Search results for: 'screw c'

- Related search terms

- Screw

- Screw Compressor

- screw comp

- screw compresso

- Screw Com

-

YY-3530 COLINES FILM EXTRUSION LINES, CAST FILM, MODEL ALLROLL EX 1500, YEAR 2018YY-3530 COLINES FILM EXTRUSION LINES, CAST FILM, MODEL ALLROLL EX 1500, YEAR 2018 1. MANUFACTURER: COLINES 2. MODEL: ALLROLL EX 1500 3. YEAR: 2018 4. NUMBER OF LAYERS: 5 QUANTITY: 1 Learn More

YY-3530 COLINES FILM EXTRUSION LINES, CAST FILM, MODEL ALLROLL EX 1500, YEAR 2018YY-3530 COLINES FILM EXTRUSION LINES, CAST FILM, MODEL ALLROLL EX 1500, YEAR 2018 1. MANUFACTURER: COLINES 2. MODEL: ALLROLL EX 1500 3. YEAR: 2018 4. NUMBER OF LAYERS: 5 QUANTITY: 1 Learn More -

TT-6229 LEISTRITZ ZSE 67 GL EXTRUSION - TWIN SCREW EXTRUDER, YEAR 1990TT-6229 LEISTRITZ ZSE 67 GL EXTRUSION - TWIN SCREW EXTRUDER, YEAR 1990 1. BRAND: LEISTRITZ 2. MODEL: ZSE 67 GL 3. YEAR: 1990 QUANTITY: 1 Learn More

TT-6229 LEISTRITZ ZSE 67 GL EXTRUSION - TWIN SCREW EXTRUDER, YEAR 1990TT-6229 LEISTRITZ ZSE 67 GL EXTRUSION - TWIN SCREW EXTRUDER, YEAR 1990 1. BRAND: LEISTRITZ 2. MODEL: ZSE 67 GL 3. YEAR: 1990 QUANTITY: 1 Learn More -

TT-6205 LEISTRITZ EXTRUDER ZSE40 MAXX44D, YEAR 2005TT-6205 LEISTRITZ EXTRUDER ZSE40 MAXX44D, YEAR 2005 1. LEISTRITZ EXTRUDER ZSE40 MAXX44D 2. YEAR 2005 QUANTITY: 1 Learn More

TT-6205 LEISTRITZ EXTRUDER ZSE40 MAXX44D, YEAR 2005TT-6205 LEISTRITZ EXTRUDER ZSE40 MAXX44D, YEAR 2005 1. LEISTRITZ EXTRUDER ZSE40 MAXX44D 2. YEAR 2005 QUANTITY: 1 Learn More -

TT-5611 DAVIS STANDARD SINGLE SCREW EXTRUDER – NEW, 100mm, YEAR 2018TT-5611 DAVIS STANDARD SINGLE SCREW EXTRUDER – NEW, 100mm, YEAR 2018 DAVIS STANDARD SINGLE SCREW EXTRUDER NEW QUANTITY: 1 Learn More

TT-5611 DAVIS STANDARD SINGLE SCREW EXTRUDER – NEW, 100mm, YEAR 2018TT-5611 DAVIS STANDARD SINGLE SCREW EXTRUDER – NEW, 100mm, YEAR 2018 DAVIS STANDARD SINGLE SCREW EXTRUDER NEW QUANTITY: 1 Learn More -

TT-3780 AMUT TWIN SCREW PIPE-PROFILE EXTRUDER WITH Ø 67mm SCREWS, 1000 X 100mmTT-3780 AMUT TWIN SCREW PIPE-PROFILE EXTRUDER WITH Ø 67mm SCREWS, 1000 X 100mm AMUT TWIN SCREW EXTRUDER AMUT PIPE-PROFILE EXTRUDER QUANTITY: 1 Learn More

TT-3780 AMUT TWIN SCREW PIPE-PROFILE EXTRUDER WITH Ø 67mm SCREWS, 1000 X 100mmTT-3780 AMUT TWIN SCREW PIPE-PROFILE EXTRUDER WITH Ø 67mm SCREWS, 1000 X 100mm AMUT TWIN SCREW EXTRUDER AMUT PIPE-PROFILE EXTRUDER QUANTITY: 1 Learn More -

TT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KVTT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KV WARTSILA 18V32 HFO GENERATOR 6MW HOURS: 4175H, 3784H ALTERNATORS: JYOTI LTD, LEROY SOMER 50Hz 6.6KV QUANTITY: 2 Learn More

TT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KVTT-1744 WARTSILA 18V32 HFO GENERATOR, 6MW, 50Hz, 6.6KV WARTSILA 18V32 HFO GENERATOR 6MW HOURS: 4175H, 3784H ALTERNATORS: JYOTI LTD, LEROY SOMER 50Hz 6.6KV QUANTITY: 2 Learn More -

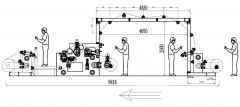

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More -

E-4258 POLYESTER PACKING TAPE MACHINE (FROM RECYCLED PET SCRAP)INVENTORY NUMBER: E-4258 POLYESTER PACKING TAPE MACHINE (FROM RECYCLED PET SCRAP): XDC TSE-65/32 PET PRODUCTION CONDITION: NEW 1. ELECTRICAL VOLTAGE: 380V/3P/50HZ OR AS PER CUSTOMER 2. MATERIAL: PET SCRAP 3. MAX. EXTRUSION OUTPUT: 350KG PER HOUR NOTE:PRODUCTION CAPACITY DEPENDS ON RAW MATERIAL AND OPERATION. 4. SPECIFICATION:WIDTH OF TAPE 9 TO 24 mm, THICKNESS: 0.5 TO 1.2 mm 5. LINE SPEED:80M/MIN 6. CENTER HEIGHT OF EXTRUDER: 1000 mm 7. OPERATION DIRECTION: FROM RIGHT TO LEFT 8. POWER REQUIREMENT: 212KW(APPROX. 127KW AT CONTINUOUS USAGE) 9. COOLING RECYCLE: ≤20℃ ≥0.3MPA ~2T/H 10. AIR CONSUMPTION: 0.4 CUBIC METER PER MINUTE; PRESSURE >0.5MPA QUANTITY AVAILABLE: 1 Learn More

E-4258 POLYESTER PACKING TAPE MACHINE (FROM RECYCLED PET SCRAP)INVENTORY NUMBER: E-4258 POLYESTER PACKING TAPE MACHINE (FROM RECYCLED PET SCRAP): XDC TSE-65/32 PET PRODUCTION CONDITION: NEW 1. ELECTRICAL VOLTAGE: 380V/3P/50HZ OR AS PER CUSTOMER 2. MATERIAL: PET SCRAP 3. MAX. EXTRUSION OUTPUT: 350KG PER HOUR NOTE:PRODUCTION CAPACITY DEPENDS ON RAW MATERIAL AND OPERATION. 4. SPECIFICATION:WIDTH OF TAPE 9 TO 24 mm, THICKNESS: 0.5 TO 1.2 mm 5. LINE SPEED:80M/MIN 6. CENTER HEIGHT OF EXTRUDER: 1000 mm 7. OPERATION DIRECTION: FROM RIGHT TO LEFT 8. POWER REQUIREMENT: 212KW(APPROX. 127KW AT CONTINUOUS USAGE) 9. COOLING RECYCLE: ≤20℃ ≥0.3MPA ~2T/H 10. AIR CONSUMPTION: 0.4 CUBIC METER PER MINUTE; PRESSURE >0.5MPA QUANTITY AVAILABLE: 1 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More