ALWAYS TEST DRILL THE CUSTOMERS FOAM. THE DRILL MACHINE IS EASY TO OPERATE AND DOES NOT PRODUCE DUST WHILE IT IS OPERATING. THE EXCESS MATERIAL (FROM THE DRILLING) IS AUTOMATICALLY REMOVED. THE DRILLS CAN BE CHANGED IN LINE BY HAND. Learn More

T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020T-7670 MATTRESS DRILL TYPE 9106 – NEW, WIDTH 2200mm, YEAR 2020 THE MATTRESS DRILL IS DESIGNED FOR DRILLING FOAM PANELS THE MACHINE CAN PROCESS VARIOUS TYPES OF FOAM IN SEVERAL DIFFERENT SIZES. SOME TYPES OF FOAM CAN DAMAGE THE DRILLS WHILE DRILLING. FOR THIS REASON WE ALWAYS TEST DRILL THE CUSTOMERS FOAM. THE DRILL MACHINE IS EASY TO OPERATE AND DOES NOT PRODUCE DUST WHILE IT IS OPERATING. THE EXCESS MATERIAL (FROM THE DRILLING) IS AUTOMATICALLY REMOVED. THE DRILLS CAN BE CHANGED IN LINE BY HAND. Learn More -

YY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mmYY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mm GENERAL TECHNICAL FEATURES: USEFUL WORKING WIDTH: 1800mm; MAXIMUM DIAMETER OF THE ROLL TO BE UNWOUND: mm. 1550 (FOAM) / 1550 (FABRIC); MAXIMUM ROLL WEIGHT: 200KG; ADJUSTABLE MECHANICAL SPEED: 400 STROKES PER MINUTE; APPROXIMATE PRODUCTION SPEED (DEPENDING ON THE TYPE OF MATERIAL AND DRILLING): M/MIN 3/6; POWER DISCHARGED ON CM: TON 120000; THREE-PHASE PRIMARY VOLTAGE + EARTH: V/Hz 380/400+E/50 Hz; INSTALLED POWER OF THE MOTORS: 26KW; AC MOTORS, ELECTRIC DRIVES, ELECTRIC CABLES AND WIRING, ARE ACCORDING TO CEI STANDARDS; EPOXY PAINTING; THE MACHINES ARE AUTOMATICALLY SYNCHRONIZED BY MEANS OF ELECTRONIC DRIVES "INVERTER" A.C. MOTORS, PNEUMATIC DANCER ROLLERS (COMPENSATORS) AND LOAD CELLS. QUANTITY: 1 Learn More

YY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mmYY-2212 PERFORATING LINE, USEFUL WORKING WIDTH 1800mm GENERAL TECHNICAL FEATURES: USEFUL WORKING WIDTH: 1800mm; MAXIMUM DIAMETER OF THE ROLL TO BE UNWOUND: mm. 1550 (FOAM) / 1550 (FABRIC); MAXIMUM ROLL WEIGHT: 200KG; ADJUSTABLE MECHANICAL SPEED: 400 STROKES PER MINUTE; APPROXIMATE PRODUCTION SPEED (DEPENDING ON THE TYPE OF MATERIAL AND DRILLING): M/MIN 3/6; POWER DISCHARGED ON CM: TON 120000; THREE-PHASE PRIMARY VOLTAGE + EARTH: V/Hz 380/400+E/50 Hz; INSTALLED POWER OF THE MOTORS: 26KW; AC MOTORS, ELECTRIC DRIVES, ELECTRIC CABLES AND WIRING, ARE ACCORDING TO CEI STANDARDS; EPOXY PAINTING; THE MACHINES ARE AUTOMATICALLY SYNCHRONIZED BY MEANS OF ELECTRONIC DRIVES "INVERTER" A.C. MOTORS, PNEUMATIC DANCER ROLLERS (COMPENSATORS) AND LOAD CELLS. QUANTITY: 1 Learn More -

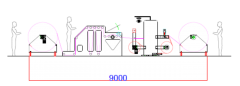

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mmM-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

OFFER 001

EXTRUSION PLANT

FOR FOAMED PET

WORKING WIDTH: SHEETS 610mm x 240mm

THICKNESS: 5mm TO 60mm

DENSITY: 80 TO 250 KG/M3

CAPACITY: UP TO 500 KG PER HOUROFFER 002

SILO FOR VIRGIN MATERIALOFFER 003

DRYING SYSTEM (SUITABLE FOR 500 KG PER HOUR)OFFER 004

GRAVIMETRIC FEEDING SYSTEMOFFER 005

GAS STOCKING SYSTEMOFFER 006

GAS FEEDING SYSTEMOFFER 007

EXTRUDEROFFER 008

SCREEN CHANGEROFFER 009

STRAND DYE WITH ELEMENTS FOR EXTRUSIONOFFER 010

PNEUMATIC SHAPER FOR SHAPING THE BOARD BY ADJUSTING THE LOADOFFER 011

HAUL OFF UNITOFFER 012

ROLLERS FOR BOARDS CONVEYINGOFFER 013

PULLER HAUL OFFOFFER 014

TRANSVERSAL CUTTING UNITOFFER 015

FINISHING EQUIPMENTOFFER 016

BLOCK WELDING MACHINEOFFER 017

FINISHING PLATFORMOFFER 018

HORIZONTAL CUTTING MACHINEOFFER 019

SHEETS WELDING MACHINEOFFER 020

SCRAPS RECYCLING SYSTEMOFFER 021

GRINDER TO MILL THE PIECES OF MATERIALOFFER 022

COMPACTING UNITOFFER 023

STORING SILOS FOR DENSIFIED FOAM PETOFFER 024

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 025

CABLES AND CABLING MATERIALSOFFER 026

PIPINGQUANTITY: 1 PLANT

Learn More