Search results for: 'pre'

-

YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013)YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013) FOURDRINIER PAPER MACHINE PM3: FACE WIDTH: 4.57 METERS, TRIM WIDTH: 4.05 METERS GRADE: BOND, OFFSET, XEROCOPY BASIS WEIGHT: 35 TO 135 GSM MAXIMUM SPEED: 914 METERS ( OPERATING SPEED 700 METERS ) WIRE WIDTH : 4.52 METERS MAXIMUM WINDER SPEED: 2000 METERS/MIN Learn More

YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013)YY-3017 HONEYWELL MODEL PRO FLOW II POSITION AUTOMATIC PROFILE (2013) FOURDRINIER PAPER MACHINE PM3: FACE WIDTH: 4.57 METERS, TRIM WIDTH: 4.05 METERS GRADE: BOND, OFFSET, XEROCOPY BASIS WEIGHT: 35 TO 135 GSM MAXIMUM SPEED: 914 METERS ( OPERATING SPEED 700 METERS ) WIRE WIDTH : 4.52 METERS MAXIMUM WINDER SPEED: 2000 METERS/MIN Learn More -

F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm QUANTITY: ONE PRODUCTION LINE Learn More

F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: F-1234 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm QUANTITY: ONE PRODUCTION LINE Learn More -

C-1141 HBD WOOLEN YARN CARDING MACHINE GALAXY, YEAR 1982, WIDTH 2500 MM, WITH 176 GOOD ENDSREFERENCE NUMBER: C-1141 HBD WOOLEN YARN CARDING MACHINE GALAXY, YEAR 1982, WIDTH 2500 MM, WITH 176 GOOD ENDS SPECIFICATIONS: 2500MM WORKING WIDTH YEAR OF CONSTRUCTION 1982 THE MACHINE IS COMPLETE WITH FEEDING CHUTE LARGE SIZE HOPPER FEEDER AND SERVOLAP CONTROL. THE TEARING CARD HAS 3 INFEED ROLLERS, 1 PRE ROLLER, 1 WORKER, 1 TURNER, 1 TRANSFER ROLLER, 1 PRE DRUM, 3 WORKER, 3 TURNER, 1 TRANSFER ROLLER, 1 MAIN TAMBOUR, 4 WORKER, 4 TURNER, 1 RUNNER, 2 DUST TURNER, 1 TAKE-OFF. TRANSFER WITH LAYDOWN. THE PRE SPINNING CARD IS WITH 4 INFEED ROLLER, 1 STRIPPER ROLLER, 1 PRE ROLLER, 1 WORKER, 1 TURNER, 1 TRANSFER ROLLER. 1 PRE CARD WITH 4 WORKER, 4 TURNER, 1 RUNNER, 2 DUST TURNER, 1 TAKE-OFF, 1 TRANSFER ROLLER. 1 MAIN DRUM, 5 WORKER, 5 TURNER, 1 RUNNER, 2 DUST TURNER, 1 TAKE-OFF, 1 TAKE-OFF CLEARER. PILE DIVIDER TYPE MB, WITH SPOOL FRAME TYPE II, DOUBLE NITSCHEL, 176 GOOD ENDS, DISTRIBUTED ONTO 16 PRE YARN ROLLERS OF EACH 11 THREADS, 12,7 MM. QUANTITY AVAILABLE: 1 Learn More

C-1141 HBD WOOLEN YARN CARDING MACHINE GALAXY, YEAR 1982, WIDTH 2500 MM, WITH 176 GOOD ENDSREFERENCE NUMBER: C-1141 HBD WOOLEN YARN CARDING MACHINE GALAXY, YEAR 1982, WIDTH 2500 MM, WITH 176 GOOD ENDS SPECIFICATIONS: 2500MM WORKING WIDTH YEAR OF CONSTRUCTION 1982 THE MACHINE IS COMPLETE WITH FEEDING CHUTE LARGE SIZE HOPPER FEEDER AND SERVOLAP CONTROL. THE TEARING CARD HAS 3 INFEED ROLLERS, 1 PRE ROLLER, 1 WORKER, 1 TURNER, 1 TRANSFER ROLLER, 1 PRE DRUM, 3 WORKER, 3 TURNER, 1 TRANSFER ROLLER, 1 MAIN TAMBOUR, 4 WORKER, 4 TURNER, 1 RUNNER, 2 DUST TURNER, 1 TAKE-OFF. TRANSFER WITH LAYDOWN. THE PRE SPINNING CARD IS WITH 4 INFEED ROLLER, 1 STRIPPER ROLLER, 1 PRE ROLLER, 1 WORKER, 1 TURNER, 1 TRANSFER ROLLER. 1 PRE CARD WITH 4 WORKER, 4 TURNER, 1 RUNNER, 2 DUST TURNER, 1 TAKE-OFF, 1 TRANSFER ROLLER. 1 MAIN DRUM, 5 WORKER, 5 TURNER, 1 RUNNER, 2 DUST TURNER, 1 TAKE-OFF, 1 TAKE-OFF CLEARER. PILE DIVIDER TYPE MB, WITH SPOOL FRAME TYPE II, DOUBLE NITSCHEL, 176 GOOD ENDS, DISTRIBUTED ONTO 16 PRE YARN ROLLERS OF EACH 11 THREADS, 12,7 MM. QUANTITY AVAILABLE: 1 Learn More -

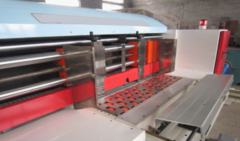

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More -

YY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mmYY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mm USED CPB-DYEING PLANT ACCORDING TO TYPE 222.11 QUANTITY: 1 CONSISTING OF 2-BOWL DYEING PADDER MAKE: EDUARD KUSTERS TYPE: 222.11 YEAR: COMPL. REFURBISHED BEFORE DELIVERY TECHNICAL DATA: WORKING WIDTH: 2000mm; ROLLER FACE WIDTH: 2200mm; DRIVE SIDE: RIGHT; SERVICE SIDE: LEFT; PRESSURE: 50 KP/CM; TOTAL PRESSURE: 10 TO / 100 NM; SPEED: 60 M/MIN; POWER: 5.5KW; VOLTAGE: 3 X 400 V, 50Hz; AIR CONNECTION: 6 BARS LOCALLY; COLOR OF PAINT: ACCORDING TO AGREEMENT. Learn More

YY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mmYY-2227 USED KUSTER PAD BATCH DYEING PLANT, WORKING WIDTH 2000mm USED CPB-DYEING PLANT ACCORDING TO TYPE 222.11 QUANTITY: 1 CONSISTING OF 2-BOWL DYEING PADDER MAKE: EDUARD KUSTERS TYPE: 222.11 YEAR: COMPL. REFURBISHED BEFORE DELIVERY TECHNICAL DATA: WORKING WIDTH: 2000mm; ROLLER FACE WIDTH: 2200mm; DRIVE SIDE: RIGHT; SERVICE SIDE: LEFT; PRESSURE: 50 KP/CM; TOTAL PRESSURE: 10 TO / 100 NM; SPEED: 60 M/MIN; POWER: 5.5KW; VOLTAGE: 3 X 400 V, 50Hz; AIR CONNECTION: 6 BARS LOCALLY; COLOR OF PAINT: ACCORDING TO AGREEMENT. Learn More -

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

YY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILERYY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILER SUPERIOR PACKAGED 250 HP 4-PASS WET BACK BOILER YEAR BUILT: 2008 DESIGN PRESSURE: 150 PSIG/STEAM OPERATING PRESSURE: 135 PSIG OR LESS CAPACITY: 8.625 LB./HR. STEAM (FROM AND AT 212 DEGREES F.) FUEL: NATURAL GAS AND #2 FUEL OIL ELECTRICAL: 460 VOLTS QUANTITY: 1 Learn More

YY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILERYY-3015 USED SUPERIOR 250 H.P. FIRETUBE PACKAGE BOILER SUPERIOR PACKAGED 250 HP 4-PASS WET BACK BOILER YEAR BUILT: 2008 DESIGN PRESSURE: 150 PSIG/STEAM OPERATING PRESSURE: 135 PSIG OR LESS CAPACITY: 8.625 LB./HR. STEAM (FROM AND AT 212 DEGREES F.) FUEL: NATURAL GAS AND #2 FUEL OIL ELECTRICAL: 460 VOLTS QUANTITY: 1 Learn More -

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More -

T-9597 FABRIC BURSTING STRENGTH TESTERT-9597 FABRIC BURSTING STRENGTH TESTER KEY SPECIFICATION: RANGE: 2.00MPA TO 10.000MPA THE MIN. DIVISION VALUE: 0.001MPA TO 0.003MPA TEST AREA: 73mm2 (Φ30.5mm), 100mm2 (Φ35.7mm), 500mm2 (Φ79.8mm), 1000mm2 (Φ112.8mm) CAN BE OPTION THICKNESS OF RUBBER DIAPHRAGM: ≤2mm PRESSURE SPEED: 20ML/MIN - 600ML/MIN MAXIMUM EXPANSION HEIGHT: 75 ± 0.02mm TESTING UNITS: KPA, KGF/ CM2, ATM, MMHG, LB/IN2 FREE SHIFT TEST METHOD: CONSTANT RATE BURSTING CONSTANT EXPANSION CONSTANT PRESSURE CONSTANT TIME BURSTING OUTPUT: PRINTER, DISPLAY OUTPUT AND CAN BE CONNECTED TO THE COMPUTER POWER SUPPLY: AC 220V 50/60HZ 200W DIMENSIONS: 550 × 450 × 700mm NET WEIGHT: 125KG Learn More

T-9597 FABRIC BURSTING STRENGTH TESTERT-9597 FABRIC BURSTING STRENGTH TESTER KEY SPECIFICATION: RANGE: 2.00MPA TO 10.000MPA THE MIN. DIVISION VALUE: 0.001MPA TO 0.003MPA TEST AREA: 73mm2 (Φ30.5mm), 100mm2 (Φ35.7mm), 500mm2 (Φ79.8mm), 1000mm2 (Φ112.8mm) CAN BE OPTION THICKNESS OF RUBBER DIAPHRAGM: ≤2mm PRESSURE SPEED: 20ML/MIN - 600ML/MIN MAXIMUM EXPANSION HEIGHT: 75 ± 0.02mm TESTING UNITS: KPA, KGF/ CM2, ATM, MMHG, LB/IN2 FREE SHIFT TEST METHOD: CONSTANT RATE BURSTING CONSTANT EXPANSION CONSTANT PRESSURE CONSTANT TIME BURSTING OUTPUT: PRINTER, DISPLAY OUTPUT AND CAN BE CONNECTED TO THE COMPUTER POWER SUPPLY: AC 220V 50/60HZ 200W DIMENSIONS: 550 × 450 × 700mm NET WEIGHT: 125KG Learn More