Search results for: 'Generator'

- Related search terms

- generator set

- generator gas

- generator new

- generator?

- Generator power pl

-

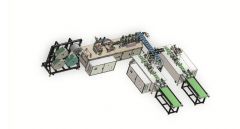

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE3 LAYER MASKS CONSTRUCTED OF NONWOVEN AND MELTBLOWN FABRIC

MASK DIMENSIONS: 175 x 95mm (ADULT) & 145 x 90mm (CHILD)---COMPOSED OF TWO MACHINES, AS BELOW

1) AUTOMATIC MASK LAYER MAKING AND CUTTING MACHINE

CAPACITY: 200 TO 300 PIECES PER MINUTE

INCLUDES

• MATERIAL FEEDING FRAME

• MACHINE FRAME

• ALUMINUM NOSE STRIP INSERTION

• ULTRASONIC WELDING

• CONVEYOR

DIMENSIONS: 4600 x 500 x 2100mm

WEIGHT: 300 KGS

POWER: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER)

2) MANUAL EAR BAND WELDING MACHINE

CAPACITY: 30 TO 40 PIECES PER MINUTE

INCLUDES

• WORKBENCH

• LIGHT

• AIR CYLINDER

• ULTRASONIC GENERATOR

• CONTROL SYSTEM

DIMENSIONS: 800 x 500 x 1000mm

WEIGHT: 43 KGS

POWER: 380 VOLTS, 50 Hz (OR AS PER CUSTOMER)WARRANTY: 1 YEAR FOR MAJOR COMPONENTS, LIFELONG SERVICE FOR THE USER

QUANTITY: 1 COMPLETE SEMI-AUTOMATIC LINE

Learn More -

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More -

J-2375 COMPLETE CERAMIC TILE PRODUCTION PLANT, PRODUCTION 7 MILLION SQUARE METERS PER YEAR

J-2375 COMPLETE CERAMIC TILE PRODUCTION PLANT, PRODUCTION 7 MILLION SQUARE METERS PER YEARTILE FACTORY DESIGNED BY SACMI / ITALY

YEAR ESTABLISHED 2014 TO 2016

THIS PLANT IS AN ENVIRONMENTALLY FRIENDLY ENTERPRISE, WHEN IT RECYCLES 100% OF ITS EFFLUENTS AND PERFORMS HEAT RECOVERY, THEREBY SAVING ENERGY

See all pictures:

https://www.flickr.com/photos/183869481@N08/albums/72157710649767958THE PLANT:

COVERS AN AREA OF 22 THOUSAND SQUARE METERS

THE PRODUCTION CAPACITY IS 7 MILLION SQUARE METERS / YEAR

CERAMIC FLOOR TILES

CERAMIC WALL TILES

BMR POLISHING LINE

BMR SQUARING & CHANFERING LINE

THE MAIN RAW MATERIALS ARE CLAY (DB-4) - 31 %, ALBITE (STD5) - 60 %

NEPHAIIN (PN9595) - 2.5 %, KAOLIN (RHB1) - 6.5 %

ON TOP OF IT THEY ARE USING GLAZE MATERIALS AND PAINTS

•FROM THE MOMENT THE MATERIAL IS PREPARED IT IS BEING DRIED PRESSED ON ONE OF FOUR (4) PRODUCTION LINES.

•TWO (2) LINES ARE WITH SACMI PRESSES OF PH 7,500 TON EACH AND HORIZONTAL DRYERS SACMI

•TWO LINES ARE WITH SACMI PRESSES OF PH 3,590 TON EACH AND VERTICAL DRYERS SACMI

•ALL FOUR (4) LINES HAVE THEIR OWN DIGITAL PRINTING MACHINE INCORPORATED

•ALL PRODUCTS ARE BEING GLAZED AND FIRED ON 1200 DEGREES IN ONE OF THE TWO (2) KILNS, SACMI

FOUR (4) SORTING, PACKING AND PALLETIZING LINES

GLAZE PREPARATION LINE

COMPLETE INSTALLATION FOR SMALL PRODUCTION CAPACITIES

COMPLETE FOILING LINE

COMPLETE ELECTRIC INSTALLATION

POWER GENERATOR UNIT

COMPRESSED AIR INSTALLATIONMACHINES ARE MADE BY:

SACMI: ITALY

NUOVA ERA / ROBOBOX: ITALY

BMR: ITALY

IN.TE.SA: ITALY

CUCCOLINI: ITALY

SYSTEM CERAMICS: ITALY

TGMAC SR.L: ITALY

DURST: GERMANY

ROTOCOLOR MAG: ITALY

NUOVA FIMA: ITALY

OMS: ITALY

MARPAK OMS: ITALY

MESSERSI PACK: ITALYTILE SIZES

THE FACTORY MANUFACTURES TILES OF VARIOUS SIZES FROM 300 X 300 TO 1200 X 1200mm IN VARIOUS TEXTURES AND DESIGNS USING DIGITAL PRINTING MACHINES

PRODUCTION CAPACITY IS 7 MILLION SQUARE METERS / YEAR

THE FACTORY IS FULLY AUTOMATED AND USING ADVANCED CONTROL SYSTEMS!HUGE AMOUNT OF ORIGINAL SPARE PARTS AVAILABLE WITH THIS PLANT

THIS PLANT IS AVAILABLE WITH THE COMPLETE ELECTRIC, AIR, GAS, RECYCLING INSTALLATIONTHIS PLANT CAN BE SOLD: WITH 4 LINES OR 2 AND 2 LINES

Learn More -

L-5951 WESTINGHOUSE 100 MW GAS TURBINES, LNG FIRED, 60 Hz, YEAR 1995

L-5951 WESTINGHOUSE 100 MW GAS TURBINES, LNG FIRED, 60 Hz, YEAR 1995REFERENCE NUMBER: L-5951

WESTINGHOUSE 100 MW GAS TURBINES, LNG FIRED, 60 Hz, YEAR 1995

GAS TURBINES

MAKE: WESTINGHOUSE

YEAR: 1995 (STOPPED IN JUNE 2013)

100 MW EACH X 6 = 600 MW TOTAL

QUANTITY: 5

Learn More -

M-7677 HIGH SPEED ALUMINUM NESPRESSO FILLING SEALING MACHINE

M-7677 HIGH SPEED ALUMINUM NESPRESSO FILLING SEALING MACHINEREFERENCE NUMBER: M-7677

Learn More

HIGH SPEED ALUMINUM NESPRESSO FILLING SEALING MACHINE

TECHNICAL PARAMETERS:

MODEL #1:

SPEED: 8,500 TO 9,600 CUPS PER HOUR

WORKING STATION: 4 LANES

MACHINE SIZE (LxWxH): 5000mm x 1000mm x 2600mm

MODEL #2:

SPEED: 4,000 TO 4,800 CUPS PER HOUR

WORKING STATION: 2 LANES

MACHINE SIZE (LxWxH): 5000mm x 900mm x 2600mm -

L-5111 M.A.N. B&W HFO FIRED POWER PLANT, 6.5 MW TOTAL, 50 Hz, YEAR 1999

L-5111 M.A.N. B&W HFO FIRED POWER PLANT, 6.5 MW TOTAL, 50 Hz, YEAR 1999REFERENCE NUMBER: L-5111

M.A.N. B&W HFO FIRED POWER PLANT, 6.5 MW TOTAL, 50 Hz, YEAR 1999

QUANTITY: 1

Learn More -

H-1591 VESTAS V29 WIND TURBINES 225 KW YEAR 1996 AND 1997

H-1591 VESTAS V29 WIND TURBINES 225 KW YEAR 1996 AND 1997REFERENCE NUMBER: H-1591

Learn More

BRAND: VESTAS

MODEL: V29

ROTOR DIAMETER: 29.00

POWER: 225KW

HUB HEIGHT: 30.00

WITH TRANSFORMER

STILL IN OPERATION

30 M TUBE TOWER ONE SECTION

GENERATORS 3X 400V AND 3X 690V

YEAR 1996 AND 1997

QUANTITY: 7 -

R-3246 STA RE-5 CONVECTION ROASTER - 5 KILOS

R-3246 STA RE-5 CONVECTION ROASTER - 5 KILOSR-3246 STA RE-5 CONVECTION ROASTER - 5 KILOS

THIS IS A REALLY GREAT ROASTER - ESPECIALLY FRIENDLY TO BLENDS AS IT CREATES A VERY EVEN ROAST WITH NO TIPPING OR SCORCHING. THIS IS A BRAND THAT IS MORE KNOWN IN ITALY - BUT THE STA ROASTING GROUP HAS A HISTORY OF PRINCIPALS WITH LOTS OF ROASTING MACHINERY BACKGROUND. THUS THEIR CHANGES ARE MORE TECHNICALLY ADVANCED AND NOT SO MUCH FOR COSMETICS.

FEATURES:

SINGLE PHASE

FOUR MOTORS

AUTOMATIC GAS BURNER TWO FANS (COOLING AND CHAFF COLLECTION)

CHAFF COLLECTION CHAMBER

CAPACITY IS 20 KG PER HOUR.

LOCATED IN CROATIATECHNICAL DATA:

CHARGE HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM IS PERFORATED FOR MAXIMUM AIR CONTROL

HEATING IS HOT CONVECTION AIR GENERATOR OF NEW GENERATION

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL - COOLING TRAY IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TRAY

ELECTRIC CONTROL BOARD TO CHECK AND CONTROL THE MACHINE ACCORDING CE RULES, INTEGRATED COMPLETE OF THERMO-REGULATOR DEVICE FOR BURNER MANAGEMENT AND DISPLAY FOR TEMPERATURES SIGHT

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TRAY

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TRAY

CYCLONE FOR CHAFF COLLECTING

SEMIAUTOMATIC MANAGEMENT OF THE ROASTING CYCLE.

FUEL: NATURAL GAS OR PROPANE

HEATING CONVECTION SYSTEM:

PATENTED SYSTEM BY STA IMPIANTI. THIS SYSTEM ALLOWS SHORTER AND HOMOGENEOUS ROASTING TIME:

BY CONVECTION OF HOT AIR FLOWING THROUGH THE COFFEE IN THE DRUM.

BY CONDUCTION (LIMITED AMOUNT ONLY) DUE TO THE HEATED AIR HITTING THE PERFORATED ROASTING DRUM.

BY RADIANCE FROM THE GRATE LOCATED BETWEEN THE FLAME AND THE ROASTING DRUM (INFRARED RAYS).SPECS:

ROASTER CAPACITY: 5 STANDARD 7 MAX TO KILOS PER CYCLE

INDICATIVE ROASTING CYCLE: 9 ÷ 20 MINUTES

INSTALLED POWER: 0,9 KW

THERMAL POWER: 10 KW

WEIGHT: 170 KG

DIMENSIONS: 850mm (34") L X 1150mm (45") W X 1530mm H (60")QUANTITY: 1

Learn More -

P-4957 STALAM RF DRYER YEAR 1997 85KW

P-4957 STALAM RF DRYER YEAR 1997 85KWP-4957 STALAM RF DRYER YEAR 1997 85KW

STALAM

MODEL: RF

DRYER

YEAR: 1997

85KW

WORK FREQUENCY OF GENERATOR: (I.S.M) 27.12 Mhz + 0.6%

COOLING SYSTEM OF GENERATORS: WATER COOLING OR AIR COOLING

AVERAGE EVAPORATION RATES: 1.2 / 1.3 KG (H20) / KW (RF) hQUANTITY: 1

Learn More -

R-1300 WARTSILA POWER PLANT, 4.2MW, 50HZ

R-1300 WARTSILA POWER PLANT, 4.2MW, 50HZR-1300 WARTSILA POWER PLANT, 4.2MW, 50HZ

DETAILS:

WARTSILA POWER PLANT

4.2MW

HFO 50HZ

COMPLETE OPERATING PLANT WITH ALL ACCESSORIES

THE WARTSILA ENGINE IS A MODEL 12V32LN

750RPM

THE GENERATOR IS MADE BY ABB AND RATED AT 5208KVA

.8 POWER FACTOR

THE EQUIPMENT INCLUDES 2 ALFA LAVAL HFO SEPARATOR UNITS

FUEL HANDLING EQUIPMENT

A COOLING TOWER AND ALL NECESSARY ACCESSORIES

INCLUDING A HSD DAY TANK WITH 999 LITER CAPACITY

ONLY 500 TOTAL OPERATING HOURS SINCE OVERHAULQUANTITY: 1

Learn More