Search results for: 'Gas en'

-

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More -

M-5193 REGGIANI FLAT BED PRINTING MACHINE WITH 6 COLORS YEAR 1973 WIDTH 2000mm GAS HEATEDREFERENCE NUMBER: M-5193 (13133ZTPM12RX) L REGGIANI FLAT BED PRINTING MACHINE WITH 6 COLORS YEAR 1973 WIDTH 2000mm GAS HEATED REGGIANI FLAT BED PRINTING MACHINE WORKING WIDTH 2000mm YEAR 1973 QUANTITY AVAILABLE: 1 Learn More

M-5193 REGGIANI FLAT BED PRINTING MACHINE WITH 6 COLORS YEAR 1973 WIDTH 2000mm GAS HEATEDREFERENCE NUMBER: M-5193 (13133ZTPM12RX) L REGGIANI FLAT BED PRINTING MACHINE WITH 6 COLORS YEAR 1973 WIDTH 2000mm GAS HEATED REGGIANI FLAT BED PRINTING MACHINE WORKING WIDTH 2000mm YEAR 1973 QUANTITY AVAILABLE: 1 Learn More -

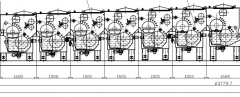

K-1016 SAMILL TENTER FRAME YEAR 2000 – 5 ZONES – 2000mm - GASREFERENCE NUMBER: K-1016 SAMILL TENTER FRAME YEAR 2000 – 5 ZONES – 2000mm - GAS HORIZONTAL PIN CHAIN GAS HEATED - 10 BURNERS 5 ZONES 2000mm WIDE TWO PADS (FOULARD ) AT ENTRANCE ONE WEFT STRAIGHTENER FLAT FOLDER AND "A" FRAME WINDER AT EXIT MACHINE IS IN LIKE NEW CONDITION , OWNER USED IT ONLY FOR TESTING AND COULD NOT GET CONTRACT ON THE FABRIC SALES QUANTITY AVAILABLE : 1 Learn More

K-1016 SAMILL TENTER FRAME YEAR 2000 – 5 ZONES – 2000mm - GASREFERENCE NUMBER: K-1016 SAMILL TENTER FRAME YEAR 2000 – 5 ZONES – 2000mm - GAS HORIZONTAL PIN CHAIN GAS HEATED - 10 BURNERS 5 ZONES 2000mm WIDE TWO PADS (FOULARD ) AT ENTRANCE ONE WEFT STRAIGHTENER FLAT FOLDER AND "A" FRAME WINDER AT EXIT MACHINE IS IN LIKE NEW CONDITION , OWNER USED IT ONLY FOR TESTING AND COULD NOT GET CONTRACT ON THE FABRIC SALES QUANTITY AVAILABLE : 1 Learn More -

TT-3268 CATERPILLAR MAK G16CM34 ENGINE SET, 5900KW, YEAR 2009 WITH 50,000 HOURSTT-3268 CATERPILLAR MAK G16CM34 ENGINE SET, 5900KW, YEAR 2009 WITH 50,000 HOURS QUANTITY: 1 Learn More

TT-3268 CATERPILLAR MAK G16CM34 ENGINE SET, 5900KW, YEAR 2009 WITH 50,000 HOURSTT-3268 CATERPILLAR MAK G16CM34 ENGINE SET, 5900KW, YEAR 2009 WITH 50,000 HOURS QUANTITY: 1 Learn More -

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More -

TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000 Learn More

TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000TT-2138 LAROCHE / THIBEAU / ASSELIN / ICBT / FLEISSNER/ SPUNLACE / JETLACE / HYDROENTANGLEMENT LINES, YEAR 2000 Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More -

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

T-6549 CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATEREFERENCE NUMBER: T-6549

CONSTANT TEMPERATURE AND HUMIDITY CHAMBER -FABRIC WATER VAPOR TRANSMISSION RATE

TESTING METER (WITH MOISTURE PERMEABLE CUP)

TECHNICAL DESCRIPTION OF THE INSTRUMENT:

IT IS MAINLY USED TO MEASURE THE MOISTURE PERMEABILITY OF ALL KINDS OF FABRICS, INCLUDING PERMEABLE COATED FABRICS. STRUCTURE PRINCIPLE: ADOPT COMPUTER CONTROL, CREATING A CONSTANT TEMPERATURE, AND HUMIDITY TEST ENVIRONMENT, TEST ENVIRONMENT IN THE CONSTANT TEMPERATURE, AND HUMIDITY, MOISTURE VAPOR TRANSMISSION CUP, PLACED 6 SAMPLE INTO THE GLASS AND THE RUBBER GASKET SEAL, THE CONTAINING HYGROSCOPIC AGENT OR WATER SEAL IS SPECIFIED BY THE WET CUP PLACED IN THE FABRIC SAMPLE TEMPERATURE AND HUMIDITY OF THE ENVIRONMENT, THE SEAL MOISTURE VAPOR TRANSMISSION CUP ACCORDING TO A CERTAIN TIME (INCLUDING SAMPLE AND HYGROSCOPIC AGENT OR WATER) TO CALCULATE THE MOISTURE TRANSMISSION QUALITY CHANGE.

TESTING STANDARD:

GB19082-2009 MEDICAL PRIMARY PROTECTIVE CLOTHING

TECHNICAL REQUIREMENTS GUIDELINES FOR THE SELECTION OF YY-T1498-2016 MEDICAL PROTECTIVE CLOTHING

GB/T12704.1 DETERMINATION OF MOISTURE PERMEABILITY OF FABRICS --HYGROSCOPIC METHOD

DETAILED TECHNICAL SPECIFICATIONS AND CONFIGURATION:

TECHNICAL INDICATORS:

1. TEMPERATURE CONTROL RANGE: -40°C ~ 150°C;RESOLUTION; 0.1 °C

2. HUMIDITY CONTROL RANGE: 50%RH ~ 95% RH±5%

3. SPEED RANGE: 2mm ~ 60mm/MIN

4. CONTROL PRECISION: TEMPERATURE <0.1°C; HUMIDITY + / -1% RH OR LESS

5. CYCLIC WIND SPEED: 0.02 ~ 0.5M/S, 0.3 ~ 0.5M/S

6. TIME CONTROL: 1 ~ 9999H

7. MOISTURE PERMEABLE AREA: 2827 mm 2 (DIAMETER IS 60 mm --NATIONAL STANDARD)

8. QUANTITY OF PERMEABLE CUPS: 6 GB;

9. DRYING BOX CONTROL TEMPERATURE: ROOM TEMPERATURE ~ 199 °C

10. TEST TIME: 1 ~ 999H

11. DRYING BOX STUDIO SIZE: 490 X 400 X 215mm

INSTRUMENT CONFIGURATION:

1. ONE MAIN MACHINE

QUANTITY: 1

Learn More -

P-4336 FULL SERVO ROTARY TYPE WIPES PACKING MACHINE

P-4336 FULL SERVO ROTARY TYPE WIPES PACKING MACHINEREFERENCE NUMBER: P-4336

FULL SERVO ROTARY TYPE WIPES PACKING MACHINE

Model: P60

SPECIFICATIONS

Packing film diameter: max 350mm

Packing film width: max width 380mm

Bag length: 100-300mm, it is set by liquid screen

Packing width: 50-125mm

Product height: 5-45mm

End seal type: rotary type hot seal

Speed control: 40-100bags/min, servo control

Operate interface:5.7" liquid screen

Film feeding system: servo motor

End seal system: servo motor

Material feeding system: servo motor

End seal protect: torsion overload stop protect

Hole system: synchronization rotary cut

Label system: servo motor

Gas resource requirement: 0.5-0.8Mpa, 50L/min

Power resource: AC 220V 50/60Hz 4KW

Machine size: L4600mm x W950mm x H2100mm

Packing size:(1) L2200mm x W1080mm x H2250mm (total two) (2) L3300mm x W450mm x H450mm

Weight: G.W.:1000kg N.W.:850kg

Option equipment: transfer printerQUANTITY: 1

Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More