Search results for: 'equip'

- Related search terms

- equipm

- equipme

- equipment

- equipment'

- equip'

-

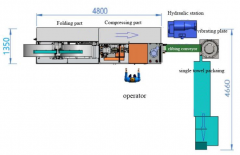

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

TT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mmTT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mm MOTHER ROLL WIDTH: 380mm OUTPUT LINE: 6 LINES MOTHER ROLL QUANTITY: 4 PIECES FINISHED PAD DIAMETER: 57mm MOTHER ROLL MATERIAL: SPUNLACE NON-WOVEN FABRIC PRODUCTION SPEED: 2500 TO 3000 PIECES/MINUTE RATED VOLTAGE: 380 VOLTS (OR 220 VOLTS) RATED FREQUENCY: 50Hz (OR 60 Hz) TOTAL POWER: 3.5 KW DIMENSIONS: LENGTH 5500mm × WIDTH 1200mm × HEIGHT 2000mm WEIGHT: 2500 KG QUANTITY: 1 Learn More

TT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mmTT-1678 ROUND CLEANING PAD MAKING MACHINE WITH EMBOSSING, WIDTH 380mm MOTHER ROLL WIDTH: 380mm OUTPUT LINE: 6 LINES MOTHER ROLL QUANTITY: 4 PIECES FINISHED PAD DIAMETER: 57mm MOTHER ROLL MATERIAL: SPUNLACE NON-WOVEN FABRIC PRODUCTION SPEED: 2500 TO 3000 PIECES/MINUTE RATED VOLTAGE: 380 VOLTS (OR 220 VOLTS) RATED FREQUENCY: 50Hz (OR 60 Hz) TOTAL POWER: 3.5 KW DIMENSIONS: LENGTH 5500mm × WIDTH 1200mm × HEIGHT 2000mm WEIGHT: 2500 KG QUANTITY: 1 Learn More -

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More -

M-5136 COMPLETE PACKAGE DYE HOUSEREFERENCE NUMBER: M-5136 (1212PZWKHH11) L COMPLETE PACKAGE DYE HOUSE 3 PRESSURE DRYERS 13 HIGH TEMPERATURE CONE DYEING MACHINES 3 LABORATORY HIGH TEMPERATURE DYEING MACHINES 2 LABORATORY HIGH TEMPERATURE DYEING MACHINES 1 COLOUR TESTER 1 LABORATORY DYEING MACHINE 1 LABORATORY HIGH TEMPERATURE CONE DYEING MACHINE 1 CONE CENTRIFUGE 1 WASHING TESTER 2 DRYING OVENS 2 COLOUR TESTER 1 CROCKTESTER QUANTITY AVAILABLE: 1 Learn More

M-5136 COMPLETE PACKAGE DYE HOUSEREFERENCE NUMBER: M-5136 (1212PZWKHH11) L COMPLETE PACKAGE DYE HOUSE 3 PRESSURE DRYERS 13 HIGH TEMPERATURE CONE DYEING MACHINES 3 LABORATORY HIGH TEMPERATURE DYEING MACHINES 2 LABORATORY HIGH TEMPERATURE DYEING MACHINES 1 COLOUR TESTER 1 LABORATORY DYEING MACHINE 1 LABORATORY HIGH TEMPERATURE CONE DYEING MACHINE 1 CONE CENTRIFUGE 1 WASHING TESTER 2 DRYING OVENS 2 COLOUR TESTER 1 CROCKTESTER QUANTITY AVAILABLE: 1 Learn More -

M-0630 SIMA PROMATECH EXTRUSION LINEREFERENCE NUMBER: M-0630 SIMA PROMATECH EXTRUSION LINE EXTRUSION LINE MADE BY SIMA/PROMATECH AND ESSENTIALLY CONSISTING OF: EXTRUDER 130mm DIAMETER AUTOSCREEN GEAR PUMP DIE 1700mm CHILL ROLL DIAMETER: 450 X 1800 AND AIR KNIFE CUTTING UNIT FIRST GODET, 3 ROLLS, DIAMETER 315 X 1650mm, PLUS 1 NIP ROLL STRETCHING OVEN 5000 X 1600 SECOND GODET, 6 ROLLS, DIAMETER 315 X 1650mm, PLUS 2 NIP ROLLS FIBRILLATOR UNIT ANNEALING GODET, 9 ROLLS + NIP ROLL CENTRAL CABINET HOT OIL EQUIPMENT FOR ANNEALING GODET WASTE SUCTION EQUIPMENT AS NEW QUANTITY AVAILABLE: 1 Learn More

M-0630 SIMA PROMATECH EXTRUSION LINEREFERENCE NUMBER: M-0630 SIMA PROMATECH EXTRUSION LINE EXTRUSION LINE MADE BY SIMA/PROMATECH AND ESSENTIALLY CONSISTING OF: EXTRUDER 130mm DIAMETER AUTOSCREEN GEAR PUMP DIE 1700mm CHILL ROLL DIAMETER: 450 X 1800 AND AIR KNIFE CUTTING UNIT FIRST GODET, 3 ROLLS, DIAMETER 315 X 1650mm, PLUS 1 NIP ROLL STRETCHING OVEN 5000 X 1600 SECOND GODET, 6 ROLLS, DIAMETER 315 X 1650mm, PLUS 2 NIP ROLLS FIBRILLATOR UNIT ANNEALING GODET, 9 ROLLS + NIP ROLL CENTRAL CABINET HOT OIL EQUIPMENT FOR ANNEALING GODET WASTE SUCTION EQUIPMENT AS NEW QUANTITY AVAILABLE: 1 Learn More -

TT-7587 SIEMENS TG50D5/W701DS GAS TURBINE GENERATOR, 127.8 MW, YEAR 1995TT-7587 SIEMENS TG50D5/W701DS GAS TURBINE GENERATOR, 127.8 MW, YEAR 1995 1. SIEMENS WESTINGHOUSE TG50D5/W701DS 127.8 MW GAS TURBINE GENERATOR PACKAGES FOR SALE. THE TURBINE PACKAGES TOGETHER OFFER 255 MW READY TO SHIP EQUIPMENT. THIS TECHNOLOGY IS ONE OF THE MOST WIDESPREAD MIDDLE SIZE ENGINES (100-104 MW) FOR POWER GENERATION AND THE ONLY TURBINE OF ITS SIZE THAT CAN OPERATE ON HEAVY FUEL OIL (HFO). 2. THE UNITS ARE OFFERED WITH SOME OF THE REQUIRED BALANCE OF PLANT BY SEPARATE NEGOTIATION. 3. THESE UNITS WERE INSTALLED AND OPERATED IN A POWER STATION FROM 1996 UNTIL THE END OF 2004, WHEN THEY WERE DISMANTLED AS THE RESULT OF A PLANT UPGRADE. THE UNITS WERE PURCHASED AND UPGRADED BY THE BUYER TO 127.8 MW NOMINAL CAPACITY EACH. THEY ALSO FULLY REFURBISHED THE UNITS TO ZERO HOURS. THE TURBINES HAVE THE CAPABILITY OF BEING ABLE TO SWITCH BETWEEN NATURAL GAS AND LIQUID FUEL WHILE STILL OPERATING UNDER LOAD. QUANTITY: 2 Learn More

TT-7587 SIEMENS TG50D5/W701DS GAS TURBINE GENERATOR, 127.8 MW, YEAR 1995TT-7587 SIEMENS TG50D5/W701DS GAS TURBINE GENERATOR, 127.8 MW, YEAR 1995 1. SIEMENS WESTINGHOUSE TG50D5/W701DS 127.8 MW GAS TURBINE GENERATOR PACKAGES FOR SALE. THE TURBINE PACKAGES TOGETHER OFFER 255 MW READY TO SHIP EQUIPMENT. THIS TECHNOLOGY IS ONE OF THE MOST WIDESPREAD MIDDLE SIZE ENGINES (100-104 MW) FOR POWER GENERATION AND THE ONLY TURBINE OF ITS SIZE THAT CAN OPERATE ON HEAVY FUEL OIL (HFO). 2. THE UNITS ARE OFFERED WITH SOME OF THE REQUIRED BALANCE OF PLANT BY SEPARATE NEGOTIATION. 3. THESE UNITS WERE INSTALLED AND OPERATED IN A POWER STATION FROM 1996 UNTIL THE END OF 2004, WHEN THEY WERE DISMANTLED AS THE RESULT OF A PLANT UPGRADE. THE UNITS WERE PURCHASED AND UPGRADED BY THE BUYER TO 127.8 MW NOMINAL CAPACITY EACH. THEY ALSO FULLY REFURBISHED THE UNITS TO ZERO HOURS. THE TURBINES HAVE THE CAPABILITY OF BEING ABLE TO SWITCH BETWEEN NATURAL GAS AND LIQUID FUEL WHILE STILL OPERATING UNDER LOAD. QUANTITY: 2 Learn More -

YY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLESYY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES BLOW MOLDING LABELING HIGH PRESSURE AIR COMPRESSOR DESCON AIRVEYOR- APPROXIMATELY 400′ CROWN FILLING MACHINE AND CAPPING MACHINE ACMI BOTTLE AND CASE CONVEYOR, SHRINK WRAPPER, PALLETIZER, STRETCH WRAPPING MACHINE WATER PROCESSING EQUIPMENT QUANTITY: 1 Learn More

YY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLESYY-3265 COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES COMPLETE LINE TO BLOW, FILL, BUNDLE, AND PALLETIZE BEVERAGES IN PET BOTTLES BLOW MOLDING LABELING HIGH PRESSURE AIR COMPRESSOR DESCON AIRVEYOR- APPROXIMATELY 400′ CROWN FILLING MACHINE AND CAPPING MACHINE ACMI BOTTLE AND CASE CONVEYOR, SHRINK WRAPPER, PALLETIZER, STRETCH WRAPPING MACHINE WATER PROCESSING EQUIPMENT QUANTITY: 1 Learn More -

K-8157 COAL FIRED POWER PLANT (2 X 50MW)

K-8157 COAL FIRED POWER PLANT (2 X 50MW)K-8157 COAL FIRED POWER PLANT (2 X 50MW)

ENERGY BOILERS (CAE)

TURBINE SYSTEMS

STEAM TURBINES (TA) - DSL ARE 50 - 1

-CONDENSING TURBINE WITH TWO ADJUSTABLE OUTLETS, SUCH AS "ACTING" ON A SINGLE LINE OF TREES, DESIGNED TO DRIVE THE AC GENERATOR DIRECT-TYPE TH 60-2

-IS COMPOSED OF TWO BODIES: THE BODY OF HIGH PRESSURE (CIP) AND MEDIUM AND LOW PRESSURE BODY (CMP + CJP)

-HAS TWO ADJUSTABLE OUTLETS (PLUG SOCKETS AND PLUG HEATING) AND FIVE FIXED DOSES REGENERATIVE CIRCUIT FEEDSQUARES OF 600 CARS OVER T/H (WITH BUCKET WHEEL AND ARM LENGTH 12 M) - 4 PCS

-TIP HAMMER CRUSHERS CCA - 160 TO 2 PIECES

- RUBBER BANDS COAL TRANSPORTTHE MAIN EQUIPMENT IS ADDED TO ENSURE PROPER OPERATION FOLLOWING:

- SOLID FUEL STORAGE

- INSTALLATIONS AND INDUSTRIAL WATER SUPPLIES AND WASTEWATER DISCHARGE

- INSTALLATION OF EXHAUST HYDRAULIC SLAG

- WATER TREATMENT STATION

TO USE COAL, WEIGHT 88%, 12% NATURAL GASQUANTITY: 1

Learn More -

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More