Search results for: 'All par'

-

TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED 4. MACHINE TYPE: BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 5. BRAND: TETRA PAK 6. MODEL: BOTTLING PLANT 7. CONDITION: USED 8. OPERATING HOURS: 500 H QUANTITY: 1 Learn More

TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED 4. MACHINE TYPE: BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 5. BRAND: TETRA PAK 6. MODEL: BOTTLING PLANT 7. CONDITION: USED 8. OPERATING HOURS: 500 H QUANTITY: 1 Learn More -

TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018 CHROMOJET PRINTING MACHINE YEAR 2018 CHR800 16X512 AND SAMPLING EQUIPMENT FULL LINE, ENTRY, STEAMER, WASHER, DRYER, ROLL UP FULL AUTOMATIC DYE KITCHEN CARPET WIDTH: 2000 TO 4200mm CARPET PILE WEIGHT: 300 TO 2500 G/M² CARPET HEIGHT: 3mm TO 20mm VOLTAGE 380 VOLTS / 3 PHASES / 50 CYCLES; +/- 5% QUANTITY: 1 Learn More

TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018 CHROMOJET PRINTING MACHINE YEAR 2018 CHR800 16X512 AND SAMPLING EQUIPMENT FULL LINE, ENTRY, STEAMER, WASHER, DRYER, ROLL UP FULL AUTOMATIC DYE KITCHEN CARPET WIDTH: 2000 TO 4200mm CARPET PILE WEIGHT: 300 TO 2500 G/M² CARPET HEIGHT: 3mm TO 20mm VOLTAGE 380 VOLTS / 3 PHASES / 50 CYCLES; +/- 5% QUANTITY: 1 Learn More -

YY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINEYY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINE Learn More

YY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINEYY-3035 WOOL FIBER OPENING MACHINE & WEIGHING FEEDER & SEMI WORSTED CARDING MACHINE Learn More -

TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE YEAR: 2014 HOUSED: YES, IN A AMBIENT CONTROLLED WAREHOUSE IN TWO LOCATIONS WHAT DOESN’T HAVE TO BE INDOORS, IS OUTSIDE ON AN ENCLOSED FIELD, 2.5 HOURS AWAY FROM THE WAREHOUSES. SKIDDED: NO PASC CONDITION RATING: A CONDITION DETAILS: NEVER USED UNITS AVAILABLE: 1 CONNECTION STATUS: DISCONNECTED WARRANTY: NO WARRANTY DETAILS: EXP DEC 2018 Learn More

TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014TT-4046 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE, 86.5 MW, YEAR 2014 GENERAL ELECTRIC 7E.03 NATURAL GAS GENERATOR PACKAGE YEAR: 2014 HOUSED: YES, IN A AMBIENT CONTROLLED WAREHOUSE IN TWO LOCATIONS WHAT DOESN’T HAVE TO BE INDOORS, IS OUTSIDE ON AN ENCLOSED FIELD, 2.5 HOURS AWAY FROM THE WAREHOUSES. SKIDDED: NO PASC CONDITION RATING: A CONDITION DETAILS: NEVER USED UNITS AVAILABLE: 1 CONNECTION STATUS: DISCONNECTED WARRANTY: NO WARRANTY DETAILS: EXP DEC 2018 Learn More -

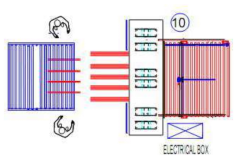

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More -

TT-2926 CHAN LI 202C 112” JRT SLITTER REWINDER WORKING WIDTH 2850mm, YEAR 2014TT-2926 CHAN LI 202C 112” JRT SLITTER REWINDER WORKING WIDTH 2850mm, YEAR 2014 CHAN LI 202C JRT SLITTER REWINDER WEB WIDTH: 112” WORKING WIDTH: 108” OUTPUT: 500 MPM CHAN LI JUMBO UNWIND STAND: 72” DIAMETER, SHAFTLESS CHAN LI DOUBLE EMBOSSING UNIT: (2) STEEL ROLLS AND (2) RUBBER ROLLS PERFORATION UNIT: 3.94” PERFORATION LENGTH LOG DIAMETER RANGE: 4.72” - 15.76” MINIMUM SLITTING WIDTH: 2.36” TRIM SLITTER AND BLOWER: 7.5 HP MITSUBISHI FX3U SERIES PLC AND AC DRIVE MOTOR SIEMENS ELECTRICAL PLATFORM ELECTRICS: 480VAC, 3PH, 60Hz YEAR OF MANUFACTURE: 2014 AVAILABILITY: IMMEDIATE INSPECTION: IN PRODUCTION QUANTITY: 1 Learn More

TT-2926 CHAN LI 202C 112” JRT SLITTER REWINDER WORKING WIDTH 2850mm, YEAR 2014TT-2926 CHAN LI 202C 112” JRT SLITTER REWINDER WORKING WIDTH 2850mm, YEAR 2014 CHAN LI 202C JRT SLITTER REWINDER WEB WIDTH: 112” WORKING WIDTH: 108” OUTPUT: 500 MPM CHAN LI JUMBO UNWIND STAND: 72” DIAMETER, SHAFTLESS CHAN LI DOUBLE EMBOSSING UNIT: (2) STEEL ROLLS AND (2) RUBBER ROLLS PERFORATION UNIT: 3.94” PERFORATION LENGTH LOG DIAMETER RANGE: 4.72” - 15.76” MINIMUM SLITTING WIDTH: 2.36” TRIM SLITTER AND BLOWER: 7.5 HP MITSUBISHI FX3U SERIES PLC AND AC DRIVE MOTOR SIEMENS ELECTRICAL PLATFORM ELECTRICS: 480VAC, 3PH, 60Hz YEAR OF MANUFACTURE: 2014 AVAILABILITY: IMMEDIATE INSPECTION: IN PRODUCTION QUANTITY: 1 Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More -

ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KITREFERENCE NUMBER: A-2481 ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KIT THIS ELECTROSPINNING SYSTEM IS DESIGNED FOR LOW-COST, SMALL-SCALE NANOFIBER RESEARCH, PRODUCING RESULTS FROM A SINGLE-NOZZLE CONFIGURATION IN A COMPACT UNIT. SPINNING DISTANCE, FLOW RATE AND APPLIED VOLTAGE ARE EASILY ADJUSTABLE IN SIDE-BY-SIDE SPINNING SYSTEM. SPECIFICATIONS: SPINNING-TYPE: SIDE BY SIDE SPINNING CHASSIS: ENCLOSED CHASSIS FOR SPINNING AREA COLLECTOR MATERIAL: STAINLESS STEEL TOTAL WEIGHT: APPROX.10 KGS DIMENSIONS: 210 X 170 X 190 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 30 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.170 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA DIRECTLY FEED INTO NOZZLE NUMBER OF NOZZLES: 1 NOZZLE NOZZLE MATERIAL: STAINLESS STEEL COMPATIBLE WITH ALL STANDARD SYRINGE NOZZLES SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 0 TO ∞ DISTANCE ADJUSTMENT METHOD: MANUAL DISTANCE CONTROL STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 180 X 300 mm UNIQUE USER INTERFACE 4.3" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 500 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 8 KGS. Learn More

ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KITREFERENCE NUMBER: A-2481 ENTRY LEVEL SINGLE NOZZLE ELECTROSPINNING UNIT - STARTER KIT THIS ELECTROSPINNING SYSTEM IS DESIGNED FOR LOW-COST, SMALL-SCALE NANOFIBER RESEARCH, PRODUCING RESULTS FROM A SINGLE-NOZZLE CONFIGURATION IN A COMPACT UNIT. SPINNING DISTANCE, FLOW RATE AND APPLIED VOLTAGE ARE EASILY ADJUSTABLE IN SIDE-BY-SIDE SPINNING SYSTEM. SPECIFICATIONS: SPINNING-TYPE: SIDE BY SIDE SPINNING CHASSIS: ENCLOSED CHASSIS FOR SPINNING AREA COLLECTOR MATERIAL: STAINLESS STEEL TOTAL WEIGHT: APPROX.10 KGS DIMENSIONS: 210 X 170 X 190 mm HIGH VOLTAGE POWER SUPPLY VOLTAGE RANGE: 0 TO 30 KV VOLTAGE PRECISION: 0.1 KV MAX CURRENT: 0.170 MA HIGH PRECISION MICRO PUMP FLOW RATE: 0.01 TO 4464 ML/H (BD 60 ML SYRINGE) FLOW RATE PRECISION: 0.01 ML/H AVAILABLE SYRINGES STANDARD: ALL TYPES ARE AVAILABLE FEEDING AREA DIRECTLY FEED INTO NOZZLE NUMBER OF NOZZLES: 1 NOZZLE NOZZLE MATERIAL: STAINLESS STEEL COMPATIBLE WITH ALL STANDARD SYRINGE NOZZLES SPINNING DISTANCE DISTANCE BETWEEN NOZZLE AND COLLECTOR: 0 TO ∞ DISTANCE ADJUSTMENT METHOD: MANUAL DISTANCE CONTROL STATIONARY PLATE COLLECTOR MATERIAL: STAINLESS STEEL DIMENSIONS OF STATIONARY PLATE: 180 X 300 mm UNIQUE USER INTERFACE 4.3" TOUCH SCREEN CONTROL PANEL WITH WELL DESIGNED USER FRIENDLY INTERFACE FULLY ABLE TO CONTROL ALL PARAMETERS TECHNICAL REQUIREMENTS POWER: 220 VOLTS AND 50/60 HZ @ MAX 25A GROUNDING: EXTERNAL GROUNDING LINE AREA: MIN. 500 X 1000 mm WORKBENCH ABLE TO CARRY MINIMUM 8 KGS. Learn More