Search results for: 'Process'

- Related search terms

- Process of clea

- Process+o

- Process of cl'

- process+eq

- process+equi'

-

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More

YY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINEYY-3146 PET / NEW FLAKES OR REGENERATED MATERIALS EXTRUSION LINE THE PLANT WAS USED IN FULLY CONTINUOUS OPERATION WHICH MEANS 24 / 7 FOR 350 DAYS PER YEAR. BULK MATERIALS OF ALL TYPES (PET BOTTLE FLAKES, RESINS / GRANULE CHIPS, REGRINDS OF VARIOUS TYPES OF MATERIALS AND AGGLOMERATES) WERE USED AS INPUT MATERIAL FROM THE EUROPEAN MARKET, BUT ALSO FROM ALL OVER THE WORLD. THE REGENERATED FIBERS PRODUCED WERE BETWEEN 3 DEN AND 25 DEN AND COULD BE USED FOR MANY DIFFERENT APPLICATIONS, SUCH AS AUTOMOTIVE, GEOTEXTILES, TECHNICAL TEXTILES AND ALL GENERAL TEXTILE SECTORS – ALWAYS IN 100% RECYCLED FIBERS. PREDOMINANTLY THE LINE WAS PRODUCING A HIGH QUALITY BLACK STAPLE FIBER! Learn More -

R-6854 BUHLER ROASTMASTER™20

R-6854 BUHLER ROASTMASTER™20R-6854 BUHLER ROASTMASTER™20

THE ROASTMASTER™20 BY BUHLER OFFERS EXACTLY WHAT START-UP BUSINESSES AND SMALL-SCALE INDUSTRIAL OPERATIONS REQUIRE TO PRODUCE TOP-QUALITY COFFEE. THE CAPACITY RANGES UP TO 70 KG OF GREEN BEANS PER HOUR. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST. ALL HOT AIR PASSES THROUGH THE ROTATING DRUM AND TRANSFERS ITS HEAT DIRECTLY TO THE BEANS IN A HOMOGENEOUS WAY. THIS HOT AIR PATHWAY ENSURES A HIGH PROPORTION OF CONVECTIVE HEAT TRANSFER RATHER THAN TO HEAT THE DRUM FROM BELOW. NO MATTER AT WHICH STAGE OF THE PROCESS, THE VARIABLE DRUM SPEED AND THE SOPHISTICATED INTERIOR DESIGN OF THE ROASTING CHAMBER DELIVER AN OPTIMAL BEAN DISTRIBUTION AND AN EFFICIENT INTERACTION OF THE BEANS WITH THE AIR. SILVERSKINS ARE SEPARATED IN THE CYCLONE. THE COMPACT DRUM ROASTER IS EQUIPPED WITH SEPARATE HEATING AND COOLING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES QUALITY CONSISTENCY DURING PRODUCTION BUT ALSO LEAVES ROOM FOR MANUAL INTERVENTION TO STEER THE PROCESSING WHEN NECESSARY.

ROASTMASTER™20. PROCESS FLEXIBILITY FOR YOUR FLAVOR SIGNATURE.

EACH COFFEE VARIETY IS UNIQUE BY NATURE AND REQUIRES INDIVIDUAL ROASTING CONDITIONS TO TRANSFORM THE FULL INTRINSIC FLAVOR POTENTIAL INTO GREAT FLAVOR. THE ROASTMASTER™20 IS EQUIPPED WITH A FULLY VARIABLE BURNER FOR FLEXIBLE ENERGY INPUT. THE FREQUENCY CONVERTER ON THE MAIN FAN ALLOWS FOR VARIABLE SPEED AND OPTIMIZED AIR-TO-BEAN-RATIO DURING THE DIFFERENT STAGES OF THE PROCESS. REGARDLESS WETHER YOU PREFER TRADITIONAL OR NON-CONVENTIONAL PROFILES, THE SOPHISTICATED MULTISTEP PROCESS CONTROL SOFTWARE INSPIRES PROFILE ROASTING FOR BEST FLAVOR GENERATION.DATA MANAGEMENT AND NEXT GENERATION CONNECTIVITY.

Learn More

THE FUTURE-SAFE CONCEPT INCLUDES AN EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, RECIPE MANAGEMENT, ONLINE TREND MONITORING, BATCH REPORT CREATION AND SAFETY FEATURES. MOREOVER THE EASY DATA EXPORT VIA USB PORT, ONLINE DATA TRANSFER TO EXTERNAL THIRD PARTY PROCESS MONITORING SOFTWARE AND REMOTE HMI VISUALIZATION AND PROCESS CONTROL ENSURE QUALITY CONSISTENCY DURING PRODUCTION. -

M-5283 ELMARCO NANOSPIDER PRODUCTION LINEREFERENCE NUMBER: M-5283 (13131CKAKT12U) L ELMARCO NANOSPIDER PRODUCTION LINE NANOSPIDER PRODUCTION LINE NS 4S1000U QUANTITY AVILABLE: 1 Learn More

M-5283 ELMARCO NANOSPIDER PRODUCTION LINEREFERENCE NUMBER: M-5283 (13131CKAKT12U) L ELMARCO NANOSPIDER PRODUCTION LINE NANOSPIDER PRODUCTION LINE NS 4S1000U QUANTITY AVILABLE: 1 Learn More -

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More

TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000TT-7724 CYKLOP BOTTLING LINE FOR BABY POWDER MILK 18000 CPH, YEAR 2000 1. BOTTLING LINE FOR BABY POWDER MILK 18000 CPH 2. BRAND: CYKLOP 3. YEAR: 2000 4. SPEED: 18000 CANS/HOUR 5. PRODUCTS: DAIRY 6. CONTAINERS: CAN Learn More -

TT-7340 TETRA PAK A3 FLEX 200S ASEPTIC FILLING LINE, CAPACITY UP TO 7000 L/H, YEAR 2003 TO 2010TT-7340 TETRA PAK A3 FLEX 200S ASEPTIC FILLING LINE, CAPACITY UP TO 7000 L/H, YEAR 2003 TO 2010 1. TETRA PAK A3 FLEX 200S ASEPTIC FILLING LINE 2. CAPACITY: UP TO 7000 L/H 3. USED 4. BRAND: TETRA PAK® 5. SPEED: 7000 L/H 6. PRODUCTS: DAIRY, JUICE 7. CONTAINERS: BRIK 8. FORMATS: 0.20 L 9. SAFETY FEATURES: YES 10. FILL TYPE: ASEPTIC 11. FILLING MACHINE TETRA PAK® A3 FLEX 200 ML SLIM YEAR 2006 12. STRAW APPLICATOR TETRA PAK® TETRA STRAW APPLICATOR 22 YEAR 2009 13. ACCUMULATOR TETRA PAK® ACHX30-0500-47M YEAR 2010 14. CASE PACKER TETRA PAK® CARDBOARD PACKER 70 YEAR 2003 QUANTITY: 1 Learn More

TT-7340 TETRA PAK A3 FLEX 200S ASEPTIC FILLING LINE, CAPACITY UP TO 7000 L/H, YEAR 2003 TO 2010TT-7340 TETRA PAK A3 FLEX 200S ASEPTIC FILLING LINE, CAPACITY UP TO 7000 L/H, YEAR 2003 TO 2010 1. TETRA PAK A3 FLEX 200S ASEPTIC FILLING LINE 2. CAPACITY: UP TO 7000 L/H 3. USED 4. BRAND: TETRA PAK® 5. SPEED: 7000 L/H 6. PRODUCTS: DAIRY, JUICE 7. CONTAINERS: BRIK 8. FORMATS: 0.20 L 9. SAFETY FEATURES: YES 10. FILL TYPE: ASEPTIC 11. FILLING MACHINE TETRA PAK® A3 FLEX 200 ML SLIM YEAR 2006 12. STRAW APPLICATOR TETRA PAK® TETRA STRAW APPLICATOR 22 YEAR 2009 13. ACCUMULATOR TETRA PAK® ACHX30-0500-47M YEAR 2010 14. CASE PACKER TETRA PAK® CARDBOARD PACKER 70 YEAR 2003 QUANTITY: 1 Learn More -

TT-7282 TETRA PAK ASEPTIC FILLING LINE A3 FLEX 200S UP TO 7000 L/H, YEAR 2003 TO 2010TT-7282 TETRA PAK ASEPTIC FILLING LINE A3 FLEX 200S UP TO 7000 L/H, YEAR 2003 TO 2010 1. BRAND: TETRA PAK® 2. SPEED: 7000 L/H 3. PRODUCTS: DAIRY, JUICE 4. CONTAINERS: BRIK 5. FORMATS: 0.20 L 6. SAFETY FEATURES: YES 7. FILL TYPE: ASEPTIC Learn More

TT-7282 TETRA PAK ASEPTIC FILLING LINE A3 FLEX 200S UP TO 7000 L/H, YEAR 2003 TO 2010TT-7282 TETRA PAK ASEPTIC FILLING LINE A3 FLEX 200S UP TO 7000 L/H, YEAR 2003 TO 2010 1. BRAND: TETRA PAK® 2. SPEED: 7000 L/H 3. PRODUCTS: DAIRY, JUICE 4. CONTAINERS: BRIK 5. FORMATS: 0.20 L 6. SAFETY FEATURES: YES 7. FILL TYPE: ASEPTIC Learn More -

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More

TT-6699 COMPLETE BOTTLING LINE, YEAR 2013TT-6699 COMPLETE BOTTLING LINE, YEAR 2013 1. COMPOSED OF FILLING MONOBLOCK + LABELING MACHINE 2. SPEED: 700 BPH 3. CONTAINERS: GLASS 4. FORMATS: 0.33 L 5. PRODUCT: BEER 6. FILL TYPE: ISOBARIC QUANTITY: 1 Learn More -

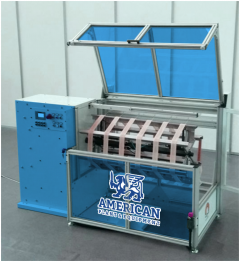

YY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLSYY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLS ELECTRIC SPECIFICATIONS: POWER CONSUMPTION: 1.0 KW SINGLE PHASE 230V 50/60Hz (CUSTOMIZABLE) SIZE OF THE MACHINE (LENGTH X WIDTH X HEIGHT): 3060 mm X 1580 mm X 2060 mm (120'' X 62'' X 81'') THE WOODEN CRATE SIZE IS 235 X 140 X 182 CM, WITH A GROSS WEIGHT OF 840 KG. THE MACHINE ITSELF WEIGHS 500 KG. QUANTITY: 1 Learn More

YY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLSYY-2756 SKEIN WINDER FOR LABORATORIES AND SMALL FIBER MILLS ELECTRIC SPECIFICATIONS: POWER CONSUMPTION: 1.0 KW SINGLE PHASE 230V 50/60Hz (CUSTOMIZABLE) SIZE OF THE MACHINE (LENGTH X WIDTH X HEIGHT): 3060 mm X 1580 mm X 2060 mm (120'' X 62'' X 81'') THE WOODEN CRATE SIZE IS 235 X 140 X 182 CM, WITH A GROSS WEIGHT OF 840 KG. THE MACHINE ITSELF WEIGHS 500 KG. QUANTITY: 1 Learn More -

TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011 QUANTITY: 1 Learn More

TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011TT-2363 LION AUTOMATIC BLOWER, NOZZLES 2, YEAR 2011 QUANTITY: 1 Learn More -

K-8157 COAL FIRED POWER PLANT (2 X 50MW)

K-8157 COAL FIRED POWER PLANT (2 X 50MW)K-8157 COAL FIRED POWER PLANT (2 X 50MW)

ENERGY BOILERS (CAE)

TURBINE SYSTEMS

STEAM TURBINES (TA) - DSL ARE 50 - 1

-CONDENSING TURBINE WITH TWO ADJUSTABLE OUTLETS, SUCH AS "ACTING" ON A SINGLE LINE OF TREES, DESIGNED TO DRIVE THE AC GENERATOR DIRECT-TYPE TH 60-2

-IS COMPOSED OF TWO BODIES: THE BODY OF HIGH PRESSURE (CIP) AND MEDIUM AND LOW PRESSURE BODY (CMP + CJP)

-HAS TWO ADJUSTABLE OUTLETS (PLUG SOCKETS AND PLUG HEATING) AND FIVE FIXED DOSES REGENERATIVE CIRCUIT FEEDSQUARES OF 600 CARS OVER T/H (WITH BUCKET WHEEL AND ARM LENGTH 12 M) - 4 PCS

-TIP HAMMER CRUSHERS CCA - 160 TO 2 PIECES

- RUBBER BANDS COAL TRANSPORTTHE MAIN EQUIPMENT IS ADDED TO ENSURE PROPER OPERATION FOLLOWING:

- SOLID FUEL STORAGE

- INSTALLATIONS AND INDUSTRIAL WATER SUPPLIES AND WASTEWATER DISCHARGE

- INSTALLATION OF EXHAUST HYDRAULIC SLAG

- WATER TREATMENT STATION

TO USE COAL, WEIGHT 88%, 12% NATURAL GASQUANTITY: 1

Learn More