Search results for: 'red pro'

- Related search terms

- Pro

- Prod

- Prod'

- Production+ca

- PRODUCT+MO

-

G-0929 FOAM PROFILE CUTTING MACHINE FOR DOUBLE MATTRESSESREFERENCE NUMBER: G-0929 FOAM PROFILE CUTTING MACHINE FOR DOUBLE MATTRESSES WORKING CUTTING WIDTH: 1800mm WORKING CUTTING LENGTH: 2100mm MAXIMUM HEIGHT FROM TABLE TO BLADE: 0/250mm LOADING TABLE: 2200 X 1980mm VERTICAL STROKE OF THE PRESS-CONVEYOR: 0/250mm PASSAGE BETWEEN OUTPUT ROLLER AND TABLE: 25/540mm MAXIMUM HEIGHT OF FOAM TO BE WORKED: 220mm MAXIMUM MATTRESS DIMENSION: 1960 X 2100mm TABLE SPEED: 0-20 M/MIN POWER KW: 15 WEIGHT APPROXIMATELY: 4900 KGS QUANTITY AVAILABLE: 1 Learn More

G-0929 FOAM PROFILE CUTTING MACHINE FOR DOUBLE MATTRESSESREFERENCE NUMBER: G-0929 FOAM PROFILE CUTTING MACHINE FOR DOUBLE MATTRESSES WORKING CUTTING WIDTH: 1800mm WORKING CUTTING LENGTH: 2100mm MAXIMUM HEIGHT FROM TABLE TO BLADE: 0/250mm LOADING TABLE: 2200 X 1980mm VERTICAL STROKE OF THE PRESS-CONVEYOR: 0/250mm PASSAGE BETWEEN OUTPUT ROLLER AND TABLE: 25/540mm MAXIMUM HEIGHT OF FOAM TO BE WORKED: 220mm MAXIMUM MATTRESS DIMENSION: 1960 X 2100mm TABLE SPEED: 0-20 M/MIN POWER KW: 15 WEIGHT APPROXIMATELY: 4900 KGS QUANTITY AVAILABLE: 1 Learn More -

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More -

M-1480 SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINE

M-1480 SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINEREFERENCE NUMBER: M-1480

SLITTER REWINDER 1800mm WIDTH AND 1000mm DIAMETER-NEW MACHINE

TECHNICAL CHARACTERISTICS:

UNWINDER

MAXIMUM WIDTH: 1800mm

MAXIMUM DIAMETER: 1100mm

MINIMUM WIDTH: 420mm

MAXIMUM WEIGHT: 300kgs

CORE ID: 3”

REWINDER:

MAXIMUM WIDTH: 1800mm

MAXIMUM DIAMETER: 1000mm

MINIMUM WIDTH: 100mm

MAXIMUM WEIGHT PER SHAFT: 300kgs

CORE ID: 3”

MATERIAL:

TYPE: 100% PP NONWOVEN

MINIMUM: 10gsm

MAXIMUM: 150gsm

TENSION:

MAXIMUM: 2 PLI

SPEED:

METERS PER MINUTE: 250

DESCRIPTION:

REWINDER MACHINE FOR NONWOVEN ROLLS: UP TO 1000 mm DIAMETER AT UNWINDER AND 1200 mm AT REWINDER.

THE WORKSTATION OFFERS EASY ACCESS TO THE TENSION CONTROL AREA AS WELL AS THE TRIMMING AREA; THIS WAY, ANY MODIFICATION ON THE MATERIAL MEASUREMENTS CAN BE DONE SAFELY.

THE WORKSTATION WILL DELIVER MODULES OF ROLLED MATERIAL WITH SPECIFIC DENSITY, AND SEPARATED FROM EACH OTHER IN ORDER TO KEEP OPERATION CONDITIONS WITHIN REQUIRED QUALITY CONTROLS.

UNWINDER WITH SHAFT:

THERE IS A CENTRAL UNWINDING SYSTEM SUPPORTED BY A 3” STEEL EXPANSION SHAFT.

THERE IS A TENSION CONTROL SYSTEM THAT WORKS THROUGH A PNEUMATIC DISK BRAKE WITH A REPLACEABLE PADS SYSTEM.

THE UNWINDER HAS A PIVOTABLE ROLLER SYSTEM WHEREBY TENSION MAY BE MODIFIED ON ONE END TO REDUCE TENSION DIFFERENCE ON MATERIAL IF NECESSARY.

THE SAFETY CHUCK HAS A MECHANICAL MOVEMENT SYSTEM FOR SHAFT INSERTION.

THE UNWINDER HAS AN ULTRASONIC OR LASER SENSOR FOR A REAL MEASURING OF ROLL DIAMETER. THIS INFORMATION WILL HELP TO KEEP A SPECIFIC TENSION ON MATERIAL DURING ALL THE PROCESS.

CUTTING:

THE LONGITUDINAL SHEAR CUT SYSTEM GUARANTEES CLEAN AND SAFE TRIMMING AT EVERY MODULE. THE CUTTING SYSTEM ADAPTED TO THE MAIN TRANSMISSION GUARANTEES AN OVER SPEED THAT MAY BE REGULATED ACCORDING TO THE MATERIAL DURING EVERY STAGE OF PROCESS. THE PNEUMATIC ACTIVATION KNIVES WILL ALLOW A FAST MODIFICATION OF THE CUTTING MEASUREMENTS.

THIS ROLLER IS LOCATED AT AN EASY ACCESS AREA FOR THE OPERATOR TO BE ABLE TO MAKE CHANGES ON THE CUTTING WIDTH SAFELY. THE COUNTER KNIVES ARE ASSEMBLED TO THE ROLLER BY 3 SETSCREWS THAT FIX THEIR POSITION ON THE ROLLER. THE COUNTERKNIVES HAVE TWO FACES, SO WHEN THE FIRST FACE HAS AN IMPORTANT WEAR, IT WILL BE REMOVED FROM THE ROLLER AND THE NEW FACE WILL BE PLACED INSTEAD. THIS WILL EXTEND THE LIFESPAN OF THIS IMPORTANT COMPONENT.

SHEAR CUT KNIVES: THERE IS AN ADJUSTMENT MECHANISM TO PLACE THEM ON THE COUNTER KNIFE AND TO ADJUST THE CUTTING LOAD ACCURATELY. THE COUNTER KNIVES ARE SUPPORTED TOWARDS THE ROLLER IN ORDER TO OBTAIN A CUTOFF. THE SPEED ON THIS SYSTEM IS AN OVER SPEED IN RELATION TO THAT OF THE MATERIAL, IN ORDER TO GENERATE A CLEAN CUT.

LONGITUDINAL SHEAR CUT: PNEUMATIC ACTIVATION.

COUNTER KNIVES ROLLER WITH 3 SUPPORT PLANES FOR THE COUNTER KNIVES; 120° DISPLACEMENT FROM EACH OTHER.

19 SLITTERS ARE INCLUDED.

REWINDER:

PERIPHERAL REWINDER FOR NONWOVEN. THIS SYSTEM HAS A COUPLE OF MAIN ROLLERS WHERE THE MATERIAL ROLL IS FORMED.

THIS SYSTEM HAS LINEAR GUIDES FOR COMPACTION THROUGH WICH A NIP IS OBTAINED ON THE MATERIAL. THE REWINDER WILL HAVE A TRANSMISSION BASED ON A VECTORIAL-TYPE MOTOR ADAPTED TO A CYCLOIDAL REDUCER. THE TRANSMISSION HAS A MECHANICAL TORQUE CONTROL SYSTEM TO CONTROL THE TORQUE DIFFERENTIAL BETWEEN MAIN ROLLS.

THIS SYSTEM WILL HAVE A 3” EXPANSION SHAFT WHERE THE CARDBOARD CORES WILL BE INSERTED AND THE MATERIAL ROLLS WILL BE FORMED.

FABRIC OPENING SYSTEM:

THIS SYSTEM IS BASED ON A VARIABLE CURVATURE SYSTEM BY A CENTER KNOB AND IT IS A BAR- TYPE SYSTEM. THIS KNOB IS THERE TO CONTROL THE CURVATURE OF THE BAR WHERE MATERIAL SLIDES THROUGH. THE SLIDING BAR IS MADE OUT OF AN ULTRA LOW FRICTION MATERIAL IN ORDER TO GENERATE A SMOOTH SLIDING OF MATERIAL WITHOUT ANY TENSION ADDED. THIS WILL REDUCE WRINKLES IN A SIGNIFICANT WAY.

AUTOMATIC TENSION SYSTEM:

THERE IS AN OPEN LOOP AUTOMATIC TENSION CONTROL SYSTEM WITH A SENSOR FOR DIAMETER MEASURING. BY THIS SYSTEM, A REAL VALUE OF DIAMETER IS OBTAINED AT THE REWINDER. PRESSURE OF PNEUMATIC BRAKE VARIES DURING PROCESS.

MANUAL POSITIONING (OPTIONAL):

THE MANUAL POSITIONING SYSTEM IS BASED ON THE POSITION CONTROL OF THE COUNTER KNIVES. THE MODULE IS POSITIONED AT A DESIRED CUTTING PARAMETER AND THE COUNTER KNIFE WILL PHYSICALLY COME ACROSS IT. THE REAL POSITION OF MODULE WILL BE SHOWN ON A SCREEN THAT OPERATOR WILL BE CONSTANTLY SUPERVISING. THIS SCREEN WILL SHOW THE REAL MEASUREMENTS OF THE CARRIAGE IN RELATION TO THE LAST ONE OR AS AN ABSOLUTE REFERENCE. OPERATOR WILL BE ABLE TO RESET THE MEASUREMENT ONCE THE COUNTER KNIFE IS REPLACED AND WILL REPEAT THIS PROCESS EVERY TIME A COUNTER KNIFE IS POSITIONED.

A DISPLAY WILL SHOW THE DESIRED POSITION IN MILLIMETERS OR INCHES.

THIS SYSTEM CAN SHOW MEASUREMENT IN AN EITHER ABSOLUTE OR INCREASING WAY.

POSITION TOLERANCE: +/- 0.30 mm.

THE POSITIONER IS INSTALLED ON A SUPPORT THAT WILL BE LOCATED ON THE REWINDER BENCHES. THEREFORE, THERE WILL BE AN EASY ACCESS TO SYSTEM AND AN EASY REPETITION OF POSITIONING PROCESS.

UNLOADING ROLL TABLE:

A HYDRAULIC PIVOTEABLE TABLE WILL HAVE AS MAIN FUNCTION THE UNLOADING OF FINISHED ROLLS THAT THEN WILL BE LOCATED ON FLOOR LEVEL. THIS SYSTEM WILL EJECT THE ROLL AND THEN IT WILL BE RECEIVED AT THE PIVOTING TABLE FOR AN EFFICIENT UNLOADING.

THE UNLOADING TABLE WILL ALSO WORK AS A PROTECTION FOR THE OPERATOR.

THIS EQUIPMENT WILL HAVE SECURITY CURTAINS AT FRONT TO KEEP OPERATOR FROM ENTERING THE REWINDING AREA. THERE WILL BE AN EMERGENCY STOP BUTTON OR WIRE WHERE OPERATOR WORKS AND WILL ALSO HAVE PHYSICAL PROTECTION WITH SECURITY SWITCHES AT CUTTING AREA.

CONTROL:

HMI CENTRAL CONTROL SYSTEM WITH TOUCH SCREEN TO PROGRAM THE OPERATION CYCLE AND ALL THE MATERIAL CHARACTERISTICS. OPERATOR WILL HAVE ACCESS TO ALL OPERATION PARAMETERS IN ORDER TO BE ABLE TO MAKE CHANGES ON THE EQUIPMENT OPERATION CONDITIONS, AND THEREFORE OBTAIN MATERIAL ROLLS WITH SPECIFIC DENSITIES.

TRANSMISSION: VECTORIAL MOTO REDUCER WITH 1000:1 TORQUE.

DIGITAL METER COUNTER WITH DISPLAY AND AUTOMATIC STOP AT DEFINED DISTANCE.

DOCUMENTS INCLUDED:

THE MACHINE WILL BE DELIVERED WITH THE FOLLOWING DOCUMENT:

OPERATION MANUAL

MAINTENANCE MANUAL

SAFETY MANUAL

ELECTRIC DIAGRAMS

CONTROL SYSTEM MANUAL

PLC BACKUP

REQUIREMENTS:

ELECTRIC 15 KW, 440 VAC, TRI PHASE.

PNEUMATIC 6 BAR - 60 LTS. / MIN.

DUCTS AND WIRING:

DUCTS AND WIRES RUNNING FROM UTILITIES SOURCES TO THE CONTROL PANEL AND FROM THE CONTROL PANEL TO THE MACHINE WILL BE AT CUSTOMER COSTS AND MUST BE DONE ACCORDING TO THE INSTRUCTIONS SHOWN IN OUR DIAGRAMS

SIEMENS PLC

Learn More -

YY-3389 SLITTER REWINDER MACHINE FOR TOILET AND TISSUE PAPER, PRODUCTION SPEED 80 TO 180 M PER MINYY-3389 SLITTER REWINDER MACHINE FOR TOILET AND TISSUE PAPER, PRODUCTION SPEED 80 TO 180 M PER MIN AUTOMATIC TOILET PAPER AND TISSUE PAPER TRIMMING AND SEALING REWINDING MACHINE INCLUDES ADVANCED PLC CONTROL SYSTEM, FREQUENCY CONVERSION SPEED CONTROL, ELECTRONIC BRAKE WITH MULTI-PICTURE HUMAN-MACHINE INTERFACE TOUCH SCREEN OPERATING SYSTEM, SPECIALIZING IN THE PRODUCTION OF FLAT ROLLS OF TOILET PAPER CORE AND CORELESS ROUND ROLLS, THE EQUIPMENT HAS AN AUTOMATIC REWINDING, PAPER ROLLS FORMED WITH AUTOMATIC DELIVERY, AUTOMATIC CORE SHAFT, AUTOMATIC CORE SHAFT PULLING, AUTOMATIC CYCLING OF THE CORE SHAFTS, AUTOMATIC SEALING AND GLUING OF THE END, AUTOMATIC COMPRESSION, AUTOMATIC TRANSPORT TO THE CUTTING SYSTEM. THE MACHINE CAN BE AUTOMATICALLY TRANSPORTED TO THE CUTTING SECTION, WHICH ALLOWS FOR UNMANNED REWINDING, IMPROVES THE WORKING EFFICIENCY, REDUCES LABOR. QUANTITY: 1 Learn More

YY-3389 SLITTER REWINDER MACHINE FOR TOILET AND TISSUE PAPER, PRODUCTION SPEED 80 TO 180 M PER MINYY-3389 SLITTER REWINDER MACHINE FOR TOILET AND TISSUE PAPER, PRODUCTION SPEED 80 TO 180 M PER MIN AUTOMATIC TOILET PAPER AND TISSUE PAPER TRIMMING AND SEALING REWINDING MACHINE INCLUDES ADVANCED PLC CONTROL SYSTEM, FREQUENCY CONVERSION SPEED CONTROL, ELECTRONIC BRAKE WITH MULTI-PICTURE HUMAN-MACHINE INTERFACE TOUCH SCREEN OPERATING SYSTEM, SPECIALIZING IN THE PRODUCTION OF FLAT ROLLS OF TOILET PAPER CORE AND CORELESS ROUND ROLLS, THE EQUIPMENT HAS AN AUTOMATIC REWINDING, PAPER ROLLS FORMED WITH AUTOMATIC DELIVERY, AUTOMATIC CORE SHAFT, AUTOMATIC CORE SHAFT PULLING, AUTOMATIC CYCLING OF THE CORE SHAFTS, AUTOMATIC SEALING AND GLUING OF THE END, AUTOMATIC COMPRESSION, AUTOMATIC TRANSPORT TO THE CUTTING SYSTEM. THE MACHINE CAN BE AUTOMATICALLY TRANSPORTED TO THE CUTTING SECTION, WHICH ALLOWS FOR UNMANNED REWINDING, IMPROVES THE WORKING EFFICIENCY, REDUCES LABOR. QUANTITY: 1 Learn More -

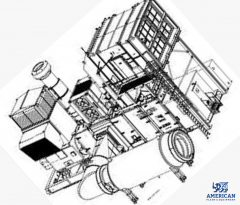

YY-2894 NEW SIEMENS SGT 400, YEAR 2018YY-2894 NEW SIEMENS SGT 400, YEAR 2018 SIEMENS SGT 400 (12.9 MW) GAS TURBINE · 11-STAGE COMPRESSOR, 6 COMBUSTION CHAMBERS, 2-STAGE POWER TURBINE · GAS FUEL SYSTEM · DLE COMBUSTION SYSTEM · HOT-END DRIVE · 2-SHAFT ENGINE · LEFT-HAND EXHAUST · MAIN LUBRICATION PUMP · EQUIVALENT OPERATING HOURS : 0H · TOTAL STARTS : 0 · NEW, NEVER INSTALLED OR COMMISSIONED QUANTITY: 1 Learn More

YY-2894 NEW SIEMENS SGT 400, YEAR 2018YY-2894 NEW SIEMENS SGT 400, YEAR 2018 SIEMENS SGT 400 (12.9 MW) GAS TURBINE · 11-STAGE COMPRESSOR, 6 COMBUSTION CHAMBERS, 2-STAGE POWER TURBINE · GAS FUEL SYSTEM · DLE COMBUSTION SYSTEM · HOT-END DRIVE · 2-SHAFT ENGINE · LEFT-HAND EXHAUST · MAIN LUBRICATION PUMP · EQUIVALENT OPERATING HOURS : 0H · TOTAL STARTS : 0 · NEW, NEVER INSTALLED OR COMMISSIONED QUANTITY: 1 Learn More -

YASHA LIST-1310-B FOR LUMMUS COTTON GIN EQUIPMENT LISTYASHA LIST-1310-B FOR LUMMUS COTTON GIN EQUIPMENT LIST American Plant & Equipment is dedicated to providing high-quality industrial machinery and equipment for various manufacturing and processing needs. Below is a detailed list of Lummus Cotton Gin Equipment, designed for efficient cotton processing. These machines are engineered to enhance productivity, reduce waste, and ensure high-quality output in the cotton ginning process. Each piece of equipment is described with its specific function and technical specifications, ensuring you have the right tools for optimal performance in your operations. Learn More

YASHA LIST-1310-B FOR LUMMUS COTTON GIN EQUIPMENT LISTYASHA LIST-1310-B FOR LUMMUS COTTON GIN EQUIPMENT LIST American Plant & Equipment is dedicated to providing high-quality industrial machinery and equipment for various manufacturing and processing needs. Below is a detailed list of Lummus Cotton Gin Equipment, designed for efficient cotton processing. These machines are engineered to enhance productivity, reduce waste, and ensure high-quality output in the cotton ginning process. Each piece of equipment is described with its specific function and technical specifications, ensuring you have the right tools for optimal performance in your operations. Learn More -

TT-1738 HUMMEL LNG CLEAN POWER GENERATING BARGE, 7.5MW, 50 TO 60 Hz, YEAR 2014TT-1738 HUMMEL LNG CLEAN POWER GENERATING BARGE, 7.5MW, 50 TO 60 Hz, YEAR 2014 THE POWER BARGE WAS ORIGINALLY DEVELOPED TO ENABLE VISITING CRUISE VESSELS TO POWER DOWN MAIN ENGINES IN PORT, REDUCING FUEL USE AND POLLUTION, WHILST RETAINING FULL ELECTRICAL POWER TO ON BOARD SYSTEMS. THE BARGE IS CAPABLE OF GENERATING A TOTAL OF 7.5 MW OF POWER FROM 5 SILENT GENERATORS FED BY TWO 17T LNG CONTAINERS. THE VESSEL IS A FLOATING POWER PLANT PROVIDING CLEAN AND EFFICIENT COLD IRONING POWER TO CRUISE HARBOURS, TERMINALS AND LOCAL INFRASTRUCTURE CURRENTLY. IT CAN ACT AS A BACKUP POWER BANK TO THE LOCAL ELECTRIC AND POWER GRID, ALSO POTENTIALLY PROVIDING HEATED WATER TO LOCAL SYSTEMS. THE POWER BARGE IS CAPABLE OF GENERATING A TOTAL OF 7.5 MW OF POWER FROM 5 SILENT GENERATORS FED BY TWO 17T LNG CONTAINERS. QUANTITY: 1 Learn More

TT-1738 HUMMEL LNG CLEAN POWER GENERATING BARGE, 7.5MW, 50 TO 60 Hz, YEAR 2014TT-1738 HUMMEL LNG CLEAN POWER GENERATING BARGE, 7.5MW, 50 TO 60 Hz, YEAR 2014 THE POWER BARGE WAS ORIGINALLY DEVELOPED TO ENABLE VISITING CRUISE VESSELS TO POWER DOWN MAIN ENGINES IN PORT, REDUCING FUEL USE AND POLLUTION, WHILST RETAINING FULL ELECTRICAL POWER TO ON BOARD SYSTEMS. THE BARGE IS CAPABLE OF GENERATING A TOTAL OF 7.5 MW OF POWER FROM 5 SILENT GENERATORS FED BY TWO 17T LNG CONTAINERS. THE VESSEL IS A FLOATING POWER PLANT PROVIDING CLEAN AND EFFICIENT COLD IRONING POWER TO CRUISE HARBOURS, TERMINALS AND LOCAL INFRASTRUCTURE CURRENTLY. IT CAN ACT AS A BACKUP POWER BANK TO THE LOCAL ELECTRIC AND POWER GRID, ALSO POTENTIALLY PROVIDING HEATED WATER TO LOCAL SYSTEMS. THE POWER BARGE IS CAPABLE OF GENERATING A TOTAL OF 7.5 MW OF POWER FROM 5 SILENT GENERATORS FED BY TWO 17T LNG CONTAINERS. QUANTITY: 1 Learn More -

R-7064 PROFESSIONAL BAKING MACHINE 100N

R-7064 PROFESSIONAL BAKING MACHINE 100NR-7064 PROFESSIONAL BAKING MACHINE 100N

POWER CONSUMPTION: 15 WATTS

COLORS: RED / YELLOW / GREEN / LIGHT BLUE / SAPPHIRE BLUE

BAKING CAPACITY: 120 GRAMS

NUMBER OF BAKING DRUMS: 60 TURNS

HEATING METHOD: GAS

PRODUCT DIMENSIONS (L X W X H): 330 X260 X320mm

PRODUCT WEIGHT: 7.1 KG

PRODUCT MATERIAL: 304 STAINLESS STEEL (INNER BARREL)

LIGHTWEIGHT, CONVENIENT AND EASY TO ENJOY PROFESSIONAL BAKING AT HOMEQUANTITY: 1

Learn More -

K-4730 MATTRESS VACUUM COMPRESSING LINEREFERENCE NUMBER: K-4730 MATTRESS VACUUM COMPRESSING LINE THIS MACHINE IS PREPARED WITH AUTOMATIC CYCLES TO REMOVE WORKERS AND REDUCE PRODUCTION TIME FROM EDGING UP TO PACKAGING OR ROLLING VACUUM. COULD BE DONE HIGH SPEED VERSIONS FOR 4 MATTRESSES PER MINUTE. QUANTITY AVAILABLE: 1 Learn More

K-4730 MATTRESS VACUUM COMPRESSING LINEREFERENCE NUMBER: K-4730 MATTRESS VACUUM COMPRESSING LINE THIS MACHINE IS PREPARED WITH AUTOMATIC CYCLES TO REMOVE WORKERS AND REDUCE PRODUCTION TIME FROM EDGING UP TO PACKAGING OR ROLLING VACUUM. COULD BE DONE HIGH SPEED VERSIONS FOR 4 MATTRESSES PER MINUTE. QUANTITY AVAILABLE: 1 Learn More -

TT-7522 BENNINGER INDIGO DYEING, SIZING AND WARPING MACHINE, WIDTH 2000mm, YEAR 2007TT-7522 BENNINGER INDIGO DYEING, SIZING AND WARPING MACHINE, WIDTH 2000mm, YEAR 2007 1. BENNINGER INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2007 3. BRAND: BENNINGER 4. INDIGO DYEING AND SIZING MACHINE - 14 BOXES (DYE AND WASH) 5. 2 SIZING BOXES 6. 25 TO 35 M/MIN (82 TO 115 FT/MIN) 7. 2000mm (78.7 IN) WIDTH 8. PLATE DIAMETER: 1400mm (55.1 IN) 9. CYLINDER DIAMETER: 456mm (17.95 IN) 10. MECHANISMS: ENTRY SCRAY 11. WASH BOX 1, 2, 3 12. OXIDATION ZONE 13. DYEING BOXES 1-7 14. VAPORIZER 15. WASH BOX 1, 2, 3, SIZING A & B 16. DRUM DRYER, EXIT Learn More

TT-7522 BENNINGER INDIGO DYEING, SIZING AND WARPING MACHINE, WIDTH 2000mm, YEAR 2007TT-7522 BENNINGER INDIGO DYEING, SIZING AND WARPING MACHINE, WIDTH 2000mm, YEAR 2007 1. BENNINGER INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2007 3. BRAND: BENNINGER 4. INDIGO DYEING AND SIZING MACHINE - 14 BOXES (DYE AND WASH) 5. 2 SIZING BOXES 6. 25 TO 35 M/MIN (82 TO 115 FT/MIN) 7. 2000mm (78.7 IN) WIDTH 8. PLATE DIAMETER: 1400mm (55.1 IN) 9. CYLINDER DIAMETER: 456mm (17.95 IN) 10. MECHANISMS: ENTRY SCRAY 11. WASH BOX 1, 2, 3 12. OXIDATION ZONE 13. DYEING BOXES 1-7 14. VAPORIZER 15. WASH BOX 1, 2, 3, SIZING A & B 16. DRUM DRYER, EXIT Learn More