Search results for: 'High tem'

- Related search terms

- high speed'

- TEMP/?'

- High temperature high pressure Ma

- High temperature high pressure Machine

- high to the

-

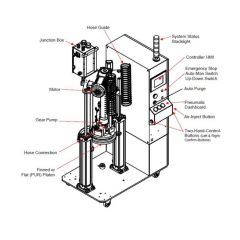

YY-2358 DM5 HOT MELT PAIL UNLOADERYY-2358 DM5 HOT MELT PAIL UNLOADER THE DM5 IS A STATIONARY PAIL MELTER (UNLOADER) THAT COMBINES A HEATED PLATEN, PUMP AND ALL CONTROLS NEEDED TO MELT AND DISPENSE HOT MELT ADHESIVES, SEALANTS, PURS OR COATINGS FROM A STANDARD 5-GALLON STEEL PAIL. THE CONTROLLER PROVIDES ACCURATE, PROPORTIONATE TEMPERATURE CONTROL FOR THE PLATEN, HOSES AND APPLICATORS. A “STANDBY” TEMPERATURE MAY BE PROGRAMMED SO THAT THE TEMPERATURE ZONES CAN BE INDEPENDENTLY MAINTAINED AT A LOWER TEMPERATURE WHEN THE UNIT IS NOT IN ACTIVE USE, ENABLING RAPID RETURN TO NORMAL OPERATION. A VARIETY OF GEAR PUMPS ARE AVAILABLE. THE MELTER CAN BE UTILIZED AS A BULK-TRANSFER UNIT OR AS A STAND-ALONE UNIT. IT CAN SUPPLY ONE OR TWO HAND-HELD APPLICATORS OR OTHER APPLICATORS. QUANTITY: 1 Learn More

YY-2358 DM5 HOT MELT PAIL UNLOADERYY-2358 DM5 HOT MELT PAIL UNLOADER THE DM5 IS A STATIONARY PAIL MELTER (UNLOADER) THAT COMBINES A HEATED PLATEN, PUMP AND ALL CONTROLS NEEDED TO MELT AND DISPENSE HOT MELT ADHESIVES, SEALANTS, PURS OR COATINGS FROM A STANDARD 5-GALLON STEEL PAIL. THE CONTROLLER PROVIDES ACCURATE, PROPORTIONATE TEMPERATURE CONTROL FOR THE PLATEN, HOSES AND APPLICATORS. A “STANDBY” TEMPERATURE MAY BE PROGRAMMED SO THAT THE TEMPERATURE ZONES CAN BE INDEPENDENTLY MAINTAINED AT A LOWER TEMPERATURE WHEN THE UNIT IS NOT IN ACTIVE USE, ENABLING RAPID RETURN TO NORMAL OPERATION. A VARIETY OF GEAR PUMPS ARE AVAILABLE. THE MELTER CAN BE UTILIZED AS A BULK-TRANSFER UNIT OR AS A STAND-ALONE UNIT. IT CAN SUPPLY ONE OR TWO HAND-HELD APPLICATORS OR OTHER APPLICATORS. QUANTITY: 1 Learn More -

T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018 QUANTITY: 2 Learn More

T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018T-6968 JENBACHER J626 GS-H102 4400KW 50Hz 10500V-SURPLUS NEW, YEAR 2018 QUANTITY: 2 Learn More -

SPINNBAU CARDING LINE, YEAR 2013REFERENCE NUMBER: T-6848 SPINNBAU CARDING LINE, YEAR 2013 BRAND: SPINNBAU SHORT DESCRIPTION: CARDING LINE YEAR: 2013 INSTALLED 2014 LIKE NEW, LITTLE RUN TIME 4 HOPPER TEMAFA BLEND LINE, 1600mm WIDE, 1 WITH CONDENSER FED FROM TRIM MACHINE CARDING WILLOW – 800mm WIDE FEED BELT AND 1200mm WIDE – TEMAFA TEMAFA MIXMASTER BLENDING BIN – 3000mm WIDE X 8000mm LONG X 4600mm HIGH (FILL HEIGHT 3000mm). 72 CUBIC METER CAPACITY. TEMAFA FINE OPENER – 2000mm WIDE WITH PINS 3000mm SPINNBAU CARD FEEDING UNIT – FEED TRUNK, VIBRATING CHUTE, WEIGHT BELT 708mm BREAST SECTION WITH 3 WORKERS AND STRIPPERS, 1500mm MAIN WITH 5 W/S AND (2) 708mm DOFFERS. 1 FOUNDATIONS AND PLATFORMS. DILO PROFILINE – BATT WEIGHT CONTROL SYSTEM MAHLO WEIGHT MEASURING UNIT – QUALISCAN CMS-12 DILO LAYER CROSSLAPPER – TYPE DLS 30/60 – 3000mm INFEED AND UP TO 6000mm LAYDOWN. MAX WEB HEIGHT 650mm. MAXIMUM SPEED 125M/MIN. SPINNBAU LAP DRAFTER TYPE VST 19 – MAX 6000mm WORKING WIDTH. 9 ROLLER PAIRS. LIFTING DEVICE TO ALLOW FOR 600mm CLEARANCE. 159mm ROLLER DIAMETER. INFEED HEIGHT 650 mm BRUCKNER THERMOBONDING OVEN – 5000mm OVEN WITH 3 HEATING AND 2 COOLING ZONE. MAGNETIC BELT. 3 NATURAL GAS MAXON BURNER. SLITTING – 9 POSITION BRUCKNER CRUSH CUTTER SLITTING HEADS. PNEUMATIC LIFTING. 450mm KNIFE DIAMETER CROSS CUTTER – ROTARY CUTTER STYLE WITH CLAMPING. CAPABLE OF 3 CUTS/MINUTES FOR MATERIALS UP TO 200mm THICK. WINDING – ASCENDING BATCH STYLE WINDER. MAX ROLL DIAMETER OF 1200mm. 3000mm DRIVEN FEED CONVEYOR. MANDREL GUIDANCE SYSTEM, MANUALLY ADJUSTABLE BRAKE SYSTEM FOR CONTROLLING TENSILE FORCE AND COMPACTION. TEMAFA FILTER HOUSE – TFS 50. MAX FLOW 50,000 CUBIC METER/H ELECTRICL INFO – 3 X 480V/60Hz. CONTROLS 110V AC/24 DC. SIEMENS PLC QUANTITY: 1 Learn More

SPINNBAU CARDING LINE, YEAR 2013REFERENCE NUMBER: T-6848 SPINNBAU CARDING LINE, YEAR 2013 BRAND: SPINNBAU SHORT DESCRIPTION: CARDING LINE YEAR: 2013 INSTALLED 2014 LIKE NEW, LITTLE RUN TIME 4 HOPPER TEMAFA BLEND LINE, 1600mm WIDE, 1 WITH CONDENSER FED FROM TRIM MACHINE CARDING WILLOW – 800mm WIDE FEED BELT AND 1200mm WIDE – TEMAFA TEMAFA MIXMASTER BLENDING BIN – 3000mm WIDE X 8000mm LONG X 4600mm HIGH (FILL HEIGHT 3000mm). 72 CUBIC METER CAPACITY. TEMAFA FINE OPENER – 2000mm WIDE WITH PINS 3000mm SPINNBAU CARD FEEDING UNIT – FEED TRUNK, VIBRATING CHUTE, WEIGHT BELT 708mm BREAST SECTION WITH 3 WORKERS AND STRIPPERS, 1500mm MAIN WITH 5 W/S AND (2) 708mm DOFFERS. 1 FOUNDATIONS AND PLATFORMS. DILO PROFILINE – BATT WEIGHT CONTROL SYSTEM MAHLO WEIGHT MEASURING UNIT – QUALISCAN CMS-12 DILO LAYER CROSSLAPPER – TYPE DLS 30/60 – 3000mm INFEED AND UP TO 6000mm LAYDOWN. MAX WEB HEIGHT 650mm. MAXIMUM SPEED 125M/MIN. SPINNBAU LAP DRAFTER TYPE VST 19 – MAX 6000mm WORKING WIDTH. 9 ROLLER PAIRS. LIFTING DEVICE TO ALLOW FOR 600mm CLEARANCE. 159mm ROLLER DIAMETER. INFEED HEIGHT 650 mm BRUCKNER THERMOBONDING OVEN – 5000mm OVEN WITH 3 HEATING AND 2 COOLING ZONE. MAGNETIC BELT. 3 NATURAL GAS MAXON BURNER. SLITTING – 9 POSITION BRUCKNER CRUSH CUTTER SLITTING HEADS. PNEUMATIC LIFTING. 450mm KNIFE DIAMETER CROSS CUTTER – ROTARY CUTTER STYLE WITH CLAMPING. CAPABLE OF 3 CUTS/MINUTES FOR MATERIALS UP TO 200mm THICK. WINDING – ASCENDING BATCH STYLE WINDER. MAX ROLL DIAMETER OF 1200mm. 3000mm DRIVEN FEED CONVEYOR. MANDREL GUIDANCE SYSTEM, MANUALLY ADJUSTABLE BRAKE SYSTEM FOR CONTROLLING TENSILE FORCE AND COMPACTION. TEMAFA FILTER HOUSE – TFS 50. MAX FLOW 50,000 CUBIC METER/H ELECTRICL INFO – 3 X 480V/60Hz. CONTROLS 110V AC/24 DC. SIEMENS PLC QUANTITY: 1 Learn More -

TT-7873 HURST SERIES 45 BOILER, 60W, YEAR 2016TT-7873 HURST SERIES 45 BOILER, 60W, YEAR 2016 1. BRAND: HURST 2. MODEL: SERIES 45 3. YEAR OF MFG.: 2016 4. CONDITION: NEW, NEVER USED QUANTITY: 1 Learn More

TT-7873 HURST SERIES 45 BOILER, 60W, YEAR 2016TT-7873 HURST SERIES 45 BOILER, 60W, YEAR 2016 1. BRAND: HURST 2. MODEL: SERIES 45 3. YEAR OF MFG.: 2016 4. CONDITION: NEW, NEVER USED QUANTITY: 1 Learn More -

TT-5551 CATERPILLAR MODEL XQ2000 SETS, YEAR 2000 TO 2004, 50/60 HzTT-5551 CATERPILLAR MODEL XQ2000 SETS, YEAR 2000 TO 2004, 50/60 Hz CATERPILLAR MODEL XQ2000 SETS YEAR MODELS 2000 TO 2004 5000 HOURS OPERATION SINCE NEW TO REBUILT ENGINES WITH 3K-TO-5K HOURS USED CATERPILLAR FEATURES EMISSIONS EPA AND CARB EMISSIONS CERTIFIED FOR NON-ROAD MOBILE APPLICATIONS. CATERPILLAR DIESEL GENERATOR SETS FACTORY DESIGNED, CERTIFIED PROTOTYPE TESTED WITH TORSIONAL ANALYSIS. PRODUCTION TESTED AND DELIVERED TO YOU IN A PACKAGE THAT IS READY TO BE CONNECTED TO YOUR FUEL AND POWER LINES. ELECTRIC POWER DESIGN PRO COMPUTER SIZING AVAILABLE. SUPPORTED 100% BY YOUR CATERPILLAR DEALER WITH WARRANTY ON PARTS AND LABOR. EXTENDED WARRANTY AVAILABLE IN SOME AREAS. THE GENERATOR SET WAS DESIGNED AND MANUFACTURED IN AN ISO 9001 COMPLIANT FACILITY. GENERATOR SET AND COMPONENTS MEET OR EXCEED THE FOLLOWING SPECIFICATIONS: AS1359, AS2789, ABGSM TM3, BS4999, DIN6271, DIN6280, EGSA101P, JEM1359, IEC 34/1, ISO3046/1, ISO8528, NEMA MG1-22. Learn More

TT-5551 CATERPILLAR MODEL XQ2000 SETS, YEAR 2000 TO 2004, 50/60 HzTT-5551 CATERPILLAR MODEL XQ2000 SETS, YEAR 2000 TO 2004, 50/60 Hz CATERPILLAR MODEL XQ2000 SETS YEAR MODELS 2000 TO 2004 5000 HOURS OPERATION SINCE NEW TO REBUILT ENGINES WITH 3K-TO-5K HOURS USED CATERPILLAR FEATURES EMISSIONS EPA AND CARB EMISSIONS CERTIFIED FOR NON-ROAD MOBILE APPLICATIONS. CATERPILLAR DIESEL GENERATOR SETS FACTORY DESIGNED, CERTIFIED PROTOTYPE TESTED WITH TORSIONAL ANALYSIS. PRODUCTION TESTED AND DELIVERED TO YOU IN A PACKAGE THAT IS READY TO BE CONNECTED TO YOUR FUEL AND POWER LINES. ELECTRIC POWER DESIGN PRO COMPUTER SIZING AVAILABLE. SUPPORTED 100% BY YOUR CATERPILLAR DEALER WITH WARRANTY ON PARTS AND LABOR. EXTENDED WARRANTY AVAILABLE IN SOME AREAS. THE GENERATOR SET WAS DESIGNED AND MANUFACTURED IN AN ISO 9001 COMPLIANT FACILITY. GENERATOR SET AND COMPONENTS MEET OR EXCEED THE FOLLOWING SPECIFICATIONS: AS1359, AS2789, ABGSM TM3, BS4999, DIN6271, DIN6280, EGSA101P, JEM1359, IEC 34/1, ISO3046/1, ISO8528, NEMA MG1-22. Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More -

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

J-4363 AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTEREFERENCE NUMBER: J-4363 AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTE FOR PRODUCTS 450 TO 1500mm, COTTON CORE BETWEEN 400 TO 1000mm TOUCH SCREEN WITH ADJUSTABLE PRODUCT REQUIREMENTS IN 450 TO 600mm, COTTON CORE IN 400 TO 550mm PRODUCT STRUCTURE: SURFACE LAYER, BACKING PAPER, COTTON CORE, SAP, BASEMENT MEMBRANE STABLE PRODUCTION SPEED: 120 METERS PER MINUTE IF THE SIZE OF THE FINISHED PRODUCT IS 600 x 600mm, THE MACHINE RUNNING SPEED IS 200 PIECES PER MINUTE (8 HOUR OUTPUT IS 96,000 PIECES) MACHINE DIMENSIONS: 16000 x 2200 x 2600mm (LENGTH x WIDTH x HEIGHT) POWER SUPPLY: 380 VOLTS, 50 Hz TOTAL POWER: ABOUT 80 KW (NOT INCLUDING GLUE) PRESSURE: 1100 LITERS PER MINUTE, 6 TO 8 BARS YIELD: 98% OR GREATER (EXCLUDING ERRORS DUE TO GLUE MACHINE, MATERIAL EXCHANGE AND JOINTS CAUSED BY DEFECTIVE GOODS) QUANTITY: 1 Learn More

J-4363 AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTEREFERENCE NUMBER: J-4363 AUTOMATIC PET PAD MAKING MACHINE, 200 PADS PER MINUTE FOR PRODUCTS 450 TO 1500mm, COTTON CORE BETWEEN 400 TO 1000mm TOUCH SCREEN WITH ADJUSTABLE PRODUCT REQUIREMENTS IN 450 TO 600mm, COTTON CORE IN 400 TO 550mm PRODUCT STRUCTURE: SURFACE LAYER, BACKING PAPER, COTTON CORE, SAP, BASEMENT MEMBRANE STABLE PRODUCTION SPEED: 120 METERS PER MINUTE IF THE SIZE OF THE FINISHED PRODUCT IS 600 x 600mm, THE MACHINE RUNNING SPEED IS 200 PIECES PER MINUTE (8 HOUR OUTPUT IS 96,000 PIECES) MACHINE DIMENSIONS: 16000 x 2200 x 2600mm (LENGTH x WIDTH x HEIGHT) POWER SUPPLY: 380 VOLTS, 50 Hz TOTAL POWER: ABOUT 80 KW (NOT INCLUDING GLUE) PRESSURE: 1100 LITERS PER MINUTE, 6 TO 8 BARS YIELD: 98% OR GREATER (EXCLUDING ERRORS DUE TO GLUE MACHINE, MATERIAL EXCHANGE AND JOINTS CAUSED BY DEFECTIVE GOODS) QUANTITY: 1 Learn More -

S-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HR

S-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HRS-1197 LAUNDRY SOAP PRODUCTION LINE, CAPACITY 1000 TO 1500 KG/HR

LAUNDRY SOAP PRODUCTION LINE

CAPACITY: 1000 TO 1500 KG/HR

I. PROJECT INSTRUCTION

THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES, VACUUM EXTRUDING AND THEN CUTTING INTO SOAPS.

THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT.

PLEASE NOTICE THAT:

IT IS A TURN-KEY PROJECT. THE PROFESSIONAL TEAM PROVIDE YOU ALL MACHINES AND ACCESSORIES, THE WHOLE PROCESS OF PRODUCTION, FORMULA, LAYOUT DESIGN, MACHINES INSTALLATION, PRODUCTS TRIAL ETC. ALL SOLUTION ACCORDING TO YOUR REQUIREMENTS.

THE QUOTATION INCLUDES ALL EXCEPT: BOILER, WORKSHOP BUILDING, HEAT INSULATING MATERIAL, WIRES, PACKING MACHINE, AND CONSUMABLE MATERIALS FOR INSTALLING (WELDING ROD, CRANE, ELECTRIC WELDER, ETC.).1. PRODUCTION REQUIREMENTS:

A. STEAM BOILER: 2 MT/HR.

B. WORKSHOP AREA: LARGER THAN 300 M². (L: 35M, W: 7M, H: 7M)

C. POWER: 130 KW, 380 V, 50 HZ.

D. WATER: CIRCULATING WATER FOR VACUUM DRYING SYSTEM: 40 M3; PRODUCTION WATER.

E. CAPACITY: 1000 TO 1500 KG/HR, 8 TO 12 TON/DAY (8 HR/DAY). OIL CONSUMTION: 5 TO 8 TON/DAY.

F. WORKER: 10 TO 12 WORKERS.

2. MATERIAL AND CONSUMING FOR PRODUCING SOAP:

OIL OR FAT OF PLANT OR ANIMAL (PALM OIL, COCONUT OIL, TALLOW OIL, ETC.), CAUSTIC SODA (NAOH), SODIUM-CHLORIDE (NACL), SODIUM SILICATE, FRAGRANCE, PIGMENT, ETC.

3. PRODUCTION PROCESS:

MIX AND MELT OIL --> SAPONIFICATION --> ADD OTHER INGREDIENTS --> VACUUM DRYING --> SOAP NOODLE --> GRINDING --> VACUUM EXTRUDING --> CUTTING.III. SPECIFICATIONS AND QUOTATION OF EQUIPMENT

1. CARBURETION WORKSHOP:

MIX KINDS OF OIL TOGETHER ON THE BASIS OF THE FORMULA. DEPOSIT AND TAKE OUT THE UNSAPONIFIABLES.ITEM 001

CARBURETION POOL

MIX KINDS OF OIL TOGETHER ON THE BASIS OF THE FORMULA.

VOLUME: 10 M3.

FIELD WORK

QUANTITY: 1ITEM 002

STORAGE TANK FOR REFINE OIL

SIZE: Φ2000X2600, 8.2 M3;

FEATURE: WITH COILER INSIDE.

QUANTITY: 1ITEM 003

WATER PUMP, OIL PUMP, CAUSTIC SODA PUMP

POWER: 1.5 KW/SET.

QUANTITY: 4ITEM 004

SEAMLESS TUBE

(Φ76X3.5) (Φ57X3.5), ETC.

QUANTITY: SEVERALITEM 005

VALVE

Φ65, Φ40, ETC.

QUANTITY: SEVERALITEM 006

FLANGE, SCREW, ELBOW, GASKET.

QUANTITY: SEVERAL2. OIL AND FAT SAPONIFICATION WORKSHOP:

OIL AND ALKALI DO REACTIONS IN THE SAPONIFICATION CAULDRONS. IT IS A GOOD COMBINATION OF FOUR SAPONIFICATION CAULDRONS, WATER CIRCULATES FROM NO. 1 CAULDRON TO NO. 4, IT SAVES WATER, NAOH AND NACL AT THE MOST.ITEM 007

SAPONIFICATION CAULDRON

SAPONIFICATION BETWEEN OIL AND NAOH, LASTING ABOUT 40 TO 60 HRS. SUFFICIENT REACTION. SAVE WATER.

SIZE: Φ2800 X 3000, 20 M3

AUXILIARY FACILITIES: LIQUID CAUSTIC SODA POOL.2 M3

FIELD WORK

QUANTITY: 4ITEM 008

HIGH TEMPERATURE AND HIGH PRESSURE SOAP PUMP

POWER: 5.5 KW/SET

QUANTITY: 3ITEM 009

SEAMLESS TUBE

(Φ76X3.5)(Φ57X3.5), ETC.

QUANTITY: SEVERALITEM 010

VALVE

Φ76, Φ48, ETC.

QUANTITY: SEVERALITEM 011

FLANGE, SCREW, ELBOW, GASKET.

QUANTITY: 13. SOAP VACUUM DRYING SYSTEM:

TO MAKE SOAP MATERIALS FLASH DRY AND COOL INSTANTLY. TO CONTROL THE FATTY ACID CONTENT FROM 50% TO 80%. TO IMPROVE THE QUALITY OF SOAP MATERIALS.ITEM 012

INGREDIENTS MIXTURE TANK

PUT ESSENCE, PIGMENT IN THE LIQUID SOAP. HEATING AND MIXING

SIZE: 1.8 M3, Φ1200X1500

FEATURE: WITH PIPE LINER, HEATING AND MIXING

POWER: 4 KW/SET.

QUANTITY: 2ITEM 013

HEAT EXCHANGER

HEAT THE LIQUID SOAP RAPIDLY

SIZE: Φ325 X 4000

QUANTITY: 1ITEM 014

VACUUM SPRAY DRYER

THE VACUUM DRYER MAKES THE SOAP FLAKES THINNER AND EVENER, AND COOLS THEM DOWN MORE QUICKLY, TO IMPROVE THE QUALITY OF SOAP NOODLES.

ADOPT HARD TOOTH SURFACE GEAR REDUCER AND THE OIL PUMP INSIDE LUBRICATES AUTOMATICALLY AND MAKES A LONG LIFESPAN. THE THICKNESS OF BARREL IS 14 MM, THE INNER WALL IS PROCESSED BY VERTICAL LATHE TO ACHIEVE THE COAXIALITY AND SMOOTH SURFACE. THE SHAFT IS MADE BY A Φ108 X 14mm SEAMLESS TUBE. THE NOZZLE (Φ10mm) IN THE SHAFT SPRAYS SOAP MATERIALS, AND THE THREE BLADES SCRAPE THEM DOWN, AND THE SOAP MATERIALS DRY OUT FAST AND UNIFORM. THE WHOLE SET OF VACUUM SYSTEM CAN MAKE SOAPS WITH FATTY ACID CONTENT FROM 55% TO 80%.

1. TYPE: XSD-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. BARREL DIAMETER: Φ 1200mm

4. MOUTH DIAMETER: 10mm

5. SPEED: 13 R/MIN

6. POWER: 3 KW

7. DIMENSION: Φ 1600 X 4500mm

8. WEIGHT: 3200 KGS

QUANTITY: 1ITEM 015

FINE SEPARATORS

SEPARATE THE SOAP POWDER FROM THE WATER WHEN VACUUM DRYING

QUANTITY: 2ITEM 016

BAROMETRIC CONDENSER

CONDENSE WATER FROM THE SOAP

QUANTITY: 1ITEM 017

ELIMINATOR

DRAW OFF WATER

QUANTITY: 1ITEM 018

PELLETIZER

IT IS USED TO PRESS THE VACUUM-DRIED SOAP MATERIALS INTO SOAP NOODLES. LONG DOUBLE SCREWS TURN INWARD TO DRIVE SOAP MATERIALS TO EXTRUDE SOAP NOODLES THROUGH PORE PLATES.

1. TYPE: XSN-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. SCREW DIAMETER: Φ 230mm X 2

4. POWER: 15 KW

5. DIMENSION: 3100 X 1200 X 1550mm

6. WEIGHT: 3000 KGS

QUANTITY: 1ITEM 019

STAGE VACUUM PUMP

KEEP THE VACUUM SYSTEM IN VACUUM STATE

POWER: 15 KW

QUANTITY: 1ITEM 020

BUFFER TANK OF VACUUM PUMP

PROTECT THE VACUUM PUMP FROM STEAM WATER

SIZE: Φ600 X1200

QUANTITY: 1ITEM 021

SOAP PUMP, WATER PUMP

SOAP PUMP: SPECIAL CONSTRUCTURE, DRAW LIQUID SOAP FROM INGREDIENTS MIXURE TANK TO HEAT EXCHANGER. POWER: 7.5 KW

WATER PUMP: FOR WATER CIRCULATING. POWER: 5.5 KW

QUANTITY: 2ITEM 022

SEAMLESS TUBE AND VALVE

Φ76 Φ48, ECT.

QUANTITY: SEVERALITEM 023

FLANGE, SCREW, ELBOW, ETC.

QUANTITY: SEVERAL4. FINISHING LINE:

MILL SOAP NOODLES TWICE, VACUUM EXTRUDING SOAP BAR, CUT SOAP CAKES, AT THE SAME TIME STAMP LOGO ON SOAP CAKES.ITEM 024

THREE-ROLL GRINDING MILL

THREE-ROLL GRINDING MILL IS USED TO GRIND, PRESS THE MATERIAL TO INCREASE ITS DENSITY AND QUALITY.

1. ROLL DIAMETER: Φ260

2. ROLL LENGTH: 780mm

3. MOTOR POWER: 7.5KW

4. ROLL SPEED RATIO: 1:3:9

5. DIMENSION: 1500 X 1200 X 1000mm

6. WEIGHT: 2400 KGS

QUANTITY: 2ITEM 025

VACUUM PLODDER

VACUUM PLODDER IS USED TO GRIND, REFINE AND PRESS SOAP MATERIAL INTO SOAP BAR. THE ABOVE AND BELOW SCREWS AND TWO ORIFICE PLATES PRESS AND REFINE THE SOAP MATERIAL AND MAKE THE SOAP BAR TIGHT AND THE SURFACE BRIGHT.

THE MOTOR AND THE REDUCER ARE SEPARATED, FOR LONG LIFE-SPAN AND MAINTENANCE. THE BELOW SCREW’ SPEED IS ADJUSTABLE TO REGULATE THE PRODUCTION CAPACITY. THE VACUUM CHAMBER HAS A VISION GLASS TO WATCH THE INNER, THE VACUUM METER TESTS THE VACUUM DEGREE. THE HEATER INSIDE THE OUTLET ADOPT AUTOMATIC TEMPERATURE CONTROL SYSTEM. THE JACKETS OF THE ABOVE AND BELOW BARRELS ARE CONNECTED TO A CIRCULATING WATER SOURCE.

1. TYPE: XS-1000

2. CAPACITY: 1000 TO 1500 KG/HR

3. DIAMETER OF SCREW: Φ230mm

4. SPEED: TOP 15; BOTTOM: 12 TO 18

5. POWER: TOP: 11 KW; BOTTOM: 15 KW

6. DIMENSION: 4350 × 1200 × 2630mm

7. WEIGHT: 4500 KGS

QUANTITY: 1ITEM 026

ELECTRONIC

CUTTING MACHINE

SOAP ELECTRONIC CUTTING MACHINE IS USED TO CUT SOAPS INTO CAKES AND STAMP PATTERNS ON THE SOAP. ADOPT DELTA SERVO MOTOR AND CONVERTER, VOLTAGE STABILIZER AND PRECISION PURIFIED AC VOLTAGE STABILIZER, TO PROTECT MOTOR AND ELECTRICAL COMPONENTS AND TO KEEP HIGH ACCURACY.

THE MOULD WHEELS RUN BY THE MOVING OF SOAP BAR FROM VACUUM PLODDER. BECAUSE OF THE ELECTRONIC TRACKING SYSTEM, IT CAN CUT SOAP BARS WITH ANY SIZES AND WEIGHT AFTER SETTING THE COMPUTER.

THE CHARACTERS AND THE SHAPE OF SOAP IS CLEAR AND NEAT

THE SIZE AND PATTERN ARE DESIGNED ACCORDING TO CUSTOMERS’ REQUIREMENTS

1. SIZE AND WEIGHT: ADJUSTED BY CUSTOMER’S REQUIREMENTS

2. POWER: 2 KW, 380 V, 50 HZ

3. CAPACITY: IN STEP OF VACUUM PLODDER

4. MOULD: WITH ONE SET

5. DIMENSION: 1000 × 400 × 1200mm

6. WEIGHT: 100 KGS

WOODEN CASE

QUANTITY: 1ITEM 027

CONVEYORS

APPEARANCE IS GOOD AND OPERATION IS STABLE, NON-NOISE AND ANTI-DUST

MOTOR: 1.1 TO 1.5 KW/PCS

QUANTITY: 4ITEM 028

VACUUM PUMP

FOR VACUUM PLODDER

POWER: 2.35 KW

QUANTITY: 15. OTHERS

ITEM 029

EQUIPMENT SUPPORT, OPERATING PLATFORM, LADDER, ETC.

USED IN CARBURATION POOL, SAPONIFICATION CAULDRONS, AND VACUUM SYSTEM

QUANTITY: 1ITEM 030

DISTRIBUTION BOX

CONTROL MACHINES, BIG BRAND ELECTRICAL COMPONENTS

WOODEN CASE

QUANTITY: 46. ADDITIONAL MACHINES AND SPARE PARTS

ITEM 031

ELECTRICAL CABLES

ALL WIRES FROM EACH MACHINE TO THE FOUR DISTRIBUTION BOXES. THE MAIN WIRE FROM THE FOUR DISTRIBUTION BOXES TO THE MAIN DISTRIBUTION BOX AND SLEEVES ARE NOT INCLUDED

QUANTITY: 1ITEM 032

HEAT INSULATING MATERIAL

ABOUT 450 M3, INCLUDING GALVANIZED SHEET 450 M3. GLASS WOOL CLOTH, NAILS

QUANTITY: 1ITEM 033

WELDING ROD

ABOUT 50 BOXES, 1 TON.

QUANTITY: 1ITEM 034

STEAM BOILER

MATERIAL: DIESEL OIL.

RATED POWER: 2000 KG/H

RATED PRESSURE: 1.25 MPA

RATED STEAM TEMPERATURE: 194 ℃

THE QUOTATION IS FOR ONE WHOLE SET OF BOILER, INCLUDING THE STEAM BOILER, WATER TREATMENT EQUIPMENTS, WATER BOXES, OIL BOXES, PUMPS, AND SOME SPARE PARTS

THE QUOTATION INCLUDES SALARY OF BOILER ENGINEER'S INSTALLATING AND TESTING

THE AIR TICKET AND ACCOMMODATION ARE NOT INCLUDED

LOADED BY A 40 'GP CONTAINER

QUANTITY: 1QUANTITY: 1 PLANT

Learn More -

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More