Search results for: 'Electric d''

- Related search terms

- Electric d

- electric co

- Electrical c

- Electrical ca

- Electrical l

-

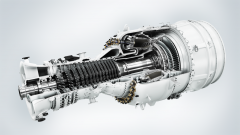

TT-2791 SIEMENS SST-400 STEAM TURBINE, 30MW, 10500V, 50HzTT-2791 SIEMENS SST-400 STEAM TURBINE, 30MW, 10500V, 50Hz QUANTITY: 1 Learn More

TT-2791 SIEMENS SST-400 STEAM TURBINE, 30MW, 10500V, 50HzTT-2791 SIEMENS SST-400 STEAM TURBINE, 30MW, 10500V, 50Hz QUANTITY: 1 Learn More -

P-5039 COMPLETE PLANT WITH DYEING – FINISHING – WEAVING - SEWING

P-5039 COMPLETE PLANT WITH DYEING – FINISHING – WEAVING - SEWINGP-5039 COMPLETE PLANT WITH DYEING – FINISHING – WEAVING - SEWING

PLAIN DYEING AND FINISHING EQUIPMENT:

7 DYEING MACHINES

9 AUTOMATIC DOSING SYSTEM

10 DYEING MACHINE – JIGGER

11 DYEING MACHINE – JIGGER

15 INSPECTION MACHINE

16 MACHINES FOR BONDING PIECES (GOODS)

18 WINDING MACHINE

19 INSPECTION MACHINE

20 MEASURING WINDING MACHINE

21 HEAT EXCHANGER

DOUBLING MACHINEYARN DYEING AND DRYING:

1 DYEING APPARATUS

2 DYEING APPARATUS

3 DYEING APPARATUS

4 PRESSURE DRYING APPARATUS – TANDEM

5 DYEING APPARATUS

6 DYEING APPARATUS

7 THE LOADING AND UNLOADING DEVICE

8 BRIDGE CRANE

9 PROCESS WATER REGENERATION + TANKSEWING:

8 SEWING MACHINE FOR WASHING GLOVES

9 CONTROL TABLES

10 PACKING MACHINESDOUBLING, TWISTING, WARPING AND WEAVING:

3 WINDING MACHINE

4 MOBILE REGALS FOR YARN STORAGEWARPING AND WEAVING:

1 WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

2 WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

3 WARPING MACHINE

4 SIZING MACHINE

5 SIZING MACHINE

13 COMPRESSOR FOR COMPRESSED AIR

14 KNOTTING MACHINES

15 ELEVATOR FOR BEAMS

16 ELEVATOR FOR BEAMS

17 PUNCH MACHINE

18 ELEVATOR FOR BEAMS

19 MOBILE REGALS FOR BEAM STORAGEWEAVING SAURER 1;2;3;4:

STAUBLI JACQUARD – WITH 560 HOOKS X 4 – 10 PIECES

STAUBLI JACQUARD – WITH 768 HOOKS X 4 – 4 PIECES

STAUBLI JACQUARD – WITH 1120 HOOKS X 2 - 2 PIECES

STAUBLI JACQUARD – WITH 912 HOOKS X 2 – 1 PIECEWEAVING SILK:

WEAVING MACHINE – LOOMS SM 93

CONTROL TABLEREADY MADE DEPARTMENT FOR TERRY BATHROBES:

CUTTING TABLE – BULLMERWERK – 1 PIECE

SEWING MACHINE – JUKI – 2 PIECES

SEWING MACHINE – JUKI – 1 PIECE

SEWING MACHINE – JUKI – 1 PIECE

SEWING MACHINE –LEVIS – 1 PIECE

SEWING MACHINE – PFAFF – 2 PIECES

SEWING MACHINE – JUKI – 2 PIECE

SEWING MACHINE – MAUSER SPECIAL – 1 PIECE

SEWING MACHINE – PFAFF – 2 PIECES

SEWING MACHINE – 1 PIECE

SEWING MACHINE – NECCHI – 4 PIECES

SEWING MACHINE – PFAFF – 1 PIECE

SEWING MACHINE – JUKI – 1 PIECELABOR MACHINES:

APPARATUS FOR MEASURING ZTWIST, TURN/ROLL – TORSIOMETER

APPARATUS FOR MEASURING THE FRICTION COEFFICIENT

LIGHTING CHAMBER

AA WINDING APPARATUS FOR THE DYEING TUBE THE SAMPLING DEVICE

WINDING APPARATUS FOR COLOR STANDARDS

YARN DYEING APPARATUS PRETEMA MULTICOLOR

DYNAMOMETER FOR SPINNING

SPEKTROFOTOMETER DATACOLOR INTERNATIONAL – LABOR MACHINE

APPARATUS FOR THE VISUAL APPEARANCE OF THE YARN – LABOR MACHINEADDITIONAL DESCRIPTION

PLAIN DYEING AND FINISHING EQUIPMENT:

7. DYEING MACHINE

SCHIRM

MODEL: SURFER

YEAR: 1994

CAPACITY : 380 – 400 KG

TECHNICAL INFORMATION:

WOVEN TERRY DYEING, WASHING AND BLEACHING AIR - FLOW

WORKING TEMPERATURE: UP TO 98˚ C (NOT HT)

SEDOMAT PC 3100

QUANTITY: 1 (NO 94)9. AUTOMATIC DOSING SYSTEM

LAWER

YEAR: 2002

CHEMICAL DISPENSING SYSTEM

20 PVC TANKS (CAPACITY 200 L TO 1200 L)

2 EXTERNAL TANKS CAPACITY 1500 L

TRANSFER PUMP

QUANTITY: 110. DYEING MACHINE - JIGGER

MCS

MODEL: S - 300 MCS

YEAR: 1993

TECHNICAL INFORMATION:

WORKING WIDTH : 3000MM

WOVEN FABRIC DYEING, WASHING AND BLEACHING AIR -FLOW

WORKING TEMPERATURE: UP TO 98˚ C (NOT HT)

MICROPROCESOR CT400

DIMENSIONS LENGTH 65000 MM X WIDTH 43000 MM X HEIGHT 25000 MM

INSTALLED ELECTRIC POWER: 3 X 63 A

QUANTITY: 1(NO 54)11. DYEING MACHINE - JIGGER

MCS

MODEL: S - 300 MCS

YEAR: 1993

TECHNICAL INFORMATION:

WORKING WIDTH : 1600MM

WOVEN FABRIC DYEING, WASHING AND BLEACHING AIR - FLOW

WORKING TEMPERATURE: UP TO 98˚ C (NOT HT)

MICROPROCESOR CT400

THE HYDRAULIC SYSTEM HAS FAILED/NOT WORKING

DIMENSIONS LENGTH 5,300 CM X WIDTH 4,300 CM X HEIGHT 2,500 CM

QUANTITY: 1(NO 53)15. INSPECTION MACHINE

MONFORTS

TECHNICAL INFORMATION:

MACHINE FOR INSPECTING THE GOOD

QUANTITY: 116. MACHINE FOR BONDING PIECES (GOODS)

GEBRUDER DOHLE

MODEL: 799/03

TECHNICAL INFORMATION:

SEWING MACHINE USED FOR BONDING GOODS

QUANTITY: 218. WINDING MACHINE

MARK: AEG

TECHNICAL INFORMATION:

WINDING GOODS

QUANTITY: 119. INSPECTION MACHINE

MONFORTS

MODEL: MBH

YEAR: 1977

TECHNICAL INFORMATION:

MACHINE FOR INSPECTING THE GOOD

QUANTITY: 120. MEASURING WINDING MACHINE

MENZEL

MODEL: MWE2

YEAR: 1986

TECHNICAL INFORMATION:

WINDING DIFFERENT LENGTHS OF GOOD

QUANTITY: 121. HEAT EXCHANGER

PT-S

YEAR: 2002

TECHNICAL INFORMATION:

RECUPERATION

QUANTITY: 123. DOUBLING MACHINE

MODEL: MLH

YEAR: 1975

TECHNICAL INFORMATION:

DOUBLING AND COMPOUNDING GOODS

QUANTITY: 1YARN DYEING AND DRYING:

1. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS

TYPE: 1250

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY:

6 INCHES BOBBIN : MAX 336 KG, MIN. 134 KG

5 INCHES BOBBIN : MAX 235 KG, MIN. 98 KG

WORKING TEMPERATURE: UP TO 140˚ C

PRESSURE : UP TO 4.5 BAR

BARCO SEDO SEDOMAT 3500

QUANTITY: 2 PCS (NO 12, NO 14)2. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS

TYPE: 850

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY;

6 INCHES BOBBIN : MAX 144 KG, MIN. 58 KG

5 INCHES BOBBIN : MAX 100 KG, MIN. 42 KG

WORKING TEMPERATURE: UP TO 140˚ C

PRESSURE : UP TO 4.5 BAR

BARCO SEDO SEDOMAT 3500

THICKNESS OF PLATE = 30 CM

PART OF A MACHINE IN THE BASEMENT, HEIGHT = 2.00 CM

DIMENSIONS: LENGTH 3100MM X WIDTH 2000MM X HEIGHT 1800MM X HEIGHT 2900MM

INSTALLED ELECTRIC

POWER: 45 KW

CUPBOARD FOR ELECTRONICS:

LENGTH 2500MM X WIDTH 600MM

INSTALLATION OF THE SOIL = 60CM DEEPER

(APPLY TO ALL INSTALLATION)

QUANTITY: 1(NO 18)3. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS TYPE 600

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY:

6 INCHES BOBBIN: MAX 84 KG, MIN. 34 KG

5 INCHES BOBBIN: MAX 59 KG, MIN. 26 KG

WORKING TEMPERATURE: UP TO 140˚ C

PRESSURE : UP TO 4.5 BAR

BARCO SEDO SEDOMAT 3500

DIMENSIONS: LENGTH 2500MM X WIDTH 2000MM X HEIGHT 1800MM X HEIGHT 2900MM

INSTALLED ELECTRIC POWER: 17 KW

CUPBOARD FOR ELECTRONICS:

LENGTH 2500MM X WIDTH 600MM

QUANTITY: 1(NO 16)4. PRESSURE DRYING APPARATUS – TANDEM

JASPER

YEAR: 1998

TECHNICAL INFORMATION:

DIMENSION: LENGTH 290CM WIDTH 3300MM X HEIGHT 1800MM X HEIGHT 2900MM

CUPBOARD FOR ELECTRONICS

LENGTH 250CM X WIDTH 60CM

QUANTITY: 2 TANDEM WORKING AS ONE UNIT5. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS

TYPE: 1250

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY:

6 INCHES BOBBIN : MAX 336 KG, MIN. 134 KG

5 INCHES BOBBIN: MAX 235 KG, MIN. 98 KG

WORKING TEMPERATURE: UP TO 98˚ C

PRESSURE: UP TO 4.5 BAR

MANUAL PROCESSOR

DIMENSIONS: LENGTH 2800MM X WIDTH 3100MM X HEIGHT 2500MM X HEIGHT 2900MM

(WITH A DOSING DEVICE IN THE FORM OF "V")

INSTALLED ELECTRIC

POWER: 45 KW

CUPBOARD FOR ELECTRONICS: LENGTH 2500MM X WIDTH 60MM

QUANTITY: 1 (NO 13)6. DYEING APPARATUS

THEN

MODEL: HL 40/7,8

YEAR: 1986

WIDTH: 1800MM

5 INCHES BOBBIN: MAX 12 PIECES

WORKING TEMPERATUR: UP TO 140˚ C

HEIGHT: 2160MM

PRESSURE: UP TO 4,5 BAR

INSTALLED ELECTRIC POWER – 3X16 A

TECHNICALINFORMATION: DYEING APPARATUS

DIMENSIONS: LENGTH 1600MM

QUANTITY: 17. THE LOADING AND UNLOADING DEVICE

JASPER

YEAR: 1998

TECHNICAL INFORMATION; LOADING DEVICE FOR BOBBINS

THICKNESS OF PLATE = 300MM (APPLY TO ALL INSTALLATIONS)

PART OF A MACHINE IN THE BASEMENT, HEIGHT = 2000MM (APPLY TO ALL INSTALLATION)

DIMENSIONS : Ø 1700MM : HEIGHT1600MM

INSTALLED ELECTRIC POWER : 10KW

QUANTITY: 18. BRIDGE CRANE

TECHNICAL INFORMATION:

THE CARGO TRANSFER

QUANTITY : 29. PROCESS WATER REGENERATION + TANK

JASPER

TECHNICAL INFORMATION:

STORAGE OF WATER FOR THE PRODUCTION PROCESS

QUANTITY : 1SEWING:

8. SEWING MACHINE FOR WASHING GLOVES

TEXPA ARBTER

MODEL: WASCHLA 10

YEAR: 1994

TECHNICAL INFORMATION:

SEWING WASHING GLOVES, FITTING LABELS AND CORD.

QUANTITY: 19. CONTROL TABLES

TECHNICAL INFORMATION:

GOOD INSPECTION AND WEIGHING

QUANTITY: 310. PACKING MACHINE

BECK

TECHNICAL INFORMATION:

PACKING TOWELS INTO FOIL

QUANTITY: 13. WINDING MACHINE

SCHLAFHORST

MODEL: BKN

YEAR: 1975

TECHNICAL INFORMATION:

96 PIECES SPINDLES (2 X 48 SPINDLES)

QUANTITY: 24. MOBILE REGALS FOR YARN STORAGE

INCLUDED SELLING YARN

QUANTITY: 3WARPING AND WEAVING:

1. WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

HACOBA

MODEL: USK T1000/SM

YEAR: 1990

TECHNICAL INFORMATION:

ELEKTRONIC COMPUTER, AUTOMATIC SETTING OF CONE,

DEVICE FOR CROSSING THE FLOOR DIVISION THREADS

PRELIMINARY SETTING : OF LENGTH IN METERS (YARN LEGTH RECORDER), NUMBER OF REVOLUTIONS, …

CONE CREEL/CREELS 2 X 32 CROSS-WOUND COME (MAX. DIAMETER CROSS-WOUND IS 225 MM)

WETTING TROUTH FOR COLD STARCHING BY APPLICATOR ROLLER

MAXIMUM WARPING WIDTH : 240 CM/ WARPING WIDTH (MARKED) 240 CM

QUANTITY: 12. WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

SUCKER MÜLLER HACOBA

MODEL: USK -S/SM

YEAR: 1998

TECHNICAL INFORMATION:

MAXIMUM WARPING WIDTH : 2000MM

QUANTITY: 13. WARPING MACHINE

BENNINGER

MODEL: 97126 FB

YEAR: 1978

TECHNICAL INFORMATION:

MAX. NUMBER OF CONES 704

QUANTITY: 14. SIZING MACHINE

BENNINGER ZELL

MODEL: BZ-7M

YEAR: 1975

TECHNICAL INFORMATION:

MAXIMUM WORKING WIDTH 2400MM

TOTAL BEAM 8 PCS

DRUM DRYER TEFLONIZED

MAHLO MOISTURE CONTROL

SIZING KITCHEN

QUANTITY: 15. SIZING MACHINE

BENNINGER ZELL

MODEL: XK Z6F

YEAR: 1986

TECHNICAL INFORMATION:

MAX. WORKING WIDTH 240 CM

TOTAL BEAM 12 PCS

DRUM DRYER TEFLONIZED

MAHLO MOISTURE CONTROL

QUANTITY: 113. COMPRESSOR FOR COMPRESSED AIR

KAESER

MODEL: CS 76, ABT 72

YEAR: 2003

NO. OF MASHINES: 314. KNOTTING MACHINE

KNOTEX

MODEL: AS/2 8013 EA03

YEAR: 2002

TECHNICAL INFORMATION:

WITH TWO TROLLEY SIZE 2500MM

QUANTITY: 515. ELEVATOR FOR BEAMS

GENKINGER

MODEL: EE-KHHR

YEAR: 1998

TECHNICAL INFORMATION:

LIFTING UP THE WEAVING BEAMS

QUANTITY: 116. ELEVATOR FOR BEAMS

HUBTEX

MODEL: KHHW

YEAR: 1988

TECHNICAL INFORMATION:

LIFTING UP THE WEAVING BEAMS

QUANTITY: 117. PUNCH MACHINE

GROSSE

MODEL: LSE 600

YEAR: 1998

TECHNICAL INFORMATION:

PUNCHING CARDS

QUANTITY: 118. ELEVATOR FOR BEAMS

TECHNICAL INFORMATION:

LIFTING UP THE WEAVING BEAMS

QUANTITY: 119. MOBILE REGALS FOR BEAM STORAGE

TECHNICAL INFORMATION:

UP - DOWN MOVING REGALS

QUANTITY: 13WEAVING SAURER 1;2;3;4:

1. STÄUBLI JACQUARD

WITH 560 HOOKS X 4

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 102. STÄUBLI JACQUARD

WITH 768 HOOKS X 4

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 43. STÄUBLI JACQUARD

WITH 1120 HOOKS X 2

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 24. STÄUBLI JACQUARD

WITH 912 HOOKS X 2

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MASHINES: 1WEAVING SILK:

1. WEAVING MACHINE

SOMET

MODEL: MASTER SM93

YEAR OF CONSTRUCTION: 1990

TECHNICAL INFORMATION:

WITH STÄUBLI JACQUARD, JC4 CONTROLLER

5-6 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 22. CONTROL TABLE

TECHNICAL INFORMATION:

GOOD INSPECTION

NUMBER OF MACHINES: 1

READY MADE DEPARTMENT FOR TERRY BATHROBES:

1. CUTTING TABLE

BULLMERWERK

MODEL: KOMET II

TECHNICAL INFORMATION:

CUTTING GOODS BY CUTTING PATTERNS FOR TERRY

BATHROBES

QUANTITY: 12. SEWING MACHINE

JUKI

TECHNICAL

INFORMATION:

SEWING TERRY

PRODUCTS

QUANTITY: 23. SEWING MACHINE

JUKI

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 15. SEWING MACHINE

JUKI

TECHNICAL

INFORMATION:

SEWING TERRY

PRODUCTS

TRIPLE STICH OVERLOK

QUANTITY: 16. SEWING MACHINE

LEWIS

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

BLIND STICH

QUANTITY: 17. SEWING MACHINE

PFAFF

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 28. SEWING MACHINE

JUKI

TECHNICAL

INFORMATION:

SEWING TERRY PRODUCTS

OVERLOK

QUANTITY: 29. SEWING MACHINE

MAUSER SPECIAL

TECHNICAL INFORMATION:

SEWING NAPKINS

OVERLOK

QUANTITY: 110. SEWING MACHINE

PFAFF

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 211. SEWING MACHINE

TECHNICAL INFORMATION:

SEWING MACHINE USED FOR BONDING GOODS

QUANTITY: 112. SEWING MACHINE

NECCHI

TECHNICAL INFORMATION:

SEWING MACHINE USED FOR

BONDING GOODS

QUANTITY: 413. SEWING MACHINE

PFAFF

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 114. SEWING MACHINE

JUKI

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 1LABOR MACHINES:

1. APPARATUS FOR MEASURING ZTWIST, TURN/ROLL - TORSIOMETER

MARK: CALDERARA BOSI

YEAR: 1989

QUANTITY: 12. APPARATURS FOR MEASURING THE FRICTION COEFFICIENT -

ZWEIGLE

MODEL: µ-METER G 530

TYPE: 530

YEAR: 1972

TECHNICAL INFORMATION:

NOT WORKING

QUANTITY: 13. LIGHTING CHAMBER

MARK: DATACOLIR INTERNATIONAL

YEAR: 2004

TECHNICAL INFORMATION:

FROM 4 TYPES OF LIGHT ONLY WORKS 1

QUANTITY: 14.AA WINDING APPARATURS FOR THE DYEING TUBE THE SAMPLING DEVICE

ZWEIGLE (REUTLIGEN)

QUANTITY: 15. WINDING APPARATURS FOR COLOR STANDARDS

IZDELANO V SVILANITU

YEAR: 2001

QUANTITY: 16. YARN DYEING APPARATURS PRETEMA MULTICOLOR

PRETEMA

MODEL: TYPE MC-320

YEAR: 1982

TECHNICAL INFORMATION:

V 22 W 1800

DIMENSIONS: LENGTH 119 CM X WIDTH 61 CM X HEIGHT 126 CM

INSTALLED ELECTRIC POWER: 1800 W

QUANTITY: 17. DYNAMOMETER FOR SPINNING

KARL SCHRÖDER

YEAR: 1977

QUANTITY: 18. SPEKTROFOTOMETER DATACOLOR INTERNATIONAL

DATACOLOR INTERNATIONAL

MODEL: SPECTRAFLASH SF600 PLUS CT

YEAR: 1999

TECHNICAL INFORMATION:

RATINGS: 100-240 V ̴47-63 HZ, 100 VA

NOT WORKING (DO NOT KNOW THE TYPE OF TROUBLE)

QUANTITY: 19. APPARATURS FOR THE VISUAL APPEARANCE OF THE YARN

ZWEIGLE KG REITLINGEN

QUANTITY: 1QUANTITY: 1 COMPLETE PLANT

Learn More -

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More -

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More -

TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019 1. MINI SUGAR CRUSHER PLANT 2. 200 TCD 3. MANUFACTURING YEAR 2019 4. PLANT RUNNING 2020 5. PLANTS RUNNING OVER 180 DAYS Learn More

TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019TT-6624 MINI SUGAR CRUSHER PLANT, 200 TCD, YEAR 2019 1. MINI SUGAR CRUSHER PLANT 2. 200 TCD 3. MANUFACTURING YEAR 2019 4. PLANT RUNNING 2020 5. PLANTS RUNNING OVER 180 DAYS Learn More -

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More -

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More -

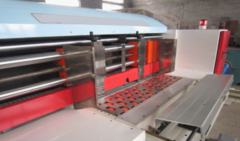

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More -

K-8157 COAL FIRED POWER PLANT (2 X 50MW)

K-8157 COAL FIRED POWER PLANT (2 X 50MW)K-8157 COAL FIRED POWER PLANT (2 X 50MW)

ENERGY BOILERS (CAE)

TURBINE SYSTEMS

STEAM TURBINES (TA) - DSL ARE 50 - 1

-CONDENSING TURBINE WITH TWO ADJUSTABLE OUTLETS, SUCH AS "ACTING" ON A SINGLE LINE OF TREES, DESIGNED TO DRIVE THE AC GENERATOR DIRECT-TYPE TH 60-2

-IS COMPOSED OF TWO BODIES: THE BODY OF HIGH PRESSURE (CIP) AND MEDIUM AND LOW PRESSURE BODY (CMP + CJP)

-HAS TWO ADJUSTABLE OUTLETS (PLUG SOCKETS AND PLUG HEATING) AND FIVE FIXED DOSES REGENERATIVE CIRCUIT FEEDSQUARES OF 600 CARS OVER T/H (WITH BUCKET WHEEL AND ARM LENGTH 12 M) - 4 PCS

-TIP HAMMER CRUSHERS CCA - 160 TO 2 PIECES

- RUBBER BANDS COAL TRANSPORTTHE MAIN EQUIPMENT IS ADDED TO ENSURE PROPER OPERATION FOLLOWING:

- SOLID FUEL STORAGE

- INSTALLATIONS AND INDUSTRIAL WATER SUPPLIES AND WASTEWATER DISCHARGE

- INSTALLATION OF EXHAUST HYDRAULIC SLAG

- WATER TREATMENT STATION

TO USE COAL, WEIGHT 88%, 12% NATURAL GASQUANTITY: 1

Learn More