Search results for: 'Control pa'"'

- Related search terms

- Control pan

- control+p

- Control+pan

- Control pan'

- control+pro'

-

YY-2616 USED GLOUCESTER 4.5″ 32:1 L/D EXTRUDERYY-2616 USED GLOUCESTER 4.5″ 32:1 L/D EXTRUDER QUANTITY: 1 Learn More

YY-2616 USED GLOUCESTER 4.5″ 32:1 L/D EXTRUDERYY-2616 USED GLOUCESTER 4.5″ 32:1 L/D EXTRUDER QUANTITY: 1 Learn More -

YY-2615 USED GLOUCESTER 3.5″ 32:1 L/D EXTRUDERYY-2615 USED GLOUCESTER 3.5″ 32:1 L/D EXTRUDER QUANTITY: 1 Learn More

YY-2615 USED GLOUCESTER 3.5″ 32:1 L/D EXTRUDERYY-2615 USED GLOUCESTER 3.5″ 32:1 L/D EXTRUDER QUANTITY: 1 Learn More -

YY-2614 USED GLOUCESTER 2.5″ 32:1 L/D EXTRUDERYY-2614 USED GLOUCESTER 2.5″ 32:1 L/D EXTRUDER QUANTITY: 1 Learn More

YY-2614 USED GLOUCESTER 2.5″ 32:1 L/D EXTRUDERYY-2614 USED GLOUCESTER 2.5″ 32:1 L/D EXTRUDER QUANTITY: 1 Learn More -

J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020 MAKE: FUNG CHANG INDUSTRIAL CO, LTD YEAR: 2020 CONSISTING OF 2 RASCHEL KNITTING LINES: ITEM 001 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE ITEM 002 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE Learn More

J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020J-4810 FUNG CHANG INDUSTRIAL RASCHEL KNITTING LINES FOR PLASTIC BAGS, YEAR 2020 MAKE: FUNG CHANG INDUSTRIAL CO, LTD YEAR: 2020 CONSISTING OF 2 RASCHEL KNITTING LINES: ITEM 001 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE ITEM 002 RASCHEL KNITTING LINE WITH AUTO-CUTTING DEVICE (COMPLETE LINE FOR ONION / POTATOES / FIRE LOG NETS), YEAR 2020 QUANTITY: 1 LINE Learn More -

TT-2177 GAS BASED COMBINED CYCLE POWER PLANT, 116 MW, YEAR 2021TT-2177 GAS BASED COMBINED CYCLE POWER PLANT, 116 MW, YEAR 2021 GENERAL ELECTRIC GAS TURBINE GAS TURBINE MODEL NUMBER: GE, 6FAG QUANTITY: 1 Learn More

TT-2177 GAS BASED COMBINED CYCLE POWER PLANT, 116 MW, YEAR 2021TT-2177 GAS BASED COMBINED CYCLE POWER PLANT, 116 MW, YEAR 2021 GENERAL ELECTRIC GAS TURBINE GAS TURBINE MODEL NUMBER: GE, 6FAG QUANTITY: 1 Learn More -

TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002 COMPLETE FLOCKING LINE WORKING WIDTH 3200mm QUANTITY: 1 Learn More

TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002 COMPLETE FLOCKING LINE WORKING WIDTH 3200mm QUANTITY: 1 Learn More -

T-8998 WESTAL ONE SHOT CHOCOLATE MOULDING LINE MOULD SIZE PLAIN 600mm X 220mmT-8998 WESTAL ONE SHOT CHOCOLATE MOULDING LINE MOULD SIZE PLAIN 600mm X 220mm ONE SHOT CHOCOLATE MOULDING LINE MANUFACTURED BY WESTAL TYPE 600 ONE SHOT CHOCOLATE MOULDING LINE QUANTITY: 1 Learn More

T-8998 WESTAL ONE SHOT CHOCOLATE MOULDING LINE MOULD SIZE PLAIN 600mm X 220mmT-8998 WESTAL ONE SHOT CHOCOLATE MOULDING LINE MOULD SIZE PLAIN 600mm X 220mm ONE SHOT CHOCOLATE MOULDING LINE MANUFACTURED BY WESTAL TYPE 600 ONE SHOT CHOCOLATE MOULDING LINE QUANTITY: 1 Learn More -

TT-1389 LAB RING SPINNING FRAMETT-1389 LAB RING SPINNING FRAME KEY SPECIFICATION: CONTROL MODE: TOUCH SCREEN & PLC NUMBER OF SPINDLES: 6 APPLICABLE FIBER LENGTH: 22 TO 50mm DRAFT RANGE: 10 TO 50 DRAFT CONTROL: AUTOMATIC ROLLER DIAMETER: FRONT ROLLER: Φ25mm, MIDDLE ROLLER: Φ25mm BACK ROLLER: Φ25mm CENTER DISTANCE OF ROLLERS: FRONT AND MIDDLE: 43mm FRONT AND BACK: 143mm PRESSURE MODE: SPRING CRADLE TWIST SETTABLE RANGE: 200 TO 2,000 TWIST/M RING DIAMETER: RING NOT NEEDED IF THERE IS NO NEED FOR TWISTING FUNCTION. THIS MACHINE WILL USE A SHAFT TO MOVE THE YARN UP AND DOWN TO WIND ON THE PIRN TOTAL KW: 1.5 KW VOLTAGE: 220 VOLTS, 3-PHASE, 60 Hz WEIGHT: 650 KG DIMENSIONS: 1750 x 760 x 1950mm SPINDLE SPEED: 3800 RPM QUANTITY: 1 SET Learn More

TT-1389 LAB RING SPINNING FRAMETT-1389 LAB RING SPINNING FRAME KEY SPECIFICATION: CONTROL MODE: TOUCH SCREEN & PLC NUMBER OF SPINDLES: 6 APPLICABLE FIBER LENGTH: 22 TO 50mm DRAFT RANGE: 10 TO 50 DRAFT CONTROL: AUTOMATIC ROLLER DIAMETER: FRONT ROLLER: Φ25mm, MIDDLE ROLLER: Φ25mm BACK ROLLER: Φ25mm CENTER DISTANCE OF ROLLERS: FRONT AND MIDDLE: 43mm FRONT AND BACK: 143mm PRESSURE MODE: SPRING CRADLE TWIST SETTABLE RANGE: 200 TO 2,000 TWIST/M RING DIAMETER: RING NOT NEEDED IF THERE IS NO NEED FOR TWISTING FUNCTION. THIS MACHINE WILL USE A SHAFT TO MOVE THE YARN UP AND DOWN TO WIND ON THE PIRN TOTAL KW: 1.5 KW VOLTAGE: 220 VOLTS, 3-PHASE, 60 Hz WEIGHT: 650 KG DIMENSIONS: 1750 x 760 x 1950mm SPINDLE SPEED: 3800 RPM QUANTITY: 1 SET Learn More -

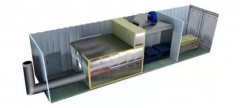

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More