Search results for: 'max-'

- Related search terms

- max-connections-per-route

-

TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRYREFERENCE NUMBER: L-6890 TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRY ITEM 001 TEXPA LONGITUDINAL HEMMING MACHINE YEAR 2005 QUANTITY: 1 ITEM 002 TEXPA CROSS HEMMING AND LABEL SEWING MACHINE YEAR: 2005 MODEL: QRSN POSSIBILE TO SEW THREE TYPES OF LABELS: U, V, FLAG PFAFF SEWING MACHINES EQUIPPED FOR TERRY TOWEL WORKING WIDTH: 300mm TO 2000mm QUANTITY: 1 STATUS: STOPPED, NOT DISMANTLED DELIVERY: DISMANTLING AND LOADING WILL NEED 3 WEEKS, REQUIRES TWO 40 FT CONTAINERS TO SHIP Learn More

TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRYREFERENCE NUMBER: L-6890 TEXPA HEMMING AND LABEL SEWING MACHINES, MODEL QRSN RUNNING TERRY ITEM 001 TEXPA LONGITUDINAL HEMMING MACHINE YEAR 2005 QUANTITY: 1 ITEM 002 TEXPA CROSS HEMMING AND LABEL SEWING MACHINE YEAR: 2005 MODEL: QRSN POSSIBILE TO SEW THREE TYPES OF LABELS: U, V, FLAG PFAFF SEWING MACHINES EQUIPPED FOR TERRY TOWEL WORKING WIDTH: 300mm TO 2000mm QUANTITY: 1 STATUS: STOPPED, NOT DISMANTLED DELIVERY: DISMANTLING AND LOADING WILL NEED 3 WEEKS, REQUIRES TWO 40 FT CONTAINERS TO SHIP Learn More -

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAY

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAYSee all pictures: https://ibb.co/album/gpK9bF

#1 GRIBETZ MPLUS PATTERN LINK 90 TACK AND JUMP 3 BAR WITH PANEL CUTTER 4 POS CREEL

#2 GRIBETZ GI4300 TACK AND JUMP 90" 3 BAR WITH PANEL CUTTER 3 POS CREEL

# 3 EMCO 2 BAR 1X3 WITH PANEL CUTTER, YEAR 2001 (FOR PARTS)

#4 EMCO COMPUSTITCH 3 BAR

WITH JAMES CASH K-10 PANEL CUTTER#5 GRIBETZ GI2300 90" SET UP FOR BORDERS 4 POS CREEL

#6 EMCO 9000 COMPUSTITCH 1X3X6 BUT RUNNING 1X6

WITH BORDER CUTTER JAMES CASH K-10 1997#7 EMCO 9000 COMPUSTITCH 3 BAR 1 POSITION CREEL

WITH BORDER CUTTER JAMES CASH K-10#8 GRIBETZ 3 BAR 92"

WITH JAMES CASH K-12#9 TAPE EDGE WITH SINGER 300UX6 STEEL TABLE 55 X 81

#10 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#11 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#12 ATLANTA ATTACHEMENT TAPE EDGE WITH PFAFF 5625 WITH STAINLESS STEEL TABLE 60 X 80

#13 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX6 WITH STAINLESS STEEL TABLE 60 X 80

#14 PORTER TAPE EDGE PFAFF DISSASSEMBLED HEAD TABLE SIZE 60 X 82

#15 ATLANTA ATTACHMENT TAPE EDGE WITH PFAFF 5625 STAINLESS STEEL TABLE 59 X 79

#16 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGERS 300UX5 STAINLESS STEEL TABLE 60 X 80 16"H

#17 BUILD UP TABLES MOSTLY 60 X 80 OF WHICH 15 ARE GLOBAL SYSTEMS AND 2 ARE HOME MADE

#19 ? SMALL BALER CONSOLIDATED MODEL STDS-2 36' WIDE X 18" FRONT TO BACK X 50"H

#20 SCREW UNBALER ATLANTA ATTACHMENT FOR 18 INNERSPRING CAPACITY

#21 PIQUA BALER 58 X 31 X 54" TALL 220 VOLT

#22 SCREW UNBALER WBSCO

#23 CART FOR INNERSPRING BALE

#24 GRIBETZ PANEL CUTTER ( I HAVE ALL THE INFO ALREADY)

#25 LAMINATOR GRIBETZ STRATA WITH HOT ROLL AND FELT BLANDET FOR LAMINATING WITH WEB SUBSTRATE (ROTARY HEAT PRESS) MODEL GLM011 220 VOLT , 2 POS CREEL

#26 HORIZONTAL FOAM CUTTER ESCO MODEL HTX 51-88 PU+

88" WIDE , X 118" LONG , KNIFE GRINDERS , SUCTION TABLE

TOUCH SCREEN PANEL , ELECTRICAL CONTROL PANEL

AUTOMATIC LUBRICATION BINKS MODEL 80-600 SG2 PLUS#27 VERTICAL FOAM CUTTER MODEL EL-4

112" WIDE

OUTSIDE TABLE 73"

INSIDE TABLE 74"

FENCE 8" PLUS 16 " EXTENSION

68" THROAT

112" OVERALL HEIGHT

194" TOTAL RAIL WIDTH#28 PORTER SERGER FLANGER MODEL 4000 WITH AIR FLOTATION TABLE

220 VOLT#29 ATLANTA ATTACHMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#30 ATLANTA ATTACHEMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#31 SINGER LONG ARM REPAIR 25"

#32 ATLANTA ATTACHEMENT RUFFLER

MODEL 13XXMF#33 ATLANTA ATTATCHMENT 9 NEEDLE SEWING MACHINE (MULTINEEDLE) MODEL 4000D

#34 SINGLE NEEDLE SIT DOWN MACHINES OF WHICH 3 ARE PORTER

#35 AVANCE EMBROIDERY MACHINE

#36 GALKIN "X" SEWING MACHINE FOR HANDLES

GAP5OBT-3 , JUKI MODEL LK1900CV#37 ATLANTA ATTACHMENT DOUBLE BORDER SERGER 25" OPENING , PEGASUS HEAD

MODEL E521-130 AND EX5203-M03#38 ATLANTA ATTACHMENT BINDER FOR HANDLE MAKING

#39 ANDERSON MULTISLITTER 10 BLADES 92" WIDE

#40 ANDERSON STAND ALONE PANEL CUTTER 103"WIDE WITH 2 EDGE SLITTERS AND ONE CROSS CUTTER

WITH 1049 HOURS ON THE CLOCK#41 CONVEYOR FOR SEW DEPARTMENTE 34" WIDE OVER 100 FEET LONG

#42 TOYOTA FORKLIFTS 6270 LBS CAPACITY MODEL 71CCUT5 (TWO)

ONE NISSAN FORKLIFT

ONE CATERPILLAR FORKLIFT#43 ONE GLUE STATION 4 GUNS , SABA GUNS , NOT THERE (BELONG TO SABA)

#44 240 FEET LONG CONVEYOR FEEDING MATTRESS WRAPPING DEPARTMENT

#45 TWO MERELLO WRAPPERS 20 INCH MAX HEIGHT X 88 " WIDE, YEAR 2016

#46 TECNOMAC (ITALY) MATTRESS ROLL AND PACK MACHINE MODEL TK381 YEAR 2015

Learn More

400 VOLT X 50HZ X 30 KW

8 BAR AIR PRESSURE -

L-6811 MODEL 100 AUTOMATIC TRANSFER MACHINE FOR BONELL SPRING UNITS

L-6811 MODEL 100 AUTOMATIC TRANSFER MACHINE FOR BONELL SPRING UNITSUP TO 80 SPRINGS PER MINUTE FOR 38,400 SPRINGS IN 8 HOURS

APPROX. 130 SPRINGS DOUBLE BED INNERSPRING UNITS PER 8 HOURS

APPROX. 210 SPRINGS SINGLE BED INNERSPRING UNITS PER 8 HOURSSPRING OUTSIDE DIAMETER: 80 TO 92mm

Learn More

SPRING WIRE DIAMETER: 1.9 TO 2.4mm

SPIRAL WIRE DIAMETER: 1.3 TO 1.4mm

SPRING HEIGHT: 80 TO 160mm

MAX. # OF JAWS: 18

MAX. SPRING UNIT WIDTH: 2000mm

POWER: 3 PHASE, 380 VOLTS

POWER: 18 KW

FREQUENCY: 50/60 Hz

WORKING TEMP: 0 TO 40C

WIRE BASKET CAPACITY: 1,000 KGS

WEIGHT: APPROX 4800 KGS

DIMENSIONS: 5600 X 3700 X 2250mm -

V-1053 POCKET COILER AND ASSEMBLER, NEW

V-1053 POCKET COILER AND ASSEMBLER, NEWREFERENCE NUMBER: V-1053

POCKET COILER AND ASSEMBLER, NEW

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE

MODEL 12PA AUTO POCKET SPRING PRODUCTION LINE IS MADE UP OF MODEL-12P POCKET SPRING MACHINE AND MODEL-08A AUTO POCKET SPRING ASSEMBLING MACHINE.

COMPLETELY AUTOMATIC, IT CAN FINISH ALL THE PROCESS OF PRODUCTION FROM POCKET SPRING TO MATTRESS.

EASY TO OPERATE, HIGH EFFICIENCY, AND LOW NOISE.

THE PRODUCTION LINE HAS A SMALL FOOT PRINT ON THE PLANT FLOOR.

THE PRODUCTION LINE IS CONTROLLED BY SERVO MOTORS, SO ACCURACY IS HIGH.

THE CONTROL PARAMETERS CAN BE SET BY THE CUSTOMER FOR DIVERSE DEMANDS.

AUTO STOP WHEN RUN OUT OF MATERIALS. (WITH CE CERTIFICATE)

TECHNICAL SPECIFICATIONS:

DESIGNATION MODEL 12P + MODEL 08A

PRODUCT EFFICIENCY 70 coils / min

SPRING DIAMETER End 45mm-60mm; Center 60mm-80mm

SPRING HEIGHT 80mm-120mm / 120mm-180mm / 160mm-220mm

STEEL WIRE DIAMETER 1.8mm-2.2mm

TOP AND BOTTOM With and without

NON-WOVEN

MAXIMUM POWER 32KW

SPACE DIMENSION (L X W X H) 9500mm x 3000mm x 1850mm

WEIGHT 4000kgs

Learn More -

V-1388 COMPUTERIZED AUTOMATIC MATTRESS BORDER QUILTING, NEW FROM CHINA

V-1388 COMPUTERIZED AUTOMATIC MATTRESS BORDER QUILTING, NEW FROM CHINAREFERENCE NUMBER: V-1388

COMPUTERIZED AUTOMATIC MATTRESS BORDER QUILTING, NEW FROM CHINA

CONDITION: NEW

VOLTAGE: SINGLE PHASE, 220V, 50HZ, SINGLE PHASE, 220V, 50HZ

POWER(W):3.98KW

DIMENSION(L X W X H): 5.6 X 1.8 X 1.6M

WEIGHT: 450kg

CERTIFICATION: CE CERTIFICATE

WARRANTY: ONE YEAR

AFTER-SALES SERVICE PROVIDED:ENGINEERS AVAILABLE TO SERVICE MACHINERY OVERSEAS

SEWING SPEED: 5M/MIN

THICKNESS OF QUILTING:<1.5cm

MOTOR TYPE: PARASONIC

CHAIN STITCH HEADS:JUKI

MULTI-NEEDLE SEWING HEAD:52 NEEDLES

SPACE BETWEEN NEEDLES: 3/16,1/4

FABRIC WIDTH: 33cm

AIR PRESSURE:60PSI

1. AUTOMATIC PROGRAMMABLE BORDER WORKSTATION

2. STATE-TO-THE-ART SERVO DRIVES AND ADVANCED MOTION CONTROLLER

3. MULTI-NEEDLE SEWING HEAD WITH 52 NEEDLES 1/4" SPACING, 33cm MAX WIDTH

4. VIRTUALLY UNLIMITED PATTERN DESIGN STORAGE

5. ADJUSTABLE TENSION REWINDER

6. BORDER UP TO 33CM

7. PATTERNS MAY BE SCALED, SHIFTED OR OFFSET ON-THE-FLY

8. DUAL PATTERN STITCHING CHAIN STITCH HEADS(JUKI)

9. BORDER EDGES MAY BE HEMMED, ELIMINATING THE DOUBLE OVERLOCK OPERATION.

PACKAGING DETAILS:MACHINE BY WOODEN BOX

DELIVERY TIME: 35 DAYS

Learn More -

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINE

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINEREFERENCE NUMBER: M-6042 (880699GY7RX) L

VACUUM PRESSING AND ROLLING UP MATTRESSES LINECOMPLETE LINE FOR VACUUM PRESSING AND ROLLING UP MATTRESSES

PRODUCTION: 3 MATTRESSES PER MINUTE

CAN WORK: VISCO / POLYURETHANE / LATEX / BONNELL SPRING / POCKET SPRING / ETC.QUANTITY: 1

Learn More -

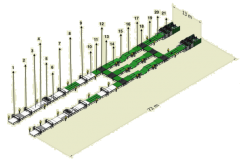

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More -

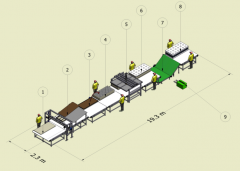

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

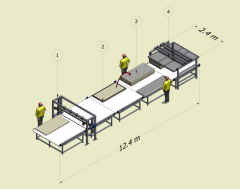

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

M-0809 HIGH POLYMER MATTRESS 25 TO 200mm TALL (POLYMAT)

M-0809 HIGH POLYMER MATTRESS 25 TO 200mm TALL (POLYMAT)REFERENCE NUMBER: M-0809 HIGH POLYMER MATTRESS 25 TO 200mm TALL (POLYMAT) QUANTITY AVAILABLE: 1

Learn More