Search results for: 'Electric di'

- Related search terms

- electric con

- electrica'[0]

- Electrical b

- Electrical l

- Electric One

-

P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mmREFERENCE NUMBER: P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mm KARL MAYER-ROTAL SIZING MACHINE YEAR: 2001 HEAD 4600mm QUANTITY AVAILABLE: 1 Learn More

P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mmREFERENCE NUMBER: P-2505 KARL MAYER ROTAL SIZING MACHINE YEAR 2001 WIDTH 4000mm KARL MAYER-ROTAL SIZING MACHINE YEAR: 2001 HEAD 4600mm QUANTITY AVAILABLE: 1 Learn More -

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More

K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORYREFERENCE NUMBER: K-1070 COMPLETE NARROW WOVEN EDGE POLYESTER SATIN FACTORY WORKING FACTORY TO MAKE ELASTIC, RIBBON OR PRINTED LABEL TAPE SUITABLE PRINTING METHODS: ROTARY, SILK-SCREEN, LETTER PRESS, HOT EDGE, STAMPING. NARROW WOVEN EDGE POLYESTER OR SATIN. YOU MAY BUY THIS FACTORY IN PARTS OR ENTIRELY, ACCORDING TO YOUR NEEDS. A THOROUGHLY MODERN PLANT. HUMAN HANDS NEVER TOUCH THE PRODUCT. CONSISTING OF: JACOB MULLER NF LOOMS NEEDLE HEADS PER MACHINE: 6 REED WIDTH: 42 mm MAX. RIBBON WIDTH: APPROX. 40mm MAX. QUANTITY: 68 BENNINGER ERGOTRONIC SECTIONAL WARPER IN PERFECT CONDITION QUANTITY: 1 JACOB MULLER WEBTEX FINISHING MACHINE QUANTITY: 1 JACOB MULLER RAM 500 MEASURING AND ROLLING MACHINE QUANTITY: 1 JACOB MULLER NF AUTOMATIC WINDERS QUANTITY: 78 QUANTITY AVAILABLE: 1 Learn More -

M-3334 RIETER BT 905 OPEN END SPINNING MACHINE YEAR 1999-2000REFERENCE NUMBER: M-3334 (880AESDXX7) K RIETER BT 905 OPEN END SPINNING MACHINE YEAR 1999-2000 RIETER BT 905 OPEN END SPINNING MACHINE YEAR: 1999, 2000 NO. OF POINTS - 288 CYLINDRICAL BEAM - 170 mm WEIGHT OF BEAM - MAX - 3 KG DIAMETER - 43 OR 50 mm TYPE OF COMB - OK 61 NIDI ROTATION OF COMB - 7000-9000 RPM PRODUCED YARN: VIS, VIS/PES, TEX 20 - 80 ROTATION OF SPIN 45-90 000 RPM ELECTRICAL QUALITY CONTROL AVAILABLE WAXING (PARAFFINING) UNIT (1 MACHINE) SUPPLY - 3 X 380 V, 50 HZ, 195 A, 10 BAR QUANTITY AVAILABLE: 2 Learn More

M-3334 RIETER BT 905 OPEN END SPINNING MACHINE YEAR 1999-2000REFERENCE NUMBER: M-3334 (880AESDXX7) K RIETER BT 905 OPEN END SPINNING MACHINE YEAR 1999-2000 RIETER BT 905 OPEN END SPINNING MACHINE YEAR: 1999, 2000 NO. OF POINTS - 288 CYLINDRICAL BEAM - 170 mm WEIGHT OF BEAM - MAX - 3 KG DIAMETER - 43 OR 50 mm TYPE OF COMB - OK 61 NIDI ROTATION OF COMB - 7000-9000 RPM PRODUCED YARN: VIS, VIS/PES, TEX 20 - 80 ROTATION OF SPIN 45-90 000 RPM ELECTRICAL QUALITY CONTROL AVAILABLE WAXING (PARAFFINING) UNIT (1 MACHINE) SUPPLY - 3 X 380 V, 50 HZ, 195 A, 10 BAR QUANTITY AVAILABLE: 2 Learn More -

P-2126 MINOX PRT 3/C JET DYEING MACHINES YEAR 1988, 1990 and 1991 300 KILOGRAMSREFERENCE NUMBER: P-2126 MINOX PRT 3/C JET DYEING MACHINES YEAR 1988, 1990 and 1991 300 KILOGRAMS MINOX TYPE: PRT 3/C JET DYEING MACHINES YEAR: 1988, 1990 and 1991 148°c 3.5 BAR 3 ROPES 300KILOGRAMS TIME / TEMPERATURE PROGRAMMER WITH PNEUMATIC VALVES AUTOMATIC SEAM DETECTOR VALVES FOR DISCHARGE AND WASHING PRODUCTS INTRODUCTION TANK WITH ELECTROPUMP ELECTRIC PANEL QUANTITY AVAILABLE: 3 Learn More

P-2126 MINOX PRT 3/C JET DYEING MACHINES YEAR 1988, 1990 and 1991 300 KILOGRAMSREFERENCE NUMBER: P-2126 MINOX PRT 3/C JET DYEING MACHINES YEAR 1988, 1990 and 1991 300 KILOGRAMS MINOX TYPE: PRT 3/C JET DYEING MACHINES YEAR: 1988, 1990 and 1991 148°c 3.5 BAR 3 ROPES 300KILOGRAMS TIME / TEMPERATURE PROGRAMMER WITH PNEUMATIC VALVES AUTOMATIC SEAM DETECTOR VALVES FOR DISCHARGE AND WASHING PRODUCTS INTRODUCTION TANK WITH ELECTROPUMP ELECTRIC PANEL QUANTITY AVAILABLE: 3 Learn More -

M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870REFERENCE NUMBER: M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870 YEAR 6X 1996, 2X, 1998 WORKING WIDTH 3900 MM / 153” STAUBLI E-JACQUARD CX-870 YEAR 1998 2688 HOOKS CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER QUANTITY AVAILABLE: 8 Learn More

M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870REFERENCE NUMBER: M-5490 SULZER MODEL P7200 B390 F4 J Q D1- STAUBLI ELECTRIC JACQUARD CX-870 YEAR 6X 1996, 2X, 1998 WORKING WIDTH 3900 MM / 153” STAUBLI E-JACQUARD CX-870 YEAR 1998 2688 HOOKS CONTROLLER JC-5 GROUND AND PILE WARP BEAM 940/1250 MM DIAMETER QUANTITY AVAILABLE: 8 Learn More -

M-5393 TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATIONREFERENCE NUMBER: M-5393 (2206YBJL1UM) L TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATION TUFTO COATING LINE FOR EMBOSSED UNITARY BACKED RUGS USING WASHABLE LATEX FOR EMBOSSED WASHABLE RUGS – SET UP FOR 12’ WIDTH AND INCLUDES THE FOLLOWING: TISI MODEL 38500 BUTT SEAMER WITH TRIMMER ON RAIL ENTRANCE J-BOX VERTICAL KEYON PIN TENTER DIRECT COAT APPLICATOR, ROLL OVER ROLL WITH TRAVERSING SYSTEM DAY TANK TO FEED LATEX TO FROTH MACHINE EASE TYPE FROTH MACHINE PRE-STEAMER BANK OF ELECTRIC INFRAREDS TWO BASKET-WEAVE EMBOSSING ROLLERS FOR 12’ WIDTHS FOUR MODULE NATURAL GAS HEATED TUFTCO CURING OVEN COOL OUT SECTION SLITTING SECTION WITH EIGHT SLITTING HEADS AND A CAMERA GUIDING SYSTEM 10 LOOP ACCUMULATOR ROLLUP ELECTRICAL CONTROL SYSTEM BY TUFTCO SPEED RANGE: LINE SPEED FOR COATING 50 OUNCE/SQUARE YARD FACE WEIGHT WITH 24 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 35FPM, LINE SPEED FOR COATING 30 OZ/SQUARE YARD FACE WEIGHT WITH 20 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 45 FPM. TOILET SEAT CONVERS ARE COATED WITH APPROXIMATELY 7 OZ/SQUARE YARD AT 70 FPM. NOTE THE MAXIMUM MECHANICAL SPEED OF THE COATING LINE IS 70 FPM. QUANTITY AVAILABLE: 1 Learn More

M-5393 TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATIONREFERENCE NUMBER: M-5393 (2206YBJL1UM) L TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATION TUFTO COATING LINE FOR EMBOSSED UNITARY BACKED RUGS USING WASHABLE LATEX FOR EMBOSSED WASHABLE RUGS – SET UP FOR 12’ WIDTH AND INCLUDES THE FOLLOWING: TISI MODEL 38500 BUTT SEAMER WITH TRIMMER ON RAIL ENTRANCE J-BOX VERTICAL KEYON PIN TENTER DIRECT COAT APPLICATOR, ROLL OVER ROLL WITH TRAVERSING SYSTEM DAY TANK TO FEED LATEX TO FROTH MACHINE EASE TYPE FROTH MACHINE PRE-STEAMER BANK OF ELECTRIC INFRAREDS TWO BASKET-WEAVE EMBOSSING ROLLERS FOR 12’ WIDTHS FOUR MODULE NATURAL GAS HEATED TUFTCO CURING OVEN COOL OUT SECTION SLITTING SECTION WITH EIGHT SLITTING HEADS AND A CAMERA GUIDING SYSTEM 10 LOOP ACCUMULATOR ROLLUP ELECTRICAL CONTROL SYSTEM BY TUFTCO SPEED RANGE: LINE SPEED FOR COATING 50 OUNCE/SQUARE YARD FACE WEIGHT WITH 24 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 35FPM, LINE SPEED FOR COATING 30 OZ/SQUARE YARD FACE WEIGHT WITH 20 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 45 FPM. TOILET SEAT CONVERS ARE COATED WITH APPROXIMATELY 7 OZ/SQUARE YARD AT 70 FPM. NOTE THE MAXIMUM MECHANICAL SPEED OF THE COATING LINE IS 70 FPM. QUANTITY AVAILABLE: 1 Learn More -

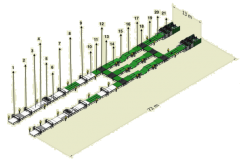

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More

K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5014 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 1000 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WIDTH: 2200mm CAPACITY: 1,000 MATTRESSES PER 8-HOUR SHIFT 1ST BRIDGE: 3 PNEUMATICALLY MOVING GUNS WITH 4 NOZZLES ON EACH HOTMELT GUN. CAN BE CONVERTED TO SPRAY AT NO EXTRA COST. 2ND BRIDGE: 2 GUNS FOR THE EDGE: ONE HAS 8 NOZZLES (T-SHAPED), THE OTHER HAS 4 NOZZLES. 3RD BRIDGE: 3 PNEUMATICALLY MOVING GUNS. THEY ARE SPRAY; LINE NOZZLES CAN BE ADDED 4TH BRIDGE: EXACTLY THE SAME AS 3RD BRIDGE. FLOORSPACE DIMENSIONS: 72000mm X 13000mm QUANTITY AVAILABLE: 1 Learn More -

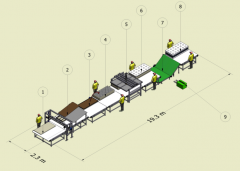

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

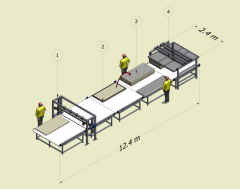

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

M-3112 FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW)REFERENCE NUMBER: M-3112 (7701171GT6UF) FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW) PROCESSING PROCEDURE: POTATO PEELING AND WASHING MACHINE—INSPECTION MACHINE—SLICING MACHINE—HOIST—BLANCHING MACHINE—DRYING MACHINE (OR VIBRATING SCREEN)—FRYING MACHINE (WITH OIL FILTER)—DRYING MACHINE—MIXER (FOR CHIPS)—PACKING MACHINE QUANTITY AVAILABLE: 1 Learn More

M-3112 FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW)REFERENCE NUMBER: M-3112 (7701171GT6UF) FROZEN FRENCH FRY PRODUCTION LINE 300KG (NEW) PROCESSING PROCEDURE: POTATO PEELING AND WASHING MACHINE—INSPECTION MACHINE—SLICING MACHINE—HOIST—BLANCHING MACHINE—DRYING MACHINE (OR VIBRATING SCREEN)—FRYING MACHINE (WITH OIL FILTER)—DRYING MACHINE—MIXER (FOR CHIPS)—PACKING MACHINE QUANTITY AVAILABLE: 1 Learn More