Search results for: 'Steel ta'

- Related search terms

- steel bolt

- steel strip

- steel and iron

- steel+and+iron

- Steel+ta

-

YY-1136 ULTRAVIOLET STERILIZERYY-1136 ULTRAVIOLET STERILIZER MAINTENANCE OF UV STERILIZER: 1 CHECK REGULARLY TO ENSURE THE NORMAL OPERATION OF THE UV LAMP. 2. AFTER 9000 HOURS OR ONE YEAR OF CONTINUOUS USE, THE ULTRAVIOLET LAMP SHOULD BE REPLACED. WHEN REPLACING A NEW LAMP, FIRST UNPLUG THE POWER SOCKET OF THE LAMP AND TAKE OUT THE ULTRAVIOLET LAMP. PAY ATTENTION NOT TO TOUCH THE QUARTZ GLASS OF THE NEW LAMP WITH YOUR FINGERS, BECAUSE THE STAIN WILL AFFECT THE INTENSITY OF THE LIGHT, AND CAREFULLY PUT THE LAMP INTO THE CHAMBER OF THE STERILIZER. Learn More

YY-1136 ULTRAVIOLET STERILIZERYY-1136 ULTRAVIOLET STERILIZER MAINTENANCE OF UV STERILIZER: 1 CHECK REGULARLY TO ENSURE THE NORMAL OPERATION OF THE UV LAMP. 2. AFTER 9000 HOURS OR ONE YEAR OF CONTINUOUS USE, THE ULTRAVIOLET LAMP SHOULD BE REPLACED. WHEN REPLACING A NEW LAMP, FIRST UNPLUG THE POWER SOCKET OF THE LAMP AND TAKE OUT THE ULTRAVIOLET LAMP. PAY ATTENTION NOT TO TOUCH THE QUARTZ GLASS OF THE NEW LAMP WITH YOUR FINGERS, BECAUSE THE STAIN WILL AFFECT THE INTENSITY OF THE LIGHT, AND CAREFULLY PUT THE LAMP INTO THE CHAMBER OF THE STERILIZER. Learn More -

TT-1984 APPLE JUICE FACILITY, 90,000 LBS/HR IN, 15,500 LBS/HR OUTTT-1984 APPLE JUICE FACILITY, 90,000 LBS/HR IN, 15,500 LBS/HR OUT ITEM 001 4-EFFECT EVAPORATOR / CONCENTRATOR, MANUFACTURED BY APV, PREVIOUSLY RUNNING DEPECTINIZED FRUIT JUICE AT RATE OF 170 GPM-IN AT 3-4 BIX, 20 GPM-OUT AT 70 BRIX (90,000 LBS/HR IN, 15,500 LBS/HR OUT). STEAM CONSUMPTION OF 16,000 POUNDS PER HOUR AT 125 PSI. TOWER WATER RUNNING 1,650 GPM AT 50 DEG F. INCLUDES MATCHED CAPACITY UHT PASTEURIZING SYSTEM. EFFECTS CONSIST OF 1A/1B, 2, 3A/3B, 4A, 4B. COMPLETE SYSTEM WITH PLATE HEAT EXCHANGERS, TANKS, PUMPS, AND CONTROLS. ITEM 002 CROSSFLOW MICROFILTRATION SYSTEM, MANUFACTURED BY TECHSEP, WITH CARBOSEP CARBON MEMBRANES. HIGH SIDE AND LOW SIDE EACH RATED FOR 40 GPM FOR A TOTAL OF 80 GPM. CARBOSEP MEMBRANES FEATURE SINTERED CARBON MEMBRANE SUPPORT, METALLIC OXIDE MEMBRANE LAYER, MEASURES 1200MM/47.25 LONG X 10 MM/0.4” OD, 6 MM/0.23” ID, RATED FOR 40 BAR/580 PSI BURSTING PRESSURE, 15 BAR/217 PSI SERVICE PRESSURE, 0 TO 14 SERVICE PH, MICROFILTRATION AT 0.14 MICRONS. STAINLESS STEEL FILTRATION HOUSING MEASURES 9” DIAMETER X 4’ LONG. (3) SKIDS, EACH DRIVEN BY 60 HP GOULDS XLT-X CENTRIFUGAL PUMP. INCLUDES (2) STAINLESS STEEL CARTS OF EXTRA PARTS AND THOUSANDS OF UNUSED SPARE FILTRATION TUBE MEMBRANES STILL IN BOXES. ITEM 003 (2) 10,000 GALLON STAINLESS STEEL TANKS, MEASURES 8’ DIAMETER X 15’ HIGH, SINGLE WALL CONSTRUCTION, INCLUDES 5 HP SIDE AGITATOR MANUFACTURED BY MIXMOR, DRIVEN BY 5 HP MOTOR. FEATURES 4” CENTER BOTTOM DISCHARGE, MANWAY OPENING, AND 7.5 HP TRANSFER PUMP. ITEM 004 GRANULAR DECOLORING CARBON FILTRATION SYSTEM, LAST USED TO PROCESS FRUIT JUICE AT RATE OF 150 GPM. CONSISTS OF (2) FILTRATION COLUMNS, EACH MEASURING 3’ DIAMETER X 16’ HIGH STRAIGHT SIDE, APPROXIMATELY 850 GALLONS WITH DISH TOP AND BOTTOM; 4,000 GALLON STAINLESS STEEL SINGLE WALL “CAUSTIC” TANK WHICH MEASURES 8’ DIAMETER X 10’ HIGH STRAIGHT SIDE, 2,000 GALLON STAINLESS STEEL TANK MEASURING 6’ DIAMETER X 10’ HIGH WITH DISH BOTTOM AND 3” OUTLET; SECONDARY FILTER SKID WITH (2) COLUMNS, EACH MEASURING 8” DIAMETER X 3’ HIGH; 200 GALLON STAINLESS STEEL CIP TANK MEASURING 40” DIAMETER X 32” HIGH WITH DISH TOP; AND 10 HP FRISTAM PUMP. ITEM 005 ALFA LAVAL / DE LAVAL AUTOMATIC DESLUDGING DISC CENTRIFUGE, MODEL BRPX 417 SEV 31CCL – 60/88 – 1008 – 13, MANUFACTURING NUMBER 2982935, RATED FOR MAX SPEED OF 3980 R/M. DRIVEN BY 50 HP, INCLUDES 10 HP TRANSFER PUMP, ALLEN BRADLEY DIGITAL CONTROLS. ITEM 006 WESTFALIA AUTOMATIC DESLUDING DISC CENTRIFUGE, MODEL SB80-06-177, SERIAL # 1668 988, MANUFACTURED IN 1980, RATED FOR MAX BOWL RPM OF 4430, 1.1 KG/DM3 OF HEAVY LIQUID, 1.3 KG/DM3 OF SLOIDS. DRIVEN BY 75 HP TOSHIBA MOTOR, INCLUDES CONTROL PANEL WITH ALLEN BRADLEY TOUCHSCREEN CONTROLS. Learn More

TT-1984 APPLE JUICE FACILITY, 90,000 LBS/HR IN, 15,500 LBS/HR OUTTT-1984 APPLE JUICE FACILITY, 90,000 LBS/HR IN, 15,500 LBS/HR OUT ITEM 001 4-EFFECT EVAPORATOR / CONCENTRATOR, MANUFACTURED BY APV, PREVIOUSLY RUNNING DEPECTINIZED FRUIT JUICE AT RATE OF 170 GPM-IN AT 3-4 BIX, 20 GPM-OUT AT 70 BRIX (90,000 LBS/HR IN, 15,500 LBS/HR OUT). STEAM CONSUMPTION OF 16,000 POUNDS PER HOUR AT 125 PSI. TOWER WATER RUNNING 1,650 GPM AT 50 DEG F. INCLUDES MATCHED CAPACITY UHT PASTEURIZING SYSTEM. EFFECTS CONSIST OF 1A/1B, 2, 3A/3B, 4A, 4B. COMPLETE SYSTEM WITH PLATE HEAT EXCHANGERS, TANKS, PUMPS, AND CONTROLS. ITEM 002 CROSSFLOW MICROFILTRATION SYSTEM, MANUFACTURED BY TECHSEP, WITH CARBOSEP CARBON MEMBRANES. HIGH SIDE AND LOW SIDE EACH RATED FOR 40 GPM FOR A TOTAL OF 80 GPM. CARBOSEP MEMBRANES FEATURE SINTERED CARBON MEMBRANE SUPPORT, METALLIC OXIDE MEMBRANE LAYER, MEASURES 1200MM/47.25 LONG X 10 MM/0.4” OD, 6 MM/0.23” ID, RATED FOR 40 BAR/580 PSI BURSTING PRESSURE, 15 BAR/217 PSI SERVICE PRESSURE, 0 TO 14 SERVICE PH, MICROFILTRATION AT 0.14 MICRONS. STAINLESS STEEL FILTRATION HOUSING MEASURES 9” DIAMETER X 4’ LONG. (3) SKIDS, EACH DRIVEN BY 60 HP GOULDS XLT-X CENTRIFUGAL PUMP. INCLUDES (2) STAINLESS STEEL CARTS OF EXTRA PARTS AND THOUSANDS OF UNUSED SPARE FILTRATION TUBE MEMBRANES STILL IN BOXES. ITEM 003 (2) 10,000 GALLON STAINLESS STEEL TANKS, MEASURES 8’ DIAMETER X 15’ HIGH, SINGLE WALL CONSTRUCTION, INCLUDES 5 HP SIDE AGITATOR MANUFACTURED BY MIXMOR, DRIVEN BY 5 HP MOTOR. FEATURES 4” CENTER BOTTOM DISCHARGE, MANWAY OPENING, AND 7.5 HP TRANSFER PUMP. ITEM 004 GRANULAR DECOLORING CARBON FILTRATION SYSTEM, LAST USED TO PROCESS FRUIT JUICE AT RATE OF 150 GPM. CONSISTS OF (2) FILTRATION COLUMNS, EACH MEASURING 3’ DIAMETER X 16’ HIGH STRAIGHT SIDE, APPROXIMATELY 850 GALLONS WITH DISH TOP AND BOTTOM; 4,000 GALLON STAINLESS STEEL SINGLE WALL “CAUSTIC” TANK WHICH MEASURES 8’ DIAMETER X 10’ HIGH STRAIGHT SIDE, 2,000 GALLON STAINLESS STEEL TANK MEASURING 6’ DIAMETER X 10’ HIGH WITH DISH BOTTOM AND 3” OUTLET; SECONDARY FILTER SKID WITH (2) COLUMNS, EACH MEASURING 8” DIAMETER X 3’ HIGH; 200 GALLON STAINLESS STEEL CIP TANK MEASURING 40” DIAMETER X 32” HIGH WITH DISH TOP; AND 10 HP FRISTAM PUMP. ITEM 005 ALFA LAVAL / DE LAVAL AUTOMATIC DESLUDGING DISC CENTRIFUGE, MODEL BRPX 417 SEV 31CCL – 60/88 – 1008 – 13, MANUFACTURING NUMBER 2982935, RATED FOR MAX SPEED OF 3980 R/M. DRIVEN BY 50 HP, INCLUDES 10 HP TRANSFER PUMP, ALLEN BRADLEY DIGITAL CONTROLS. ITEM 006 WESTFALIA AUTOMATIC DESLUDING DISC CENTRIFUGE, MODEL SB80-06-177, SERIAL # 1668 988, MANUFACTURED IN 1980, RATED FOR MAX BOWL RPM OF 4430, 1.1 KG/DM3 OF HEAVY LIQUID, 1.3 KG/DM3 OF SLOIDS. DRIVEN BY 75 HP TOSHIBA MOTOR, INCLUDES CONTROL PANEL WITH ALLEN BRADLEY TOUCHSCREEN CONTROLS. Learn More -

E-4553INVENTORY NUMBER: E-4553 FOAM MACHINERY FOR SALE QUANTITY AVAILABLE: 33 LOTS Learn More

E-4553INVENTORY NUMBER: E-4553 FOAM MACHINERY FOR SALE QUANTITY AVAILABLE: 33 LOTS Learn More -

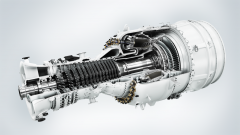

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More -

TT-1512 TOBY II BARGE TRUCK TRAILER, DIMENSIONS 56’ X 8’6”, YEAR 2002TT-1512 TOBY II BARGE TRUCK TRAILER, DIMENSIONS 56’ X 8’6”, YEAR 2002 BARGE TRUCK TRAILER DIMENSIONS 56’ X 8’6” TOBY II BARGE PACKAGE YEAR: 2002 MODEL: BARGE, TRUCK & TRAILER ENGINE: CAT ULTRAJET 375 HULL: STEEL INCREDIBLY RARE 56’ X 8’6” STEEL SELF PROPELLED BARGE WITH CAT DIESEL AND ULTRAJET DRIVE. VERY SHALLOW DRAFT. PACKAGE INCLUDES 1986 FREIGHTLINER - VERY HEAVY-DUTY TRACTOR AND TRAILER. FLEXIBLE PACKAGE TO TAKE ANYWHERE FOR WORK. EXTREMELY LOW HOURS. OFFERS CONSIDERED FOR BARGE ONLY OR BARGE AND TRAILER ONLY. BARGE IS IN EXCELLENT CONDITION. QUANTITY: 1 Learn More

TT-1512 TOBY II BARGE TRUCK TRAILER, DIMENSIONS 56’ X 8’6”, YEAR 2002TT-1512 TOBY II BARGE TRUCK TRAILER, DIMENSIONS 56’ X 8’6”, YEAR 2002 BARGE TRUCK TRAILER DIMENSIONS 56’ X 8’6” TOBY II BARGE PACKAGE YEAR: 2002 MODEL: BARGE, TRUCK & TRAILER ENGINE: CAT ULTRAJET 375 HULL: STEEL INCREDIBLY RARE 56’ X 8’6” STEEL SELF PROPELLED BARGE WITH CAT DIESEL AND ULTRAJET DRIVE. VERY SHALLOW DRAFT. PACKAGE INCLUDES 1986 FREIGHTLINER - VERY HEAVY-DUTY TRACTOR AND TRAILER. FLEXIBLE PACKAGE TO TAKE ANYWHERE FOR WORK. EXTREMELY LOW HOURS. OFFERS CONSIDERED FOR BARGE ONLY OR BARGE AND TRAILER ONLY. BARGE IS IN EXCELLENT CONDITION. QUANTITY: 1 Learn More -

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More -

J-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINEJ-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINE MAKE: AIM (AUTOMATED INDUSTRIAL MACHINERY) MODEL: AFM 2 DG (ACCUFORM MODULAR 2DX) TILTING TABLE SINGLE STAGE BENDING HEAD OPTIONS: P8 F1 WE SERIAL NUMBER: C 3 F0701 2009 WIRING DIAGRAM: AFM 2D6 – P8WEF1 – 490 – V8 – 3 VOLTAGE: 460 VOLTS FREQUENCY: 50 / 60 Hz FULL LOAD: 40 KVA LARGEST LOAD: 9 KVA DIMENSIONS OF THE STAINLESS STEEL TABLE: WIDTH 15 FEET 1 INCH x LENGTH 10 FEET 5 inches LOWER STAINLESS STEEL TABLE EXPENSION DIMENSIONS: WIDTH 8 FEET x LENGTH 37.5 INCHES QUANTITY: 1 Learn More

J-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINEJ-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINE MAKE: AIM (AUTOMATED INDUSTRIAL MACHINERY) MODEL: AFM 2 DG (ACCUFORM MODULAR 2DX) TILTING TABLE SINGLE STAGE BENDING HEAD OPTIONS: P8 F1 WE SERIAL NUMBER: C 3 F0701 2009 WIRING DIAGRAM: AFM 2D6 – P8WEF1 – 490 – V8 – 3 VOLTAGE: 460 VOLTS FREQUENCY: 50 / 60 Hz FULL LOAD: 40 KVA LARGEST LOAD: 9 KVA DIMENSIONS OF THE STAINLESS STEEL TABLE: WIDTH 15 FEET 1 INCH x LENGTH 10 FEET 5 inches LOWER STAINLESS STEEL TABLE EXPENSION DIMENSIONS: WIDTH 8 FEET x LENGTH 37.5 INCHES QUANTITY: 1 Learn More -

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More

YY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLERYY-2144 MULTIFUNCTION COATING HEAD, 1650mm BY KNIFE OR 1750mm BY ENGRAVED ROLLER DETAILS: 1. COMBINED COATING MACHINE FOR ONE FINISHING AND COATING NOMINAL WIDTH 1800mm. MAXIMUM COATING WIDTH: BY KNIFE 1650mm, BY ENGRAVED ROLLER 1750mm WITH FOLLOWING WORKING MODES POSSIBILITIES: - REVERSE ROLL - SYNCHRO ROLL - REVERSE ROLL "ON AIR" - SYNCHRO ROLL "ON AIR" - BLADE "ON AIR" - BLADE ON COUNTER- ROLLER COMPOSED OF: - WELDED STEEL FRAMEWORK WITH HIGH; - ORSION RIGIDITY; - RUBBERIZED COUNTER-ROLLER DIAMETER 400mm, OIL AND SOLVENTS RESISTANT; - HARDNESS 85 SHORE A, MAX ECCENTRICITY TOLERANCE ±1/100mm; - A/C GEARMOTOR TO DRIVE THE COUNTER ROLLER; - ROLLER CHANGING DEVICE (BRIDGE), ARRANGED TO MOUNT TWO ENGRAVED ROLLERS AND ONE COATING KNIFE; - PNEUMATIC LIFTING OF CHANGING DEVICE (BRIDGE); - MANUAL ROTATION OF THE ROLLER CHANGING DEVICE; - MOTORIZED MICROMETRIC ADJUSTMENT OF COATING THICKNESS, INDEPENDENT RIGHT/LEFT OR IN TANDEM, WITH DIGITAL DISPLAY ON CONTROL PANEL, BY TWO JACKS; - COATING SIDE LIMITERS, MANUALLY ADJUSTABLE EITHER SINGLE OR TANDEM; - FEEDING THROUGH IN FRONT OF THE COATING KNIFE; - A/C GEARMOTOR TO DRIVE THE ENGRAVED ROLLER; - TWO COLOUR DOCTOR BLADES (SYNCHRO / REVERSE) WITH PNEUMATIC OPENING AND CLOSING FOR A SMOOTHER MOVEMENT OF THE BLADE TOWARDS THE ROLLER, WITH OSCILLATING MOVEMENT; - ENTRY IDLER ROLLER, THE UPPER ONE LIFTABLE BY PNEUMATIC PISTONS FOR "ON AIR" COATING; - PIPING FOR THE WASHING OF THE ENGRAVED ROLLER; - TWO SIDE GUTTERS IN STAINLESS-STEEL WITH TEFLON COATING, WITH SOLVENT RESISTANT RUBBER PIPE FOR WASTEWATER OR CHEMICALS COLLECTION AND RECIRCULATION; - WASTEWATER RECOVERY BASIN, WITH DRAIN, UNDER THE COUNTER-ROLLER; - MANUAL SEAM JUMPER; - VARIABLE SPEED FROM 2,5 TO 50 M/MIN FOR THE COUNTER-ROLLER AND FROM 2,5 TO 99 M/MIN FOR THE ENGRAVED ROLLER; - PIVOTING CONTROL PANEL WITH DIGITAL SCREEN, MOUNTED ON THE MACHINE FRAME, TO CONTROL AND SET THE MACHINE FUNCTIONS; - MAIN ELECTRICAL PANEL EQUIPPED WITH PLC AND INVERTERS, PROTECTION IP54, MOUNTED INSIDE THE LEFT HAND MACHINE SHOULDER; - SET OF MACHINE ACCESSORIES AND INSTRUCTION & MAINTENANCE MANUAL. Learn More -

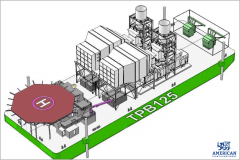

TT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANTTT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANT 173 MWE POWER BARGE SGT SERIES 5 2000E TURBINE AMOUNTED ON BARGE BRAND NEW UNIT TWIN INSTALLATION. 300MW 2856 RPM 60Hz - CAN OPERATE ON EITHER LIQUID FUEL OR GAS; - TRANSPORTABLE BY TOWING OR ON HEAVY LIFT VESSELS; - CAN BE MOORED AT BERTH OR POSITIONED IN PROTECTED WATERS USING SPUDS; - FUEL SUPPLY BY STORAGE BARGE OR PIPED FROM LAND-BASED STORAGE; - ENVIRONMENTALLY FRIENDLY; - BARGE & SYSTEMS ABS CLASSED; - APPROVED BY LLOYDS OF LONDON. Learn More

TT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANTTT-3411 REVERSE OSMOSIS PLANT, PRODUCTION 20 MILLION US GALLONS PER DAY – SEA WATER DESALINATION PLANT 173 MWE POWER BARGE SGT SERIES 5 2000E TURBINE AMOUNTED ON BARGE BRAND NEW UNIT TWIN INSTALLATION. 300MW 2856 RPM 60Hz - CAN OPERATE ON EITHER LIQUID FUEL OR GAS; - TRANSPORTABLE BY TOWING OR ON HEAVY LIFT VESSELS; - CAN BE MOORED AT BERTH OR POSITIONED IN PROTECTED WATERS USING SPUDS; - FUEL SUPPLY BY STORAGE BARGE OR PIPED FROM LAND-BASED STORAGE; - ENVIRONMENTALLY FRIENDLY; - BARGE & SYSTEMS ABS CLASSED; - APPROVED BY LLOYDS OF LONDON. Learn More -

P-5072 STA IMPIANTI ROASTER 15 KILOS

P-5072 STA IMPIANTI ROASTER 15 KILOSP-5072 STA IMPIANTI ROASTER 15 KILOS

ROASTING MACHINES LINE PARTICULARLY SUITABLE FOR ARTISANAL SPECIALIZED ACTIVITIES IN MEDIUM BATCHES OF HIGH-QUALITY ROASTED COFFEE, SUCH AS ARTISAN MARKET OR COFFEE SHOPS. TECHNOLOGICALLY ADVANCED, CONFIRMS THEMELVES AS IDEAL TOOL FOR ROASTING COMPANIES SPECIALIZED IN SELECTED COFFEES OF HIGHER QUALITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS OR DIESEL-FUEL BURNER AT MULTIPLE LEVELS OF FLAME AND MANUAL OR AUTOMATIC CONTROL SYSTEM.

TECHNICAL DATA:

ROASTER CAPACITY: 15 KG. | MAX. 19 KG./ CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 60 KG. ÷ 90

INSTALLED ELECTRIC POWER: 1,8 KW | 380 VOLT THREEPHASE + NEUTRAL 50 HZ

THERMAL POWER: 24,000 KCAL/H/ 29 KW.

(NATURAL GAS OR LPG)MAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL.

COOLING TANK IN STAINLESS STEEL WITH DOOR FOR CLEANING OPERATIONS

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD TO CHECK AND CONTROL THE MACHINE ACCORDING CE RULES, COMPLETE OF PLC + TOUCH SCREEN FOR MACHINE MANAGEMENT AND TEMPERATURES SIGHT.

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTINGDETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE AND DOOR UNLOADING SYSTEM

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM ALLOWS THE PRODUCT UNLOADING.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM (N°2 FLAME LEVELS)

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH 3 ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE ELEMENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD FOR MACHINE MANAGEMENT ACCORDING CE RULES INTEGRATED.

COMPLETE OF PLC + TOUCH SCREEN FOR MACHINE MANAGEMENT AND TEMPERATURES VISUALIZATION.

POSSIBLE RECORDING OF ROASTING PARAMETERS.

CYCLONE FOR CHAFFS COLLECTING

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC FAN FOR COOLING TANK.QUANTITY: 1

Learn More