Search results for: 'Production capa''

- Related search terms

- Production+cap

- production line

- Production capacity'

- Production+capa'

- PRODUCTION REMARKS

-

M-6423 AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOUR

M-6423 AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOURREFERENCE NUMBER: M-6423

AUTOMATIC YOGURT CUP FILLING AND SEALING MACHINE – ROTARY TYPE – OUTPUT 800 TO 1,000 CUPS PER HOURAUTOMATIC CUP FILLING AND SEALING MACHINE – FILLING YOGURT

ROTARY TYPE

DIAMETER: 9.5 CM

OUTPUT: 800 TO 1,000 CUPS PER HOUR

ROLL FILMQUANTITY: 1

Learn More -

C-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MW

C-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MWC-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MW

A. ONCE THROUGH STEAM GENERATOR

B. BARGE

C. CHILLERS

D. AIR COMPRESSOR

E. GAS TURBINE

F. STEAM TURBINE

G. FEEDWATER SYSTEM

H. CLOSED COOLING WATER SYSTEM

I. AUXILIARY COOLING WATER SYSTEM

J. CONDENSATE POLISHING UNIT (CPU)

K. WASTE WATER SYSTEM

L. PLANT ELECTRICAL SYSTEM

M. BLACK START DG SET

N. PLANT CONTROLS AND INSTRUMENTATION

O. PLANT FIRE FIGHTING SYSTEM

P. START UP VACUUM SYSTEM

Q. STEAM TURBINE DEAERATING CONDENSERQUANTITY: 1 PLANT

Learn More -

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

M-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mmM-6054 EXTRUSION PLANT FOR FOAMED PET, WORKING WIDTH SHEETS 610mm x 240mm

OFFER 001

EXTRUSION PLANT

FOR FOAMED PET

WORKING WIDTH: SHEETS 610mm x 240mm

THICKNESS: 5mm TO 60mm

DENSITY: 80 TO 250 KG/M3

CAPACITY: UP TO 500 KG PER HOUROFFER 002

SILO FOR VIRGIN MATERIALOFFER 003

DRYING SYSTEM (SUITABLE FOR 500 KG PER HOUR)OFFER 004

GRAVIMETRIC FEEDING SYSTEMOFFER 005

GAS STOCKING SYSTEMOFFER 006

GAS FEEDING SYSTEMOFFER 007

EXTRUDEROFFER 008

SCREEN CHANGEROFFER 009

STRAND DYE WITH ELEMENTS FOR EXTRUSIONOFFER 010

PNEUMATIC SHAPER FOR SHAPING THE BOARD BY ADJUSTING THE LOADOFFER 011

HAUL OFF UNITOFFER 012

ROLLERS FOR BOARDS CONVEYINGOFFER 013

PULLER HAUL OFFOFFER 014

TRANSVERSAL CUTTING UNITOFFER 015

FINISHING EQUIPMENTOFFER 016

BLOCK WELDING MACHINEOFFER 017

FINISHING PLATFORMOFFER 018

HORIZONTAL CUTTING MACHINEOFFER 019

SHEETS WELDING MACHINEOFFER 020

SCRAPS RECYCLING SYSTEMOFFER 021

GRINDER TO MILL THE PIECES OF MATERIALOFFER 022

COMPACTING UNITOFFER 023

STORING SILOS FOR DENSIFIED FOAM PETOFFER 024

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 025

CABLES AND CABLING MATERIALSOFFER 026

PIPINGQUANTITY: 1 PLANT

Learn More -

C-3980 KRAFT PAPER MAKING MACHINE WITH GAS BOILER, CAPACITY 3 TO 5 T/D, NET PAPER WIDTH 1200mm

C-3980 KRAFT PAPER MAKING MACHINE WITH GAS BOILER, CAPACITY 3 TO 5 T/D, NET PAPER WIDTH 1200mmC-3980 KRAFT PAPER MAKING MACHINE WITH GAS BOILER, CAPACITY 3 TO 5 T/D, NET PAPER WIDTH 1200mm

KRAFT PAPER MAKING MACHINE

WITH GAS BOILER

CAPACITY: 3 TO 5 T/D KRAFT PAPER MACHINE

1092 KRAFT CORRUGATED PAPER MACHINE

WITH RECYCLE PAPER AS RAW MATERIAL

TECHNICAL PARAMETER:

OUTPUT: KRAFT PAPER, CORRUGATED PAPER

WEIGHT: 60 TO 180G/M2

NET PAPER WIDTH: 1200mmQUANTITY: 1

Learn More -

A-1502 MONT-MAC CROSS

A-1502 MONT-MAC CROSSREFERENCE NUMBER: A-1502

Learn More

MONT-MAC CROSS CUTTING AND HEMMING LINE FOR TERRY TOWELS

MODEL: TEKNA 2000

MONT-MAC CROSS CUTTING AND HEMMING LINE FOR TERRY TOWELS

YEAR: 2010

QUANTITY: 1 -

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More -

M-3150 COMPLETE OPEN END PLANT WITH 1200 ROTORS YEAR 1990-2005

M-3150 COMPLETE OPEN END PLANT WITH 1200 ROTORS YEAR 1990-2005REFERENCE NUMBER: M-3150

COMPLETE OPEN END PLANT WITH 1200 ROTORS YEAR 1990-2005

COMPLETE OPEN END PLANT WITH 1.200 ROTORS

YEAR FROM 1990 TO 2005

1 LINE WORKED 100% PURE COTTON

1 LINE WORKED 100% COTTON WASTE

PRODUCTION CAPACITY MAX 10.000 KGS PER DAY

NE COUNTS: FROM NE 5 TO NE 30

380 VOLTS 50 HZ

BLOWROOM01 TRUETZSCHLER BLENDOMAT BDT-019/2.300 , YEAR 1993, W.W. 2.300 MM

01 RIETER MONOCYLINDER B4/1, YEAR 199001 RIETER FEEDER B3/3R, YEAR 1990

01 RIETER UNIMIX B7/3, YEAR 1990

01 TRUETZSCHLER CAGE CONDENSER BRC01,YEAR 2005

01 TRUETZSCHLER MXU6- MULTI MIXER, YEAR 2005

01 TRUETZSCHLER MXU6- MULTI MIXER INCORPORATE WHIT CLC1, YEAR 200501 TRUETZSCHLER SCFO SECUROMAT FOREIGN FIBRE DETECTOR, YEAR 2005

01 TRUETZSCHLER FEEDER BOU3, YEAR 2005

01 TRUETZSCHLER CVT3 CLEANER, YEAR 199902 TRUETZSCHLER DX DUSTEX, YEAR 1993 AND 2005

01 JOSSI VISION SHELD, YEAR 2007

CARDS10 TRUTZSCHLER DK 803 CARDS, YEAR 1999

TRUTZSCHLER CHUTE FEED

ALLUMINIUM FLATH

CANS DIA 1000MM X 1190MM

AUTOMATIC CAN CHANGERS

DRAWFRAMES02 RIETER SB 51 DRAWFRAMES, YEAR 1990

CAN DIA 600MM X 1200MM

AUTOMATIC CAN CHANGER01 RIETER RSB 51 DRAWFRAMES, YEAR 1990

CAN DIA 600MM X 1200MM

AUTOMATIC CAN CHANGER

01 RIETER RSB D30 DRAWFRAMES , YEAR 2001

CAN DIA 450MM X 1070MM

WITH AUTO LEVELLING AND AUTOMATIC CAN CHANGERS01 RIETER RSB D35 DRAWFRAMES , YEAR 2005

CAN DIA 450MM X 1070MM

WITH AUTO LEVELLING AND AUTOMATIC CAN CHANGERS

02 VOUK SH802 , YEAR 1994 AND 1995

CAN DIA 450MM X 1070MM

WITH AUTO LEVELLING AND AUTOMATIC CAN CHANGERSOPEN END

03 SCHLAFHORST AUTOCORO OPEN END SPINNING FRAME , 2 X YEAR 2000 , 1 X YEAR 2001

TYPE ACO 288 WITH SE 11 SPINBOX , SRZ 6”

240 ROTORS , ROTOR 33/36/40 ,OPENING ROLLER TYPE B174 OR OB20

WAXING, WITH CLEARERS COROLAB MODEL V.3.6. 2 X AUTOMATIC YARN PIECER ASW

02 SCHLAFHORST AUTOCORO OPEN END SPINNING FRAME , YEAR 1995

TYPE ACO 288 WITH SE 9 SPINBOX , SRZ 6”

240 ROTORS , ROTOR 33,OPENING ROLLER TYPE B174 OR OB20

WAXING, CLEARERS COROLAB FOREING FIBER MODEL V.3.6.U1.39 , 2 X AUTOMATIC YARN PIECER ASW

INCLUDED IN THE PLANTCENTRAL SUCTION

CANS02 HORIZONTAL PRESS RIETER A5/1, YEAR 1990 ,WHIT FASER COMPACTOR

SPARE PARTS

CATALOGS

Learn More -

P-2067 SCLAVOS HT DYE MACHINE YEAR 1994 3 PORTSREFERENCE NUMBER: P-2067 SCLAVOS HT DYE MACHINE YEAR 1994 3 PORTS SCLAVOS HT DYE MACHINE YEAR: 1994 3 PORTS 140 DEGREE C CAPACITY: 500 KILOGRAMS EQUIPPED WITH: HEAT EXCHANGER ADD TANKS DOSING PUMPS OPERATOR PLAT FORM & COMPLETE WITH ELECTRICAL PANEL MACHINE IS STILL IN PRODUCTION 15 HP MAIN PUMP 50HZ 1HP 3HP LOWER N UNLOADING QUANTITY AVAILABLE: 1 Learn More

P-2067 SCLAVOS HT DYE MACHINE YEAR 1994 3 PORTSREFERENCE NUMBER: P-2067 SCLAVOS HT DYE MACHINE YEAR 1994 3 PORTS SCLAVOS HT DYE MACHINE YEAR: 1994 3 PORTS 140 DEGREE C CAPACITY: 500 KILOGRAMS EQUIPPED WITH: HEAT EXCHANGER ADD TANKS DOSING PUMPS OPERATOR PLAT FORM & COMPLETE WITH ELECTRICAL PANEL MACHINE IS STILL IN PRODUCTION 15 HP MAIN PUMP 50HZ 1HP 3HP LOWER N UNLOADING QUANTITY AVAILABLE: 1 Learn More -

C-2476 NONWOVEN LINE FOR RUBBER-COIR MATERIALS DOA, WIDTH 1500mm TO 2150mm, YEAR 1994REFERENCE NUMBER: C-2476 NONWOVEN LINE FOR RUBBER-COIR MATERIALS DOA, WIDTH 1500mm TO 2150mm, YEAR 1994 SPECIFICATIONS: NONWOVEN LINE FOR RUBBER-COIR MATERIALS DOA WORKING WIDTH (ADJUSTABLE) 1500 TO 2150mm YEAR OF CONSTRUCTION 1994 SUITABLE FOR WEBS OF A SQUARE METER WEIGHT RANGE OF 150 - 1000 GR/SQM. HEATING OF THE OVEN BY SATURATED STEAM, 8 BAR. POWER REQUIREMENTS APPROX. 105 KW SPEED OF THE LINE: MAX. 15 M/MIN PRODUCTION CAPACITY MAX. 750 KG/H DEPENDING ON FIBERS. THE LINE IS CONSISTING OF: LAYING MACHINE TYPE 711 - 2200. THE WIDTH IS INFINITELY VARIABLE ADJUSTABLE FROM 1500 TO 2200 mm INFEED SYSTEM OF THE FLEECE LAYER WITH 6 ROLLERS MAGNET BAR SPRAYING AND DRYING LINE 737 + 745/310. MAX. 2200 mm WORKING WIDTH. RECIPE CONTROL. QUANTITY AVAILABLE: 1 Learn More

C-2476 NONWOVEN LINE FOR RUBBER-COIR MATERIALS DOA, WIDTH 1500mm TO 2150mm, YEAR 1994REFERENCE NUMBER: C-2476 NONWOVEN LINE FOR RUBBER-COIR MATERIALS DOA, WIDTH 1500mm TO 2150mm, YEAR 1994 SPECIFICATIONS: NONWOVEN LINE FOR RUBBER-COIR MATERIALS DOA WORKING WIDTH (ADJUSTABLE) 1500 TO 2150mm YEAR OF CONSTRUCTION 1994 SUITABLE FOR WEBS OF A SQUARE METER WEIGHT RANGE OF 150 - 1000 GR/SQM. HEATING OF THE OVEN BY SATURATED STEAM, 8 BAR. POWER REQUIREMENTS APPROX. 105 KW SPEED OF THE LINE: MAX. 15 M/MIN PRODUCTION CAPACITY MAX. 750 KG/H DEPENDING ON FIBERS. THE LINE IS CONSISTING OF: LAYING MACHINE TYPE 711 - 2200. THE WIDTH IS INFINITELY VARIABLE ADJUSTABLE FROM 1500 TO 2200 mm INFEED SYSTEM OF THE FLEECE LAYER WITH 6 ROLLERS MAGNET BAR SPRAYING AND DRYING LINE 737 + 745/310. MAX. 2200 mm WORKING WIDTH. RECIPE CONTROL. QUANTITY AVAILABLE: 1 Learn More -

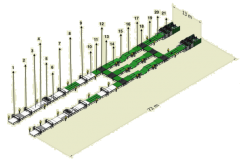

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More