Search results for: 'block d'

- Related search terms

- block diagram

- block+dia

- block+foam+cutting

- blocking

- blockin

-

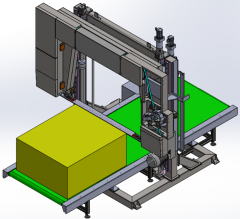

YY-2318 HORIZONTAL BANDSAW FOR PU BLOCKS, DIMENSION OF BLOCK (MAXIMUM) 2000 X 2400 X 1300 mmYY-2318 HORIZONTAL BANDSAW FOR PU BLOCKS, DIMENSION OF BLOCK (MAXIMUM) 2000 X 2400 X 1300 mm QUANTITY: 1 Learn More

YY-2318 HORIZONTAL BANDSAW FOR PU BLOCKS, DIMENSION OF BLOCK (MAXIMUM) 2000 X 2400 X 1300 mmYY-2318 HORIZONTAL BANDSAW FOR PU BLOCKS, DIMENSION OF BLOCK (MAXIMUM) 2000 X 2400 X 1300 mm QUANTITY: 1 Learn More -

V-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mmV-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mm WORKING TABLE SIZE: 2600 x 2300mm MAXIMUM FOAM SIZE: 2300 x 2600 x 1300mm PRESSURE: 120 TONS WEIGHT: 25,000 KG EXTERNAL DIMENSIONS: 11720 x 3610 x 4000mm TOTAL POWER: 56.5 KW VOLTAGE: 3-PHASE, 380 VOLTS, 50 OR 60 Hz CE CERTIFICATE SPARE PARTS ARE SIEMENS BRAND REQUIRES 2 40 FOOT HQ CONTAINERS TO SHIP QUANTITY: 1 Learn More

V-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mmV-1947 BLOCK FOAM COMPRESSION ROLLING SYSTEM, 120 TON CAPACITY, OUTPUT DIAMETER 500 TO 800mm WORKING TABLE SIZE: 2600 x 2300mm MAXIMUM FOAM SIZE: 2300 x 2600 x 1300mm PRESSURE: 120 TONS WEIGHT: 25,000 KG EXTERNAL DIMENSIONS: 11720 x 3610 x 4000mm TOTAL POWER: 56.5 KW VOLTAGE: 3-PHASE, 380 VOLTS, 50 OR 60 Hz CE CERTIFICATE SPARE PARTS ARE SIEMENS BRAND REQUIRES 2 40 FOOT HQ CONTAINERS TO SHIP QUANTITY: 1 Learn More -

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More -

F-1227 EPS BLOCK (6000×1200×600mm) PRODUCTIONREFERENCE NUMBER: F-1227 EPS BLOCK (6000×1200×600mm) PRODUCTION LINE (NEW) CONSIST OF: 1. EPS BATCH PRE-EXPANDER MODEL SJ1400 2. EPS AUTO AIR-COOLING BLOCK MOLDING MACHINE SB6000 3. EPS CUTTING MACHINE PSC6000 4. CNC CUTTING MACHINE SCS3000 5. AUTO SHAPE MOLDING MACHINE WITH VACUUM SZ-172 6. AUXILIARY EQUIPMENT QUANTITY AVAILABLE: 1 Learn More

F-1227 EPS BLOCK (6000×1200×600mm) PRODUCTIONREFERENCE NUMBER: F-1227 EPS BLOCK (6000×1200×600mm) PRODUCTION LINE (NEW) CONSIST OF: 1. EPS BATCH PRE-EXPANDER MODEL SJ1400 2. EPS AUTO AIR-COOLING BLOCK MOLDING MACHINE SB6000 3. EPS CUTTING MACHINE PSC6000 4. CNC CUTTING MACHINE SCS3000 5. AUTO SHAPE MOLDING MACHINE WITH VACUUM SZ-172 6. AUXILIARY EQUIPMENT QUANTITY AVAILABLE: 1 Learn More -

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More -

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More

E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINEINVENTORY NUMBER: E-9384 HORIZONTAL AUTOMATIC CONTINUOUS FOAMING LINE OVEN LENGTH: 16.9 M. FOAMING HEIGHT: 1.0 TO 1.3 M. FOAMING WIDTH: 1.15 TO 2.3 M. FOAMING DENSITY: 10 TO 50KG/M3. CONVEYOR BELT LENGTH: 16.9 M. SIDE BOARD WIDTH ADJUSTMENT: 0.98 TO 2.4M. CONVEYOR BELT SPEED: 2.0 TO 7.0M/MIN. MIXING-HEAD POWER: 37KW. WITH BLOCK CUTTING MACHINE. TOTAL POWER: 130KW. TOTAL OUTPUT: 200 TO 350KG/MIN. MACHINE EXTERNAL SIZE: L34000 X W4550 X H4200mm. CE CERTIFICATE GUARANTEE FOR ONE YEAR. QUANTITY AVAILABLE: 1 Learn More -

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More

TT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFTTT-1175 HENNECKE BFM COMPACT FOAMING LINE, 80 BUNS PER 8 HOUR SHIFT INCLUDES 3 MOLDS, DIMENSIONS 2100 x 2100 x 1400mm A COMPLETE LINE FOR DISCONTINUOUS PRODUCTION OF SLABSTOCK FOAM. THE BFM IS STATE-OF-THE-ART EQUIPMENT FOR PRODUCING FOAM WITH QUICK START UP, MINIMUM SPACE REQUIRED AND FLEXIBLE PRODUCTION. WITH THIS LINE POLYURETHANE FOAMS BLOCKS CAN BE PRODUCED, SUCH AS FOAMS FOR UPHOLSTERED FURNITURES, CUSHIONS, MATTRESSES, SEATS, SOFAS AND PACKAGING. WITH THIS MACHINE EVEN HIGH RESILIENCE HR, HYPER SOFT HS AND VISCO ELASTIC FOAMS CAN BE PRODUCED. BENEFITS WITH BFM COMPACT - A BROAD RANGE OF FOAM DENSITY 20 TO 50 KG/m3 - MANUFACTURE DIFFERENT TYPES OF POLYETHER BASED FOAMS - POSSIBLITY TO CONTROL MIXER SPEED => HIGH INFLUENCE ON CELL STRUCTURE - HIGH REPRODUCIBILITY, THANKS TO FORMULATIONS AND MODERN CONTROL SYSTEM - SIEMENS CONTROL PANEL - COMPACT DESIGN => SMALL SPACE REQUIREMENTS - AUTOMATIC FLUSHING WITH POLYOL AVOIDS THE COSTS OF DISPOSAL OF MIXTURE TECHNICAL DETAILS DIMENSIONS OF THE MACHINE WITHOUT MOULD: LENGHT APPROX: 5000mm WIDTH APPROX: 2350mm HEIGHT APPROX: 2550mm CAPACITY: DEPENDING ON QUANTITY AND SIZE OF THE MOULDS – ABOUT 80 RECTANGUAL BLOCKS PER 8-HOUR-SHIFT. AMOUNT OF MOULDS: 3 Learn More -

E-4553INVENTORY NUMBER: E-4553 FOAM MACHINERY FOR SALE QUANTITY AVAILABLE: 33 LOTS Learn More

E-4553INVENTORY NUMBER: E-4553 FOAM MACHINERY FOR SALE QUANTITY AVAILABLE: 33 LOTS Learn More -

TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014 1. HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE 2. YEAR OF CONSTRUCTION 2014 3. MACHINE TYPE: BLOCK FOAMING LINE 4. BRAND: HENNECKE GMBH 5. MODEL: BFM COMPACT 6. CONDITION: EXCELLENT (USED) QUANTITY: 1 Learn More

TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014TT-7474 HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE, YEAR 2014 1. HENNECKE GMBH BFM COMPACT BLOCK FOAMING LINE 2. YEAR OF CONSTRUCTION 2014 3. MACHINE TYPE: BLOCK FOAMING LINE 4. BRAND: HENNECKE GMBH 5. MODEL: BFM COMPACT 6. CONDITION: EXCELLENT (USED) QUANTITY: 1 Learn More -

M-1663 BD4-45 CEMENT BLOCK MAKING MACHINEREFERENCE NUMBER: M-1663 (66042BK5UF) BD4-45 CEMENT BLOCK MAKING MACHINE BD4-45 CEMENT BLOCK MAKING MACHINE IS ONE KIND OF SMALL SIZED BLOCK FORMING MACHINE IT ADOPTS DIESEL ENGINE TO SUPPLY HYDRAULIC PRESSURE, THE BLOCK DENSITY IS HIGHER, SHAPING SPEED IS QUICKER AND BLOCK STRENGTH IS MORE EVEN DIESEL ENGINE, IT CAN WORK WELL WITHOUT ELECTRICITY MOBILE TYPE, CONVENIENT TO MOVE ANYWHERE NO NEED PALLETS, REDUCES INVESTMENTS, AND IT SAVES LABOR TO PUT PALLETS NO CHIMNEY TO POLLUTE THE ENVIRONMENT EASY TO OPERATE QUANTITY AVAILABLE: 1 Learn More

M-1663 BD4-45 CEMENT BLOCK MAKING MACHINEREFERENCE NUMBER: M-1663 (66042BK5UF) BD4-45 CEMENT BLOCK MAKING MACHINE BD4-45 CEMENT BLOCK MAKING MACHINE IS ONE KIND OF SMALL SIZED BLOCK FORMING MACHINE IT ADOPTS DIESEL ENGINE TO SUPPLY HYDRAULIC PRESSURE, THE BLOCK DENSITY IS HIGHER, SHAPING SPEED IS QUICKER AND BLOCK STRENGTH IS MORE EVEN DIESEL ENGINE, IT CAN WORK WELL WITHOUT ELECTRICITY MOBILE TYPE, CONVENIENT TO MOVE ANYWHERE NO NEED PALLETS, REDUCES INVESTMENTS, AND IT SAVES LABOR TO PUT PALLETS NO CHIMNEY TO POLLUTE THE ENVIRONMENT EASY TO OPERATE QUANTITY AVAILABLE: 1 Learn More