Search results for: 'Continuous+fo'

- Related search terms

- continuous+foamin

- CONTINUOUS+FOAM+LINE

- Continuous+foa

- Continuous+foam

- CONTINUOUS+FOAMING+MACHINE

-

TT-2959 CIBITEX CONTINUOUS OPEN WIDTH SANFORIZING MACHINE, WIDTH 2400mm, YEAR 2013TT-2959 CIBITEX CONTINUOUS OPEN WIDTH SANFORIZING MACHINE, WIDTH 2400mm, YEAR 2013 BRAND: CIBITEX / ITALY MODEL: HEATED PIPE YEAR: 2013 QUANTITY: 1 Learn More

TT-2959 CIBITEX CONTINUOUS OPEN WIDTH SANFORIZING MACHINE, WIDTH 2400mm, YEAR 2013TT-2959 CIBITEX CONTINUOUS OPEN WIDTH SANFORIZING MACHINE, WIDTH 2400mm, YEAR 2013 BRAND: CIBITEX / ITALY MODEL: HEATED PIPE YEAR: 2013 QUANTITY: 1 Learn More -

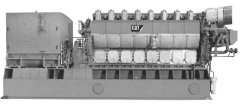

YY-2590 NEW CATERPILLAR 16CM32 5 UNITSYY-2590 NEW CATERPILLAR 16CM32 5 UNITS QUANTITY: 5 Learn More

YY-2590 NEW CATERPILLAR 16CM32 5 UNITSYY-2590 NEW CATERPILLAR 16CM32 5 UNITS QUANTITY: 5 Learn More -

TT-1766 STX-NIIGATA 8L22HLX CONTAINERIZED POWER PLANT, 50-60HzTT-1766 STX-NIIGATA 8L22HLX CONTAINERIZED POWER PLANT, 50-60Hz TYPE: STANDARD CATEGORY: ENGINES/GENERATORS/MOTORS/TRANSMISSIONS TYPE: USED CONDITION: EXCELLENT OUTPUT CAPACITY: 1.7 MW FREQUENCY: 50Hz/60Hz FUEL: DIESEL QUANTITY: 1 Learn More

TT-1766 STX-NIIGATA 8L22HLX CONTAINERIZED POWER PLANT, 50-60HzTT-1766 STX-NIIGATA 8L22HLX CONTAINERIZED POWER PLANT, 50-60Hz TYPE: STANDARD CATEGORY: ENGINES/GENERATORS/MOTORS/TRANSMISSIONS TYPE: USED CONDITION: EXCELLENT OUTPUT CAPACITY: 1.7 MW FREQUENCY: 50Hz/60Hz FUEL: DIESEL QUANTITY: 1 Learn More -

YY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOURYY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOUR DETAILS: TECHNICAL PARAMETERS DIMENSIONS (L X W X H): 5400 X 1650 X 2360mm GROSS WEIGHT: 5800 KG MAIN SHAFT SPEED: 500 TO 1300 RPM PRODUCTION SPEED: 60 TO 300 METERS PER HOUR STITCH LENGTH: 3 TO 8mm NEEDLE TYPE: 24/180, 23/160, 22/140, 21/130 SPACE BETWEEN NEEDLE ROWS: (50.8, 76.2, 127) 5″, (76.2, 76.2, 152.4) 6″ SPACE BETWEEN NEEDLES: 12.7 / 25.4mm MAXIMUM HORIZONTAL MOVEMENT: 304.8mm QUILTING WIDTH: 2450mm QUILTING THICKNESS: ≤80mm VOLTAGE: 220 VOLTS OR 380 VOLTS, 50/60Hz, 3-PHASE POWER: 11 KW QUANTITY: 1 Learn More

YY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOURYY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOUR DETAILS: TECHNICAL PARAMETERS DIMENSIONS (L X W X H): 5400 X 1650 X 2360mm GROSS WEIGHT: 5800 KG MAIN SHAFT SPEED: 500 TO 1300 RPM PRODUCTION SPEED: 60 TO 300 METERS PER HOUR STITCH LENGTH: 3 TO 8mm NEEDLE TYPE: 24/180, 23/160, 22/140, 21/130 SPACE BETWEEN NEEDLE ROWS: (50.8, 76.2, 127) 5″, (76.2, 76.2, 152.4) 6″ SPACE BETWEEN NEEDLES: 12.7 / 25.4mm MAXIMUM HORIZONTAL MOVEMENT: 304.8mm QUILTING WIDTH: 2450mm QUILTING THICKNESS: ≤80mm VOLTAGE: 220 VOLTS OR 380 VOLTS, 50/60Hz, 3-PHASE POWER: 11 KW QUANTITY: 1 Learn More -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More -

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More -

T-8553 CNC SEWING UNIT KSL 110, SEWING FIELD 600 x 600 TO 3500 x 2500mm, YEAR 2003, PARACHUTE PRODUTIONT-8553 CNC SEWING UNIT KSL 110, SEWING FIELD 600 x 600 TO 3500 x 2500mm, YEAR 2003, PARACHUTE PRODUTION CONTINUOUS MULTIPLE FOOT TRANSPORT EXACT SEAM PATTERN / THREAD TIGHTENING IN ALL SEWING DIRECTIONS LIFTABLE AND / OR MOVABLE SEWING HEAD FOR DIRECT ROUTE PROGRAMMING AUTOMATIC MATERIAL HOLDER RECOGNITION OVERLAPPING WORKING METHOD DURING THE SEWING PROCESS CURRENTLY SEWING CLOTHS FOR FILTERS QUANTITY: 1 Learn More

T-8553 CNC SEWING UNIT KSL 110, SEWING FIELD 600 x 600 TO 3500 x 2500mm, YEAR 2003, PARACHUTE PRODUTIONT-8553 CNC SEWING UNIT KSL 110, SEWING FIELD 600 x 600 TO 3500 x 2500mm, YEAR 2003, PARACHUTE PRODUTION CONTINUOUS MULTIPLE FOOT TRANSPORT EXACT SEAM PATTERN / THREAD TIGHTENING IN ALL SEWING DIRECTIONS LIFTABLE AND / OR MOVABLE SEWING HEAD FOR DIRECT ROUTE PROGRAMMING AUTOMATIC MATERIAL HOLDER RECOGNITION OVERLAPPING WORKING METHOD DURING THE SEWING PROCESS CURRENTLY SEWING CLOTHS FOR FILTERS QUANTITY: 1 Learn More -

YY-1413 HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mmYY-1413 HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mm SPECIFICATION: 1. PRESS FORCE: 10 TONS 2. DAYLIGHT: 28mm 3. DIE CUTTING SPEED: 220 TIMES PER MINUTE 4. WIDTH ADJUST: ±5mm 5. SHUT HEIGHT OF METAL MOLD: 115mm 6. EFFECTIVE SIZE OF METAL MOLD: 300 X 290mm 7. MOLD SIZE: 350 X 350mm 8. TURNING WAY: ELECTRICALLY ADJUST 9. PRESS STYLE: JOG/SINGLE/CONTINUOUS 10. TYPE OF MOLD: PLASTIC BOARD MOLD, CHEMICAL SCULPTURE MOLD, METAL MOLD 11. MAX FEEDING WIDTH: ≤350mm 12. FEEDING SPEED: ≤30 METERS PER MINUTE 13. PRECISION OF FEEDING: <0.1mm 14. MATERIAL THICKNESS: 0.025 TO 2mm 15. DIE CUTTING PRECISION: ± 0.03mm 16. FEEDING ROLLER: PU/NBR 17. MATERIALS DRIVEN: SERVO MOTORS 18. LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM 19. PROTECTION: 3 OPTICAL SAFETY SENSORS 20. POWER SUPPLY: AC 380 VOLTS 5 KW 21. AIR SOURCE: 0.5 TO 0.6 MPA 22. WEIGHT OF MACHINE: AROUND 2000KGS 23. MACHINE SIZES (L X W X H): 1700 X 1150 X 1500mm QUANTITY: 1 Learn More

YY-1413 HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mmYY-1413 HIGH SPEED PRECISION DIE CUTTING MACHINE, PLATE DIMENSIONS 300 X 290mm, DAYLIGHT 28mm SPECIFICATION: 1. PRESS FORCE: 10 TONS 2. DAYLIGHT: 28mm 3. DIE CUTTING SPEED: 220 TIMES PER MINUTE 4. WIDTH ADJUST: ±5mm 5. SHUT HEIGHT OF METAL MOLD: 115mm 6. EFFECTIVE SIZE OF METAL MOLD: 300 X 290mm 7. MOLD SIZE: 350 X 350mm 8. TURNING WAY: ELECTRICALLY ADJUST 9. PRESS STYLE: JOG/SINGLE/CONTINUOUS 10. TYPE OF MOLD: PLASTIC BOARD MOLD, CHEMICAL SCULPTURE MOLD, METAL MOLD 11. MAX FEEDING WIDTH: ≤350mm 12. FEEDING SPEED: ≤30 METERS PER MINUTE 13. PRECISION OF FEEDING: <0.1mm 14. MATERIAL THICKNESS: 0.025 TO 2mm 15. DIE CUTTING PRECISION: ± 0.03mm 16. FEEDING ROLLER: PU/NBR 17. MATERIALS DRIVEN: SERVO MOTORS 18. LUBRICATE: FULLY AUTOMATIC CENTRAL LUBRICATION SYSTEM 19. PROTECTION: 3 OPTICAL SAFETY SENSORS 20. POWER SUPPLY: AC 380 VOLTS 5 KW 21. AIR SOURCE: 0.5 TO 0.6 MPA 22. WEIGHT OF MACHINE: AROUND 2000KGS 23. MACHINE SIZES (L X W X H): 1700 X 1150 X 1500mm QUANTITY: 1 Learn More -

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More -

T-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MINT-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MIN CARTON SET: WOODEN BOX CTN SIZE: 1270, 540, 1200mm QUANTITY/CTN: 1 CBM: 0.82 SINGLE MOTOR OUTPUT POWER: 2500W WPOWER INPUT: 220V OUTPUT FREQUENCY: 20KHz WORKING TEMPERATURE: -10-28C WORKING SPEED: 0 TO 26M/MIN EQUIPPED PATTERN MOULD: 0 TO 200mm WEIGHT OF MACHINE: 95KG QUANTITY: 1 Learn More

T-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MINT-7655 ULTRASONIC SEWING MACHINE, WORKING SPEED 0 TO 26M/MIN CARTON SET: WOODEN BOX CTN SIZE: 1270, 540, 1200mm QUANTITY/CTN: 1 CBM: 0.82 SINGLE MOTOR OUTPUT POWER: 2500W WPOWER INPUT: 220V OUTPUT FREQUENCY: 20KHz WORKING TEMPERATURE: -10-28C WORKING SPEED: 0 TO 26M/MIN EQUIPPED PATTERN MOULD: 0 TO 200mm WEIGHT OF MACHINE: 95KG QUANTITY: 1 Learn More