Search results for: 'heat t'

- Related search terms

- heat press

- heated

- heatin

- heating el

- heating ele

-

TT-6637 CATERPILLAR 3516B HD - NEW, 1820 KW, YEAR 2022 TO 2023, 50Hz/60HzTT-6637 CATERPILLAR 3516B HD - NEW, 1820 KW, YEAR 2022 TO 2023, 50Hz/60Hz 1. CATERPILLAR 3516B HD 2. YEAR: 2022 TO 2023 3. VOLTAGE: 10.5KV/50Hz/60Hz 4. POWER: 1820 KW 5. HOURS: ZERO 6. NEW 7. FUEL:DIESEL OIL QUANTITY: 5 Learn More

TT-6637 CATERPILLAR 3516B HD - NEW, 1820 KW, YEAR 2022 TO 2023, 50Hz/60HzTT-6637 CATERPILLAR 3516B HD - NEW, 1820 KW, YEAR 2022 TO 2023, 50Hz/60Hz 1. CATERPILLAR 3516B HD 2. YEAR: 2022 TO 2023 3. VOLTAGE: 10.5KV/50Hz/60Hz 4. POWER: 1820 KW 5. HOURS: ZERO 6. NEW 7. FUEL:DIESEL OIL QUANTITY: 5 Learn More -

TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023 CATERPILLAR 3516B HD – NEW YEAR: 2022 AND 2023 HOURS: ZERO 1820 KW FUEL: DIESEL OIL IMMEDIATE DELIVERY QUANTITY: 5 Learn More

TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023TT-5991 CATERPILLAR 3516B HD PRIME DIESEL GENERATOR – NEW, 1820 KW, YEAR 2022 AND 2023 CATERPILLAR 3516B HD – NEW YEAR: 2022 AND 2023 HOURS: ZERO 1820 KW FUEL: DIESEL OIL IMMEDIATE DELIVERY QUANTITY: 5 Learn More -

TT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHPTT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHP 1. MIURA LXH-300 IS A HIGH-PRESSURE, GAS-FIRED STEAM BOILER. 2. WATER TUBE, CAPACITY OF 300 BOILER HORSEPOWER (BHP). 3. RATED 30 PSI. QUANTITY: 1 Learn More

TT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHPTT-7162 MIURA LXH-300 HIGH-PRESSURE GAS-FIRED STEAM BOILER, 300 BHP 1. MIURA LXH-300 IS A HIGH-PRESSURE, GAS-FIRED STEAM BOILER. 2. WATER TUBE, CAPACITY OF 300 BOILER HORSEPOWER (BHP). 3. RATED 30 PSI. QUANTITY: 1 Learn More -

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

TT-5641 AGGRETECH S250P COMBINED HEAT AND POWER PLANT, 225KW, YEAR 2006TT-5641 AGGRETECH S250P COMBINED HEAT AND POWER PLANT, 225KW, YEAR 2006 MACHINE TYPE: COMBINED HEAT AND POWER PLANT BRAND: AGGRETECH MODEL: S250P YEAR OF CONSTRUCTION: 2006 QUANTITY: 1 Learn More

TT-5641 AGGRETECH S250P COMBINED HEAT AND POWER PLANT, 225KW, YEAR 2006TT-5641 AGGRETECH S250P COMBINED HEAT AND POWER PLANT, 225KW, YEAR 2006 MACHINE TYPE: COMBINED HEAT AND POWER PLANT BRAND: AGGRETECH MODEL: S250P YEAR OF CONSTRUCTION: 2006 QUANTITY: 1 Learn More -

V-2157 SIEMENS SGT 400 COMBINED HEAT AND POWER (CHP) UNIT, YEAR 2017, PRODUCING 12.9 MW (ISO)V-2157 SIEMENS SGT 400 COMBINED HEAT AND POWER (CHP) UNIT, YEAR 2017, PRODUCING 12.9 MW (ISO), 11KV, 50HZ INSTALLED IN PLACE NOW (ONE TURBINE GENERATOR) WITH WASTE HEAT STEAM BOILER FIRE TUBE TYPE AND ECONOMIZER, OPTIMIZED FOR 16 TONS PER HOUR OF SATURATED STEAM PRODUCTION (PROCESS STEAM THAT CAN BE USED FOR DRYING PRODUCTS) INCLUDES SCADA SYSTEM AND VALMET SYSTEM DNA DCS Learn More

V-2157 SIEMENS SGT 400 COMBINED HEAT AND POWER (CHP) UNIT, YEAR 2017, PRODUCING 12.9 MW (ISO)V-2157 SIEMENS SGT 400 COMBINED HEAT AND POWER (CHP) UNIT, YEAR 2017, PRODUCING 12.9 MW (ISO), 11KV, 50HZ INSTALLED IN PLACE NOW (ONE TURBINE GENERATOR) WITH WASTE HEAT STEAM BOILER FIRE TUBE TYPE AND ECONOMIZER, OPTIMIZED FOR 16 TONS PER HOUR OF SATURATED STEAM PRODUCTION (PROCESS STEAM THAT CAN BE USED FOR DRYING PRODUCTS) INCLUDES SCADA SYSTEM AND VALMET SYSTEM DNA DCS Learn More -

TT-8285 POWER BARGE, 16.2MW EACH (TOTAL 120MW), YEAR 1998, 50HzTT-8285 POWER BARGE, 16.2MW EACH (TOTAL 120MW), YEAR 1998, 50Hz TECHNICAL DETAILS LIKE LENGTH, WIDTH, DEPTH OF THE BARGE: L= 96540mm, B= 30480mm DEPTH = 6090mm YEAR OF BUILT: 1998 SINGLE BARGE: YES Learn More

TT-8285 POWER BARGE, 16.2MW EACH (TOTAL 120MW), YEAR 1998, 50HzTT-8285 POWER BARGE, 16.2MW EACH (TOTAL 120MW), YEAR 1998, 50Hz TECHNICAL DETAILS LIKE LENGTH, WIDTH, DEPTH OF THE BARGE: L= 96540mm, B= 30480mm DEPTH = 6090mm YEAR OF BUILT: 1998 SINGLE BARGE: YES Learn More -

TT-7161 MIURA LXH-300 GAS-FIRED STEAM BOILER, 300 HP, HIGH-PRESSURE, ENERGY-EFFICIENTTT-7161 MIURA LXH-300 GAS-FIRED STEAM BOILER, 300 HP, HIGH-PRESSURE, ENERGY-EFFICIENT 1. MIURA LX GAS FIRED STEAM BOILER, MODEL LXH-300. 2. HIGH-PRESSURE. 3. 300 HP CAPACITY. 4. RATED 30 PSI. QUANTITY: 1 Learn More

TT-7161 MIURA LXH-300 GAS-FIRED STEAM BOILER, 300 HP, HIGH-PRESSURE, ENERGY-EFFICIENTTT-7161 MIURA LXH-300 GAS-FIRED STEAM BOILER, 300 HP, HIGH-PRESSURE, ENERGY-EFFICIENT 1. MIURA LX GAS FIRED STEAM BOILER, MODEL LXH-300. 2. HIGH-PRESSURE. 3. 300 HP CAPACITY. 4. RATED 30 PSI. QUANTITY: 1 Learn More -

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More

T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008T-8968 BATTENFELD BLOWN FILM MACHINE EXTRUDER DIAMETER 4.5” (115mm), OUTPUT MAX 180KG/H (400 LBS/H), YEAR 2008 YEAR 2008, PILOT RUN YEAR 2009, STOPPED PRODUCTION YEAR 2017 FILM MACHINE EXTRUDER: BATTENFELD EXTRUDER DIAMETER 4.5” (115mm) L/D RATIO 24:1 460V 3P 60Hz 125HP AC VECTOR MOTOR RESIN TEMPARETURE: 230°C (446 DEGREEF) OUTPUT: MAX 180KG/H (400 LBS/H) PRESSURE RATINGS ARE: BARREL 20,000PSI BARREL CLAMP 10,000PSI RUPTURED DISC 7,500PSI Learn More -

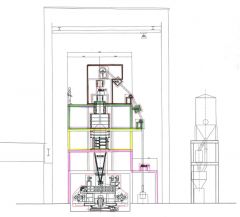

M-4009 FORMALDEHYDE PLANT & SYSTEMS -90,000 TON PER YEAR

M-4009 FORMALDEHYDE PLANT & SYSTEMS -90,000 TON PER YEARREFERENCE NUMBER: M-4009

FORMALDEHYDE PLANT & SYSTEMS -90,000 TON PER YEAR

90,000 TON/YEAR

(200 MILLION LBS/YR @ 37% CONCENTRATION)SHUT DOWN: SPRING 2010

PLANT PRODUCES A 37% AND A 50% FORMALDEHYDE SOLUTION BY PARTIAL OXIDATION AND DEHYDROGENATION OF METHANOL.

RAW MATERIALS:

METHANOL

SILVER CATALYST

ORIGINAL PLANT EQUIPPED WITH:

MONSANTO PROCESS

(2) CONVERTERS AND ASSOCIATED EQUIPMENT, ABSORBER AND DISTILLATION COLUMN

MODIFICATIONS:

ADDED 3RD CONVERTER FOR CAPACITY IMPROVEMENTS

METHANOL VENTS SCRUBBER ADDED

WASTE HEAT BOILER ADDED

INSTALLED A DCS ON THE REACTOR SECTION (2006)

PRODUCT SPECIFICATIONS:

CLEAR AQUEOUS SOLUTIONS OF:

50U: 50.0 - 50.45% FA, <1.05% MEOH, <0.055% FORMIC ACID

37U: 37.0 - 37.3% FA, <1.05% MEOH, <0.035% FORMIC ACID

37M: 37.0 - 37.5% FA, 9 - 13% MEOH

OTHER CONCENTRATIONS AS REQUIRED UP TO 50% BOTH INHIBITED AND UNINHIBITED

CONTACT IPP FOR A COMPLETE PROCESS DESCRIPTION AND FLOW DIAGRAM

COMPLETE DOCUMENTATION AVAILABLE

FORMALDEHYDE PROCESS UNITS FOR SALE

(MAJOR UNITS ONLY. CONTACT IPP FOR A COMPLETE LIST)2.9 - 20 MM BTU/HR JOHN ZINK THERMAL OXIDIZER SYSTEM

DESIGNED TO INCINERATE TWO SOLVENT LADEN GAS STREAMS USING A SMALL AMOUNT OF NATURAL GAS.

ONE SMALL SOLVENT GAS STREAM WITH A FLOW OF 120 - 320 SCFM, THE OTHER LARGER OFF GAS STREAM OF 8,200 - 17,500 LBS/HR.

GAS BURNER IS RATED FOR 2.9 - 20 MM BTU/HR (INSTALLED NEW IN 2006)

THE WASTE HEAT BOILER PORTION GENERATES STEAM AT 25,000 LBS/HR WITH A PRESSURE OF 75 PSIG (NORMAL) UP TO 125 PSIG (DESIGN).

THE UNIT USES STAGED BURNER TECHNOLOGY TO REDUCE OR ELIMINATE NOX.

CONTACT IPP FOR A MAJOR LIST OF COMPONENTS

DISTILLATION COLUMN SYSTEM

13,000 LBS/HR LIGHT ALDEHYDES AND LIGHT ALCOHOL DISTILLATION

COMPLETE SYSTEM INCLUDES:

72" DIA. X 75' 316LSS BUEHLER-MORRIS DISTILLATION TRAY COLUMN

(2) SS SHELL AND TUBE HEAT EXCHANGERS

2,889 SQ. FT. 304SS, 1,090 SQ. FT. 316SS

(2) 316SS PLATE AND FRAME HEAT EXCHANGERS

478.35 SQ. FT., 73.2 SQ. FT.

(3) PUMPS

241 LBS/HR TO 13,000 LBS/HR

BEPEX BRIQUETTER SYSTEM

MODEL 300 MS28

SKID MOUNTED

2.5" DIA.

3,000 PSI MAX. OPERATING PRESSURE

22 RPM ROLL SPEED

INCLUDES 300 HP SIEMENS AC MOTOR, FOOTE JONES GEARBOX AND FEED HOPPER

316SS 3-EFFECT BUFLOVAK-BLAW KNOX EVAPORATION SYSTEM

36,900 LBS/HR (16,000 KG/HR)

FIRST EFFECT: 1,480 SQ. FT.

SECOND AND THIRD EFFECT: 2,950 SQ. FT.

INCLUDES (3) VAPOR BODIES WITH 1,900 GALLON CAPACITY, (3) STEAM CHESTS AND (2) OVERHEAD CONDENSERS (1,728 SQ. FT AND 1,605 SQ. FT.)

304SS STRUTHERS WELLS "KRYSTAL" CRYSTALLIZER SYSTEM

7' DIA. X 60" WITH 9' CONE BOTTOM

THIS UNIT WILL EVAPORATE APPROXIMATELY 4,400 LBS/HR OF H2O (5 LBS PER SQ. FT. SURFACE AREA OF HEATER)

INCLUDES COMPLETE ACCESSORY PACKAGE: VAPORIZER AND SUSPENSION CONTAINER, STEAM CHEST HEATER, 4,000 GALLON 347SS TANK, LIGHTNIN RIGHT ANGLE MIXER, ELBOW PUMP, OVERHEADS CONDENSER AND HYPULSE FILTER

25,400 CFM 321SS FULLER FLUIDIZED BED DRYER

12' DIA. CHAMBER

1,555 CU. FT. DRYING CHAMBER CAPACITY

DESIGNED TO DRY 8,560 LBS/HR OF PELLETS (@ 15% MOISTURE) WITH A DENSITY OF 40 LBS/CU. FT.

114,240 LBS/HR AIR FLOW

1,325,000 BTU/HR HEAT TRANSFER

INCLUDES (3) HEATING COILS (40 PSI STEAM) FOR UNDER BED HEATING

Learn More