Search results for: 'red pro'

- Related search terms

- Prod'

- Produ'

- Process o

- Production ca

- Production+ca

-

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

H-1261 GOOSE FEATHER CLEANING MACHINE

H-1261 GOOSE FEATHER CLEANING MACHINEH-1261 GOOSE FEATHER CLEANING MACHINE

LIST OF COMPONENTS FOR THE GOOSE FEATHER CLEANING MACHINE:

1) RINSING MACHINE OF THE TYPE 2000 (STAINLESS STEEL USED FOR IT)

EXTERIOR DIMENSION: 4000×2000×2600×Ф1800MM

QUANTITY: 12) GOOSE FEATHER ADDING MACHINE

EXTERIOR DIMENSION: 4000×1800×3300MM

QUANTITY: 13) WATER TANK

EXTERIOR DIMENSION: Ф1930MM×2440MM

QUANTITY: 14) DEWATERING MACHINE FLAT PLATE TYPE (BEING EQUIPPED WITH VARIABLE FREQUENCY CONTROL) - 2 SETS

QUANTITY: 25)DRYER OF THE TYPE 2000 (BEING EQUIPPED WITH ELECTRONIC WEIGHING)

EXTERIOR DIMENSION: 4500×2100×2900MM

QUANTITY: 16)GOOSE FEATHER ADDING MACHINE FOR DRYER(STAINLESS STEEL USED FOR IT AND ELECTRONIC WEIGHING INCLUDED)

EXTERIOR DIMENSION: 1500×1200×3600MM

QUANTITY: 17)THE COOLER OF THE TYPE 4700(STEEL & WOOD STRUCTURE, OPTIMIZED MOISTURE PROOF PANEL)

EXTERIOR DIMENSION: 4700×2350×2600×Ф2000MM

QUANTITY: 18) SORTING EQUIPMENT

QUANTITY: 29) POWER DISTRIBUTION CABINET

QUANTITY: 2RINSING MACHINE: TYPE 2000

1. EXTERIOR DIMENSION: 4000×2000×2600×Ф1800MM DIAMETER

2.THE MATERIAL OF 14MM IN THICKNESS STAINLESS STEEL IS USED FOR THE WALL FOR WASHING MACHINE AND 5MM IN THICKNESS FOR BARREL

3. THE MATERIAL OF AISI 1045 IS USED FOR THE SPINDLE OF THE SQUARE SHAPE(SPECIFICATION =108MMX108MM). WRAPPED WITH 2MM STAINLESS STEEL IN THE OUTER.

10MM IN THICKNESS STAINLESS STEEL IS FOR HOOP OF VANE.

4MM IN THICKNESS STAINLESS STEEL WHICH IS FOLDED IS FOR VANE.

HOOP SCREW OF M14 X 70 (HIGH STRENGTH GRADE) ARE USED.

THE BEARING HOUSING &BEARING OF UKP318 IS USED FOR THE SPINDLE.4.THE SIEVE OF 1.5MM IN THICKNESS STAINLESS STEEL IS USED FOR WACHING MACHINE.THE HOLE IS 1.8MM IN DIAMETER. HOLE SPACING 3.8MM .THE STAINLESS STEEL OF 2MM IS USED FOR THE OBLIQUE OF OUTPUTTING THE GOOSE FEATHER.THE OUTLET NEAR DEWATERING MACHINE FOR GOOSE FEATHER CAN BE TURNED UPWARD. FOR GOOSE FEATHER.

5.THE PIPE FOR WATER INLET IS 114MM IN DIAMETER

6.THE POWER OF FAN: 7.5KW AND SPEED: 2900R/M

7.THE PIPE FOR FEEDING GOOSE FEATHER IS 250MM IN DIAMETER.

8.THE REDUCER FOR THE SPINDLE: JZQ-400. THE POWER OF MOTOR IS 15KW AND OUTPUT SPEED IS 42 R/M

9.EXTERIOR DIMENSION OF THE BOTTOM FOR WASHING MACHINE: WIDTH=1600MM;LENGTH=3500MM.ONE SIEVE OF 1MM IN THICKNESS FOR IT.

WATER TANK

1. THE DIMENSION OF TANK: Ф1930MM×2440MM

2.THE STAINLESS STEELOF 2MM IN THICKNESS FOR ITS BARREL AND 3MM FOR THE BOTTOM.THE COVER IS CONSTUCTED WITH ANGLE IRON OF STAINLESS STEEL AND INNER COVER 2MM STAINLESS STEEL PLATE.

DEWATERING MACHINE OF TYPE 1600

1. ONE SETS OF RINSING MACHING OF THE TYPE 2000 IS EQUIPPED WITH TWO SETS DEWATERING MACHINE OF THE TYPE 1600

2.THE POWER OF MOTOR=11KW-17KW.DOUBLE SPEED MOTOR WITH VARIABLE FREQUENCY CONTROL.

DRYER OF TYPE 2000

1. EXTERIOR DIMENSION: 4500×2100×2900×Ф1800MM(DIAMETER)

2. THE MATERIAL OF 14MM IN THICKNESS STAINLESS STEEL(Q345R) IS USED FOR THE WALL FOR WASHING MACHINE. 10MM STAINLESS STEEL(Q345R) IS USED FOR INNER COVER OF THE BARREL AND 10MM STAINLESS STEEL (Q345R) PLATE FOR OUTER COVER OF THE BARREL.

3. THE INNER WALL OF WIND PLATE IS 0.5MM IN THICKNESS AND THE HOLE 1.5MM IN DIAMETER STAINLESS STEEL. 3MM COLD ROLLED PLATE IS USED FOR THE OUTER GATE.

4. THE SEAMLESS PIPE OF Ф108MM×10MM IS FOR THE MAIN SPINDLE.THE STEEL PLATE OF 10MM IN THICKNESS IS FOR THE VANE.THE WIDTH OF THE VANE IS 80MM. HOOP SCREW IS M12X70

6. THERE ARE FOUR INLET OF 1.5INCH IN DIAMETER FOR STEAM.

RELIEF VALVE FROM 3 KILO TO 7 (1 SETS)

THE PRESSURE GAGE (0-16 KILO) (2 SETS)

THE THERMOMETER (0-150 DEGREE) (1 SETS)

THERE ARE THREE DRAIN HOLE OF 1.5 INCH IN DIAMETER AT THE BOTTOM6. THERE ARE TWO LAYERS FOR GOOSE FEATHER ADDING FOR DRYER: 1.5×1.2×3.6M.THEY ARE MADE WITH STAINLESS STEEL.THE SPECIFICATION OF CHARGING SPOUT ON THE TOP OF DRYER IS 1.55 X 0.55M.

7. THE OUTLET FOR GOOSE FEATHER OF DRYER CAN BE TURNED UPWARD.THE PIPE FOR OUTPUTTING GOOSE FEATHER IS 300MM IN DIAMETER.

8. TWO FANS ARE EQUIPPED FOR PRECISE WASHING LINE.THE POWER OF FAN FOR ADDING GOOSE FEATHER IS 7.5KW,SPEED: 2900R/M.WHICH IS USED TOGETHER WITH GOOSE ADDING MACHINE OF WASHING MACHINE.THE POWER OF FAN FOR DRYER IS 5.5KW,SPEED IS 2900 R/M.

9. MAIN SHAFT SPEED REDUCER FOR BELT BRIDGE MOTOR 7.5KW.OUTPUT SPEED IS 52 R/M

THE COOLER IS OF TYPE 47001. EXTERIOR DIMENSION: 4700×2350×2600×Ф2000MM DIAMETER

2. THE EXTERIOR IS CONSTRUCTED WITH THE WHOLE WOOD STRUCTURE.THE MATERIAL OF STEEL WITH 4# ANGLE STEEL AND 30X30 SQUARE TUBE IS FOR THE INNER SKELETON.

3. THE SEAMLESS PIPE OF Ф108MM×10MM IS FOR THE MAIN SPINDLE.THE STEEL PLATE OF 14MM IN THICKNESS IS FOR THE VANE.THE WIDTH OF THE VANE IS 80MM. HOOP SCREW IS M16X70

4. THE DIAMETER OF WIND PIPE: MAIN PIPE IS 300MM IN DIAMETER AND BRANCH IS 250MM IN DIAMETER.THERE ARE FOUR AIR OUTLET OF 300MM IN DIAMETER EQUIPPED EQUALLY SPACE.

5. ONE SIEVE IS EQUIPPED FOR THE COOLER.THE SIEVE IS MADE WITH 0.6MM IN THICKNESS GALVANIZED STEEL SHEET.THE HEIGHT OF HOLE IS 1.1MM.THE SCREEN FRAME IS MADE WITH 3# ANGLE STEEL.

6.THERE ARE TWO SORTING BOX WHICH IS CONSTRUCTED WITH STEEL FRAME AND WOODEN STRUCTURE. SIEVE 14 MESH GALVANIZED MESH BOLD

7. ONE FAN IS FOR THE COOLER.THE POWER OF THE FAN IS 11KW AND OUTPUT SPEED IS 2900 R/M

8. THE MOTOR FOR THE MAIN SPINDLE IS 15KW (6 POLE).THE SPEED OF 140 R/M IS FOR THE COOLER.

QUANTITY: 1

Learn More -

M-5957 SLAUGHTERING EQUIPMENT – 3,000 BIRDS PER HOURREFERENCE NUMBER: M-5957 (770137RDP6UX) L SLAUGHTERING EQUIPMENT – 3,000 BIRDS PER HOUR SLAUGHTERING EQUIPMENT PRODUCT: WHOLE BIRDS & CUT-UP PLANT TYPE: SEMI-AUTO KIND OF BIRDS: BROILER MINIMUM LIVE WEIGHT: 1.2 KG MAXIMUM LIVE WEIGHT: 2.2 KG AVERAGE LIVE WEIGHT: 1.7 KG CAPACITY PER HOUR: 3,000 BIRDS BLEEDING TIME: 4 MINUTES SCALDING TEMPERATURE: 58 TO 63 °C SCALDING TIME: 90 SECONDS PRE-CHILLING TIME: 45 MINUTES TOTAL TIME OF WORK PER DAY: 10 HOURS Learn More

M-5957 SLAUGHTERING EQUIPMENT – 3,000 BIRDS PER HOURREFERENCE NUMBER: M-5957 (770137RDP6UX) L SLAUGHTERING EQUIPMENT – 3,000 BIRDS PER HOUR SLAUGHTERING EQUIPMENT PRODUCT: WHOLE BIRDS & CUT-UP PLANT TYPE: SEMI-AUTO KIND OF BIRDS: BROILER MINIMUM LIVE WEIGHT: 1.2 KG MAXIMUM LIVE WEIGHT: 2.2 KG AVERAGE LIVE WEIGHT: 1.7 KG CAPACITY PER HOUR: 3,000 BIRDS BLEEDING TIME: 4 MINUTES SCALDING TEMPERATURE: 58 TO 63 °C SCALDING TIME: 90 SECONDS PRE-CHILLING TIME: 45 MINUTES TOTAL TIME OF WORK PER DAY: 10 HOURS Learn More -

C-1866 HORIZONTAL CROSS LAPPER, WIDTH 4700mm, WITH CONVEYOR SPEED MAX 80 M/MIN (NEW)REFERENCE NUMBER: C-1866 HORIZONTAL CROSS LAPPER, WIDTH 4700mm, WITH CONVEYOR SPEED MAX 80 M/MIN (NEW) DETAILS: HORIZONTAL CROSS LAPPER SHCH4 90” M/C DIMENSION: 3400W X 8000L X 1900H mm LAYING WIDTH: 2300mm WORKING WIDTH: 4700mm CONVEYOR SPEED: MAXIMUM 80 m/min CONVEYOR MATERIAL: SIEGRING (MADE IN GERMANY) DRIVE: A.MAIN MOTOR: 7.5 HP (SERVO MOTOR) -1 B.CARRIAGE MOTOR: 7.5 Hp (SERVO MOTOR) -2 C. UNDER LATTICE MOTOR: 1 HP (AC INVERTER, GEAR REDUCER)-1 D. UNDER LATTICE UP/DOWN: 1 HP (GEAR REDUCER) -1 MACHINE HAS PROFILING CONTROL QUANTITY AVAILABLE: 1 Learn More

C-1866 HORIZONTAL CROSS LAPPER, WIDTH 4700mm, WITH CONVEYOR SPEED MAX 80 M/MIN (NEW)REFERENCE NUMBER: C-1866 HORIZONTAL CROSS LAPPER, WIDTH 4700mm, WITH CONVEYOR SPEED MAX 80 M/MIN (NEW) DETAILS: HORIZONTAL CROSS LAPPER SHCH4 90” M/C DIMENSION: 3400W X 8000L X 1900H mm LAYING WIDTH: 2300mm WORKING WIDTH: 4700mm CONVEYOR SPEED: MAXIMUM 80 m/min CONVEYOR MATERIAL: SIEGRING (MADE IN GERMANY) DRIVE: A.MAIN MOTOR: 7.5 HP (SERVO MOTOR) -1 B.CARRIAGE MOTOR: 7.5 Hp (SERVO MOTOR) -2 C. UNDER LATTICE MOTOR: 1 HP (AC INVERTER, GEAR REDUCER)-1 D. UNDER LATTICE UP/DOWN: 1 HP (GEAR REDUCER) -1 MACHINE HAS PROFILING CONTROL QUANTITY AVAILABLE: 1 Learn More -

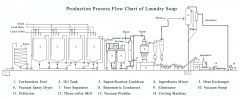

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More -

M-3982 AUTEFA LAPPER 3000 X 4500 YEAR 2003 - 100 METERS PER MINUTEREFERENCE NUMBER: M-3982 (9905HKMF8U)-D AUTEFA LAPPER 3000 X 4500 YEAR 2003 - 100 METERS PER MINUTE AUTEFA CROSSLAPPER 100 METERS PER MINUTE YEAR 2003 3000 X 4500 QUANTITY AVAILABLE: 1 Learn More

M-3982 AUTEFA LAPPER 3000 X 4500 YEAR 2003 - 100 METERS PER MINUTEREFERENCE NUMBER: M-3982 (9905HKMF8U)-D AUTEFA LAPPER 3000 X 4500 YEAR 2003 - 100 METERS PER MINUTE AUTEFA CROSSLAPPER 100 METERS PER MINUTE YEAR 2003 3000 X 4500 QUANTITY AVAILABLE: 1 Learn More -

G-1606 SPECIALTY FOAM FORM MACHINEREFERENCE NUMBER: G-1606 SPECIALTY FOAM FORM MACHINE FOR BIKER PADS, OFFICE CHAIRS, PILLOWS, ETC. FORM-PROFILE-CUTTING MACHINE SC11 S TECHNICAL DATA: WORKING CUTTING WIDTH: 1100mm WORKING CUTTING LENGTH: 1200mm VERTICAL ADJUSTMENT OF THE BLADE FROM TABLE: 0/195mm VERTICAL STROKE OF THE PRESS-CONVEYOR: 0/195mm MAXIMUM HEIGHT OF THE FOAM TO BE WORKED: 220mm MAXIMUM DIMENSION OF THE MOULD: 1100 X 1200mm TABLE SPEED: 5/17 M/MIN POWER: 6 KW TENSION: 400 V APPROXIMATE WEIGHT: 1200 KGS QUANTITY AVAILABLE: 1 Learn More

G-1606 SPECIALTY FOAM FORM MACHINEREFERENCE NUMBER: G-1606 SPECIALTY FOAM FORM MACHINE FOR BIKER PADS, OFFICE CHAIRS, PILLOWS, ETC. FORM-PROFILE-CUTTING MACHINE SC11 S TECHNICAL DATA: WORKING CUTTING WIDTH: 1100mm WORKING CUTTING LENGTH: 1200mm VERTICAL ADJUSTMENT OF THE BLADE FROM TABLE: 0/195mm VERTICAL STROKE OF THE PRESS-CONVEYOR: 0/195mm MAXIMUM HEIGHT OF THE FOAM TO BE WORKED: 220mm MAXIMUM DIMENSION OF THE MOULD: 1100 X 1200mm TABLE SPEED: 5/17 M/MIN POWER: 6 KW TENSION: 400 V APPROXIMATE WEIGHT: 1200 KGS QUANTITY AVAILABLE: 1 Learn More -

G-1567 BIKER PANT PAD MOULDREFERENCE NUMBER: G-1567 BIKER PANT PAD MOULD FORM-PROFILE-CUTTING MACHINE SC11 S TECHNICAL DATA: WORKING CUTTING WIDTH: 1100mm WORKING CUTTING LENGTH: 1200mm VERTICAL ADJUSTMENT OF THE BLADE FROM TABLE: 0/195mm VERTICAL STROKE OF THE PRESS-CONVEYOR: 0/195mm MAXIMUM HEIGHT OF THE FOAM TO BE WORKED: 220mm MAXIMUM DIMENSION OF THE MOULD: 1100 X 1200mm TABLE SPEED: 5/17 M/MIN POWER: 6 KW TENSION: 400 V APPROXIMATE WEIGHT: 1200 KGS QUANTITY AVAILABLE: 1 Learn More

G-1567 BIKER PANT PAD MOULDREFERENCE NUMBER: G-1567 BIKER PANT PAD MOULD FORM-PROFILE-CUTTING MACHINE SC11 S TECHNICAL DATA: WORKING CUTTING WIDTH: 1100mm WORKING CUTTING LENGTH: 1200mm VERTICAL ADJUSTMENT OF THE BLADE FROM TABLE: 0/195mm VERTICAL STROKE OF THE PRESS-CONVEYOR: 0/195mm MAXIMUM HEIGHT OF THE FOAM TO BE WORKED: 220mm MAXIMUM DIMENSION OF THE MOULD: 1100 X 1200mm TABLE SPEED: 5/17 M/MIN POWER: 6 KW TENSION: 400 V APPROXIMATE WEIGHT: 1200 KGS QUANTITY AVAILABLE: 1 Learn More -

G-6332 BOX MIXING TANK FOR FOAM WITH AUTOMATIC COMPUTERIZED CHEMICAL FEEDREFERENCE NUMBER: G-6332 BOX MIXING TANK FOR FOAM (NEW) WITH AUTOMATIC COMPUTERIZED CHEMICAL FEED QUANTITY AVAILABLE: 1 Learn More

G-6332 BOX MIXING TANK FOR FOAM WITH AUTOMATIC COMPUTERIZED CHEMICAL FEEDREFERENCE NUMBER: G-6332 BOX MIXING TANK FOR FOAM (NEW) WITH AUTOMATIC COMPUTERIZED CHEMICAL FEED QUANTITY AVAILABLE: 1 Learn More