Search results for: 'Reference+No'

-

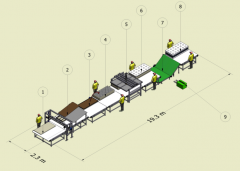

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

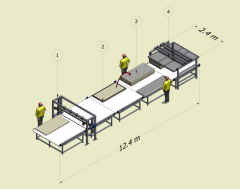

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

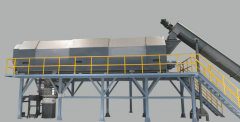

TT-7164 MIURA HIGH PRESSURE STEAM BOILER, GAS-FIREDTT-7164 MIURA HIGH PRESSURE STEAM BOILER, GAS-FIRED 1. MIURA INDUSTRIAL HIGH-PRESSURE, GAS-FIRED MODEL LXH-300 STEAM BOILER. 2. CAPACITY OF 300 BOILER HORSEPOWER (BHP). 3. RATED 30 PSI. QUANTITY: 1 Learn More

TT-7164 MIURA HIGH PRESSURE STEAM BOILER, GAS-FIREDTT-7164 MIURA HIGH PRESSURE STEAM BOILER, GAS-FIRED 1. MIURA INDUSTRIAL HIGH-PRESSURE, GAS-FIRED MODEL LXH-300 STEAM BOILER. 2. CAPACITY OF 300 BOILER HORSEPOWER (BHP). 3. RATED 30 PSI. QUANTITY: 1 Learn More -

TT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHPTT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHP 1. MIURA LXH-300 IS A HIGH-PRESSURE, GAS-FIRED STEAM BOILER. 2. WATER TUBE, CAPACITY OF 300 BOILER HORSEPOWER (BHP). 3. RATED 30 PSI. QUANTITY: 1 Learn More

TT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHPTT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHP 1. MIURA LXH-300 IS A HIGH-PRESSURE, GAS-FIRED STEAM BOILER. 2. WATER TUBE, CAPACITY OF 300 BOILER HORSEPOWER (BHP). 3. RATED 30 PSI. QUANTITY: 1 Learn More -

TT-5475 ALUMINIUM LANDING CRAFT LCM-8-2565, 75FT, YEAR 1969TT-5475 ALUMINIUM LANDING CRAFT LCM-8-2565, 75FT, YEAR 1969 75FT ALUMINIUM LCM-8 LANDING CRAFT REPORTED IN GOOD OVERALL CONDITION. OPERATIONAL BOW RAMP. 60 LONG TON DECK CAPACITY USED YEAR BUILT: 1969 BUILDER: MARINETTE, WI FOR US GOVERNMENT CLASSIFICATION: NONE REQUIRED CONSTRUCTION: ALUMINIUM GROSS / NET TONS: 110 / 88 # OF PASSENGERS: 0 LOADLINE: NONE REQUIRED Learn More

TT-5475 ALUMINIUM LANDING CRAFT LCM-8-2565, 75FT, YEAR 1969TT-5475 ALUMINIUM LANDING CRAFT LCM-8-2565, 75FT, YEAR 1969 75FT ALUMINIUM LCM-8 LANDING CRAFT REPORTED IN GOOD OVERALL CONDITION. OPERATIONAL BOW RAMP. 60 LONG TON DECK CAPACITY USED YEAR BUILT: 1969 BUILDER: MARINETTE, WI FOR US GOVERNMENT CLASSIFICATION: NONE REQUIRED CONSTRUCTION: ALUMINIUM GROSS / NET TONS: 110 / 88 # OF PASSENGERS: 0 LOADLINE: NONE REQUIRED Learn More -

TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE YEAR: 2014 HOUSED: YES, IN A AMBIENT CONTROLLED WAREHOUSE IN TWO LOCATIONS WHAT DOESN’T HAVE TO BE INDOORS, IS OUTSIDE ON AN ENCLOSED FIELD, 2.5 HOURS AWAY FROM THE WAREHOUSES. SKIDDED: NO PASC CONDITION RATING: A CONDITION DETAILS: NEVER USED UNITS AVAILABLE: 1 CONNECTION STATUS: DISCONNECTED WARRANTY: NO WARRANTY DETAILS: EXP DEC 2018 Learn More

TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE YEAR: 2014 HOUSED: YES, IN A AMBIENT CONTROLLED WAREHOUSE IN TWO LOCATIONS WHAT DOESN’T HAVE TO BE INDOORS, IS OUTSIDE ON AN ENCLOSED FIELD, 2.5 HOURS AWAY FROM THE WAREHOUSES. SKIDDED: NO PASC CONDITION RATING: A CONDITION DETAILS: NEVER USED UNITS AVAILABLE: 1 CONNECTION STATUS: DISCONNECTED WARRANTY: NO WARRANTY DETAILS: EXP DEC 2018 Learn More -

TT-3996 STEEL LANDING CRAFT, 135FT, STEEL LCUTT-3996 STEEL LANDING CRAFT, 135FT, STEEL LCU 135 X 30 X 3 LIGHT DRAFT, STEEL LCU USED 135FT LANDING CRAFT CLASSIFICATION: NONE REQUIRED CONSTRUCTION: STEEL GROSS / NET TONS: 187 CERTIFIED: NO # OF PASSENGERS: 0 LOADLINE: NONE REQUIRED COMMENTS USED 135FT STEEL LANDING CRAFT(LCU) FOR SALE. IN CURRENT OPERATION. HAS 200 TON DECK CAPACITY. OPERATING BOW AND STERN RAMPS. HAS FLANKING RUDDERS. THE VESSEL IS EQUIPPED WITH STATEROOM, CREW QUARTERS FOR 13, OFFICE, LOUNGE, AND GALLEY. Learn More

TT-3996 STEEL LANDING CRAFT, 135FT, STEEL LCUTT-3996 STEEL LANDING CRAFT, 135FT, STEEL LCU 135 X 30 X 3 LIGHT DRAFT, STEEL LCU USED 135FT LANDING CRAFT CLASSIFICATION: NONE REQUIRED CONSTRUCTION: STEEL GROSS / NET TONS: 187 CERTIFIED: NO # OF PASSENGERS: 0 LOADLINE: NONE REQUIRED COMMENTS USED 135FT STEEL LANDING CRAFT(LCU) FOR SALE. IN CURRENT OPERATION. HAS 200 TON DECK CAPACITY. OPERATING BOW AND STERN RAMPS. HAS FLANKING RUDDERS. THE VESSEL IS EQUIPPED WITH STATEROOM, CREW QUARTERS FOR 13, OFFICE, LOUNGE, AND GALLEY. Learn More -

TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR BRAND: NORDMECCANICA MODEL: SUPER SIMPLEX YEAR: 1995 AVAILABLE: NOW QUANTITY: 1 Learn More

TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR BRAND: NORDMECCANICA MODEL: SUPER SIMPLEX YEAR: 1995 AVAILABLE: NOW QUANTITY: 1 Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

ENTRY LEVEL MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2479 ENTRY LEVEL MULTI NOZZLE ELECTROSPINNING UNIT THIS MACHINE IS DESIGNED TO ACCOMMODATE THE MAXIMUM COMPONENTS REQUIRED FOR AN OPTIMIZED AND VERSATILE ELECTROSPINNING PROCESS. IT’S AN IDEAL SOLUTION FOR LOWER-BUDGET PROJECTS WORKING ON SMALL-SCALE NANOFIBERS RESEARCH. IT HAS 3 HYBRID NOZZLES, SPINNING ON A ROTATING DRUM COLLECTOR OR PLATE COLLECTOR, THEREFORE ENABLING THE PRODUCTION OF BOTH WELL-ALIGNED AND RANDOMLY COLLECTED NANOFIBERS. THE HOMOGENEITY SYSTEM ALLOWS THE USER TO PRODUCE A UNIFORM AND HOMOGENEOUS NANOFIBERS MEMBRANES. SPECIFICATIONS: SPINNING-TYPE: SIDE BY SIDE SPINNING CHASSIS: ENCLOSED CHASSIS FOR SPINNING AREA FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN TOTAL WEIGHT: APPROX.60 KGS DIMENSIONS: 740 X 645 X 770 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 30 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.170 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES: 3 NOZZLE NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRINGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML ROTATING COLLECTOR MATERIAL ALUMINUM DIMENSIONS OF THE DRUM: 100 X 220 mm FIBER DEPOSITION AREA: 314 X 220 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED (CM/S): 52.3 CM/S TO 261.6 CM/S STROKE OF COATING HOMOGENEITY SYSTEM: 30 TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm /SEC STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE 275 X 150 mm UNIQUE USER INTERFACE 4.3" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAFETY FUNCTION EMERGENCY BUTTON HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More

ENTRY LEVEL MULTI NOZZLE ELECTROSPINNING UNITREFERENCE NUMBER: A-2479 ENTRY LEVEL MULTI NOZZLE ELECTROSPINNING UNIT THIS MACHINE IS DESIGNED TO ACCOMMODATE THE MAXIMUM COMPONENTS REQUIRED FOR AN OPTIMIZED AND VERSATILE ELECTROSPINNING PROCESS. IT’S AN IDEAL SOLUTION FOR LOWER-BUDGET PROJECTS WORKING ON SMALL-SCALE NANOFIBERS RESEARCH. IT HAS 3 HYBRID NOZZLES, SPINNING ON A ROTATING DRUM COLLECTOR OR PLATE COLLECTOR, THEREFORE ENABLING THE PRODUCTION OF BOTH WELL-ALIGNED AND RANDOMLY COLLECTED NANOFIBERS. THE HOMOGENEITY SYSTEM ALLOWS THE USER TO PRODUCE A UNIFORM AND HOMOGENEOUS NANOFIBERS MEMBRANES. SPECIFICATIONS: SPINNING-TYPE: SIDE BY SIDE SPINNING CHASSIS: ENCLOSED CHASSIS FOR SPINNING AREA FEEDING AREA MATERIAL: PE 1000 (HIGH DENSITY, CHEMICAL RESISTANT) COLLECTOR MATERIAL: 7000 SERIES ALUMINUM ALLOY, STAINLESS STEEL LED ILLUMINATION EXHAUST FAN TOTAL WEIGHT: APPROX.60 KGS DIMENSIONS: 740 X 645 X 770 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 30 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.170 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA NUMBER OF NOZZLES: 3 NOZZLE NOZZLE MATERIAL: ELECTRICALLY CONDUCTIVE STAINLESS STEEL NOZZLE INNER DIAMETER: 0.8 mm COMPATIBLE WITH STANDARD SYRINGE NOZZLES MINIMUM REQUIRED SOLUTION FOR SINGLE NOZZLE FEEDING: 2 ML ROTATING COLLECTOR MATERIAL ALUMINUM DIMENSIONS OF THE DRUM: 100 X 220 mm FIBER DEPOSITION AREA: 314 X 220 mm DRUM ROTATING SPEED: 100 TO 500 RPM SURFACE SPEED (CM/S): 52.3 CM/S TO 261.6 CM/S STROKE OF COATING HOMOGENEITY SYSTEM: 30 TO 80 mm SPEED OF COATING HOMOGENEITY SYSTEM: 2 TO 20 mm /SEC STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE 275 X 150 mm UNIQUE USER INTERFACE 4.3" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS SAFETY FUNCTION EMERGENCY BUTTON HV WARNING LIGHT ELECTRICAL ISOLATED & GROUNDED CABINET OVER CURRENT PROTECTION TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 1000 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 150 KGS. Learn More