Search results for: 'GAS V'

-

TT-5655 JOULE THOMSON EFFECT (J-T) NATURAL GAS LIQUIDS EXTRACTION PLANTTT-5655 JOULE THOMSON EFFECT (J-T) NATURAL GAS LIQUIDS EXTRACTION PLANT NATURAL GAS LIQUIDS EXTRACTION PLANT JOULE THOMSON EFFECT REFRIGERATED USED Learn More

TT-5655 JOULE THOMSON EFFECT (J-T) NATURAL GAS LIQUIDS EXTRACTION PLANTTT-5655 JOULE THOMSON EFFECT (J-T) NATURAL GAS LIQUIDS EXTRACTION PLANT NATURAL GAS LIQUIDS EXTRACTION PLANT JOULE THOMSON EFFECT REFRIGERATED USED Learn More -

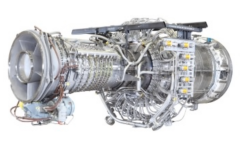

YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2 ITEM 001 2500 HOURS AFTER ENGINE OVERHAUL ITEM 002 6500 HOURS AFTER ENGINE OVERHAUL Learn More

YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2YY-2425 LM2500 PE SAC, 22.4 MW, WITH GE 6 STAGE POWER TURBINE, GAS TURBINES, QUANTITY 2 ITEM 001 2500 HOURS AFTER ENGINE OVERHAUL ITEM 002 6500 HOURS AFTER ENGINE OVERHAUL Learn More -

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More -

YY-2894 NEW SIEMENS SGT 400, YEAR 2018YY-2894 NEW SIEMENS SGT 400, YEAR 2018 SIEMENS SGT 400 (12.9 MW) GAS TURBINE · 11-STAGE COMPRESSOR, 6 COMBUSTION CHAMBERS, 2-STAGE POWER TURBINE · GAS FUEL SYSTEM · DLE COMBUSTION SYSTEM · HOT-END DRIVE · 2-SHAFT ENGINE · LEFT-HAND EXHAUST · MAIN LUBRICATION PUMP · EQUIVALENT OPERATING HOURS : 0H · TOTAL STARTS : 0 · NEW, NEVER INSTALLED OR COMMISSIONED QUANTITY: 1 Learn More

YY-2894 NEW SIEMENS SGT 400, YEAR 2018YY-2894 NEW SIEMENS SGT 400, YEAR 2018 SIEMENS SGT 400 (12.9 MW) GAS TURBINE · 11-STAGE COMPRESSOR, 6 COMBUSTION CHAMBERS, 2-STAGE POWER TURBINE · GAS FUEL SYSTEM · DLE COMBUSTION SYSTEM · HOT-END DRIVE · 2-SHAFT ENGINE · LEFT-HAND EXHAUST · MAIN LUBRICATION PUMP · EQUIVALENT OPERATING HOURS : 0H · TOTAL STARTS : 0 · NEW, NEVER INSTALLED OR COMMISSIONED QUANTITY: 1 Learn More -

YY-3063 USED SOLAR TITAN 250S TURBINE-DRIVEN C51 CENTRIFUGAL COMPRESSORS SETSYY-3063 USED SOLAR TITAN 250S TURBINE-DRIVEN C51 CENTRIFUGAL COMPRESSORS SETS - USED - TWO (2) T250 TURBINE/C51-COMPRESSOR SETS AVAILABLE. - MANUFACTURED IN 2014 BY SOLAR TURBINES. Learn More

YY-3063 USED SOLAR TITAN 250S TURBINE-DRIVEN C51 CENTRIFUGAL COMPRESSORS SETSYY-3063 USED SOLAR TITAN 250S TURBINE-DRIVEN C51 CENTRIFUGAL COMPRESSORS SETS - USED - TWO (2) T250 TURBINE/C51-COMPRESSOR SETS AVAILABLE. - MANUFACTURED IN 2014 BY SOLAR TURBINES. Learn More -

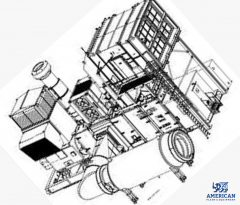

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More -

TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007 SOLAR TITAN 130 GAS TURBINE 15,000KWE 11,170 RPM / 60Hz 11,197 RPM / 50Hz FUEL GAS QUANTITY: 1 Learn More

TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007TT-1418 SOLAR TITAN 130 GAS TURBINE, 50Hz / 60Hz, YEAR 2007 SOLAR TITAN 130 GAS TURBINE 15,000KWE 11,170 RPM / 60Hz 11,197 RPM / 50Hz FUEL GAS QUANTITY: 1 Learn More -

2KG COFFEE ROASTER - GAS TYPEREFERENCE NUMBER: A-2483 2KG COFFEE ROASTER - GAS TYPE ROASTER SIZE: 1200 X 800 X1100 mm ROASTER WEIGHT: 130 KG CHAFF COLLECTOR SIZE: 310 X 250 X910 mm CHAFF COLLECTOR WEIGHT: 20 KG DRUM CONSTRUCTION: DOUBLE-WALLED DRUM, 310 STAINLESS STEEL, WELDED BATCH SIZE: 0.5 TO 2.5KG AVERAGE ROASTING TIME: < 15 MINUTES BATCH INPUT POWER SINGLE PHASE, 220V, 15A, 50-60Hz DRUM MOTOR: 90W EXHAUST FAN MOTOR: 50W COOLING FAN MOTOR: 50W COOLING TRAY STIRRING MOTOR: 20W FUEL TYPE: LP GAS -OR- NATURAL GAS MAX. BTU: 30,000 BURNER CONTROL: MANUAL VALVE GAS CONNECTION: 1/2" NPT GAS PRESSURE REQUIRED: LP GAS: 7” OF WATER COLUMN NATURAL GAS: 11” OF WATER COLUMN GAS ORIFICES SIZE: LP GAS: 0.7 mm (INSTALLED AT FACTORY) NATURAL: 0.9 mm MAX GAS USAGE 3.3 LB/HR (0.5 KG/HR) TYPICAL ROASTER EXHAUST HIGH TEMPERATURE: 400°F TO 450°F CHAFF COLLECTOR EXHAUST HIGH TEMPERTURE: 300°F MAX EXHAUST: 600 CFM EXHAUST VENTING TYPE REQUIRED: CLASS III, POSITIVE PRESSURE BLUETOOTH DATA LOGGER: MODBUS CP210/ARTISAN SOFTWARE LOGGING THERMCOUPLE: BT, ET, INCOMING AIR COLOR ON ROASTER BODY: BLACK, RED, WHITE, PINK COLOR ON HOUSING PLATE: GOLDEN,SILVER,ROSE GOLD (MIRROR OR NO FINGERPRINT): BLACK TITANIUM, RIFFLED PLATE NET/GROSS WEIGHT: 150KG /160KG Learn More

2KG COFFEE ROASTER - GAS TYPEREFERENCE NUMBER: A-2483 2KG COFFEE ROASTER - GAS TYPE ROASTER SIZE: 1200 X 800 X1100 mm ROASTER WEIGHT: 130 KG CHAFF COLLECTOR SIZE: 310 X 250 X910 mm CHAFF COLLECTOR WEIGHT: 20 KG DRUM CONSTRUCTION: DOUBLE-WALLED DRUM, 310 STAINLESS STEEL, WELDED BATCH SIZE: 0.5 TO 2.5KG AVERAGE ROASTING TIME: < 15 MINUTES BATCH INPUT POWER SINGLE PHASE, 220V, 15A, 50-60Hz DRUM MOTOR: 90W EXHAUST FAN MOTOR: 50W COOLING FAN MOTOR: 50W COOLING TRAY STIRRING MOTOR: 20W FUEL TYPE: LP GAS -OR- NATURAL GAS MAX. BTU: 30,000 BURNER CONTROL: MANUAL VALVE GAS CONNECTION: 1/2" NPT GAS PRESSURE REQUIRED: LP GAS: 7” OF WATER COLUMN NATURAL GAS: 11” OF WATER COLUMN GAS ORIFICES SIZE: LP GAS: 0.7 mm (INSTALLED AT FACTORY) NATURAL: 0.9 mm MAX GAS USAGE 3.3 LB/HR (0.5 KG/HR) TYPICAL ROASTER EXHAUST HIGH TEMPERATURE: 400°F TO 450°F CHAFF COLLECTOR EXHAUST HIGH TEMPERTURE: 300°F MAX EXHAUST: 600 CFM EXHAUST VENTING TYPE REQUIRED: CLASS III, POSITIVE PRESSURE BLUETOOTH DATA LOGGER: MODBUS CP210/ARTISAN SOFTWARE LOGGING THERMCOUPLE: BT, ET, INCOMING AIR COLOR ON ROASTER BODY: BLACK, RED, WHITE, PINK COLOR ON HOUSING PLATE: GOLDEN,SILVER,ROSE GOLD (MIRROR OR NO FINGERPRINT): BLACK TITANIUM, RIFFLED PLATE NET/GROSS WEIGHT: 150KG /160KG Learn More -

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More -

TT-8253 MWM 2032V16, 4.2 MW EACH, NATURAL GAS, YEAR 2009, 50HzTT-8253 MWM 2032V16, 4.2 MW EACH, NATURAL GAS, YEAR 2009, 50Hz 1. BRAND: MWM 2. MODEL: 2032V16 3. FUEL: NATURAL GAS 4. YEAR OF CONSTRUCTION: 2009 5. OPERATING HOURS: 41,600 (AVERAGE) 6. MAJOR OVERHAUL E60: 2015 (AT AVERAGE 33.600 HOURS) 7. MOTHBALLED: 2019 8. ALTERNATOR: AVK 9. FREQUENCY: 50Hz 10. VOLTAGE: 11 KV QUANTITY: 14 Learn More

TT-8253 MWM 2032V16, 4.2 MW EACH, NATURAL GAS, YEAR 2009, 50HzTT-8253 MWM 2032V16, 4.2 MW EACH, NATURAL GAS, YEAR 2009, 50Hz 1. BRAND: MWM 2. MODEL: 2032V16 3. FUEL: NATURAL GAS 4. YEAR OF CONSTRUCTION: 2009 5. OPERATING HOURS: 41,600 (AVERAGE) 6. MAJOR OVERHAUL E60: 2015 (AT AVERAGE 33.600 HOURS) 7. MOTHBALLED: 2019 8. ALTERNATOR: AVK 9. FREQUENCY: 50Hz 10. VOLTAGE: 11 KV QUANTITY: 14 Learn More