Search results for: 'complete+no'

-

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More -

TT-1698 TOSHIBA DUAL FUEL INLET STEAM TURBINE & GENERATOR POWER PLANT (NEVER USED), 215 MW, 50 Hz, YEAR 2008TT-1698 TOSHIBA DUAL FUEL INLET STEAM TURBINE & GENERATOR POWER PLANT (NEVER USED), 215 MW, 50 Hz, YEAR 2008 RATING: 215 MW TYPE: STEAM TURBINE & GENSET BRAND: TOSHIBA MODEL: SGLFLOW CONDENSING FUEL: DUAL FUEL 50 Hz YEAR: 2008 QUANTITY: 1 Learn More

TT-1698 TOSHIBA DUAL FUEL INLET STEAM TURBINE & GENERATOR POWER PLANT (NEVER USED), 215 MW, 50 Hz, YEAR 2008TT-1698 TOSHIBA DUAL FUEL INLET STEAM TURBINE & GENERATOR POWER PLANT (NEVER USED), 215 MW, 50 Hz, YEAR 2008 RATING: 215 MW TYPE: STEAM TURBINE & GENSET BRAND: TOSHIBA MODEL: SGLFLOW CONDENSING FUEL: DUAL FUEL 50 Hz YEAR: 2008 QUANTITY: 1 Learn More -

YY-2241 124 MW GE FRAME 9E CHP COMPLETE POWER PLANT, 50 HzYY-2241 124 MW GE FRAME 9E CHP COMPLETE POWER PLANT, 50 Hz GAS TURBINE MODEL / TYPE: GENERAL ELECTRIC -GE FRAME 9E - PG9171(E) 50Hz; SINGLE TURBINE DESIGN OUTPUT: 124 MW; DESIGN HEAT RATE: NET HEAT RATE AT GENERATOR TERMINALS KJ/KWH 10 716 ±1%; DLN SYSTEM: DLN1; COMMISSIONING DATE: 2009; SHUT-DOWN DATE: NOVEMBER 2017. WELL PRESERVED TO DATE; TOTAL FIRED TIME: 56500; PLANNED MAINTENANCE DATE: 2012 HOT GAS PATH INSPECTION, 2015 MAJOR INSPECTION; RATED OUTPUT / TERMINAL VOLTAGE: 150 MVA – 15 KV; TRANSFORMERS: STEP UP TRANSFORMER: 153 MVA. TURBINE EFFICIENCY: NET HEAT RATE AT GENERATOR TERMINAL IS 10,760 kJ/kWh QUANTITY: 1 Learn More

YY-2241 124 MW GE FRAME 9E CHP COMPLETE POWER PLANT, 50 HzYY-2241 124 MW GE FRAME 9E CHP COMPLETE POWER PLANT, 50 Hz GAS TURBINE MODEL / TYPE: GENERAL ELECTRIC -GE FRAME 9E - PG9171(E) 50Hz; SINGLE TURBINE DESIGN OUTPUT: 124 MW; DESIGN HEAT RATE: NET HEAT RATE AT GENERATOR TERMINALS KJ/KWH 10 716 ±1%; DLN SYSTEM: DLN1; COMMISSIONING DATE: 2009; SHUT-DOWN DATE: NOVEMBER 2017. WELL PRESERVED TO DATE; TOTAL FIRED TIME: 56500; PLANNED MAINTENANCE DATE: 2012 HOT GAS PATH INSPECTION, 2015 MAJOR INSPECTION; RATED OUTPUT / TERMINAL VOLTAGE: 150 MVA – 15 KV; TRANSFORMERS: STEP UP TRANSFORMER: 153 MVA. TURBINE EFFICIENCY: NET HEAT RATE AT GENERATOR TERMINAL IS 10,760 kJ/kWh QUANTITY: 1 Learn More -

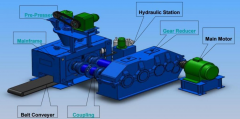

YY-2223 BRIQUETTING MACHINESYY-2223 BRIQUETTING MACHINES ASK FOR MORE DETAILS! Learn More

YY-2223 BRIQUETTING MACHINESYY-2223 BRIQUETTING MACHINES ASK FOR MORE DETAILS! Learn More -

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More -

TT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEMTT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEM BARUDAN NAPKIN SEWING SYSTEM MODEL BEST-3R 4 WORKING MACHINES AND 2 NON-WORKING MACHINES. QUANTITY: 6 Learn More

TT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEMTT-1269 BARUDAN AUTOMATED NAPKIN SEWING SYSTEM BARUDAN NAPKIN SEWING SYSTEM MODEL BEST-3R 4 WORKING MACHINES AND 2 NON-WORKING MACHINES. QUANTITY: 6 Learn More -

TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018 ITEM 001 TOYOTA MAKE AIRJET LOOMS, WIDTH 2100mm, YEAR 2016 TO 2017, WITH DOBBY. QUANTITY: 100 ITEM 002 JUPITER MAKE INDIGO SLASHER DYEING RANGE WITH SIZING PLANT, 16 BEAMS, YEAR 2018, ROLLER WIDTH 2000mm, WITH STEAMER 60000mm QUANTITY: 2 ITEM 003 JUPITER MAKE WARPING MACHNE WITH 672 ENDS, YEAR 2017 TO 2018 QUANTITY: 3 ITEM 004 DHALL MAKE SINGEING MACHINE, ROLLER WIDTH 2400mm, YEAR 2018 QUANTITY: 1 ITEM 005 DHALL MAKE CHAINLESS MERCERISER, YEAR 2018 QUANTITY: 1 ITEM 006 DHALL MAKE STENTOR, 8 CHAMBERS. QUANTITY: 1 ITEM 007 DHALL MAKE DESIZE AND OVER DYE MACHINE QUANTITY: 1 ITEM 008 DHALL MAKE WET FINISH MACHINE, YEAR 2018 ITEM 009 LUWA HUMDIFICATION PLANT, 2 NOS. KAISER COMPRESSOR, CAUSTIC RECOVERY PLANT, THERMA COAL FIRED BOILER, THERMPOC. QUANTITY: 2 Learn More

TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018TT-1263 COMPLETE DENIM PLANT, 2000mm TO 2400mm, YEAR 2016 TO 2018 ITEM 001 TOYOTA MAKE AIRJET LOOMS, WIDTH 2100mm, YEAR 2016 TO 2017, WITH DOBBY. QUANTITY: 100 ITEM 002 JUPITER MAKE INDIGO SLASHER DYEING RANGE WITH SIZING PLANT, 16 BEAMS, YEAR 2018, ROLLER WIDTH 2000mm, WITH STEAMER 60000mm QUANTITY: 2 ITEM 003 JUPITER MAKE WARPING MACHNE WITH 672 ENDS, YEAR 2017 TO 2018 QUANTITY: 3 ITEM 004 DHALL MAKE SINGEING MACHINE, ROLLER WIDTH 2400mm, YEAR 2018 QUANTITY: 1 ITEM 005 DHALL MAKE CHAINLESS MERCERISER, YEAR 2018 QUANTITY: 1 ITEM 006 DHALL MAKE STENTOR, 8 CHAMBERS. QUANTITY: 1 ITEM 007 DHALL MAKE DESIZE AND OVER DYE MACHINE QUANTITY: 1 ITEM 008 DHALL MAKE WET FINISH MACHINE, YEAR 2018 ITEM 009 LUWA HUMDIFICATION PLANT, 2 NOS. KAISER COMPRESSOR, CAUSTIC RECOVERY PLANT, THERMA COAL FIRED BOILER, THERMPOC. QUANTITY: 2 Learn More -

J-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEWJ-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEW SEWING MACHINE FOLDS FABRIC, STITCHES EDGE OF FABRIC FOR TWILL EFFECT WORKS TOGETHER WITH WINDING MACHINE AND STRIP CUTTING MACHINE WINDING MACHINE OPENS PREVIOUSLY FORMED TUBE MATERIAL, SPIRALLY, IN THE BIAS, AND REWINDS A SINGLE PLY ROLL, AT BOTTOM OF MACHINE THERE IS A KNIFE TO CUT SEWING FABRIC SEPARATELY, PREPARED FOR THE SLITTER SLITTER MACHINE HAS MANUAL, SEMI-AUTOMATIC AND FULLY AUTOMATIC MODES. WILL SLIT ANY TYPE OF MATERIAL ON THE ROLL (OPEN KNITS, WOVEN FABRIC, LEATHER, POLYESTER, SOME PAPER PRODUCTS, NONWOVEN, ETC) QUANTITY: 1 SLITTER, 1 WINDER Learn More

J-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEWJ-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEW SEWING MACHINE FOLDS FABRIC, STITCHES EDGE OF FABRIC FOR TWILL EFFECT WORKS TOGETHER WITH WINDING MACHINE AND STRIP CUTTING MACHINE WINDING MACHINE OPENS PREVIOUSLY FORMED TUBE MATERIAL, SPIRALLY, IN THE BIAS, AND REWINDS A SINGLE PLY ROLL, AT BOTTOM OF MACHINE THERE IS A KNIFE TO CUT SEWING FABRIC SEPARATELY, PREPARED FOR THE SLITTER SLITTER MACHINE HAS MANUAL, SEMI-AUTOMATIC AND FULLY AUTOMATIC MODES. WILL SLIT ANY TYPE OF MATERIAL ON THE ROLL (OPEN KNITS, WOVEN FABRIC, LEATHER, POLYESTER, SOME PAPER PRODUCTS, NONWOVEN, ETC) QUANTITY: 1 SLITTER, 1 WINDER Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More