Search results for: 'combin machine'

- Related search terms

- Machine+c

- Machine+op

- MACHINE+S

- Machine fe'

- machine''''

-

A-1228 SCHLAFHORST SRZ SE 9 ACO 288 YEARS 1993 & 1995 BELCORO 340BDREFERENCE NUMBER: A-1228 (0101GHBXX12) A SCHLAFHORST SRZ SE 9 ACO 288 YEARS 1993 & 1995 BELCORO 340BD 7 MACHINES 1993 1 MACHINE 1995 QUANTITY AVAILABLE: 8 Learn More

A-1228 SCHLAFHORST SRZ SE 9 ACO 288 YEARS 1993 & 1995 BELCORO 340BDREFERENCE NUMBER: A-1228 (0101GHBXX12) A SCHLAFHORST SRZ SE 9 ACO 288 YEARS 1993 & 1995 BELCORO 340BD 7 MACHINES 1993 1 MACHINE 1995 QUANTITY AVAILABLE: 8 Learn More -

TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS)TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS) SLITTER REWINDER MAX SLITTING WIDTH: 1600mm (CAN BE CUSTOMIZED FROM 800mm TO 3000mm) MINI SLITTING WIDTH: 10mm UNWINDING DIAMETER: 600mm REWINDING DIAMETER: 300mm AUTOMATIC CUTTING MACHINE FOR FILM ROLLS: AFTER YOU SET THE PARAMETER IT WOULD CUT THE FILM ROLLS TO SMALL WIDTH ROLLS AUTOMATICALY WORKING WIDTH: 1500mm LARGE ROLL MATERIAL DIAMETER MAX: 350mm NO PROBLEM FOR THIS MACHINE TO SLIT YOUR PVC FILM MATERIAL Learn More

TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS)TT-3204 SINGLE SHAFT AUTO CUTTING MACHINE, WORKING WIDTH 1500mm (BALONEY SLITTER, SUITABLE FOR FILMS) SLITTER REWINDER MAX SLITTING WIDTH: 1600mm (CAN BE CUSTOMIZED FROM 800mm TO 3000mm) MINI SLITTING WIDTH: 10mm UNWINDING DIAMETER: 600mm REWINDING DIAMETER: 300mm AUTOMATIC CUTTING MACHINE FOR FILM ROLLS: AFTER YOU SET THE PARAMETER IT WOULD CUT THE FILM ROLLS TO SMALL WIDTH ROLLS AUTOMATICALY WORKING WIDTH: 1500mm LARGE ROLL MATERIAL DIAMETER MAX: 350mm NO PROBLEM FOR THIS MACHINE TO SLIT YOUR PVC FILM MATERIAL Learn More -

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

P-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOSP-5075 BUHLER VARIABLE PROFILE ROASTER 20 KILOS

THIS ROASTER OFFERS EXACTLY WHAT CUSTOMERS NEED TO PRODUCE TOP-QUALITY COFFEE. AN INNOVATIVE AND EASY-TO-USE PLC CONTROL SYSTEM ENSURES CONSTANT QUALITY DURING PRODUCTION BUT ALSO RETAINS THE ABILITY TO INFLUENCE THE PROCESSING WHEN NECESSARY. OPTIMIZED PARAMETERS CAN BE SAVED IN THE MACHINE’S MEMORY AND RE-USED. THE MACHINE IS MADE OF STAINLESS STEEL AND OTHER HIGH-QUALITY MATERIALS WHICH PROVIDE SUPERIOR HYGIENE AND MAKE CLEANING COMFORTABLE. THIS ROASTER PROVES THAT DURABILITY AND A MODERN DESIGN CAN BE COMBINED.

THE ROASTER BECOMES A PLUG-AND-PLAY MACHINE BY THE COMBINATION OF SEPARATE COOLING AND HEATING FANS WHICH ALLOW TO ROAST AND COOL AT THE SAME TIME WITH THE INCLUDED CYCLONE. HOT AIR IS THE BEST CHOICE TO ENSURE A UNIFORM ROAST, BECAUSE OF THE HOMOGENOUS HEAT TRANSFER.

THE VARIABLE DRUM SPEED OF THE ROASTING CHAMBER AND THE TWO STEP BURNER ALWAYS DELIVER THE BEST CONDITIONS FOR THE PRODUCT – NO MATTER IF THE BEANS ARE HEAVY AND SMALL AT THE BEGINNING OF THE PROCESS OR IF THEY HAVE ALREADY BECOME LIGHTER TOWARDS TO THE END OF THE ROAST. THE HELICOIDAL BLADES POWERED BY A VARIABLE DRUM SPEED DRIVE OFFER A PERFECT BLENDING AND AN OPTIMAL HEAT EXCHANGE AT ANY TIME OF THE PROCESS. MOREOVER, THE ERGONOMICALLY DESIGNED ROASTER PROVIDES MAXIMUM SAFETY.

THIS ROASTER WAS DESIGNED TO PROVIDE SMALL AND MEDIUM-SIZED COMPANIES WITH A FLEXIBLE HIGH-QUALITY SOLUTION. THE SOPHISTICATED DESIGN OF THE ROASTING MACHINE PLUS MODERN PROCESS TECHNOLOGY ENSURES A HIGH-QUALITY COFFEE PRODUCT THAT IS UNIFORMLY ROASTED – FROM THE SURFACE TO THE CORE OF EVERY SINGLE COFFEE BEAN.

THE COFFEE AND THE HOT AIR TEMPERATURE AS WELL AS THE ROASTING TIME PER BATCH IS PERMANENTLY MONITORED VIA THE TOUCH SCREEN. THE MACHINE’S DESIGN FEATURES AND INSULATING MATERIALS REDUCE INERTIA AND HEAT LOSS TO A MINIMUM, WHICH IMPACTS POSITIVELY ON WORKING ENVIRONMENTS AND FUEL CONSUMPTION.

FEATURES:

AUTOMATIC AND EASY-TO-USE PLC CONTROL SYSTEM WITH INTEGRATED TOUCH PANEL, PARAMETER MEMORY, TEMPERATURE TREND AND SAFETY FEATURES.

GOOD VALUE FOR MONEY.

INDIRECT, CONVECTIVE HOT-AIR SYSTEM FOR UNIFORM ROASTING.

FULL RANGE HEAT CONTROL - BURNER MODULATES BETWEEN 130,000 BTU ALL THE WAY DOWN TO A MERE 20,000 BTU

VARIABLE DRUM SPEEDS OFFER OPTIMAL HEAT TRANSFER AND PRODUCT QUALITY.

FUNCTIONAL AND ATTRACTIVE MACHINE DESIGN MADE OF HIGH-QUALITY MATERIAL.

STATE-OF-THE-ART TECHNOLOGY AND A PLC CONTROL SYSTEM OFFER USER-FRIENDLY AND EFFICIENT COFFEE ROASTING.

A WIDE VARIETY OF GREEN COFFEE CHARACTERISTICS AND BLENDS CAN BE PROCESSED TO HIGH-CLASS COFFEE PRODUCTS.

A USER-FRIENDLY AUTOMATION-PANEL ALLOWS THE PERFECT CONTROL OVER VARIOUS PROCESS PARAMETERS.

UL LISTED AND MADE RIGHT HERE IN MINNEAPOLIS.

GAS CONSUMPTION: RATED AT MAXIMUM - UP TO 150,000BTU (44KW/HR) OPERATES BEST BETWEEN 75 - 80,000 BTUOPTIONAL FEATURES:

PNEUMATIC FEEDER

PNEUMATIC DESTONER/DISCHARGE UNIT

AFTERBURNERQUANTITY: 1

Learn More -

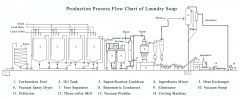

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

M-3803 SCHLAFHORST SRZ SE ACO 288 FOR COTTON DENIM YARNS YEAR 1993-1995

M-3803 SCHLAFHORST SRZ SE ACO 288 FOR COTTON DENIM YARNS YEAR 1993-1995REFERENCE NUMBER: M-3803

SCHLAFHORST SRZ SE ACO 288 FOR COTTON DENIM YARNS YEAR 1993-1995

SCHLAFHORST OPEN END SPINNING MACHINES FOR COTTON DENIM YARNS

SCHLAFHORST SRZ SE 9 ACO 288

7 X YEAR 1993

1 X YEAR 1995

240 ROTORS PER MACHINE

ROTOR TYPE: BELCORO 340BD

NAVAL: KN4 (SCHLAFHORST)

PIECER: TWO (2) PER MACHINE

DOFFER/SHUTTLE: ONE (1) PER MACHINE

COROLAB CLEARING SYSTEM INSTALLED PER MACHINE

NO WAXING DEVICES

(1) STARTER STATION PER MACHINE

COMBING ROLL: B174

SLUBBING DEVICE: ENGINEERED TO MODEL AMSLER MACHINE

VOLTAGE: 480/60HZ

(5) SPARE SECTIONS (48 POSITIONS COMPLETE, 48 POSITIONS WITH SPIN BOX, BUT WINDING ENDS MISSING, 24 POSITIONS STRIPPED OF PARTS)

(3) SPARE PIECERS (MOST PARTS MISSING)

(1) SPARE DOFFER

(1) SPARE SHUTTLE

QUANTITY: 8

Learn More -

TT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mmTT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mm MANUFACTURER: DILO NON WOVEN CONDITION: NEW MIN. ORDER: 1 PIECE APPLICATION: CARDING FIBER AUTOMATIC GRADE: AUTOMATIC QUANTITY: 1 Learn More

TT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mmTT-3472 NEEDLE PUNCHING FELT MACHINE SIMILAR DESIGN AS DILO NEEDLE PUNCHING MACHINE, WORKING WIDTH: 2000mm TO 9000mm MANUFACTURER: DILO NON WOVEN CONDITION: NEW MIN. ORDER: 1 PIECE APPLICATION: CARDING FIBER AUTOMATIC GRADE: AUTOMATIC QUANTITY: 1 Learn More -

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More -

YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004 HIGH PRODUCTION DIRECT FEEDING SYSTEM MADE BY MASIAS ON 2004 SUITABLE FOR THE PRODUCTION OF QUILTS (DUVETS & MATTRESSES) AND/OR WADDING. ALSO, SOME NEEDLEPUNCHED SPECIAL PRODUCTS FOR FURNITURE/MATTRESSES/TRANSPORT PROTECTION. Learn More

YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004 HIGH PRODUCTION DIRECT FEEDING SYSTEM MADE BY MASIAS ON 2004 SUITABLE FOR THE PRODUCTION OF QUILTS (DUVETS & MATTRESSES) AND/OR WADDING. ALSO, SOME NEEDLEPUNCHED SPECIAL PRODUCTS FOR FURNITURE/MATTRESSES/TRANSPORT PROTECTION. Learn More -

YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98%YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98% DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS CORE COMPONENTS: BEARING APPLICATION: TEXTILE/ FIBER /WOOL/ CASHMERE AUTOMATIC GRADE: AUTOMATIC PRODUCTION EFFICIENCY: 98% POWER: 3.0 KW DIMENSIONS (L X W X H): 4450 X 2400 X 1550 mm WEIGHT: 4500 KG NAME: OPENING MACHINE MACHINE TYPE: RIGHT HAND FEEDING TYPE: PHOTOELECTRIC CONTROL AUTOMATIC FEEDING QUANTITY: 1 Learn More

YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98%YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98% DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS CORE COMPONENTS: BEARING APPLICATION: TEXTILE/ FIBER /WOOL/ CASHMERE AUTOMATIC GRADE: AUTOMATIC PRODUCTION EFFICIENCY: 98% POWER: 3.0 KW DIMENSIONS (L X W X H): 4450 X 2400 X 1550 mm WEIGHT: 4500 KG NAME: OPENING MACHINE MACHINE TYPE: RIGHT HAND FEEDING TYPE: PHOTOELECTRIC CONTROL AUTOMATIC FEEDING QUANTITY: 1 Learn More -

J-3943 CONVOLUTER, MAXIMUM WORKING WIDTH 2150mm (84”)J-3943 CONVOLUTER, MAXIMUM WORKING WIDTH 2150mm (84”) DELIVERY 3RD WEEK OF NOVEMBER 2021 IN ALMOST NEW CONDITION LOCATED IN THE UNITED STATES CONVOLUTING WIDTH MAX: W 2150 mm (84") CONVOLUTING PIN DEPTH: 30 mm (1.18") CONVOLUTING RUNNING SPEED: 0 TO 25 RPM TOTAL POWER: 10.74 KW CUTTING SPEED: 0 TO 25 METERS PER MINUTE CUTTER BLADE TOTAL LENGTH: 9800 mm BLADE WIDTH x THICKNESS: 50mm x 0.65mm MACHINE WEIGHT: 2500 KG MACHINE OVERALL DIMENSIONS: 15.4 FEET WIDE X 4.1 FEET DEEP X 5 FEET TALL MAXIMUM HEIGHT OF FOAM: 200mm (8”) QUANTITY: 1 Learn More

J-3943 CONVOLUTER, MAXIMUM WORKING WIDTH 2150mm (84”)J-3943 CONVOLUTER, MAXIMUM WORKING WIDTH 2150mm (84”) DELIVERY 3RD WEEK OF NOVEMBER 2021 IN ALMOST NEW CONDITION LOCATED IN THE UNITED STATES CONVOLUTING WIDTH MAX: W 2150 mm (84") CONVOLUTING PIN DEPTH: 30 mm (1.18") CONVOLUTING RUNNING SPEED: 0 TO 25 RPM TOTAL POWER: 10.74 KW CUTTING SPEED: 0 TO 25 METERS PER MINUTE CUTTER BLADE TOTAL LENGTH: 9800 mm BLADE WIDTH x THICKNESS: 50mm x 0.65mm MACHINE WEIGHT: 2500 KG MACHINE OVERALL DIMENSIONS: 15.4 FEET WIDE X 4.1 FEET DEEP X 5 FEET TALL MAXIMUM HEIGHT OF FOAM: 200mm (8”) QUANTITY: 1 Learn More