Search results for: 'FINISH'

- Related search terms

- finishing

- finisher

- Finishi

- Finishing padder

- Finishing padde

-

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

TT-1368 SIMA MONOFILAMENT EXTRUDER LINE TYPE T/FIL 1483, YEAR 2006TT-1368 SIMA MONOFILAMENT EXTRUDER LINE TYPE T/FIL 1483, YEAR 2006 SIMA MONOFILAMENT EXTRUDER LINE TYPE T-FIL 1483 YEAR 2006 BRAND: SIMA MONOFILAMENT EXTRUSION LINES MODEL: MONOFILAMENT EXTRUDER LINE TYPE T-FIL 1483 YEAR: 2006 WORKING WIDTH CAPACITY: 100 QUANTITY: 1 Learn More

TT-1368 SIMA MONOFILAMENT EXTRUDER LINE TYPE T/FIL 1483, YEAR 2006TT-1368 SIMA MONOFILAMENT EXTRUDER LINE TYPE T/FIL 1483, YEAR 2006 SIMA MONOFILAMENT EXTRUDER LINE TYPE T-FIL 1483 YEAR 2006 BRAND: SIMA MONOFILAMENT EXTRUSION LINES MODEL: MONOFILAMENT EXTRUDER LINE TYPE T-FIL 1483 YEAR: 2006 WORKING WIDTH CAPACITY: 100 QUANTITY: 1 Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More -

YY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPMYY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPM FEATURES: 1. MAXIMUM SPEED: 3000RPM; 2. PRODUCTIVITY: 10 M/MIN; 3. ZIPPER WIDTH: 32mm (OTHERS SIZES CAN BE CUSTOMIZED); 4. FINISHED PRODUCTS WIDTH: ≤350mm (CUSTOMIZABLE); 5. ZIPPER RELATIVE POSITION CAN BE ADJUSTED ACCORDING TO THE PRODUCT TECHNICS; 6. SYNCHRONOUS CUTTER DESIGN, PNEUMATIC CONTROL CUTTER PRESSURE, EASY TO MAKE ADJUSTMENT; 7. MATTRESS BORDER LEFT-RIGHT LIMITS SET-GUIDE MECHANISM, APPLY FOR BORDER WIDTH AND LEFT RIGHT POSITION ADJUSTMENT; 8. AUTOMATIC THREAD BREAKAGE DETECT. 9. PRODUCTION OUTPUT COUNTING FUNCTION. 10. AUTOMATIC WINDING FUNCTION. 11. MATTRESS BORDER WIDTH: MAXIMUM 350mm, OTHER WIDTH CAN BE CUSTOMIZED; 12. WITH PNEUMATIC CUTTING KNIFE; 13. WITH THREAD BROKEN DETECTIVE FUNCTION; 14. WITH PRODUCTION COUNTING FUNCTION; 15. WITH AUTO RE-ROLLING FUNCTION; 16. STITCH TYPE: MULTI-NEEDLES DOUBLE THREAD CHAIN STITCH; 17. NEEDLE QUANTITY: 4 NEEDLES; 18. STITCH LINE DISTANCE: 1/4-1/2-1/4; 19. STITCH LENGTH: 5-6 STITCHES PER INCH; 20. MAX SEWING THICKNESS: 8mm; 21. POWER: SINGLE PHASE, 220V; 22. POWER CAPACITY: 2.2KW; 23. INSTALLATION SIZE: 4100X1100X1900mm. QUANTITY: 1 Learn More

YY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPMYY-2155 MATTRESS BORDER ZIPPER AUTOMATIC SEWING MACHINE, MAXIMUM SPEED 3000RPM FEATURES: 1. MAXIMUM SPEED: 3000RPM; 2. PRODUCTIVITY: 10 M/MIN; 3. ZIPPER WIDTH: 32mm (OTHERS SIZES CAN BE CUSTOMIZED); 4. FINISHED PRODUCTS WIDTH: ≤350mm (CUSTOMIZABLE); 5. ZIPPER RELATIVE POSITION CAN BE ADJUSTED ACCORDING TO THE PRODUCT TECHNICS; 6. SYNCHRONOUS CUTTER DESIGN, PNEUMATIC CONTROL CUTTER PRESSURE, EASY TO MAKE ADJUSTMENT; 7. MATTRESS BORDER LEFT-RIGHT LIMITS SET-GUIDE MECHANISM, APPLY FOR BORDER WIDTH AND LEFT RIGHT POSITION ADJUSTMENT; 8. AUTOMATIC THREAD BREAKAGE DETECT. 9. PRODUCTION OUTPUT COUNTING FUNCTION. 10. AUTOMATIC WINDING FUNCTION. 11. MATTRESS BORDER WIDTH: MAXIMUM 350mm, OTHER WIDTH CAN BE CUSTOMIZED; 12. WITH PNEUMATIC CUTTING KNIFE; 13. WITH THREAD BROKEN DETECTIVE FUNCTION; 14. WITH PRODUCTION COUNTING FUNCTION; 15. WITH AUTO RE-ROLLING FUNCTION; 16. STITCH TYPE: MULTI-NEEDLES DOUBLE THREAD CHAIN STITCH; 17. NEEDLE QUANTITY: 4 NEEDLES; 18. STITCH LINE DISTANCE: 1/4-1/2-1/4; 19. STITCH LENGTH: 5-6 STITCHES PER INCH; 20. MAX SEWING THICKNESS: 8mm; 21. POWER: SINGLE PHASE, 220V; 22. POWER CAPACITY: 2.2KW; 23. INSTALLATION SIZE: 4100X1100X1900mm. QUANTITY: 1 Learn More -

TT-1312 COLOMBO PVC LACQUER COATING MACHINE, WORKING WIDTH 2600mm, YEAR 2000TT-1312 COLOMBO PVC LACQUER COATING MACHINE, WORKING WIDTH 2600mm, YEAR 2000 QUANTITY: 1 Learn More

TT-1312 COLOMBO PVC LACQUER COATING MACHINE, WORKING WIDTH 2600mm, YEAR 2000TT-1312 COLOMBO PVC LACQUER COATING MACHINE, WORKING WIDTH 2600mm, YEAR 2000 QUANTITY: 1 Learn More -

TT-1265 DUSENBERY 825, WIDTH 2600mm, YEAR 1984TT-1265 DUSENBERY 825, WIDTH 2600mm, YEAR 1984 OTHER DETAILS: PERFORED STATION BURCKHARDT INSTALLED + TOTALLY NEW STATION NOT INSTALLED FOR EACH LINE SPARE PARTS AS: BRUSH ROLLS, NEEDLE RINGS, ETC 4 PCS. ROUND-KNIVES ARE ON EACH MACHINE APPROX. 55 KW INSTALLED AND ABSORBED POWER 40 KW ON EACH OF THE TWO MACHINES. QUANTITY: 2 Learn More

TT-1265 DUSENBERY 825, WIDTH 2600mm, YEAR 1984TT-1265 DUSENBERY 825, WIDTH 2600mm, YEAR 1984 OTHER DETAILS: PERFORED STATION BURCKHARDT INSTALLED + TOTALLY NEW STATION NOT INSTALLED FOR EACH LINE SPARE PARTS AS: BRUSH ROLLS, NEEDLE RINGS, ETC 4 PCS. ROUND-KNIVES ARE ON EACH MACHINE APPROX. 55 KW INSTALLED AND ABSORBED POWER 40 KW ON EACH OF THE TWO MACHINES. QUANTITY: 2 Learn More -

TT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEMTT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEM BARUDAN NAPKIN SEWING SYSTEM MODEL BEST-3R 4 WORKING MACHINES AND 2 NON-WORKING MACHINES. QUANTITY: 6 Learn More

TT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEMTT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEM BARUDAN NAPKIN SEWING SYSTEM MODEL BEST-3R 4 WORKING MACHINES AND 2 NON-WORKING MACHINES. QUANTITY: 6 Learn More -

TT-1268 AUTOMATEX AUTOMATED NAPKIN SEWING SYSTEMTT-1268 AUTOMATEX AUTOMATED NAPKIN SEWING SYSTEM SEWS NAPKINS FROM ROLL TO FINISH QUANTITY: 1 Learn More

TT-1268 AUTOMATEX AUTOMATED NAPKIN SEWING SYSTEMTT-1268 AUTOMATEX AUTOMATED NAPKIN SEWING SYSTEM SEWS NAPKINS FROM ROLL TO FINISH QUANTITY: 1 Learn More -

TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018 ITEM 001 TOYOTA MAKE AIRJET LOOMS, WIDTH 2100mm, YEAR 2016 TO 2017, WITH DOBBY. QUANTITY: 100 ITEM 002 JUPITER MAKE INDIGO SLASHER DYEING RANGE WITH SIZING PLANT, 16 BEAMS, YEAR 2018, ROLLER WIDTH 2000mm, WITH STEAMER 60000mm QUANTITY: 2 ITEM 003 JUPITER MAKE WARPING MACHNE WITH 672 ENDS, YEAR 2017 TO 2018 QUANTITY: 3 ITEM 004 DHALL MAKE SINGEING MACHINE, ROLLER WIDTH 2400mm, YEAR 2018 QUANTITY: 1 ITEM 005 DHALL MAKE CHAINLESS MERCERISER, YEAR 2018 QUANTITY: 1 ITEM 006 DHALL MAKE STENTOR, 8 CHAMBERS. QUANTITY: 1 ITEM 007 DHALL MAKE DESIZE AND OVER DYE MACHINE QUANTITY: 1 ITEM 008 DHALL MAKE WET FINISH MACHINE, YEAR 2018 ITEM 009 LUWA HUMDIFICATION PLANT, 2 NOS. KAISER COMPRESSOR, CAUSTIC RECOVERY PLANT, THERMA COAL FIRED BOILER, THERMPOC. QUANTITY: 2 Learn More

TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018 ITEM 001 TOYOTA MAKE AIRJET LOOMS, WIDTH 2100mm, YEAR 2016 TO 2017, WITH DOBBY. QUANTITY: 100 ITEM 002 JUPITER MAKE INDIGO SLASHER DYEING RANGE WITH SIZING PLANT, 16 BEAMS, YEAR 2018, ROLLER WIDTH 2000mm, WITH STEAMER 60000mm QUANTITY: 2 ITEM 003 JUPITER MAKE WARPING MACHNE WITH 672 ENDS, YEAR 2017 TO 2018 QUANTITY: 3 ITEM 004 DHALL MAKE SINGEING MACHINE, ROLLER WIDTH 2400mm, YEAR 2018 QUANTITY: 1 ITEM 005 DHALL MAKE CHAINLESS MERCERISER, YEAR 2018 QUANTITY: 1 ITEM 006 DHALL MAKE STENTOR, 8 CHAMBERS. QUANTITY: 1 ITEM 007 DHALL MAKE DESIZE AND OVER DYE MACHINE QUANTITY: 1 ITEM 008 DHALL MAKE WET FINISH MACHINE, YEAR 2018 ITEM 009 LUWA HUMDIFICATION PLANT, 2 NOS. KAISER COMPRESSOR, CAUSTIC RECOVERY PLANT, THERMA COAL FIRED BOILER, THERMPOC. QUANTITY: 2 Learn More -

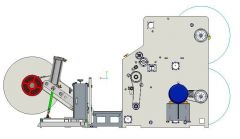

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More