Search results for: 'and+ma'''

-

S-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HR

S-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HRS-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HR

LAUNDRY SOAP PRODUCTION LINE

CAPACITY: 1000 TO 1500 KG/HR

I. PROJECT INSTRUCTION

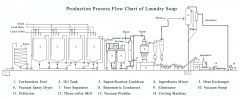

THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES, VACUUM EXTRUDING AND THEN CUTTING INTO SOAPS.

THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT.

PLEASE NOTICE THAT:

IT IS A TURN-KEY PROJECT. THE PROFESSIONAL TEAM PROVIDE YOU ALL MACHINES AND ACCESSORIES, THE WHOLE PROCESS OF PRODUCTION, FORMULA, LAYOUT DESIGN, MACHINES INSTALLATION, PRODUCTS TRIAL ETC. ALL SOLUTION ACCORDING TO YOUR REQUIREMENTS.

THE QUOTATION INCLUDES ALL EXCEPT: BOILER, WORKSHOP BUILDING, HEAT INSULATING MATERIAL, WIRES, PACKING MACHINE, AND CONSUMABLE MATERIALS FOR INSTALLING (WELDING ROD, CRANE, ELECTRIC WELDER, ETC.).1. PRODUCTION REQUIREMENTS:

A. STEAM BOILER: 2 MT/HR.

B. WORKSHOP AREA: LARGER THAN 300 M². (L: 35M, W: 7M, H: 7M)

C. POWER: 130 KW, 380 V, 50 HZ.

D. WATER: CIRCULATING WATER FOR VACUUM DRYING SYSTEM: 40 M3; PRODUCTION WATER.

E. CAPACITY: 1000 TO 1500 KG/HR, 8 TO 12 TON/DAY (8 HR/DAY). OIL CONSUMTION: 5 TO 8 TON/DAY.

F. WORKER: 10 TO 12 WORKERS.

2. MATERIAL AND CONSUMING FOR PRODUCING SOAP:

OIL OR FAT OF PLANT OR ANIMAL (PALM OIL, COCONUT OIL, TALLOW OIL, ETC.), CAUSTIC SODA (NAOH), SODIUM-CHLORIDE (NACL), SODIUM SILICATE, FRAGRANCE, PIGMENT, ETC.

3. PRODUCTION PROCESS:

MIX AND MELT OIL --> SAPONIFICATION --> ADD OTHER INGREDIENTS --> VACUUM DRYING --> SOAP NOODLE --> GRINDING --> VACUUM EXTRUDING --> CUTTING.III. SPECIFICATIONS AND QUOTATION OF EQUIPMENT

1. CARBURETION WORKSHOP:

MIX KINDS OF OIL TOGETHER ON THE BASIS OF THE FORMULA. DEPOSIT AND TAKE OUT THE UNSAPONIFIABLES.ITEM 001

CARBURETION POOL

MIX KINDS OF OIL TOGETHER ON THE BASIS OF THE FORMULA.

VOLUME: 10 M3.

FIELD WORK

QUANTITY: 1ITEM 002

STORAGE TANK FOR REFINE OIL

SIZE: Φ2000X2600, 8.2 M3;

FEATURE: WITH COILER INSIDE.

QUANTITY: 1ITEM 003

WATER PUMP, OIL PUMP, CAUSTIC SODA PUMP

POWER: 1.5 KW/SET.

QUANTITY: 4ITEM 004

SEAMLESS TUBE

(Φ76X3.5) (Φ57X3.5), ETC.

QUANTITY: SEVERALITEM 005

VALVE

Φ65, Φ40, ETC.

QUANTITY: SEVERALITEM 006

FLANGE, SCREW, ELBOW, GASKET.

QUANTITY: SEVERAL2. OIL AND FAT SAPONIFICATION WORKSHOP:

OIL AND ALKALI DO REACTIONS IN THE SAPONIFICATION CAULDRONS. IT IS A GOOD COMBINATION OF FOUR SAPONIFICATION CAULDRONS, WATER CIRCULATES FROM NO. 1 CAULDRON TO NO. 4, IT SAVES WATER, NAOH AND NACL AT THE MOST.ITEM 007

SAPONIFICATION CAULDRON

SAPONIFICATION BETWEEN OIL AND NAOH, LASTING ABOUT 40 TO 60 HRS. SUFFICIENT REACTION. SAVE WATER.

SIZE: Φ2800 X 3000, 20 M3

AUXILIARY FACILITIES: LIQUID CAUSTIC SODA POOL.2 M3

FIELD WORK

QUANTITY: 4ITEM 008

HIGH TEMPERATURE AND HIGH PRESSURE SOAP PUMP

POWER: 5.5 KW/SET

QUANTITY: 3ITEM 009

SEAMLESS TUBE

(Φ76X3.5)(Φ57X3.5), ETC.

QUANTITY: SEVERALITEM 010

VALVE

Φ76, Φ48, ETC.

QUANTITY: SEVERALITEM 011

FLANGE, SCREW, ELBOW, GASKET.

QUANTITY: 13. SOAP VACUUM DRYING SYSTEM:

TO MAKE SOAP MATERIALS FLASH DRY AND COOL INSTANTLY. TO CONTROL THE FATTY ACID CONTENT FROM 50% TO 80%. TO IMPROVE THE QUALITY OF SOAP MATERIALS.ITEM 012

INGREDIENTS MIXTURE TANK

PUT ESSENCE, PIGMENT IN THE LIQUID SOAP. HEATING AND MIXING

SIZE: 1.8 M3, Φ1200X1500

FEATURE: WITH PIPE LINER, HEATING AND MIXING

POWER: 4 KW/SET.

QUANTITY: 2ITEM 013

HEAT EXCHANGER

HEAT THE LIQUID SOAP RAPIDLY

SIZE: Φ325 X 4000

QUANTITY: 1ITEM 014

VACUUM SPRAY DRYER

THE VACUUM DRYER MAKES THE SOAP FLAKES THINNER AND EVENER, AND COOLS THEM DOWN MORE QUICKLY, TO IMPROVE THE QUALITY OF SOAP NOODLES.

ADOPT HARD TOOTH SURFACE GEAR REDUCER AND THE OIL PUMP INSIDE LUBRICATES AUTOMATICALLY AND MAKES A LONG LIFESPAN. THE THICKNESS OF BARREL IS 14 MM, THE INNER WALL IS PROCESSED BY VERTICAL LATHE TO ACHIEVE THE COAXIALITY AND SMOOTH SURFACE. THE SHAFT IS MADE BY A Φ108 X 14mm SEAMLESS TUBE. THE NOZZLE (Φ10mm) IN THE SHAFT SPRAYS SOAP MATERIALS, AND THE THREE BLADES SCRAPE THEM DOWN, AND THE SOAP MATERIALS DRY OUT FAST AND UNIFORM. THE WHOLE SET OF VACUUM SYSTEM CAN MAKE SOAPS WITH FATTY ACID CONTENT FROM 55% TO 80%.

1. TYPE: XSD-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. BARREL DIAMETER: Φ 1200mm

4. MOUTH DIAMETER: 10mm

5. SPEED: 13 R/MIN

6. POWER: 3 KW

7. DIMENSION: Φ 1600 X 4500mm

8. WEIGHT: 3200 KGS

QUANTITY: 1ITEM 015

FINE SEPARATORS

SEPARATE THE SOAP POWDER FROM THE WATER WHEN VACUUM DRYING

QUANTITY: 2ITEM 016

BAROMETRIC CONDENSER

CONDENSE WATER FROM THE SOAP

QUANTITY: 1ITEM 017

ELIMINATOR

DRAW OFF WATER

QUANTITY: 1ITEM 018

PELLETIZER

IT IS USED TO PRESS THE VACUUM-DRIED SOAP MATERIALS INTO SOAP NOODLES. LONG DOUBLE SCREWS TURN INWARD TO DRIVE SOAP MATERIALS TO EXTRUDE SOAP NOODLES THROUGH PORE PLATES.

1. TYPE: XSN-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. SCREW DIAMETER: Φ 230mm X 2

4. POWER: 15 KW

5. DIMENSION: 3100 X 1200 X 1550mm

6. WEIGHT: 3000 KGS

QUANTITY: 1ITEM 019

STAGE VACUUM PUMP

KEEP THE VACUUM SYSTEM IN VACUUM STATE

POWER: 15 KW

QUANTITY: 1ITEM 020

BUFFER TANK OF VACUUM PUMP

PROTECT THE VACUUM PUMP FROM STEAM WATER

SIZE: Φ600 X1200

QUANTITY: 1ITEM 021

SOAP PUMP, WATER PUMP

SOAP PUMP: SPECIAL CONSTRUCTURE, DRAW LIQUID SOAP FROM INGREDIENTS MIXURE TANK TO HEAT EXCHANGER. POWER: 7.5 KW

WATER PUMP: FOR WATER CIRCULATING. POWER: 5.5 KW

QUANTITY: 2ITEM 022

SEAMLESS TUBE AND VALVE

Φ76 Φ48, ECT.

QUANTITY: SEVERALITEM 023

FLANGE, SCREW, ELBOW, ETC.

QUANTITY: SEVERAL4. FINISHING LINE:

MILL SOAP NOODLES TWICE, VACUUM EXTRUDING SOAP BAR, CUT SOAP CAKES, AT THE SAME TIME STAMP LOGO ON SOAP CAKES.ITEM 024

THREE-ROLL GRINDING MILL

THREE-ROLL GRINDING MILL IS USED TO GRIND, PRESS THE MATERIAL TO INCREASE ITS DENSITY AND QUALITY.

1. ROLL DIAMETER: Φ260

2. ROLL LENGTH: 780mm

3. MOTOR POWER: 7.5KW

4. ROLL SPEED RATIO: 1:3:9

5. DIMENSION: 1500 X 1200 X 1000mm

6. WEIGHT: 2400 KGS

QUANTITY: 2ITEM 025

VACUUM PLODDER

VACUUM PLODDER IS USED TO GRIND, REFINE AND PRESS SOAP MATERIAL INTO SOAP BAR. THE ABOVE AND BELOW SCREWS AND TWO ORIFICE PLATES PRESS AND REFINE THE SOAP MATERIAL AND MAKE THE SOAP BAR TIGHT AND THE SURFACE BRIGHT.

THE MOTOR AND THE REDUCER ARE SEPARATED, FOR LONG LIFE-SPAN AND MAINTENANCE. THE BELOW SCREW’ SPEED IS ADJUSTABLE TO REGULATE THE PRODUCTION CAPACITY. THE VACUUM CHAMBER HAS A VISION GLASS TO WATCH THE INNER, THE VACUUM METER TESTS THE VACUUM DEGREE. THE HEATER INSIDE THE OUTLET ADOPT AUTOMATIC TEMPERATURE CONTROL SYSTEM. THE JACKETS OF THE ABOVE AND BELOW BARRELS ARE CONNECTED TO A CIRCULATING WATER SOURCE.

1. TYPE: XS-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. DIAMETER OF SCREW: Φ230mm

4. SPEED: TOP 15; BOTTOM: 12 TO 18

5. POWER: TOP: 11 KW; BOTTOM: 15 KW

6. DIMENSION: 4350 × 1200 × 2630mm

7. WEIGHT: 4500 KGS

QUANTITY: 1ITEM 026

ELECTRONIC

CUTTING MACHINE

SOAP ELECTRONIC CUTTING MACHINE IS USED TO CUT SOAPS INTO CAKES AND STAMP PATTERNS ON THE SOAP. ADOPT DELTA SERVO MOTOR AND CONVERTER, VOLTAGE STABILIZER AND PRECISION PURIFIED AC VOLTAGE STABILIZER, TO PROTECT MOTOR AND ELECTRICAL COMPONENTS AND TO KEEP HIGH ACCURACY.

THE MOULD WHEELS RUN BY THE MOVING OF SOAP BAR FROM VACUUM PLODDER. BECAUSE OF THE ELECTRONIC TRACKING SYSTEM, IT CAN CUT SOAP BARS WITH ANY SIZES AND WEIGHT AFTER SETTING THE COMPUTER.

THE CHARACTERS AND THE SHAPE OF SOAP IS CLEAR AND NEAT

THE SIZE AND PATTERN ARE DESIGNED ACCORDING TO CUSTOMERS’ REQUIREMENTS

1. SIZE AND WEIGHT: ADJUSTED BY CUSTOMER’S REQUIREMENTS

2. POWER: 2 KW, 380 V, 50 HZ

3. CAPACITY: IN STEP OF VACUUM PLODDER

4. MOULD: WITH ONE SET

5. DIMENSION: 1000 × 400 × 1200mm

6. WEIGHT: 100 KGS

WOODEN CASE

QUANTITY: 1ITEM 027

CONVEYORS

APPEARANCE IS GOOD AND OPERATION IS STABLE, NON-NOISE AND ANTI-DUST

MOTOR: 1.1 TO 1.5 KW/PCS

QUANTITY: 4ITEM 028

VACUUM PUMP

FOR VACUUM PLODDER

POWER: 2.35 KW

QUANTITY: 15. OTHERS

ITEM 029

EQUIPMENT SUPPORT, OPERATING PLATFORM, LADDER, ETC.

USED IN CARBURATION POOL, SAPONIFICATION CAULDRONS, AND VACUUM SYSTEM

QUANTITY: 1ITEM 030

DISTRIBUTION BOX

CONTROL MACHINES, BIG BRAND ELECTRICAL COMPONENTS

WOODEN CASE

QUANTITY: 46. ADDITIONAL MACHINES AND SPARE PARTS

ITEM 031

ELECTRICAL CABLES

ALL WIRES FROM EACH MACHINE TO THE FOUR DISTRIBUTION BOXES. THE MAIN WIRE FROM THE FOUR DISTRIBUTION BOXES TO THE MAIN DISTRIBUTION BOX AND SLEEVES ARE NOT INCLUDED

QUANTITY: 1ITEM 032

HEAT INSULATING MATERIAL

ABOUT 450 M3, INCLUDING GALVANIZED SHEET 450 M3. GLASS WOOL CLOTH, NAILS

QUANTITY: 1ITEM 033

WELDING ROD

ABOUT 50 BOXES, 1 TON.

QUANTITY: 1ITEM 034

STEAM BOILER

MATERIAL: DIESEL OIL.

RATED POWER: 2000 KG/H

RATED PRESSURE: 1.25 MPA

RATED STEAM TEMPERATURE: 194 ℃

THE QUOTATION IS FOR ONE WHOLE SET OF BOILER, INCLUDING THE STEAM BOILER, WATER TREATMENT EQUIPMENTS, WATER BOXES, OIL BOXES, PUMPS, AND SOME SPARE PARTS

THE QUOTATION INCLUDES SALARY OF BOILER ENGINEER'S INSTALLATING AND TESTING

THE AIR TICKET AND ACCOMMODATION ARE NOT INCLUDED

LOADED BY A 40 'GP CONTAINER

QUANTITY: 1QUANTITY: 1 PLANT

Learn More -

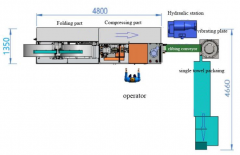

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More -

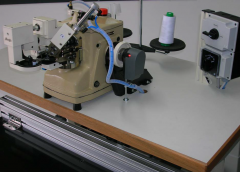

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More

M-1004 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSFOR CLOSING PILLOWS AND CUSHIONS (IN FEATHER, BALL FIBER, RECYCLED FIBER AND SIMILAR) THIS MACHINE IS SPECIFIC FOR THE CLOSING OF ROLOFIL CUSHIONS, FEATHER PILLOWS, CARDED CUSHIONS, CUSHIONS WITH FOAM AND SYNTHETIC FIBRES, ALL KIND OF CUSHIONS, EVEN BIG SHAPED SIZES. THE RANGE OF SEWING MACHINE HAS BEEN STUDIED AND BUILT FOLLOWING THE MOST MODERN CONCEPT OF TECHNOLOGY; THEIR COMPONENTS ARE THE MOST ADVANCED AND THE MATERIALS ARE HIGHLY SELECTED: THIS MAKES THE MACHINES STRONG, SAFE, SILENT AND EASY TO BE USED. OPERATIONS FEATURES: THE SPECIAL PLATES (BOTH MOTORIZED) AND THE EXTENDED SEWING BLOCK HELP THE OPERATOR IN THE SEWING OF ANY KIND OF SHAPED CUSHIONS AND DIFFERENT MATERIALS. WITH THE DOUBLE CONVEYING SYSTEM THE MATERIAL IS CONVEYING REGULARLY AND THIS GIVES AN HIGH QUALITY TO THE SEAM AND TO THE PRODUCE, ESPECIALLY WHEN THE PRODUCT IS A “REMOVABLE COVER” SOFA, AND NOT ONLY. VERSATILITY AND PERFORMANCE: KITS AND ACCESSORIES ARE AVAILABLE TO MEET THE MOST DIFFERENT REQUIREMENTS. IT IS POSSIBLE TO SEW (NEVER MIND THE SIZE, THE SHAPE AND THE WEIGHT): - LIGHT COTTON, NONWOVEN, FABRICS COUPLED WITH SYNTHETIC FIBRES, POLYESTER, CARDED AND SIMILAR. - FEATHER PILLOWS - HEAVY MATERIAL SUCH AS CUSHIONS IN SYNTHETIC FIBRES OR DACRON COUPLED WITH FOAM, CUSHIONS WITH SPRINGS ETC. COMPLETE WITH: - EXTENDED SEWING GROUP WITH DOUBLE MOTORIZED TOOTHED PLATES. - SEWING HEAD (OVERLOCK – 1 YARN) STITCH LENGTH: 1 TO 5mm - YARN CUTTING (TRIMMER), CUPS OPENING AND PNEUMATIC OIL PUMP - ELECTRONIC EFKA MOTOR 220V/240V SINGLE PHASE - SPEED: 1900 RPM - PERFORMANCE: 6 SECONDS PER CUSHION (SEWING 15 TO 20 CENTIMETERS) - ELECTRONIC MOBILE FOOTBOARD ALSO INCLUDES 1 SET OF NEEDLES, 1 INSTRUCTION BOOK, 1 CE CONFORMITYPRODUCTIVITY: 10/12 CUSHIONS PER MINUTE (CONSIDERED A OPEN SIDE OF 6/8”) Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More -

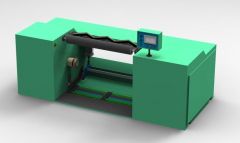

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003 1. SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA Learn More

TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003TT-7524 SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE, WIDTH 2000mm, YEAR 2003 1. SUCKER MULLER HACOBA INDIGO DYEING AND SIZING MACHINE 2. YEAR: 2003 3. BRAND: SUCKER MULLER HACOBA Learn More -

M-4747 INDUSTRIAL BREWERY WITH BREWHOUSE 20 HLREFERENCE NUMBER: M-4747 (1111NBRTHH10) L INDUSTRIAL BREWERY WITH BREWHOUSE 20 HL INDUSTRIAL BREWERY WITH CAPACITY OF 20 HL PER BREW YEAR PRODUCTIVITY OF 6,000 TO 7,000 HL, 3 SORTS OF BEER BREWERY IS NOT LOCATED AT A SEISMIC AREA EQUIPMENT DESIGNED ACCORDING TO EUROPEAN STANDARD STEAM HEATED 2-VESSEL BREW HOUSE OF 20 HECTOLITRES IN STAINLESS STEEL SCOPE OF SUPPLY: MALT MILL 1 X 2-ROLL MILL WITH CAPACITY OF 400 TO 800 KG/H WITH INLET FROM THE TOP FOR MALT SACKS BREW HOUSE 20HL STEAM HEATED STAINLESS STEEL 1.1 MASH/WORTH – KETTLE DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 LLC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL 2 STEAM HEATING ZONES (BOTTOM AND CYLINDRICAL PART) AGITATOR AND SHAFT IN STAINLESS STEEL, MATERIAL 1.4301. INSTALLATION OF BOTTOM CENTER. DRIVE VIA GEAR MOTOR, SPEED CONTROLLABLE BY FREQUENCY CONVERTER 1 SPRAY BALL 1 MAN HOLE WITH GLASS 1 PRESSURE RELIEF VALVE – SAFETY VALVE 1 LEVELMEASUREMENT DESIGNED FOR NON PRESSURE OPERATION 1.2 LAUTER TUN DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL ISOLATION OF THE CYLINDRICAL PART AND THE BOTTOM - 100 MM HALOGEN-FREE MINERAL WOOL. BOTTOM OF THE LAUTER TUN WITH OUTLET VALVES, BACK WASH VALVES AND A DRAIN VALVE MULTIPART SIEVE PLATE 1.4301 REMOVABLE THROUGH MANHOLE. HOEING 1.4301 TWO-ARMED WITH KNIVES AND TREBERN SWORD. INSTALLATION OF BOTTOM CENTER. 1 LAUTER STATION WITH CIP SPRAY BALL 1 MANHOLE WITH GLASS 1 SPRAY BALL 1 TREBERN FLAP AT THE CYLINDRICAL PART DESIGNED FOR NON PRESSURE OPERATION THE PACKAGE INCLUDES ALL VALVES, CHECK VALVES, BUTTERFLY VALVES, 2 PUMPS AND TEMPERATURE PROBES LANDING AND STAIRS MADE OF STAINLESS STEEL SQUARE ROOF BARS, COVERED WITH CORRUGATED SHEET METAL, HEIGHT ADJUSTABLE FEET WITH DOMES. THE PAN DUST WILL BE COLD DOWN WITH COLD WATER AND THE CONDENSATE WILL BE TRANSFERRED TO THE DRAIN WHIRLPOOL 20HL VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION WORTHCOOLING + WORTH AERATION VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION 1. SECTION: 20 HL WORTH IS COOLED WITH COLD WATER FROM 98°C TO 17°C IN 60 MINUTES (COLD WATER FROM CLIENT SIDE MUST BE MAX. 15°C OR LOWER) 2. SECTION: WITH ICE WATER OR GLYCOL THE WORTH IS COOLED TO 5°C CONTROL SYSTEM EACH PNEUMATIC CONTROLLED VALVE WILL HAVE A SWITCH BUTTON ON A CONTROL PANEL IN THE MIDDLE OF THE BREW HOUSE. ALSO THE TEMPERATURE CONTROL OF THE MASH KEETEL AND WORTH KETTLE WILL BE IMPLEMENTED AT THE CONTROL PANEL WITH A HARD WARE CONTROLLER. HOT WATER TANK 30 HL VERTICAL DESIGN, MATERIAL 1.4301 DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF MATERIAL 1.4301 WITH GRAIN 220 1 HOT WATER PUMP 1 CIRCULATION PUMP 1 PT 100 AN CONTROLLER 1 STEAM VALVE AND CONDENSATE VALVE 1 LEVEL INDICATION 10 X CYLINDER CONICAL TANKS 40/48 HL VERTICAL DESIGN WITH DISHED BOTTOM AND 60° CONE. CONE AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 4.050MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) AND CONE COOLING (2 ZONE), BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. SEPARATE CONNECTIONS FOR COOLING FOR CASING AND CONE : NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 2 OUTLET DN 32 INSTALLED IN A DN 125 - THREAD , PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 50, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 2 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 2 SOLENOID VALVE FOR THE COOLING DUCT 4 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. FILTRATION 20 HL/H KISELGUR- FILTER WITH HORIZONTAL SLICES AND CAPACITY OF 20HL / HOUR 3 X PRESSURE DISPENDING TANKS 40/46 HL VERTICAL DESIGN WITH DISHED BOTTOM LOWER + UPPER BOTTOM AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 3.350MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. CONNECTION FOR COOLING: NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 1OUTLET DN 32 PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN 25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32 FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 32, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 1 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 1 SOLENOID VALVE FOR THE COOLING DUCT 2 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. COOLING UNIT COOLING UNIT FOR THE OFFERT TANKS AND FOR THE WORTH COOLING. DESIGNED FOR OPERATION WITH GLYCOL COMPRESSOR OIL FREE FULLY AUTOMATIC, OIL-FREE AIR COMPRESSOR STATION WITH STAGE, MOUNTED ON A PRESSURE VESSEL, EQUIPPED WITH PRESSURE SWITCH, OUTLET VALVE, SAFETY VALVE, PRESSURE GAUGE AND MICRO FILTER. STEAM GENERATOR OIL OPERATED OIL OPERATED STEAM GENERATOR WITH A CAPACITY OF 200 KG/H INCLUDING FEED WATER TREATMENT AND FEED WATER CONTROL MOBILE BEER PUMP BEER PUMP WITH FREQUENCY CONVERTER, SINGLE MECHANICAL SEAL, ON STAINLESS STEEL FRAME (WITH CEE PLUG, MOTOR PROTECTION AND 10 M CABLE) FOR PUMPING FROM THE FERMENTATION TANKS TO THE PRESSURIZED TANK 4 PCS. BEER HOSES SET KEG-CLEANER WITH KEG-HANDFILLER CLEANER: CAPACITY: 10 – 15 KEGS / HOUR SEMI AUTOMATICALLY CLEANING PROCESS FOR ALL STANDARD KEGS KEG-HAND FILLER: COMPLETE MADE OF STAINLESS STEEL TUBES 2M LONG FOR ALL STANDARD KEGS PACKAGING WOODEN BOX AND FOILING FOR TRANSPORT IN A CONTAINER (SEA WAY), THE WOODEN BOX ALONE IS NOT ENOUGH FOR THE SEA WAY DOCUMENTATION IN ENGLISH (DEVICE DOCUMENTATION) IN ELECTRONIC FORM MOUNTING MATERIAL FOR MECHANICAL AND ELECTRICAL WORK UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING MOUNTING AND COMMISSIONING FOR MECHANIC WORK AND ELECTRIC WORK (LIFTING DEVICES- CRANE, ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET, LABOURER FOR MOUNTING SUPPORT) UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING 4 TEST BREWS (ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET) AND TRAINING OF THE OPERATOR STAFF UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING LABORATORY CIVIL WORK CO2 – SUPPLY PERMITS AND LICENSES FROM LOCAL AUTHORITIES TRANSPORT WATER TREATMENT AND COLD WATER TANK (IF REQUIRED) YEAST MANIPULATION (IF REQUIRED) Attached 3 photos from similar equipment. F1: brewhouse F2: CCT (cylindroconicalk tanks) and BBT (bright beer tanks = dispensing tanks) F3: PHE(plate heat exchanger = wort cooling, whirlpool, hot water tank) QUANTITY AVAILABLE: 1 Learn More

M-4747 INDUSTRIAL BREWERY WITH BREWHOUSE 20 HLREFERENCE NUMBER: M-4747 (1111NBRTHH10) L INDUSTRIAL BREWERY WITH BREWHOUSE 20 HL INDUSTRIAL BREWERY WITH CAPACITY OF 20 HL PER BREW YEAR PRODUCTIVITY OF 6,000 TO 7,000 HL, 3 SORTS OF BEER BREWERY IS NOT LOCATED AT A SEISMIC AREA EQUIPMENT DESIGNED ACCORDING TO EUROPEAN STANDARD STEAM HEATED 2-VESSEL BREW HOUSE OF 20 HECTOLITRES IN STAINLESS STEEL SCOPE OF SUPPLY: MALT MILL 1 X 2-ROLL MILL WITH CAPACITY OF 400 TO 800 KG/H WITH INLET FROM THE TOP FOR MALT SACKS BREW HOUSE 20HL STEAM HEATED STAINLESS STEEL 1.1 MASH/WORTH – KETTLE DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 LLC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL 2 STEAM HEATING ZONES (BOTTOM AND CYLINDRICAL PART) AGITATOR AND SHAFT IN STAINLESS STEEL, MATERIAL 1.4301. INSTALLATION OF BOTTOM CENTER. DRIVE VIA GEAR MOTOR, SPEED CONTROLLABLE BY FREQUENCY CONVERTER 1 SPRAY BALL 1 MAN HOLE WITH GLASS 1 PRESSURE RELIEF VALVE – SAFETY VALVE 1 LEVELMEASUREMENT DESIGNED FOR NON PRESSURE OPERATION 1.2 LAUTER TUN DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF STAINLESS STEEL ISOLATION OF THE CYLINDRICAL PART AND THE BOTTOM - 100 MM HALOGEN-FREE MINERAL WOOL. BOTTOM OF THE LAUTER TUN WITH OUTLET VALVES, BACK WASH VALVES AND A DRAIN VALVE MULTIPART SIEVE PLATE 1.4301 REMOVABLE THROUGH MANHOLE. HOEING 1.4301 TWO-ARMED WITH KNIVES AND TREBERN SWORD. INSTALLATION OF BOTTOM CENTER. 1 LAUTER STATION WITH CIP SPRAY BALL 1 MANHOLE WITH GLASS 1 SPRAY BALL 1 TREBERN FLAP AT THE CYLINDRICAL PART DESIGNED FOR NON PRESSURE OPERATION THE PACKAGE INCLUDES ALL VALVES, CHECK VALVES, BUTTERFLY VALVES, 2 PUMPS AND TEMPERATURE PROBES LANDING AND STAIRS MADE OF STAINLESS STEEL SQUARE ROOF BARS, COVERED WITH CORRUGATED SHEET METAL, HEIGHT ADJUSTABLE FEET WITH DOMES. THE PAN DUST WILL BE COLD DOWN WITH COLD WATER AND THE CONDENSATE WILL BE TRANSFERRED TO THE DRAIN WHIRLPOOL 20HL VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION WORTHCOOLING + WORTH AERATION VESSEL MADE OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220. NON INSULATED. 1 WHIRLPOOL PUMP 2 LATERAL OUTLETS WITH HAND VALVES 1 FLOOR DRAIN WITH HAND VALVE 1 TANGENTIAL INLET PORT WITH THREADED CONNECTOR 1 SAFETY VALVE 1 MANHOLE 1 SPRAY BALL DESIGNED FOR NON PRESSURE OPERATION 1. SECTION: 20 HL WORTH IS COOLED WITH COLD WATER FROM 98°C TO 17°C IN 60 MINUTES (COLD WATER FROM CLIENT SIDE MUST BE MAX. 15°C OR LOWER) 2. SECTION: WITH ICE WATER OR GLYCOL THE WORTH IS COOLED TO 5°C CONTROL SYSTEM EACH PNEUMATIC CONTROLLED VALVE WILL HAVE A SWITCH BUTTON ON A CONTROL PANEL IN THE MIDDLE OF THE BREW HOUSE. ALSO THE TEMPERATURE CONTROL OF THE MASH KEETEL AND WORTH KETTLE WILL BE IMPLEMENTED AT THE CONTROL PANEL WITH A HARD WARE CONTROLLER. HOT WATER TANK 30 HL VERTICAL DESIGN, MATERIAL 1.4301 DOUBLE WALLED INNER SHELL OF STAINLESS STEEL, MATERIAL 1.4301 IIIC, WELDS GROUND WITH GRAIN SIZE 220 OUTER SHEATH MADE OF MATERIAL 1.4301 WITH GRAIN 220 1 HOT WATER PUMP 1 CIRCULATION PUMP 1 PT 100 AN CONTROLLER 1 STEAM VALVE AND CONDENSATE VALVE 1 LEVEL INDICATION 10 X CYLINDER CONICAL TANKS 40/48 HL VERTICAL DESIGN WITH DISHED BOTTOM AND 60° CONE. CONE AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 4.050MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) AND CONE COOLING (2 ZONE), BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. SEPARATE CONNECTIONS FOR COOLING FOR CASING AND CONE : NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 2 OUTLET DN 32 INSTALLED IN A DN 125 - THREAD , PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 50, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 2 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 2 SOLENOID VALVE FOR THE COOLING DUCT 4 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. FILTRATION 20 HL/H KISELGUR- FILTER WITH HORIZONTAL SLICES AND CAPACITY OF 20HL / HOUR 3 X PRESSURE DISPENDING TANKS 40/46 HL VERTICAL DESIGN WITH DISHED BOTTOM LOWER + UPPER BOTTOM AND CYLINDRICAL PART IS INSULTED AND THE FULL TANK IS EQUIPPED WITH WELDED STAINLESS STEEL EXTERIOR FINISH. TANK HEIGHT APPROX.: 3.350MM TANK EQUIPPED WITH COOLING JACKET (1 ZONE) BY TEMP- PLATE, SUITABLE FOR ICE WATER / GLYCOL. CONNECTION FOR COOLING: NIPPLE ¾ " EXTERNAL THREAD TANK WITH MANHOLE 500 X 400 MM, WITH MANHOLE COVER AND DUAL HINGE. 1OUTLET DN 32 PULLED FORWARD AND ENDED BUTTERFLY VALVE DN 32 G / S , WITH BLANKING CAP. UPPER FLOOR PROVIDED WITH 2 THREADED CONNECTION DN 32 FOR CONNECTION OF AN RLV - FITTING. ONE OF THE TERMINALS INSTALLED IN A FITTING DN 100 AND DN 25 PROVIDED WITH REMOVABLE SPRAY BALL CLEANING PIPE DN 25, TOP PROVIDED WITH CONNECTION CONE / NUT DN 32 FOR CONNECTION TO THE RLV COMBINATION, PULLED DOWN AND ENDING ON OPERATING HEIGHT IN THREADED CONNECTION DN 32, INCLUDING BLANKING CAP. IN THE CLEANING DUCT 2 CONNECTOR WITH THREADED CONNECTION DN 20 FOR SPUND APPARATUS AND WITH BALL VALVE FOR THE GAS SUPPORT 1 CONNECTOR FOR SAMPLE VALVE: THREADED CONNECTION DN 20 1 CONNECTION FOR PT -100: IMMERSION SLEEVE 260 MM LONG, WITH SLEEVE ½ " . 1 SOLENOID VALVE FOR THE COOLING DUCT 2 MANUAL VALVES IN THE COOLANT INLET AND COOLANT OUTLET LINE 4 THE HEIGHT ADJUSTABLE TUBE FEET , INCLUDING FOOTPLATE. MATERIAL: 1.4301. FINISH: - INSIDE: - 2B (IIIC-SHEET), DISHED BOTTOM GROUND. - WELDS - ROUND & LONG SEAMS SANDED. - REST STAINED / BRUSHED. - OUTSIDE: - 2B (IIIC-SHEET). - WELDS - ROUND & LONGITUDINAL SEAMS SANDED. - REST STAINED / BRUSHED TANK SUITABLE FOR 3 BAR G. (20 ° C), DECREASE ACCORDING TO PED 97/23/EC. COOLING UNIT COOLING UNIT FOR THE OFFERT TANKS AND FOR THE WORTH COOLING. DESIGNED FOR OPERATION WITH GLYCOL COMPRESSOR OIL FREE FULLY AUTOMATIC, OIL-FREE AIR COMPRESSOR STATION WITH STAGE, MOUNTED ON A PRESSURE VESSEL, EQUIPPED WITH PRESSURE SWITCH, OUTLET VALVE, SAFETY VALVE, PRESSURE GAUGE AND MICRO FILTER. STEAM GENERATOR OIL OPERATED OIL OPERATED STEAM GENERATOR WITH A CAPACITY OF 200 KG/H INCLUDING FEED WATER TREATMENT AND FEED WATER CONTROL MOBILE BEER PUMP BEER PUMP WITH FREQUENCY CONVERTER, SINGLE MECHANICAL SEAL, ON STAINLESS STEEL FRAME (WITH CEE PLUG, MOTOR PROTECTION AND 10 M CABLE) FOR PUMPING FROM THE FERMENTATION TANKS TO THE PRESSURIZED TANK 4 PCS. BEER HOSES SET KEG-CLEANER WITH KEG-HANDFILLER CLEANER: CAPACITY: 10 – 15 KEGS / HOUR SEMI AUTOMATICALLY CLEANING PROCESS FOR ALL STANDARD KEGS KEG-HAND FILLER: COMPLETE MADE OF STAINLESS STEEL TUBES 2M LONG FOR ALL STANDARD KEGS PACKAGING WOODEN BOX AND FOILING FOR TRANSPORT IN A CONTAINER (SEA WAY), THE WOODEN BOX ALONE IS NOT ENOUGH FOR THE SEA WAY DOCUMENTATION IN ENGLISH (DEVICE DOCUMENTATION) IN ELECTRONIC FORM MOUNTING MATERIAL FOR MECHANICAL AND ELECTRICAL WORK UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING MOUNTING AND COMMISSIONING FOR MECHANIC WORK AND ELECTRIC WORK (LIFTING DEVICES- CRANE, ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET, LABOURER FOR MOUNTING SUPPORT) UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING 4 TEST BREWS (ENERGY, RAW MATERIAL, CLEANING SOLUTION, HOTEL, FLIGHT TICKET) AND TRAINING OF THE OPERATOR STAFF UPON RECEIPT OF THE LAYOUT DRAWING, SPECIFICATIONS OR INTERFACES AND CLARIFYING THE SCOPE OF DELIVERY WE CAN MAKE A DETAILED QUOTE FOR DELIVERY, INSTALLATION, AND COMMISSIONING LABORATORY CIVIL WORK CO2 – SUPPLY PERMITS AND LICENSES FROM LOCAL AUTHORITIES TRANSPORT WATER TREATMENT AND COLD WATER TANK (IF REQUIRED) YEAST MANIPULATION (IF REQUIRED) Attached 3 photos from similar equipment. F1: brewhouse F2: CCT (cylindroconicalk tanks) and BBT (bright beer tanks = dispensing tanks) F3: PHE(plate heat exchanger = wort cooling, whirlpool, hot water tank) QUANTITY AVAILABLE: 1 Learn More -

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINEYY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE QUANTITY: 1 Learn More

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINEYY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE QUANTITY: 1 Learn More